Hydraulic control system for stepless brake retarder

A technology of hydraulic control system and reducer, which is applied in the direction of track brakes, railway car body parts, transportation and packaging, etc. It can solve the problems that restrict the development of hump speed regulation technology, the balanced braking method cannot be realized, and the reducer cannot be adjusted. Achieve the effect of braking force generation and soft change, reducer and speed change smoothly, and ease speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

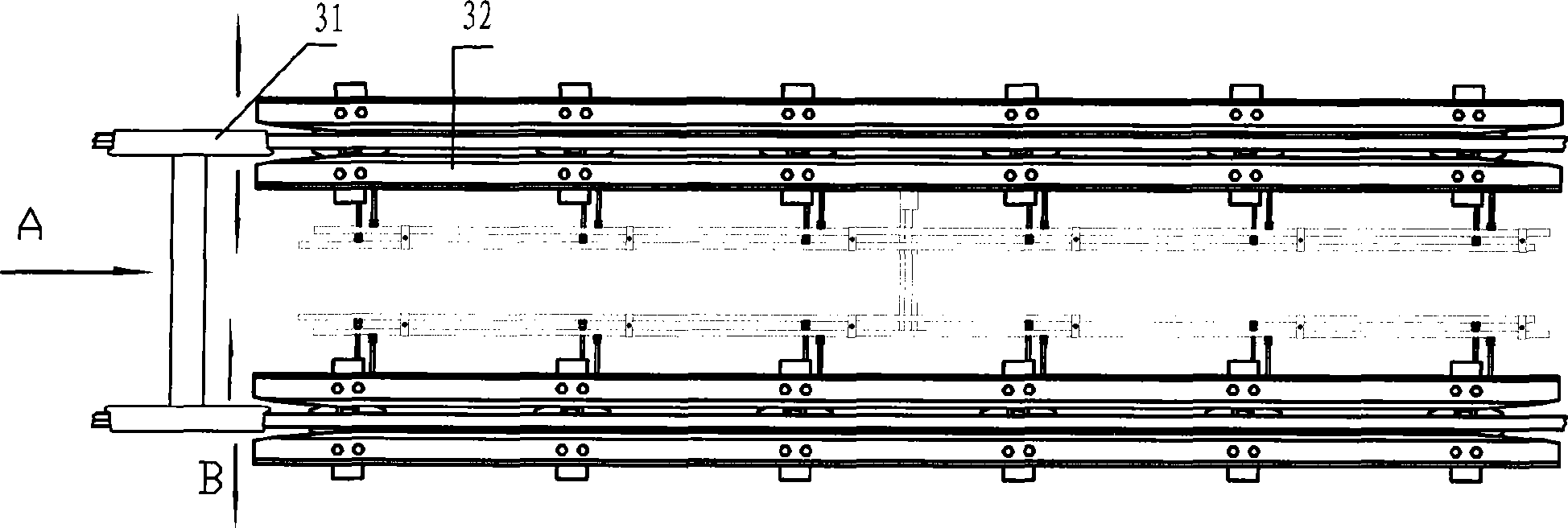

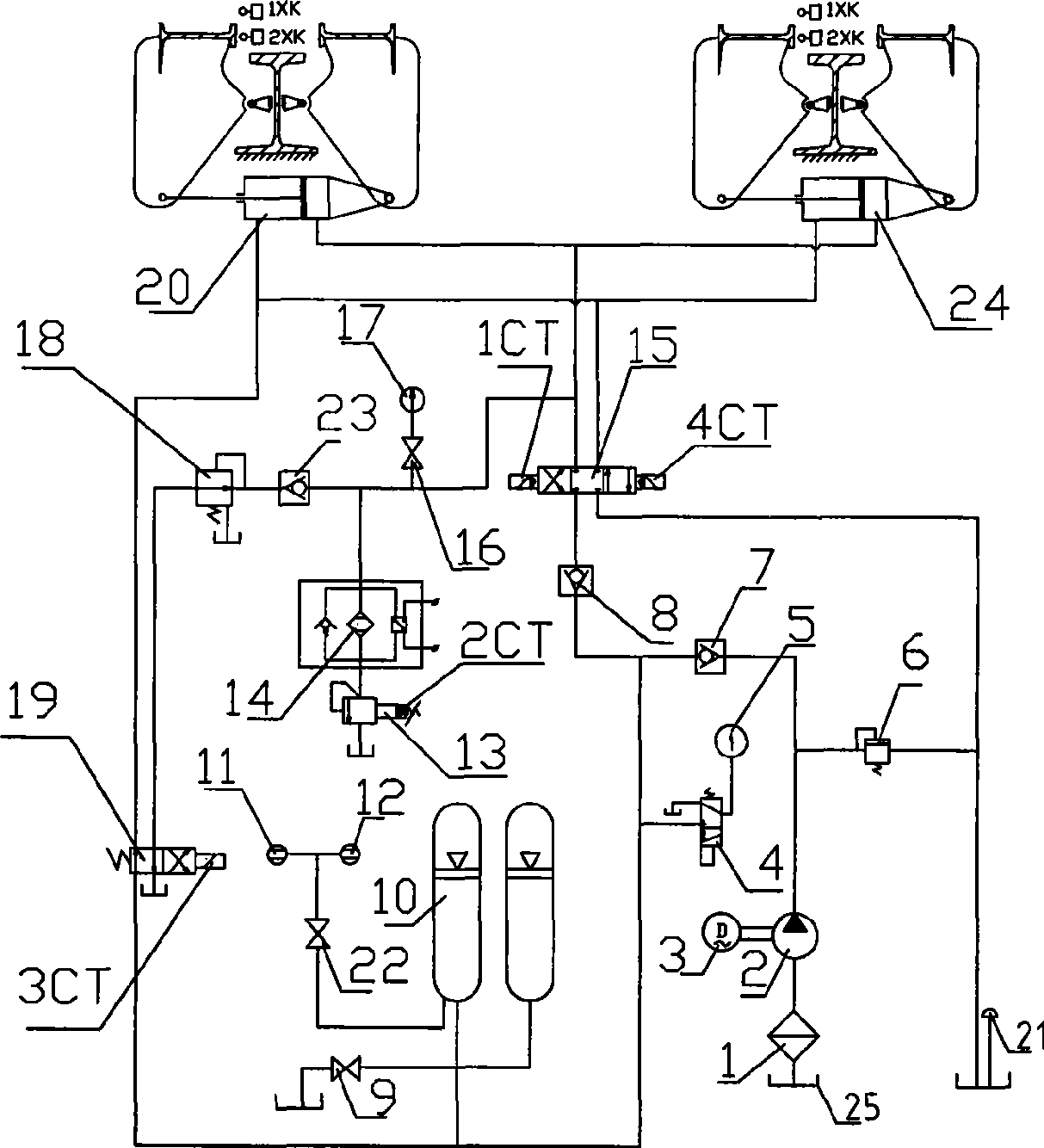

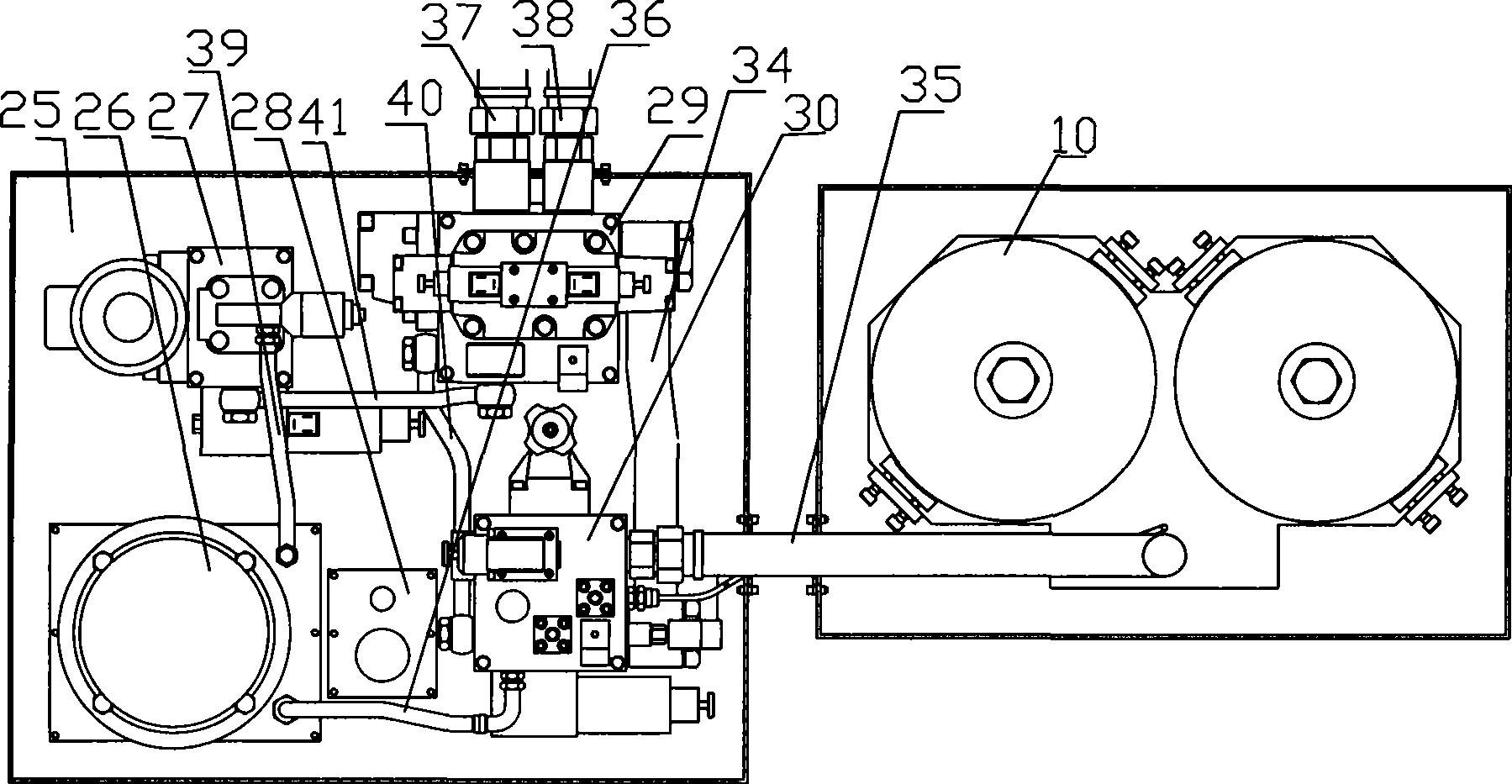

[0024] see figure 1 , the working principle of the present invention is as follows:

[0025] Driven by the hydraulic system, the actuator moves to the braking position. When the vehicle slides down from the hump along the A direction and enters the reducer (working position), it will squeeze the brake rail 32 along the B direction, and the cylinder brake chamber 24 The oil pressure is compressed, and the pressure rises. The pressure is transmitted to the brake rail 32→wheel 31 through the brake chamber 24 of the oil cylinder in turn, and the friction torque is applied to the wheel 31 through the brake rail 32 to brake the vehicle. Since the system pressure is directly proportional to the braking force, adjusting the system pressure will change the braking force.

[0026] The generation of braking force and the force of hydraulic pressure reacting on the wheels come from: wheels 31 brake rail 32 The hydraulic cylinder brake chamber 24 realizes the interaction of braking fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com