Centering and clamping device for multi-diameter pipe

A clamping device and multi-diameter technology, which is applied in positioning device, workpiece clamping device, clamping, etc., can solve the problems of pipe clamping without multi-diameter, high production cost, and damage to the pipe surface, etc., to improve the appearance Surface quality and processing efficiency, reducing tooling costs, and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

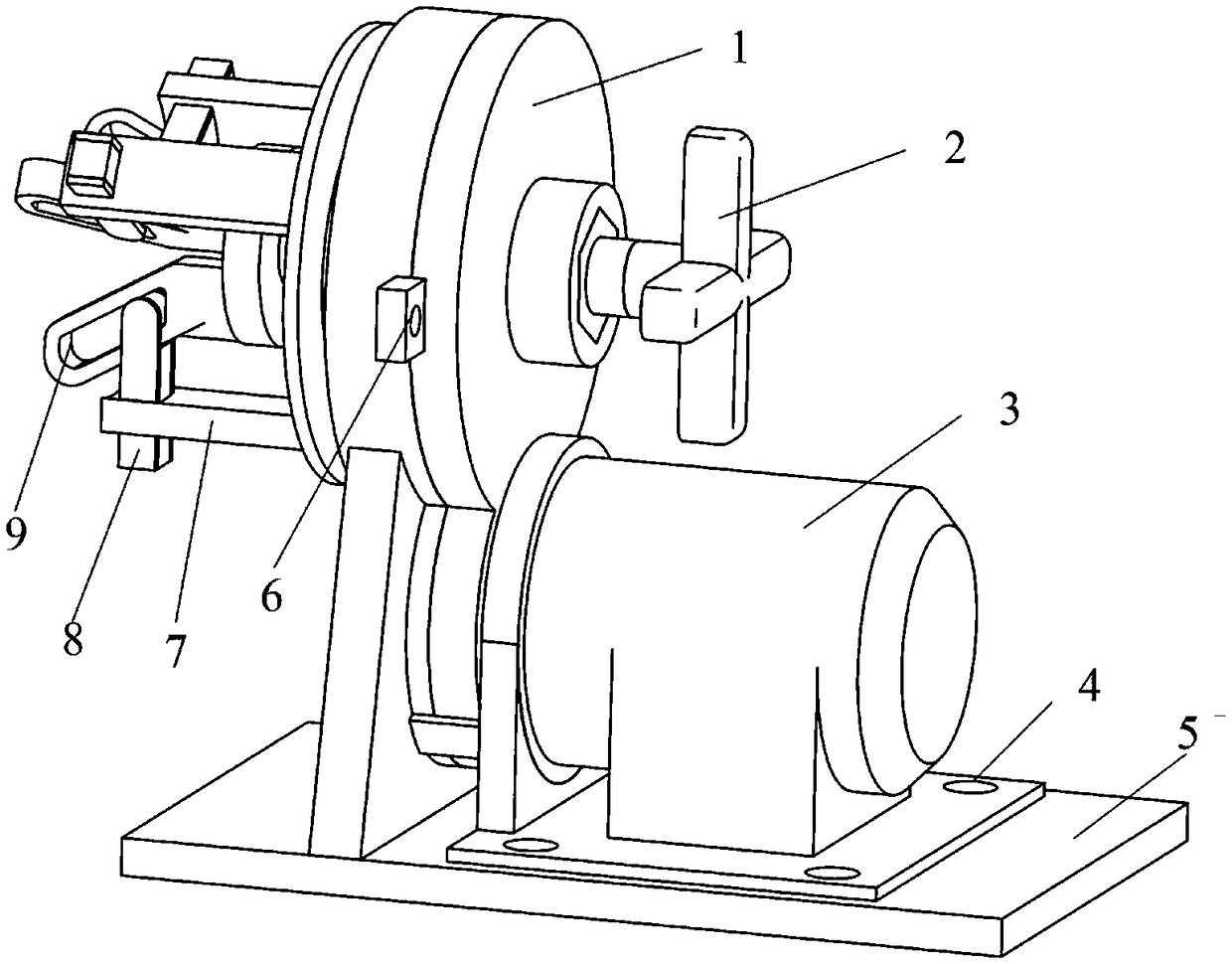

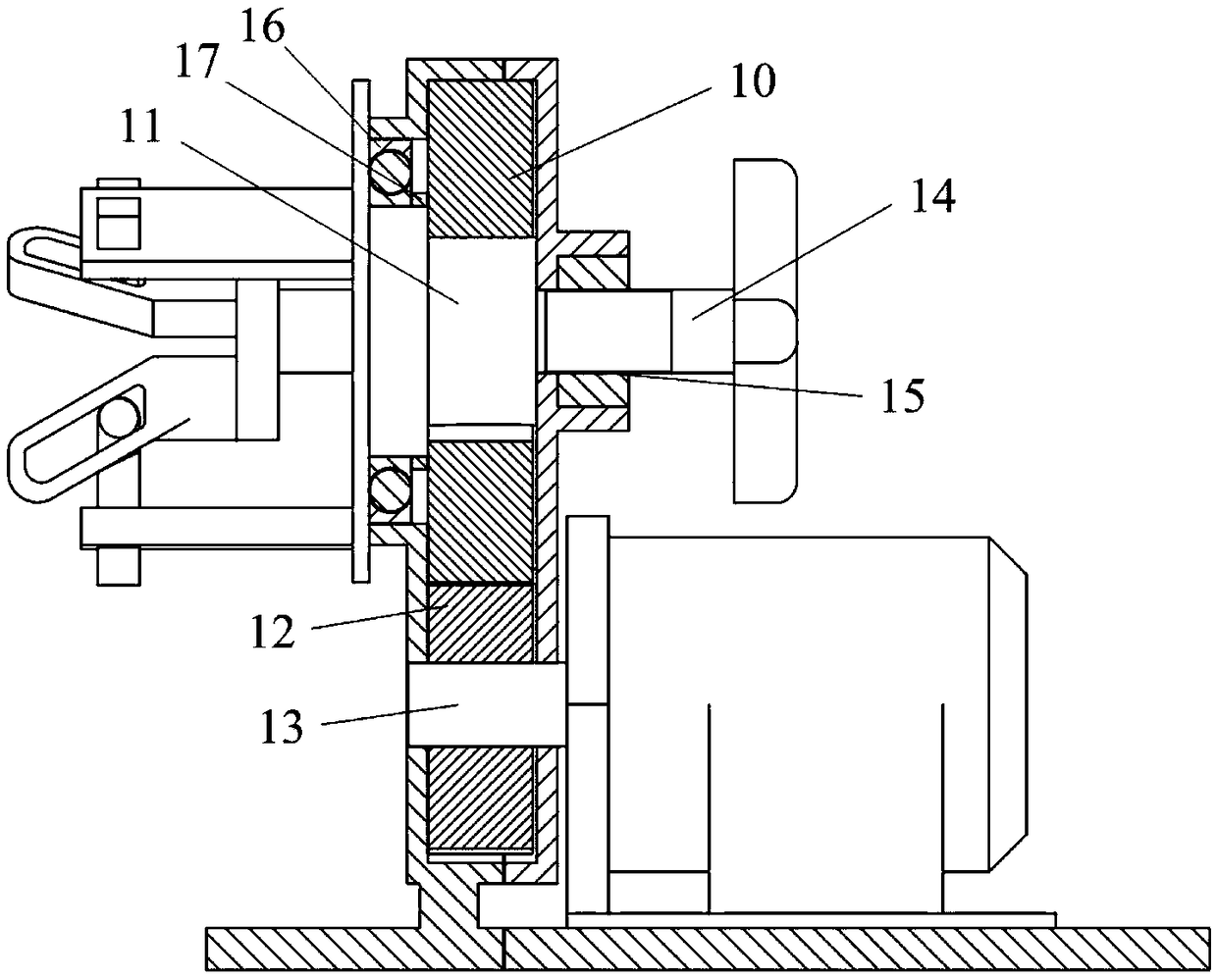

[0022] as attached figure 1 And attached figure 2 shown

[0023] The invention provides a centering and clamping device for multi-diameter pipes, which includes a frame end cover 1, a rocker 2, a motor 3, a motor base 4, a frame 5, a connecting block 6, a slider column 7, and a moving slider 8 , screw into the carriage 9, the transmission gear 10, the rotating shaft frame 11, the motor gear 12, the motor shaft 13, the threaded rod 14, the fixing nut 15, the ball bearing 16 and the bushing 17, and the frame end cover 1 bolts are installed On the right side of the upper part of the frame 5; the rocking bar 2 is clamped on the right end of the threaded rod 14; the motor 3 is welded on the top of the motor base 4; the motor base 4 bolts are installed on the frame 5 The upper middle part; the connecting block 6 is welded on the front and rear ends of the upper middle part of the frame end cover 1; the slider column 7 bolts are installed on the left end of the rotating frame 11; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com