Heading machine cutting head with rake teeth, extensible structure and attached drilling tools

A technology of telescopic structure and cutting head, which is applied to the cutting head of roadheader, telescopic structure and auxiliary drilling tools, and mining equipment fields, can solve the problems of unrealistic, limited focus area, affecting efficiency, etc., and achieves a small degree of wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

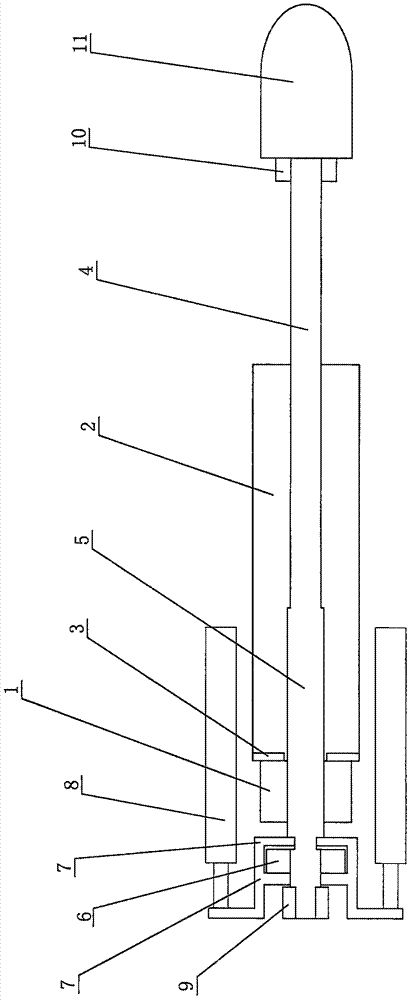

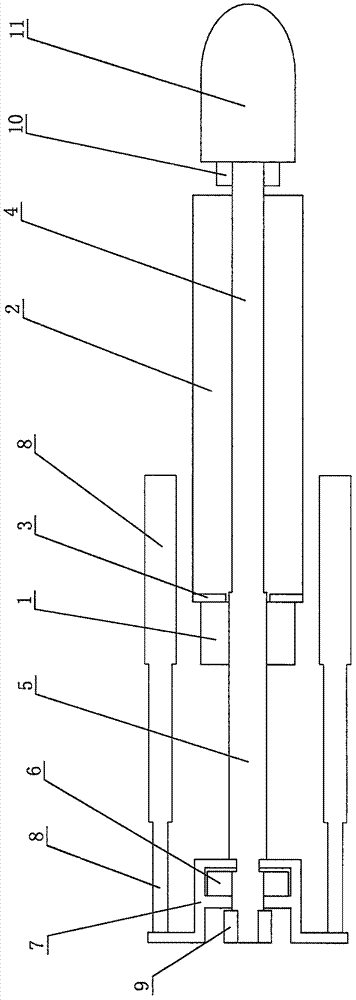

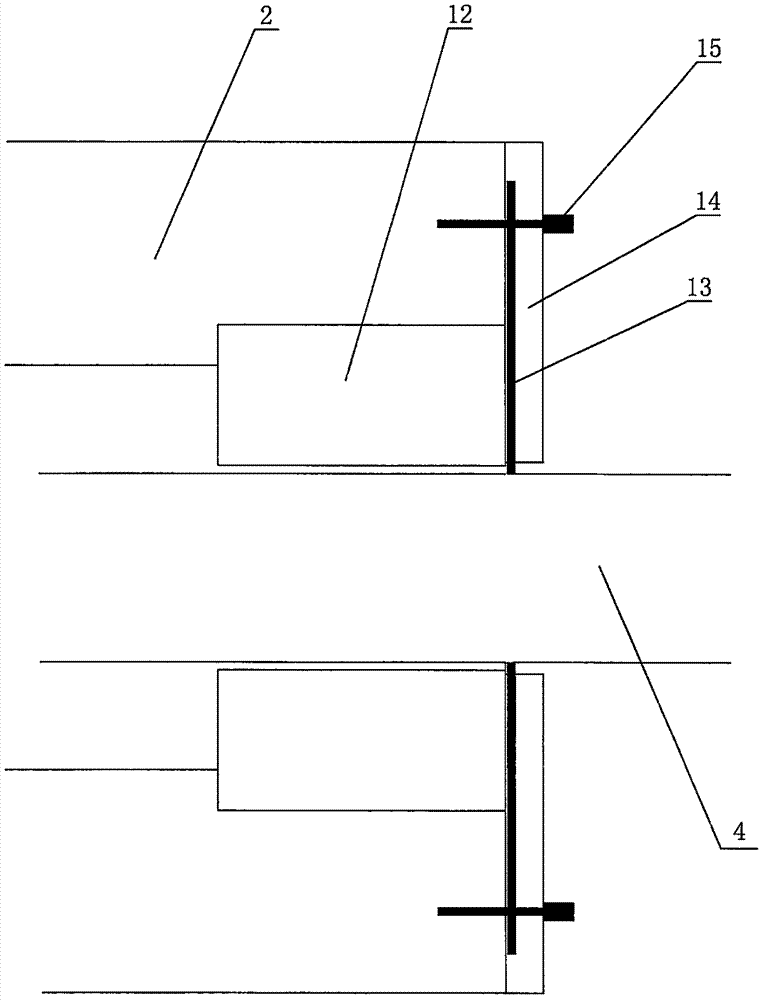

[0035] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0036] Among the above-mentioned accompanying drawings: the structure of the first embodiment when the present invention is used is shown; Referring to the accompanying drawings, its basic structure is: the roadheader cutting head and telescopic structure with rake teeth are existing The roadheader is restructured, and the characteristics are: the motor is directly driven to directly drive the spindle 4 to rotate through the hollow shaft hydraulic motor 1, and the planetary gear structure is no longer used. This section of the spindle 4 has a spline about 1.8 meters long. The outer diameter of the key is 24 centimeters, the outer diameter of the bottom of the spline groove is 20 centimeters, the spline groove is a common spline groove, or the spline groove is a semicircle, which is commonly called the spline mandrel 5, and the spline mandrel 5 and the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com