Compact gear structure for eliminating lateral clearance and design method thereof

A technology of side clearance and gear structure, which is applied in the field of precision transmission, can solve the problems that the structure of the anti-backlash gear is not compact enough and affects the transmission accuracy, and achieves a compact design of the structure of the gear train that eliminates the clearance, improves the transmission accuracy, and eliminates the backlash. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

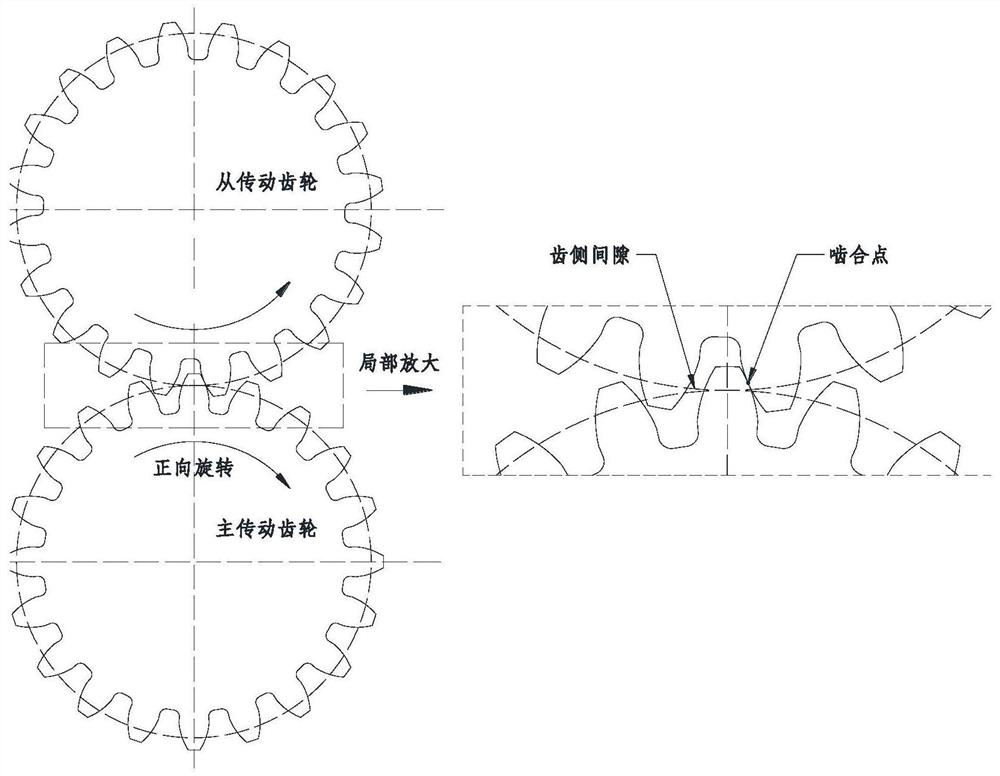

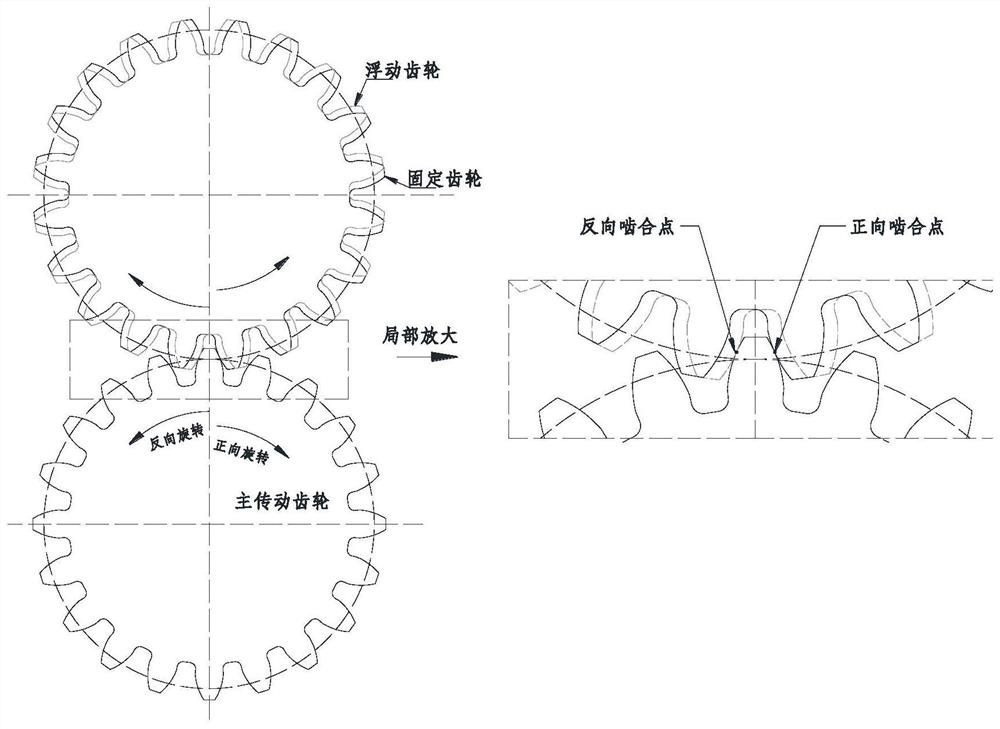

Problems solved by technology

Method used

Image

Examples

Embodiment 1

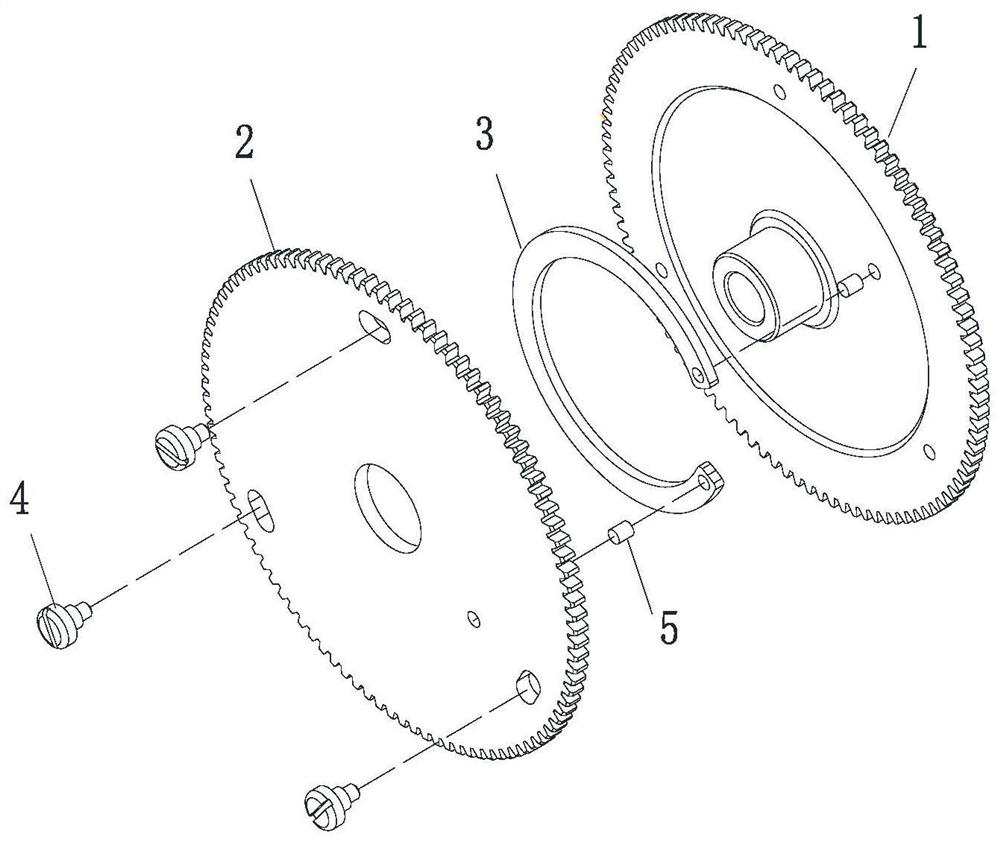

[0045] Such as Figure 1-3 As shown, the present invention provides a compact gear structure for eliminating lateral backlash, including a fixed gear 1, a floating gear 2 and a C-shaped spring 3;

[0046] The fixed gear 1 includes a central hole provided with a keyway; the gear shaft extends into the central hole and is connected with the fixed gear 1 through a key;

[0047] The floating gear 2 is rotatably mounted on the central hole hub of the fixed gear 1 through clearance fit;

[0048] The tooth surface of the fixed gear 1 is provided with three threaded holes at intervals of 120° along the circumference, and the tooth surface of the floating gear 2 is provided with three ring-shaped elongated holes at intervals of 120° along the circumference. 1 and the floating gear 2 are axially fixed through the stepped screw 4 installed in the threaded hole and the annular elongated hole, and the length of the annular elongated hole is 3 times the diameter of the stepped screw 4; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com