Multi-rotation type versatile electric actuating mechanism

A technology for electric actuators and motors, applied in engine components, mechanical equipment, valve details, etc., can solve problems such as bad electrical or mechanical shocks of electric actuators, idle running and oscillation of electric actuators, and inability to achieve speed control. Achieve the effect of realizing absolute position coding, avoiding loss and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

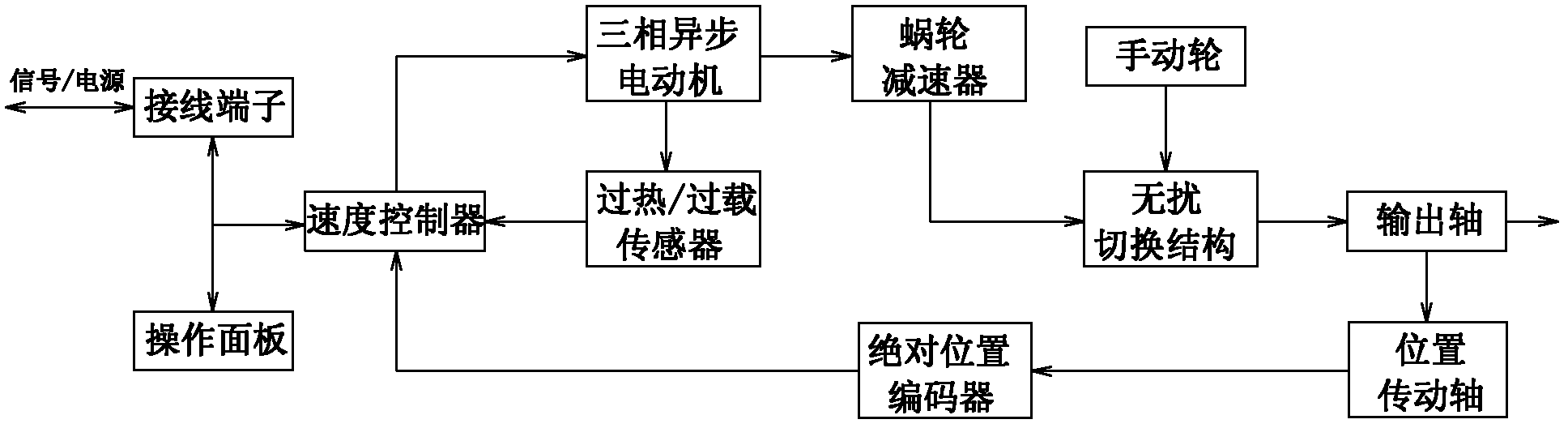

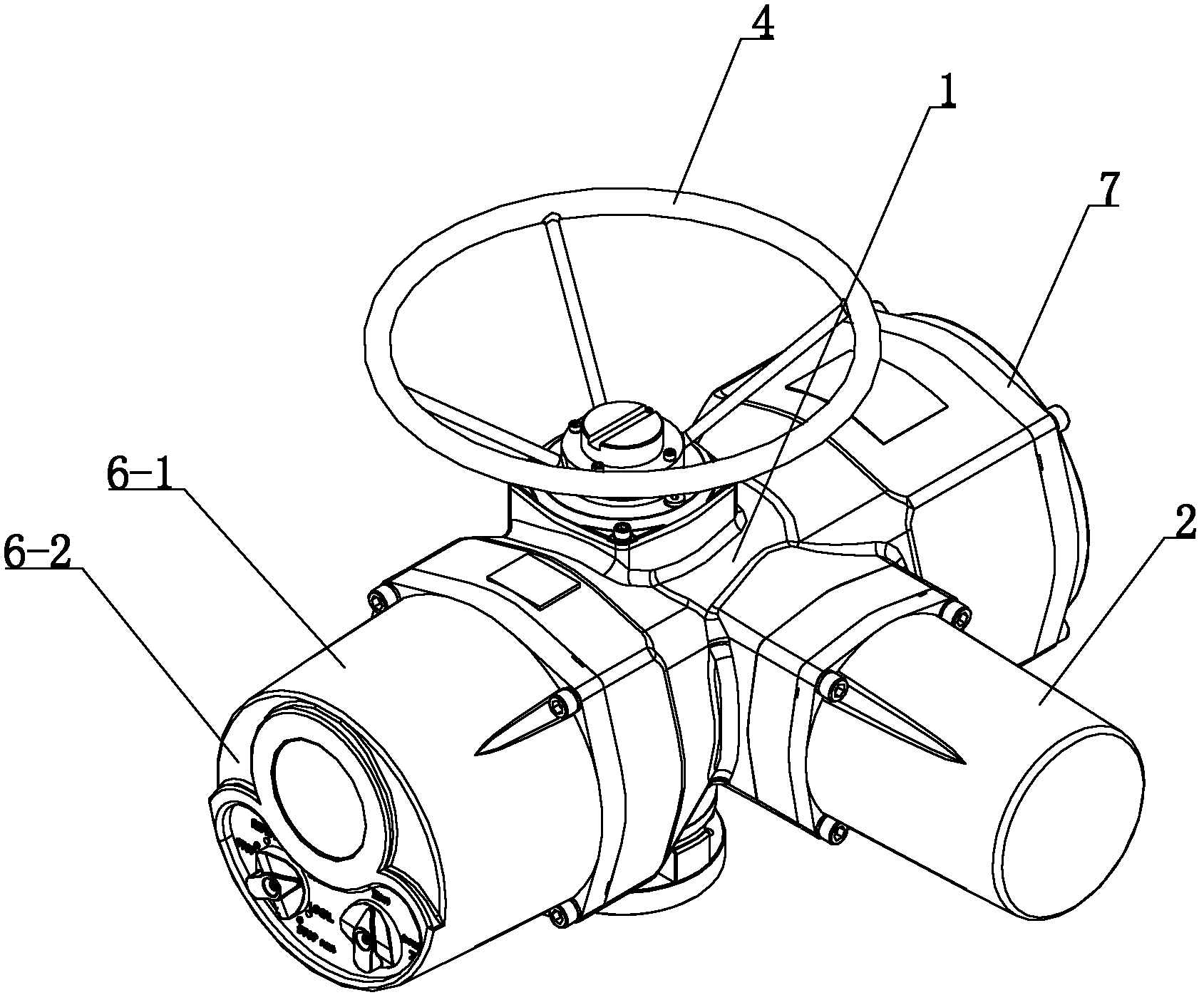

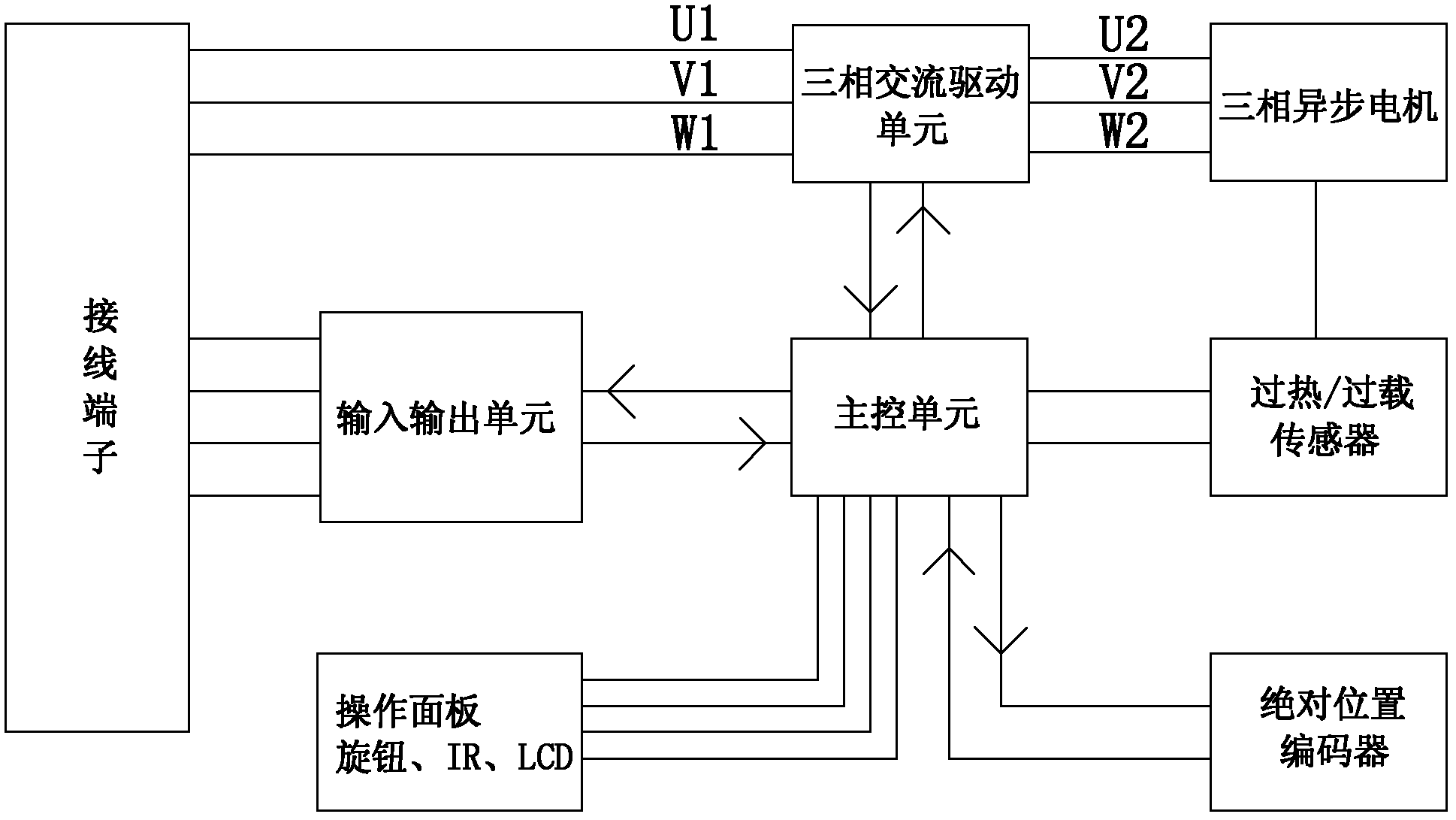

[0040] see Figure 1-13, Almighty multi-turn electric actuator, including housing 1, motor 2, worm gear reducer 3, manual wheel 4 and output shaft 5. The shell is a T-shaped structure, and five ports are formed on the shell. The motor and the manual wheel are respectively installed at the front port and the upper port of the casing, and a speed controller 6-1 and an operation panel 6-2 are installed on one side port of the casing, and the speed controller is used to control the starting of the motor , Stop and run and adjust its speed. The operation panel is specifically equipped with an operation knob, IR (infrared receiver), and LCD (liquid crystal display). The other side port of the housing is equipped with a connection terminal 7 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com