Variable-diameter crankshaft type gear stepless speed change method and speed changer

A technology of continuously variable speed and crankshaft, which is applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., and can solve the problems of maximum torque, transmission power limitation, slow response of speed change belt, slipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A variable-diameter slider is set on the end face of the power input shaft to form a friction pair on the end face. The variable-diameter slider is coaxial with the planetary gear of the planetary gear train. By controlling the displacement of the axis line of the variable-diameter slider and the axis line of the power input, a The radius of the crankshaft, through the input power of the power input shaft, drives the variable-diameter slider to rotate, so that the axis of the variable-diameter slider rotates around the axis centerline of the power input shaft to form the crankshaft motion; the crankshaft passing through the axis of the variable-diameter slider The motion drives the rotation of the planetary gears of the planetary gear train, and under the limit action of the ring gear of the planetary gear train, the planetary gears transmit the power of the variable diameter slider to the output shaft, realizing the continuous stepless speed change function.

Embodiment 2

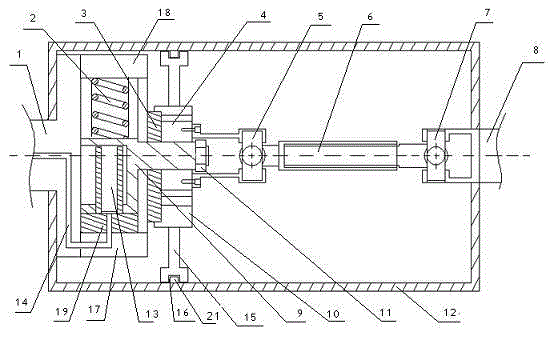

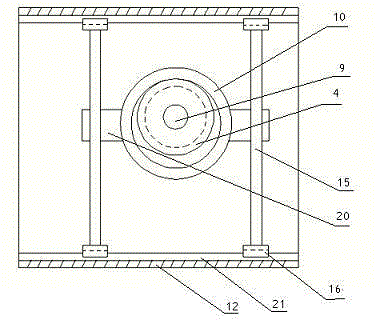

[0020] according to figure 1 As shown, the present invention mainly consists of a power output shaft 1, a return spring 2, a planetary gear follower plate 3, a planetary gear 4, a first universal joint 5, a rotating shaft 6, a second universal joint 7, and a power output shaft 8 , reducing slider 9, follower ring gear 10, box body 12, plunger 13, guide rail 15, chute 16, oil pump top plate 17, spring top plate 18, plunger pump 19, guide sleeve 20, slide rail 21, etc. Wherein, the end face of the power input shaft 1 and the end face of the variable diameter slider 9 are fixedly connected through the spring top plate 18 and the oil pump top plate 17 to form an end face friction pair, and a plunger pump 19 is arranged between the spring top plate 18 and the oil pump top plate 17. Diameter slider 9 is sleeved on the plunger 13 of plunger pump 19 and can move radially. The top of variable diameter slider 9 is connected with return spring 2 to control the displacement of variable d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com