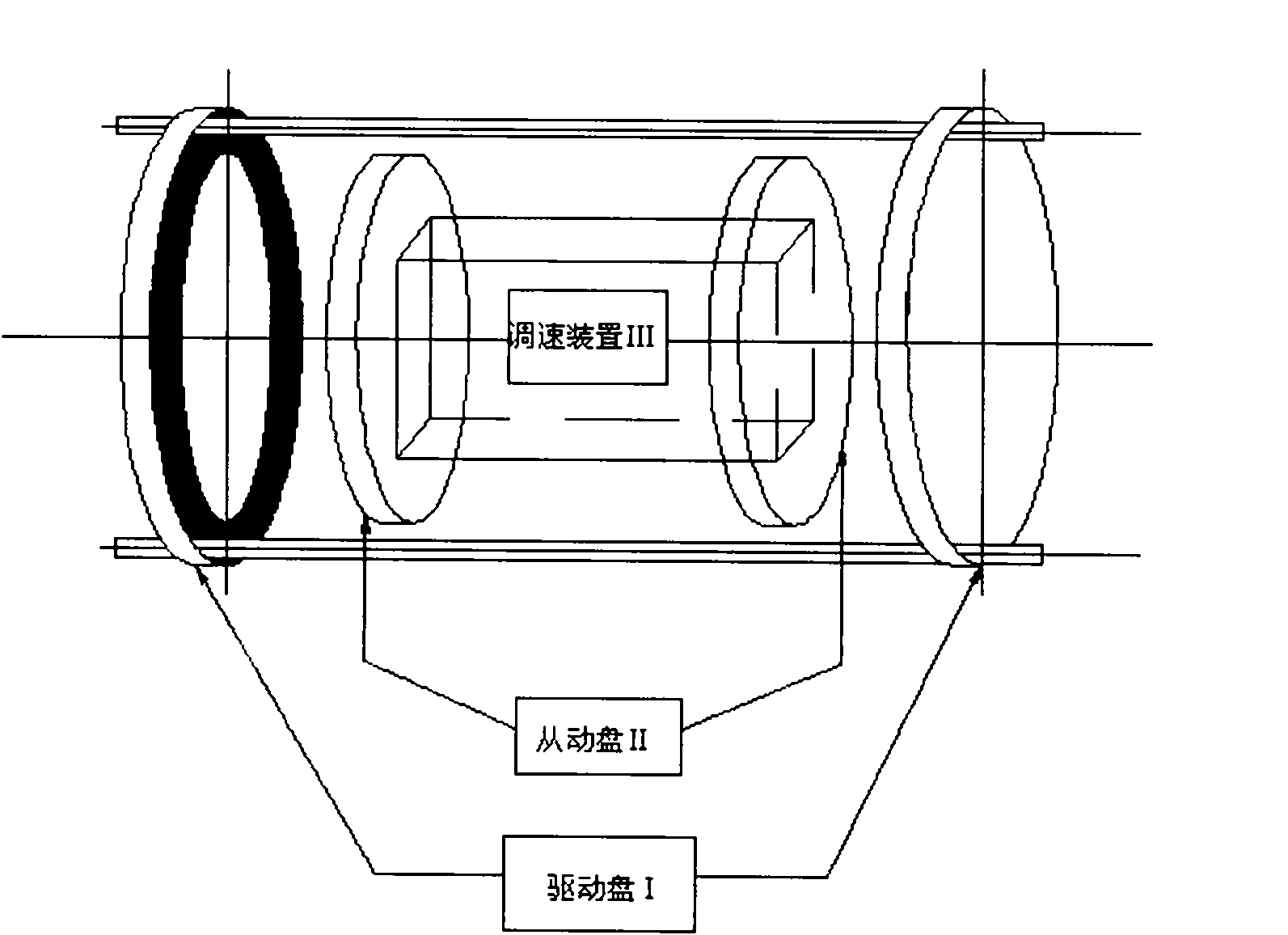

Remote automatic control adjustable-speed disc magnetic coupling

A magnetic coupling and coupling technology, applied in the direction of electric components, electromechanical transmissions, electrical components, etc., can solve the problems of motor heating and failure, reduce loss, improve precision, avoid restoring force and torque and The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

