Synchronization motor and its speed adjustment of DC armature three-phase AC excitation

A synchronous motor, three-phase AC technology, applied in synchronous motors for single-phase current, AC motor control, single motor speed/torque control, etc. The price of the governor is very expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

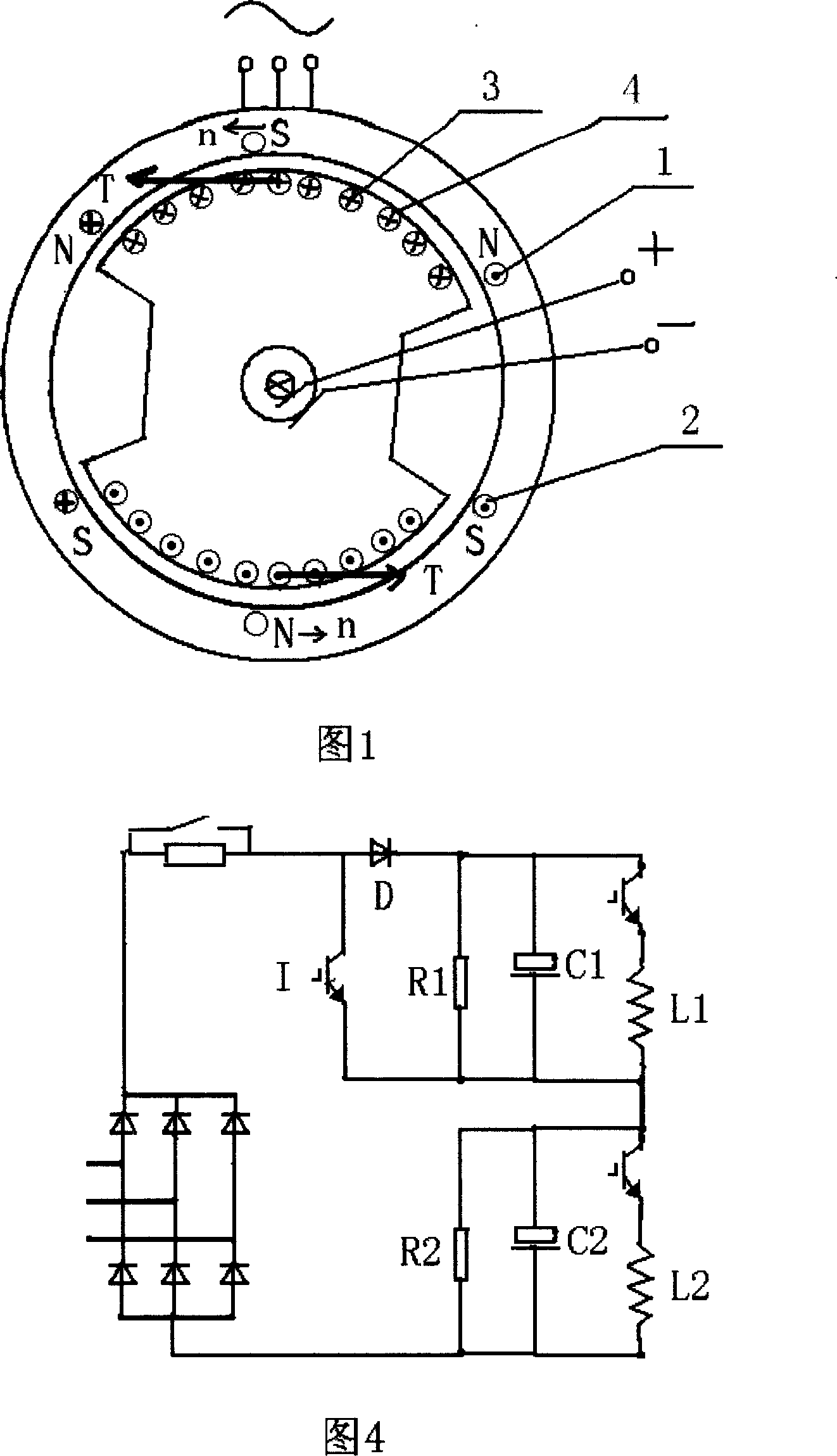

[0021] As shown in Figure 1, the rotating magnetic field generated by the three-phase AC excitation winding 1 rotates counterclockwise, and the magnetic field has an S pole on the bottom and an N pole on the bottom. Current, according to the left-hand rule, the electromagnetic torque T of the DC armature winding 3 is also counterclockwise.

[0022] To change the direction of the motor, the rotating magnetic field generated by the three-phase AC excitation winding 1 rotates clockwise but the polarity does not change, and the DC armature winding 3 passes through the slip ring into the DC current from the upper and lower paper surfaces, or three-phase The rotating magnetic field generated by the AC excitation winding 1 rotates clockwise, while the polarity changes, and the direction of the DC current in the DC armature winding 3 remains unchanged.

[0023] To generate braking torque, change the current direction of the DC armature winding 3 under the condition of keeping the pola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com