Wind-driven generator synchronous belt transmission automatic wind-aiming drift device

A wind turbine, synchronous belt drive technology, applied in wind turbines, wind turbine control, wind power generation and other directions, can solve the problems of increasing the long-term self-protection capability of wind turbines, unsuitable use, and the inability of manual maintenance of wind turbines, etc. Achieve the effects of reliable automatic yaw, reliable automatic wind control, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

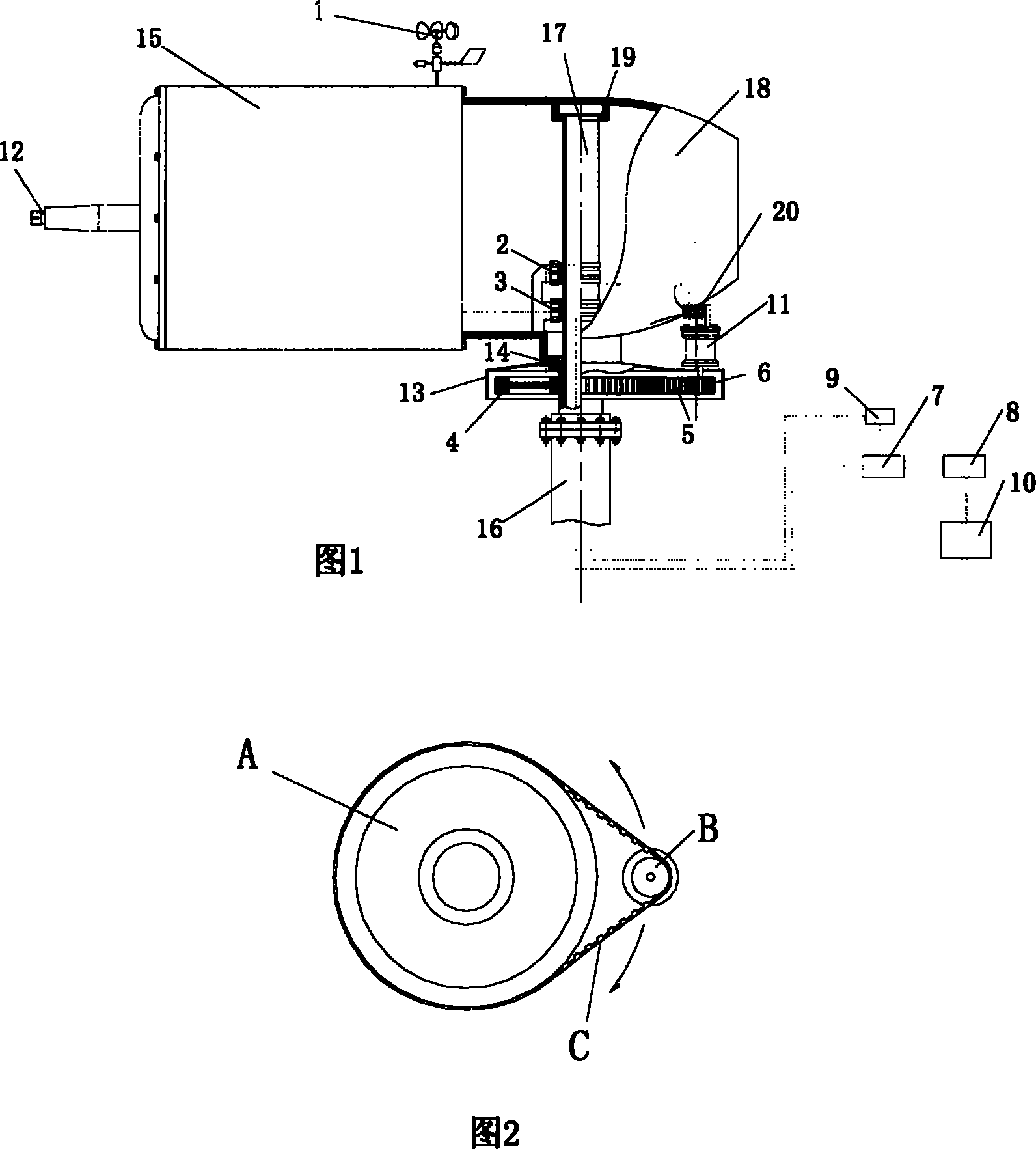

[0009] As shown in Figure 1: the power generation of the wind power generator is realized in this way. When the wind blade drives the generator shaft 12 to start rotating, the generator 15 starts to generate electricity, and the current is sent to the main controller 7 through the carbon brush 3. , the inverter 8 oscillates the current, charges it into the power storage device 10, and the process of generating electricity by the wind-driven generator is completed.

[0010] As shown in Figure 1: the automatic wind-facing of the wind generator is realized in this way, when the external wind speed and direction sensor 1 of the rotating body detects the deviation angle between the wind direction and the wind blade, the sensor 1 transmits the signal to the main controller 7, and the main controller 7 The controller sends the stepping motor controller 9 through the electricity of the storage device 10 through the carbon brush 2, and the stepping motor controller controls the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com