Quantitative control valve of fuel gas entering cylinder on gas engine

A gas engine, quantitative control technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of engine output power limitation, high gas consumption rate, poor dynamic response of gas volume adjustment, etc., to eliminate backfire and deflagration low risk, low gas consumption rate and good dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

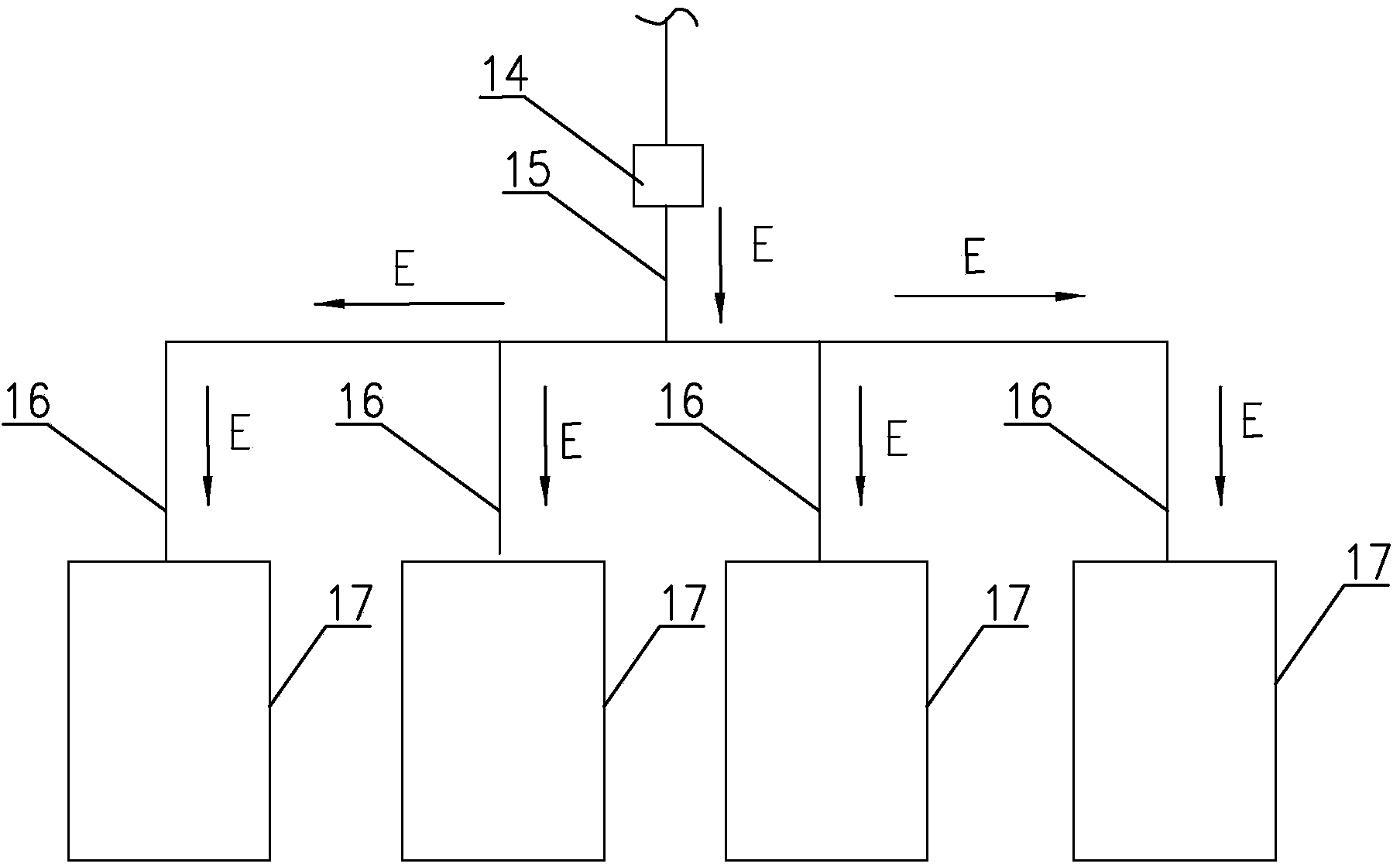

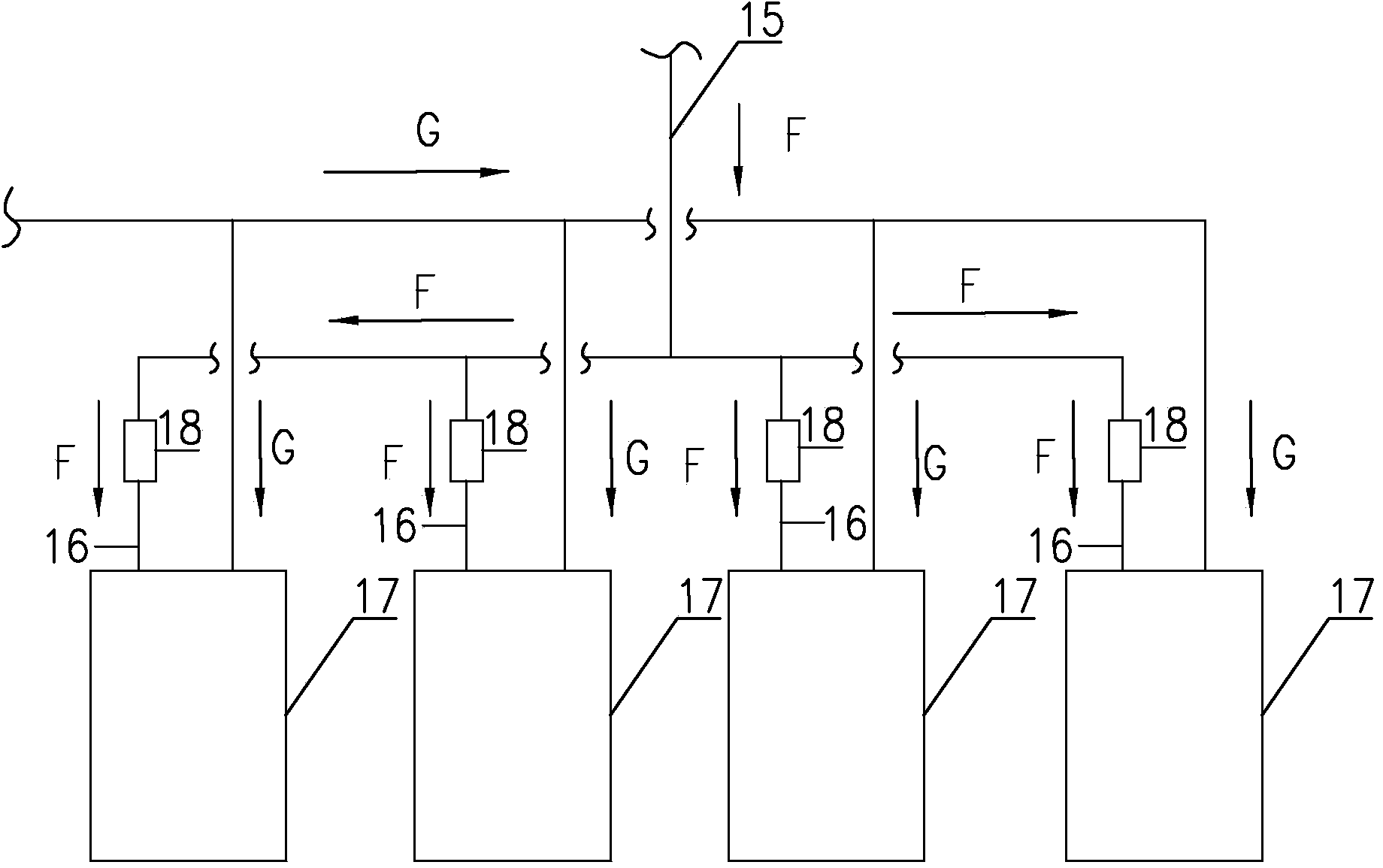

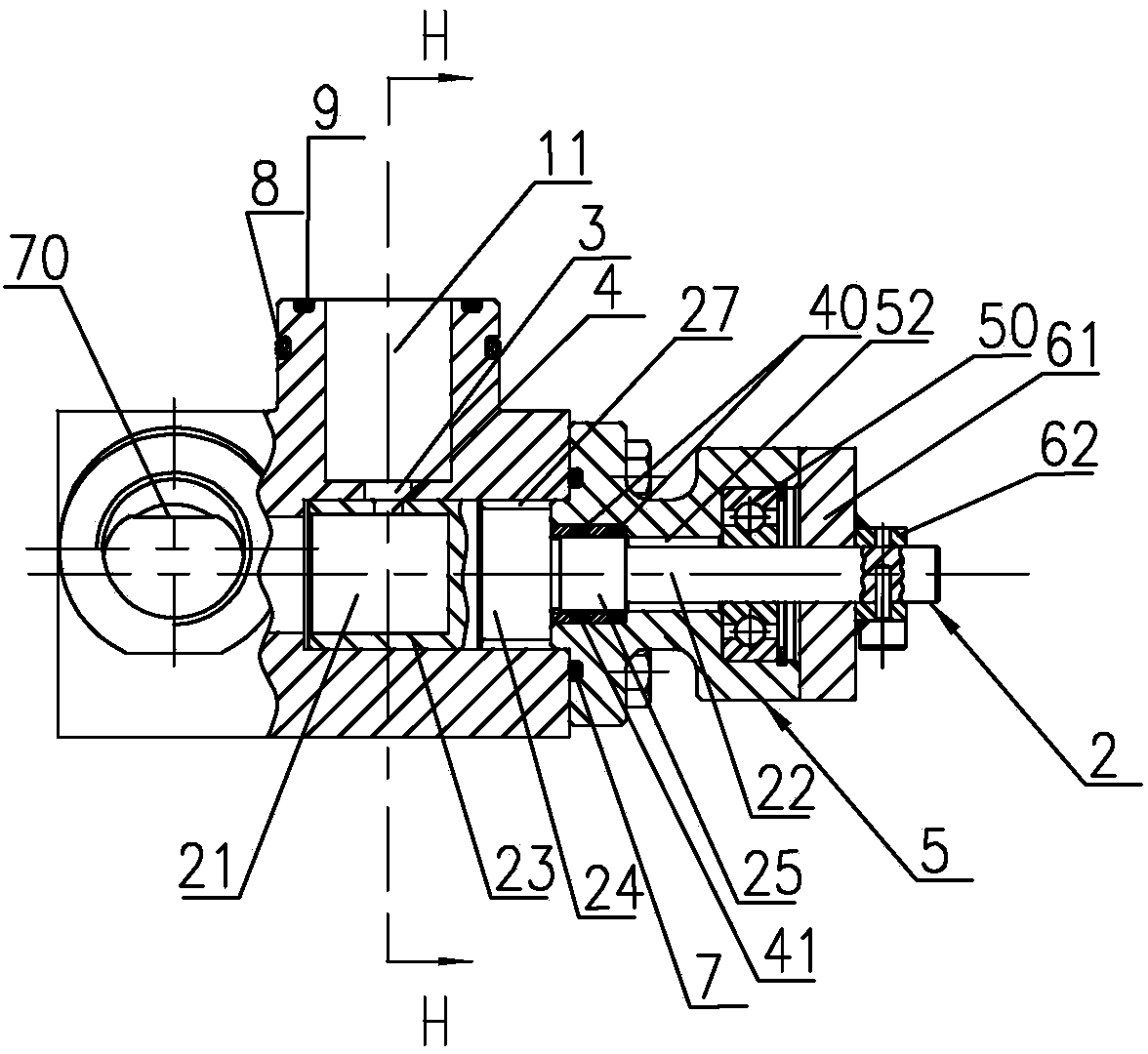

[0041] Such as Figure 3-12 Shown is a gas engine gas cylinder quantitative control valve 18 of the present invention, which includes a valve body 1, a valve stem 2 and a valve handle 6 installed in the valve body 1, and the valve body 1 is an elongated block body. The valve body 1 is provided with an air inlet hole and an air outlet hole whose centerlines are perpendicular to each other. An air outlet hole 11 is provided, and one end of the air inlet hole 11 is an air intake end for connecting gas, and the other end is set on one end surface of the valve body 1 as an adjustment end for inserting the valve stem 2, and the air outlet hole 11 is located at On the wall of the valve body close to the adjustment end of the air inlet passage, the inner port of the air outlet passage 11 communicates with the air intake passage to form the outer port 3 for adjustment, and the outer port of the air outlet passage 11 is used to connect with the engine cylinder; the front end 23 of the val...

Embodiment 2

[0049] Such as Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that a valve seat 45 is added at the regulating end of the valve body 1, which is formed by the flange cover of Embodiment 1 corresponding to the gap between the inner and outer ends of the shaft hole. The elongated valve seat 45 formed by partial extension.

[0050] In other embodiments, the central lines of the air inlet hole and the air outlet hole in the valve body may cross each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com