Permanent-magnet variable-speed hub motor with complementing excitation rotor

A variable speed hub and excitation technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of complex motor structure, unsatisfactory technical effect, increased cost, etc., and achieve simple and compact structure, easy Mobile, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

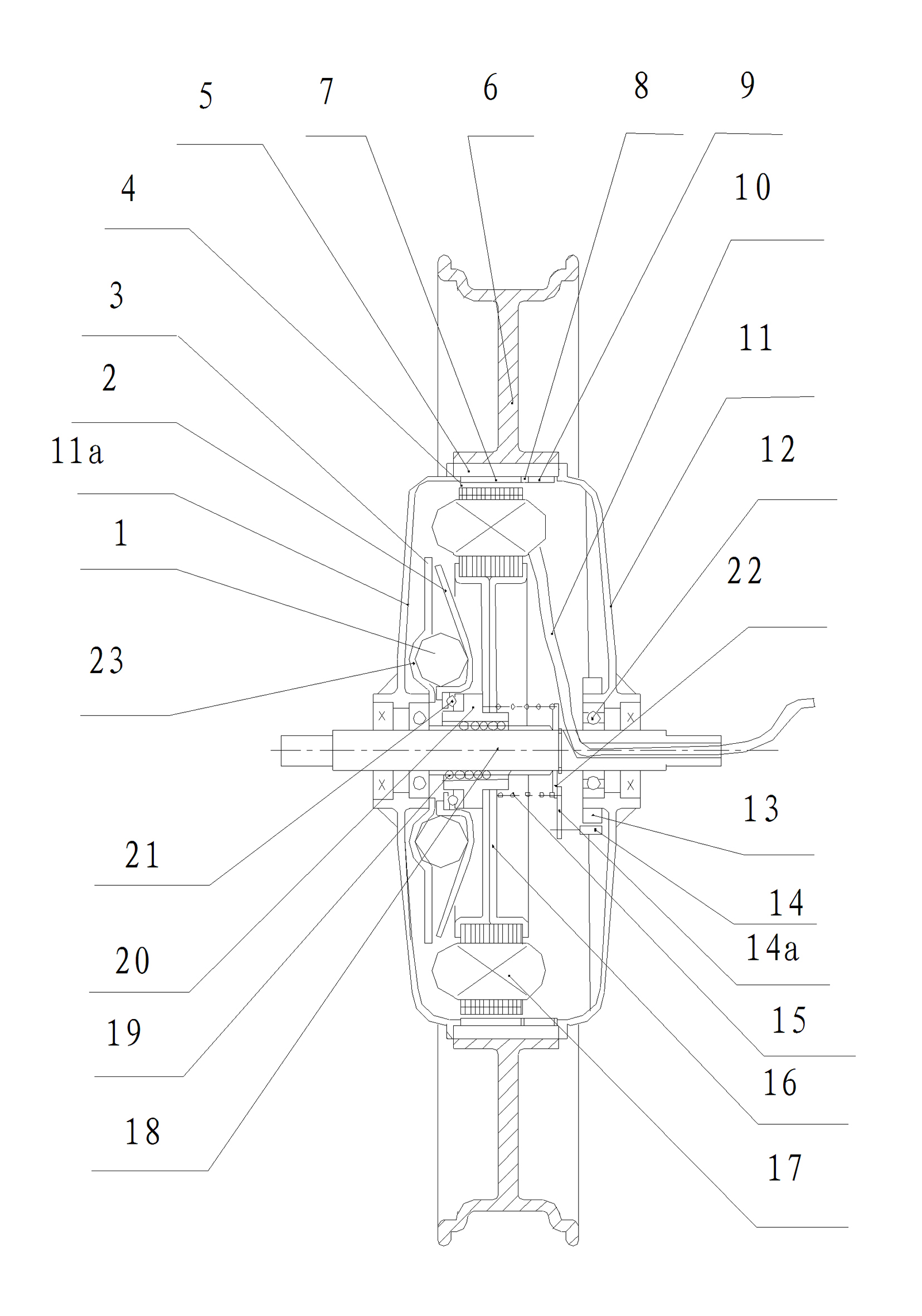

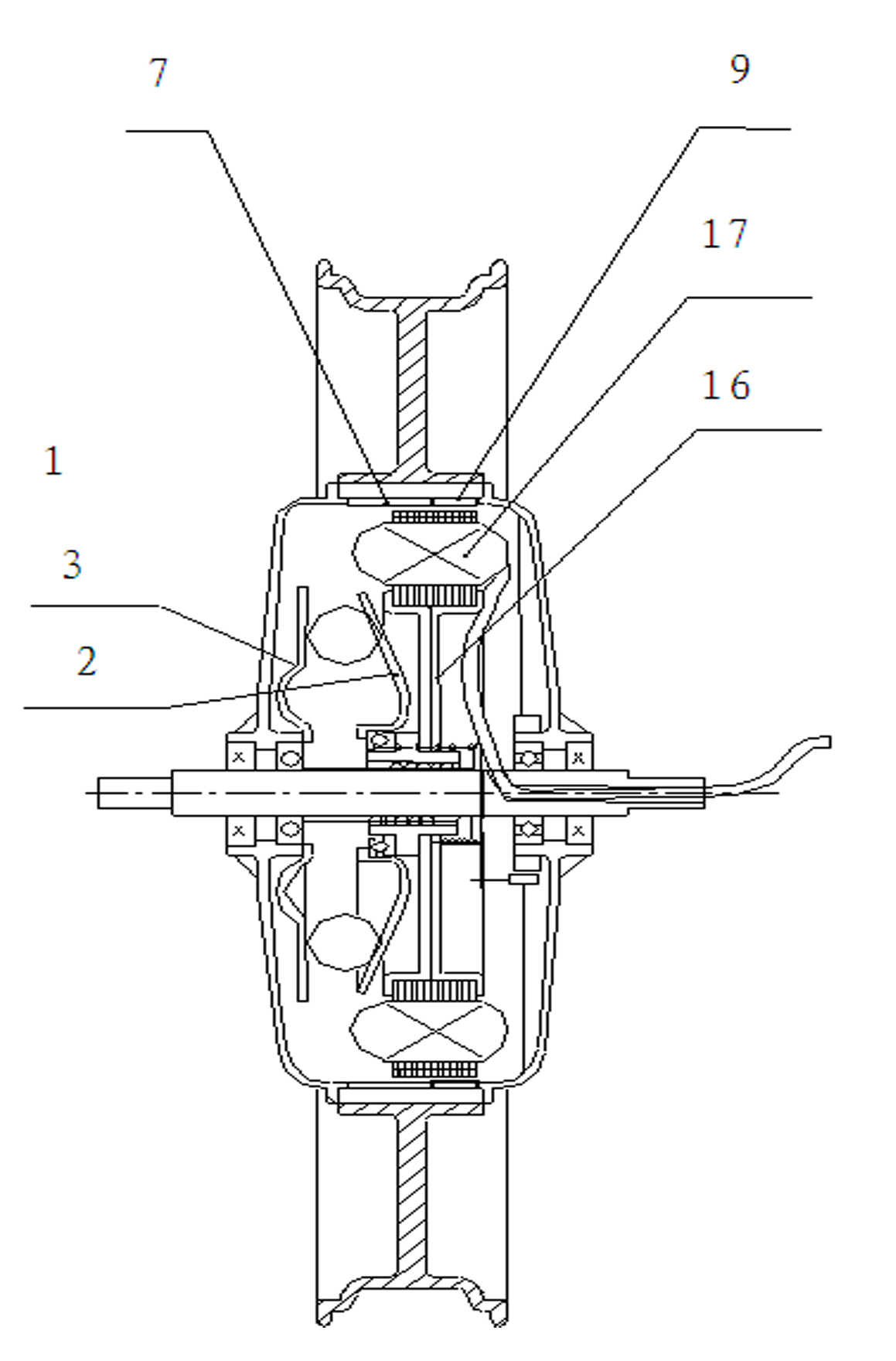

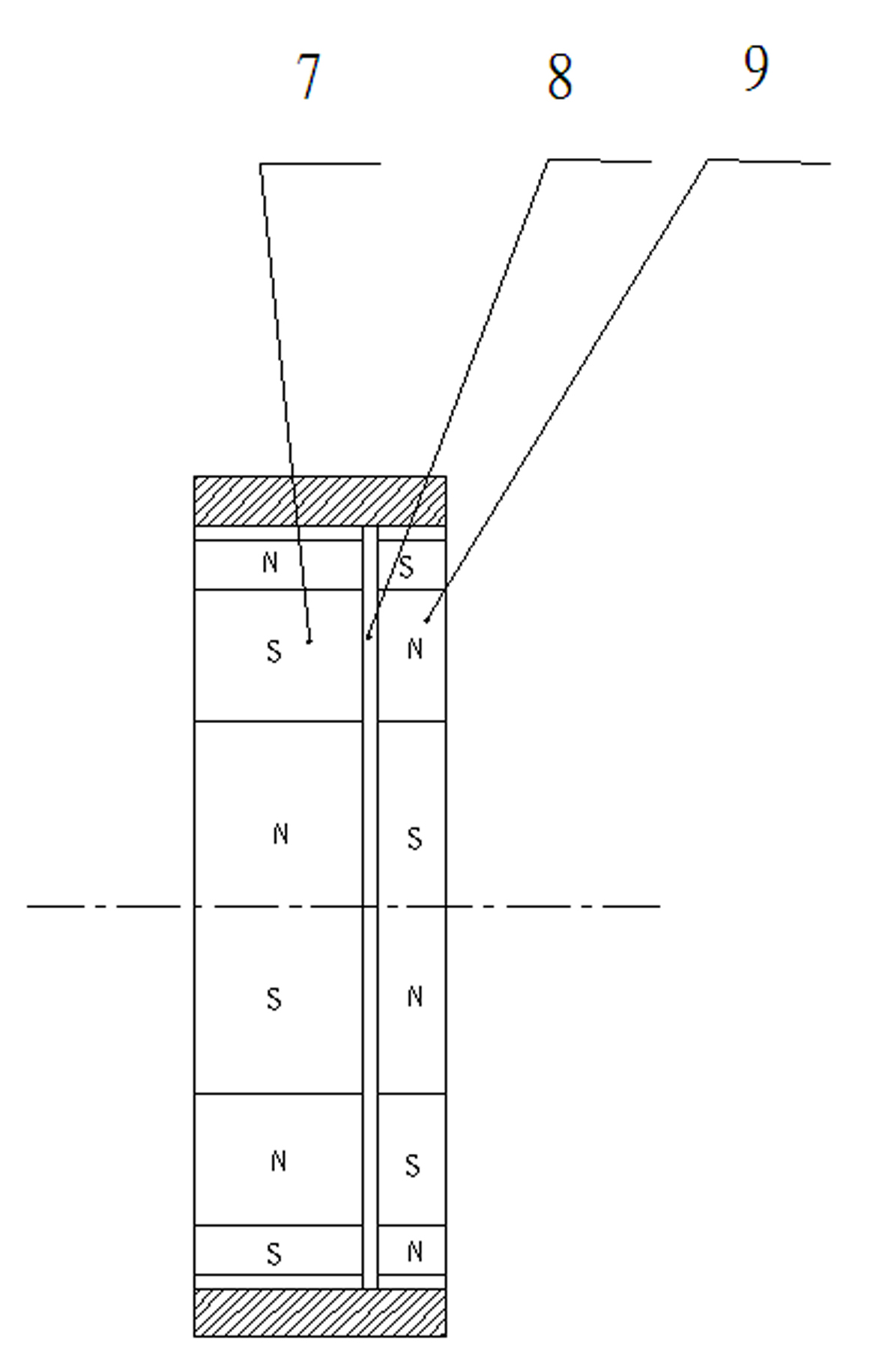

[0045] figure 1 It is a structural schematic diagram of the present invention, the rotor is a permanent magnet variable speed wheel hub motor with complementary excitation, including a hub 6, a rotor yoke 5 fixed on the inner circle of the hub, and a stator 16 located in the inner circle of the rotor yoke 5, the rotor yoke 5 The inner circle is provided with an excitation magnetic source, the circumference of the stator 16 is provided with a winding 17, the lead cable 10 of the winding 17 passes through the hole on the stator shaft 18, and there is an air gap 4 between the iron core of the winding 17 and the excitation magnetic source , the two ends of the stator shaft 18 are respectively provided with bearings 12, the end covers at the left and right ends of the wheel hub 6 are supported on the stator shaft 18 through the bearings 12, and the left and right end covers 11a, 11b are respectively connected to the wheel hub 6 through screws or / and keys. fixed in the direction so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com