Lifting device

A technology of lifting device and deceleration device, applied in the field of lifting system, to achieve the effect of improving lifting capacity, meeting restrictions, reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

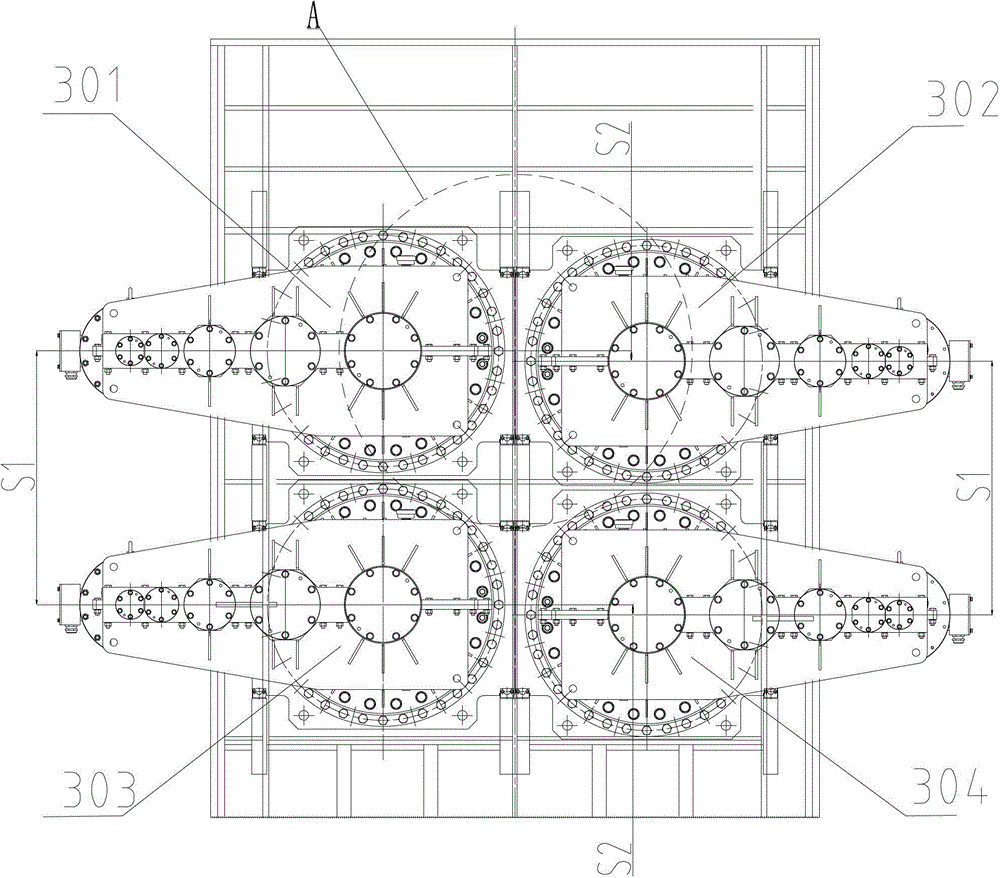

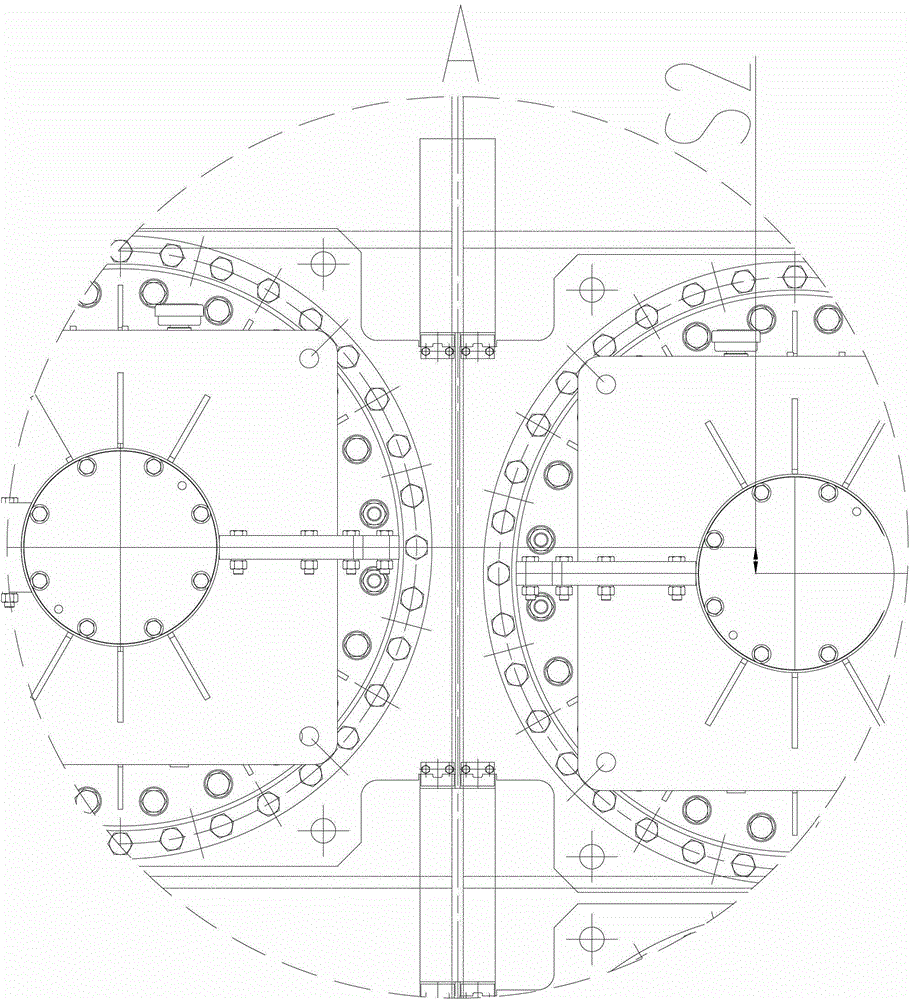

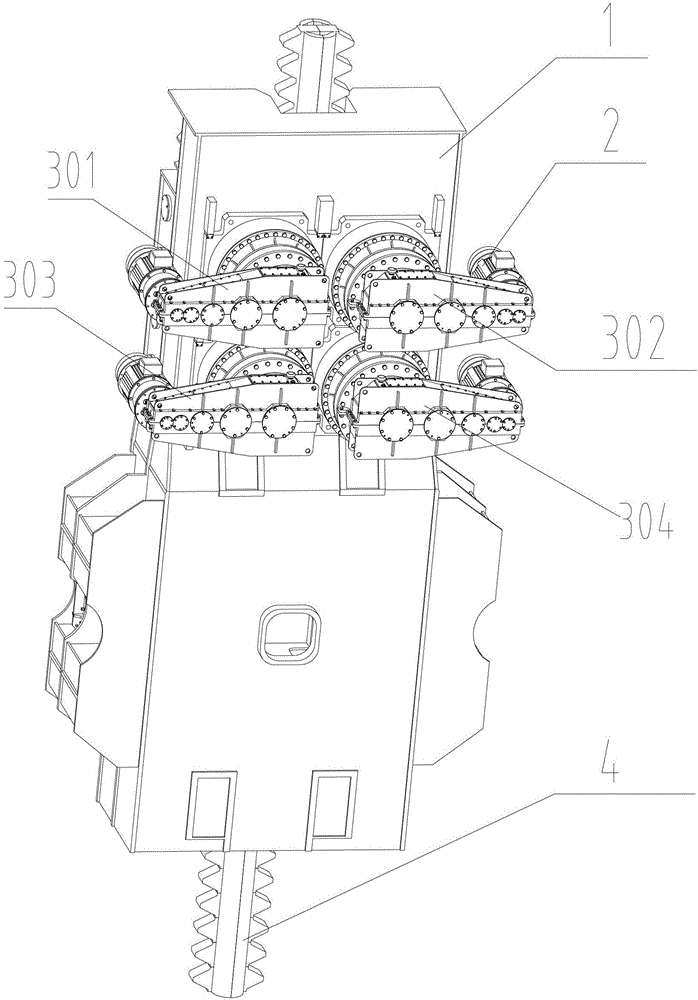

[0017] The lifting platform is a mobile offshore engineering platform used for offshore energy exploration and exploration. Its main components are the working platform, the legs supporting the platform, and the lifting system that controls the lifting of the working platform. The lifting system is mainly composed of motor, reduction device, main lifting gear shaft assembly and so on. Such as image 3 The three-dimensional structure diagram of a lifting device shown, the leg rack 4 and the lifting gear are arranged inside the pile box 1, the first reduction device 301, the second reduction device 302, the third reduction device 303 and the fourth reduction device 304 are arranged on the side of the pile box 1, and the tooth pitch of the leg rack 4 is mπ, where m represents the modulus of the leg rack. The four motors 2 are respectively connected to the input shafts of the first deceleration device 301, the second deceleration device 302, the third deceleration device 303 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com