Hydraulic system capable of independently adjusting speed by adopting two pressure compensators

A pressure compensation, hydraulic system technology, applied in the hydraulic field, can solve the problems of easy instability of the system, improper matching of pressure compensator and balance valve parameters, etc., to achieve the effect of achieving stability and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

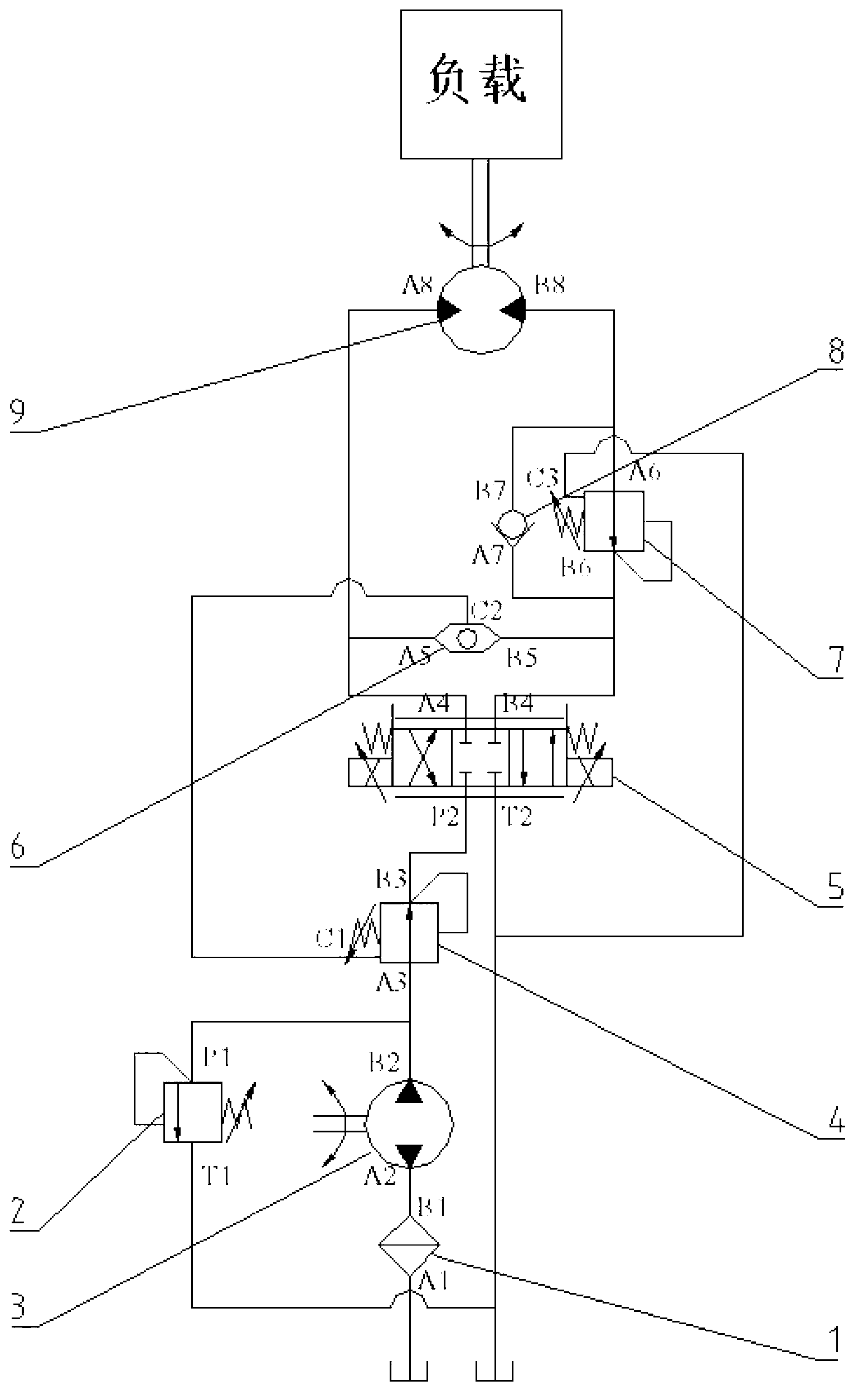

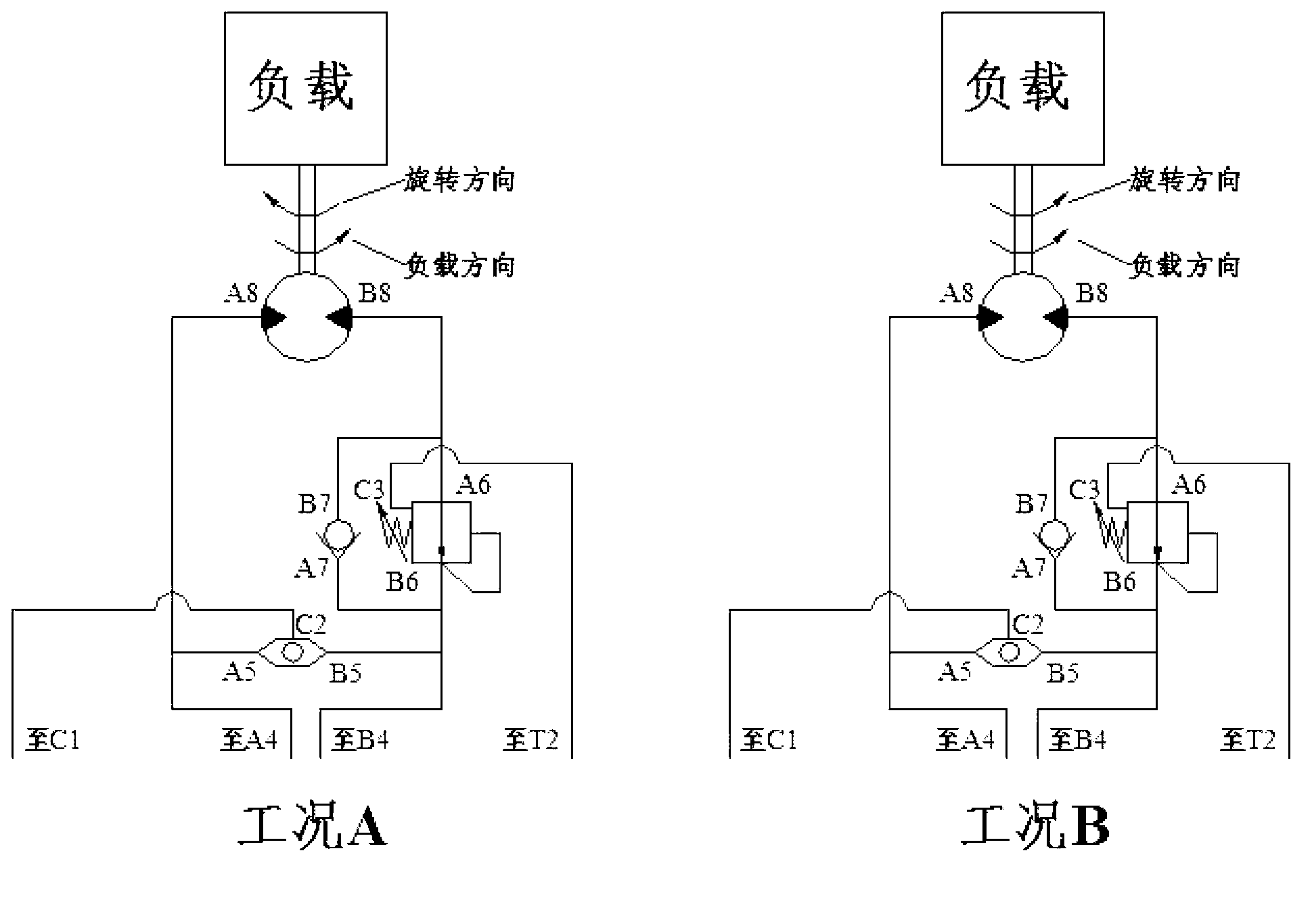

[0021] Embodiment 1. A hydraulic system using dual pressure compensators for independent speed regulation, such as figure 1 Said, including oil filter 1, overflow valve 2, quantitative pump 3, pressure compensator I4, pressure compensator II7, proportional reversing valve 5, shuttle valve 6, one-way valve 8 and two-way motor 9.

[0022] The oil inlet A1 of the oil filter 1 is connected to the oil tank, the oil outlet B1 of the oil filter 1 is connected to the oil inlet A2 of the quantitative pump 3, and the oil outlet B2 of the quantitative pump 3 is respectively connected to the oil inlet P1 of the relief valve 2 And the oil inlet A3 of the pressure compensator 4I, and the oil outlet T1 of the relief valve 2 communicate with the oil tank. The oil outlet B3 of the pressure compensator I4 is connected to the oil inlet P2 of the proportional directional valve 5, the oil return port T2 of the proportional directional valve 5 is connected to the oil tank, and the oil outlet A4 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com