Column mechanism of vertical high speed drilling and milling machining centre for moveable pillar

A column and vertical technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems that cannot meet the high-speed and composite processing requirements of large parts, and achieve the effect of widening the processing range and high dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

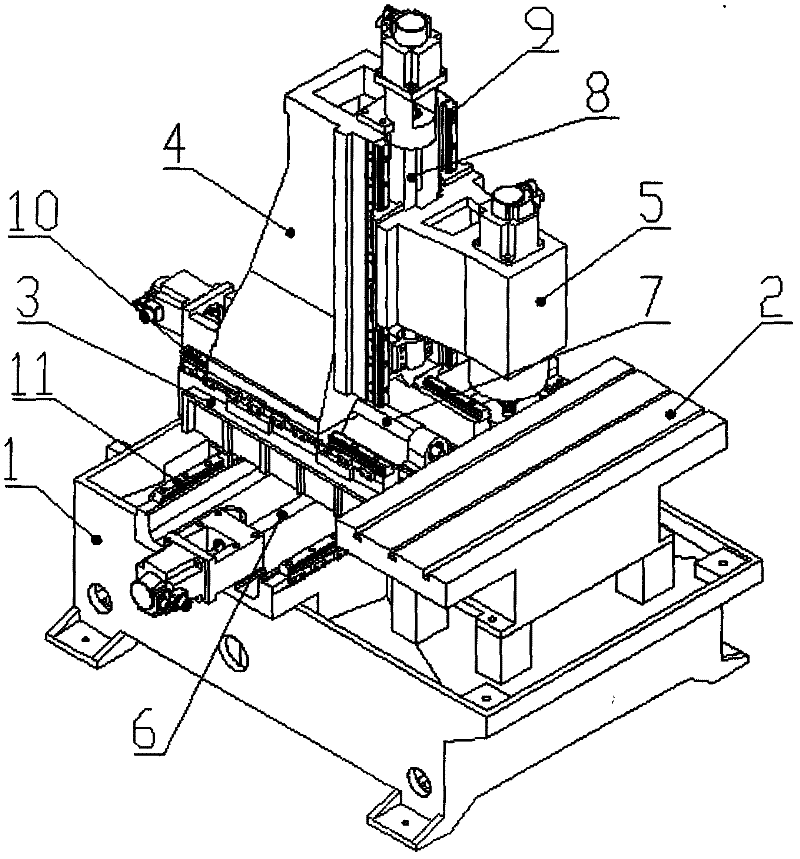

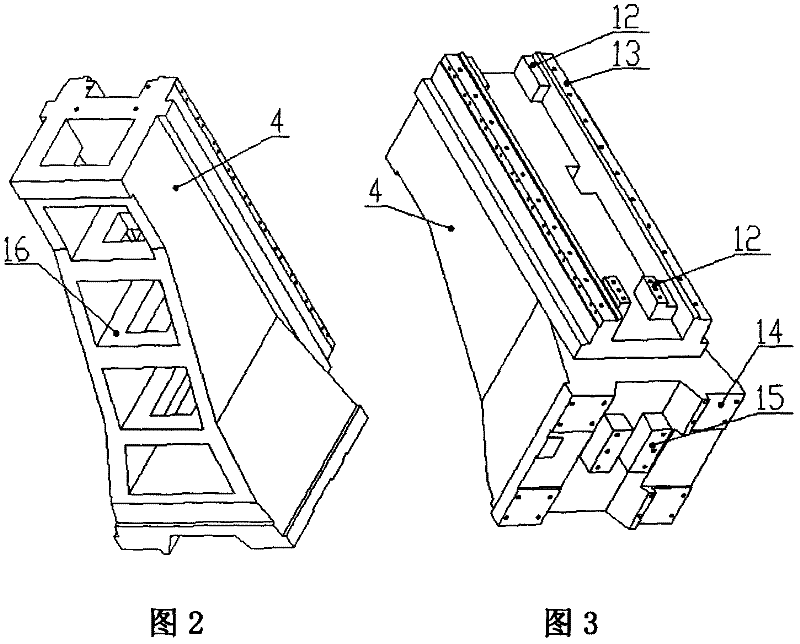

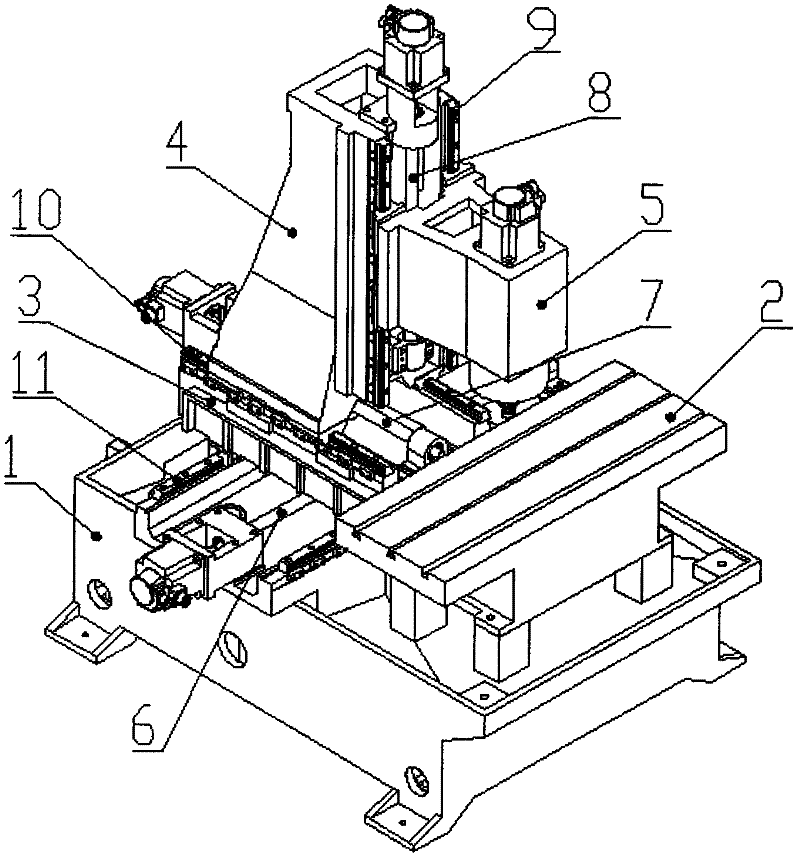

[0013] Attached below figure 1 , figure 2 , image 3 And embodiment, the content of the invention of the present invention is further described.

[0014] Such as figure 1 , figure 2 , image 3 As shown, the specific embodiment of the present invention: the column mechanism of the vertical high-speed drilling and milling machining center of the moving column, including the base mechanism 1, the workbench mechanism 2, the saddle mechanism 3, the column mechanism 4, and the headstock mechanism 5, characterized in that: The column mechanism 4 includes a Z-direction screw rod installation platform 12, a Z-direction line rail installation platform 13, an X-direction line rail installation platform 14, an X-direction screw rod installation platform 15, and an annular rib 16. The front end of the column mechanism 4 is provided with a X The linear guide rail 9 is connected with the spindle box mechanism 5, and a servo motor is equipped at the same time; the bottom end of the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com