Forming and driving method for triggering type permanent magnet brushless direct-current motor

A DC motor and permanent magnet brushless technology, applied in the field of DC motors and electric motors, achieves the effects of cost saving, simple driving circuit and easy material acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The following describes in detail with reference to the best embodiment shown in the accompanying drawings.

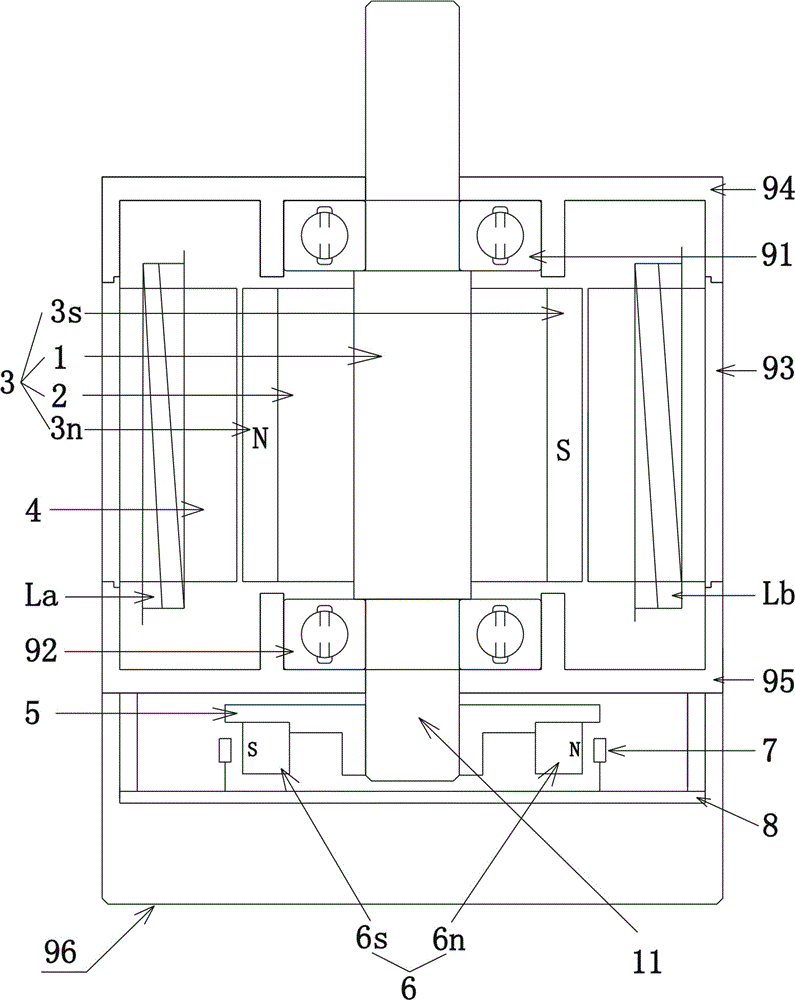

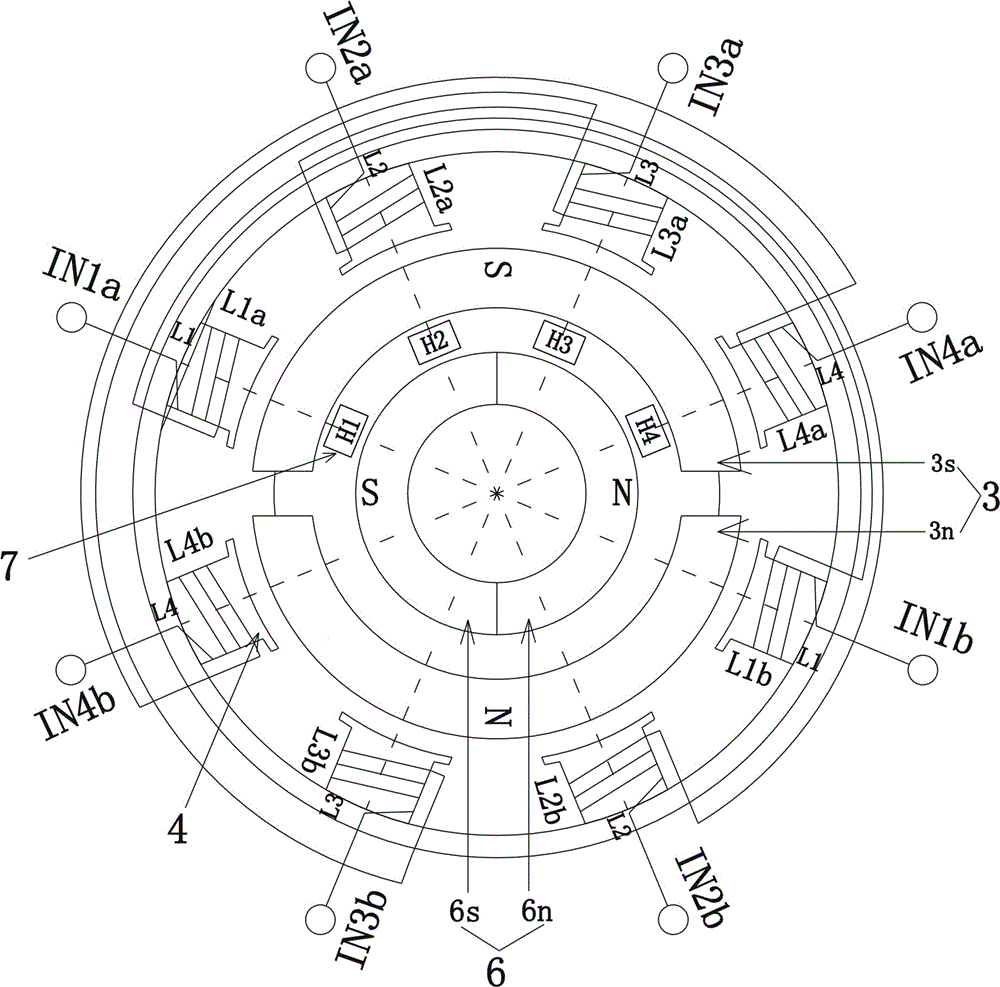

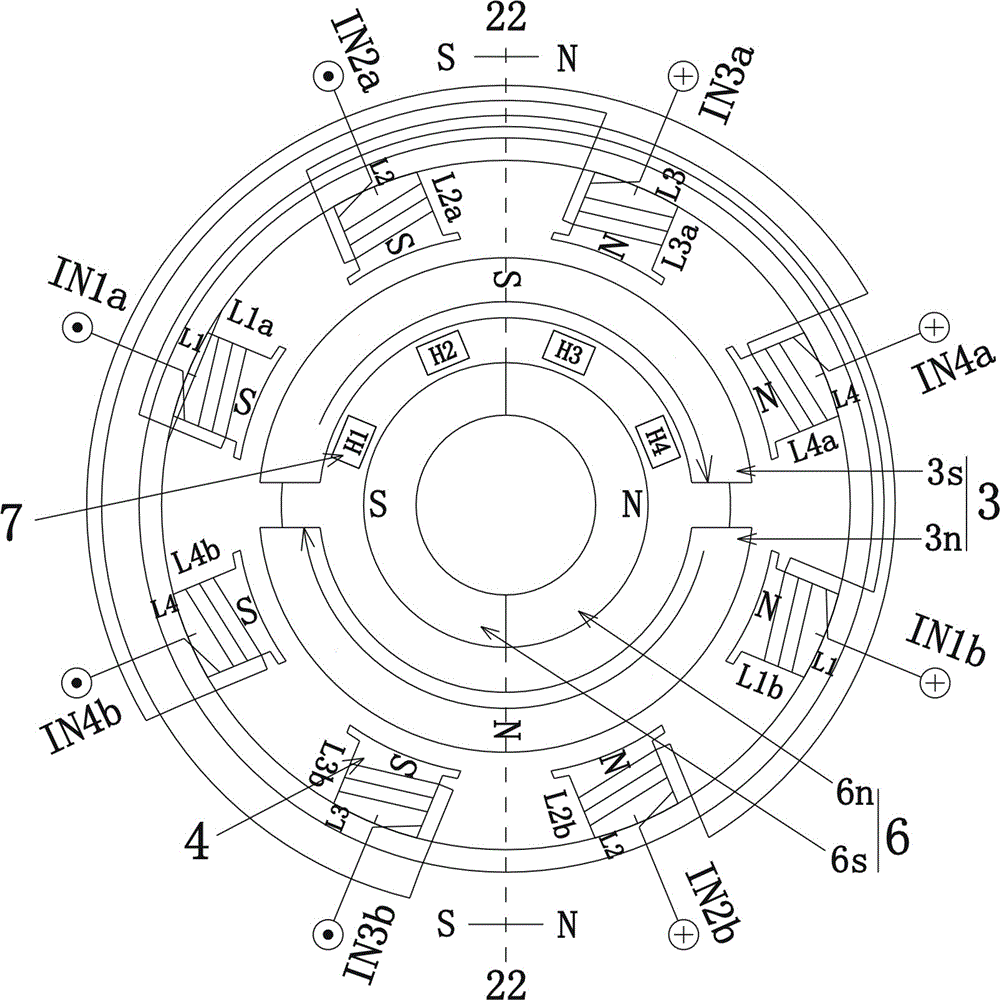

[0075] Such as figure 1 -- Figure 6 As shown, a trigger type permanent magnet brushless DC motor is designed and manufactured, and the motor includes:

[0076] The rotor core 2 is set on the rotor shaft 1, and the permanent magnets 3n and 3s are fixed on the rotor core 2 to form the magnetic poles of the permanent magnet rotor 3. The permanent magnets 3n and 3s are prefabricated by magnetic materials and magnetized. The magnetic tile; the permanent magnet rotor 3 has two poles or four poles.

[0077] A stator is provided with a plurality of stator pole cores 4, and the stator pole cores 4 are arranged in an even number; pole core coils are wound on the stator pole cores, and two coils winding to the same pole core coils are connected in series to form a phase winding L.

[0078] In a two-pole motor, the stator armature winding consists of at least two phase wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com