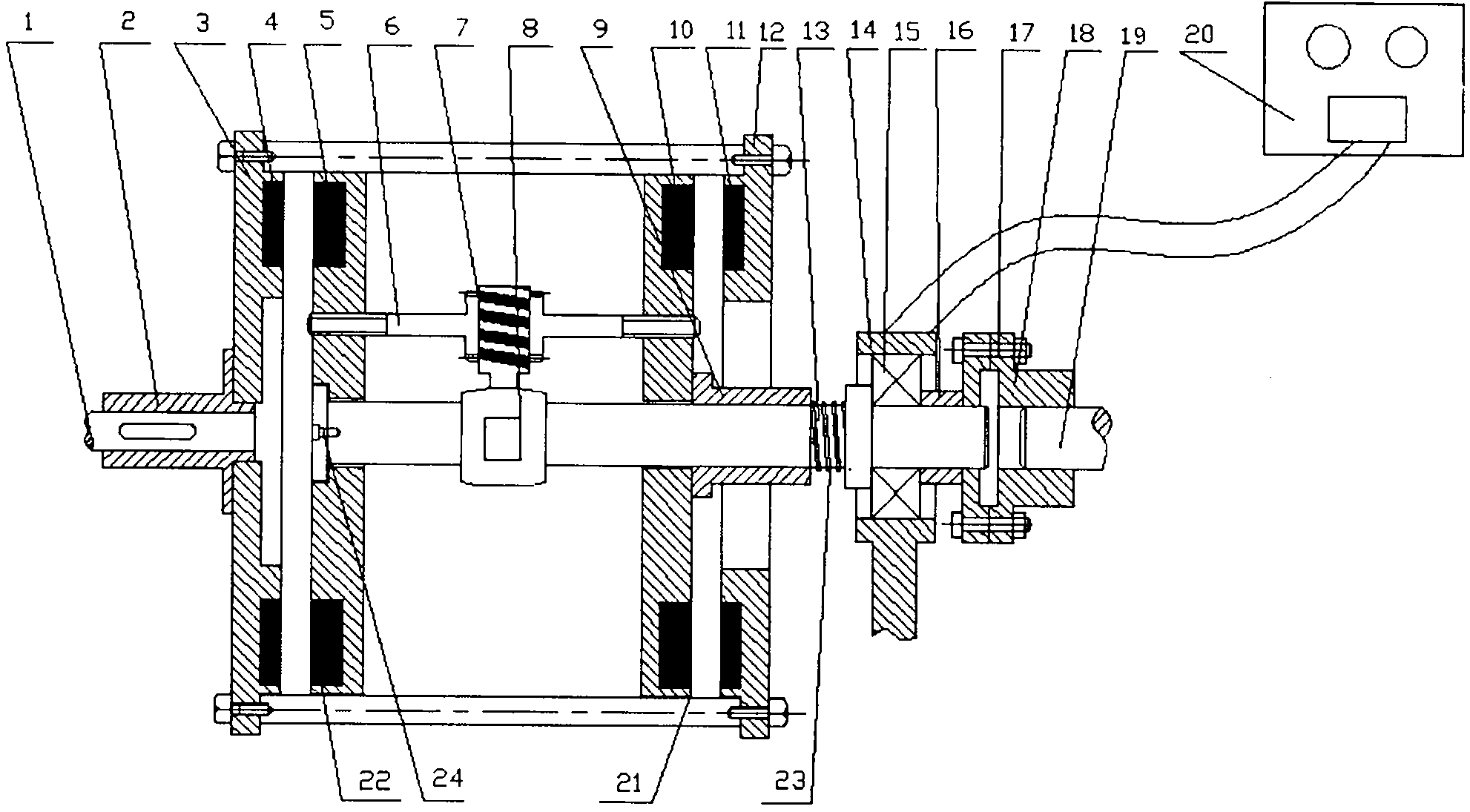

Examples

Embodiment 2

[0030] Embodiment 2: On the basis of Embodiment 1, a rotational speed or torque sensor can be added to the drive shaft 1 and output shaft 19 of the adjustable-speed magnetic induction coupling to sample the drive shaft 1 and output shaft 19 of the magnetic coupling in real time Speed or torque signal, and send the signal to the central control unit in the speed controller. After the central control unit analyzes and processes these signals, it sends an instruction to control the forward or reverse rotation of the micro motor through the speed controller 20, so that The speed difference between the main and driven discs is within the specified range. The rotational speed difference requirement between the main and driven discs can be set in the speed controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com