Motor coach hybrid power driving system

A hybrid power and drive system technology, applied in the field of drive systems in the field of vehicle engineering technology, to achieve the effects of reducing installation space, reducing power, good matching and optimal control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

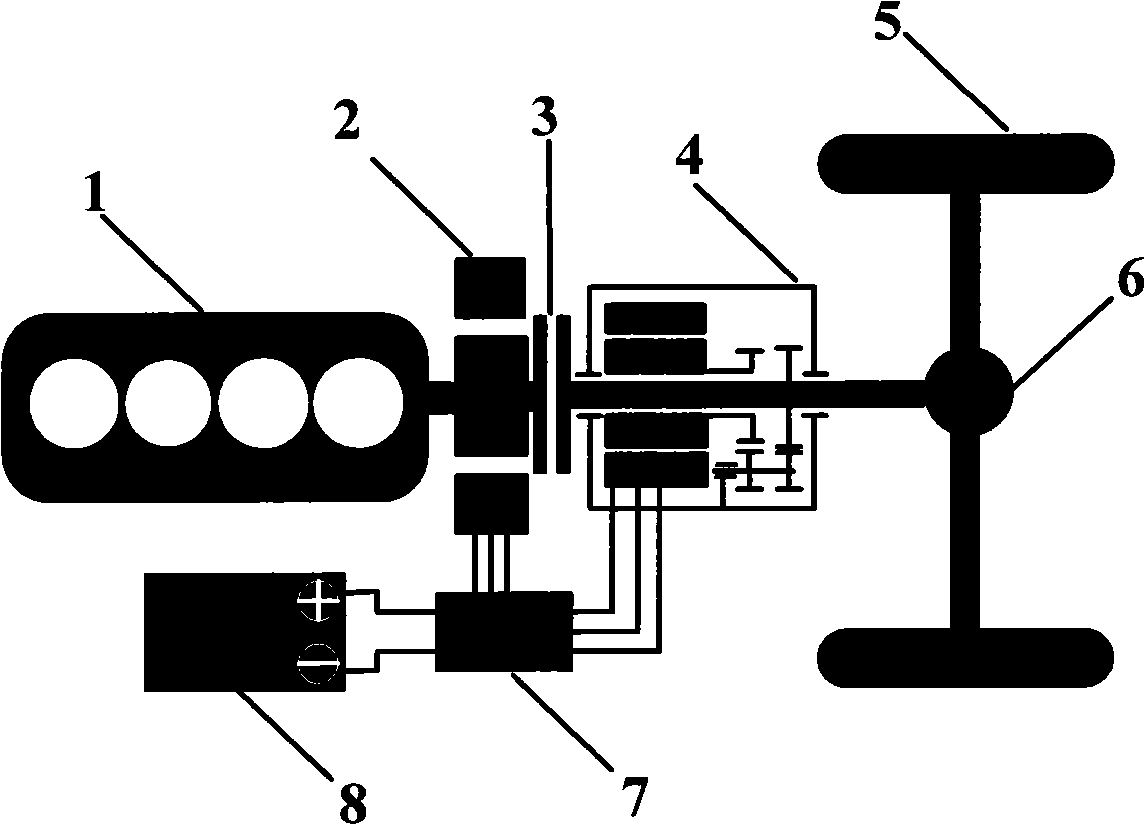

[0027] Such as figure 1 As shown, the driving system of this embodiment includes an engine 1, an integrated starter generator 2, an automatic clutch 3, an electromechanical coupling mechanism 4, wheels 5, a final reducer-differential 6, a motor controller 7, and a power battery pack 8, Among them: the electromechanical coupling mechanism 4 is composed of a driving motor and a reduction mechanism, the engine 1 and the integrated starter generator 2 are coaxially connected, the integrated starter generator 2 is connected to the active disc of the automatic clutch 3, and the automatic clutch 3 passes through the electromechanical coupling mechanism 4. The drive motor is connected to the reduction mechanism, the reduction mechanism is respectively connected to the drive motor and the final reducer-differential 6, the final reducer-differential 6 is connected to the wheel 5 through the drive axle, and the power battery pack 8 is connected to the motor controller through a cable 7, ...

Embodiment 2

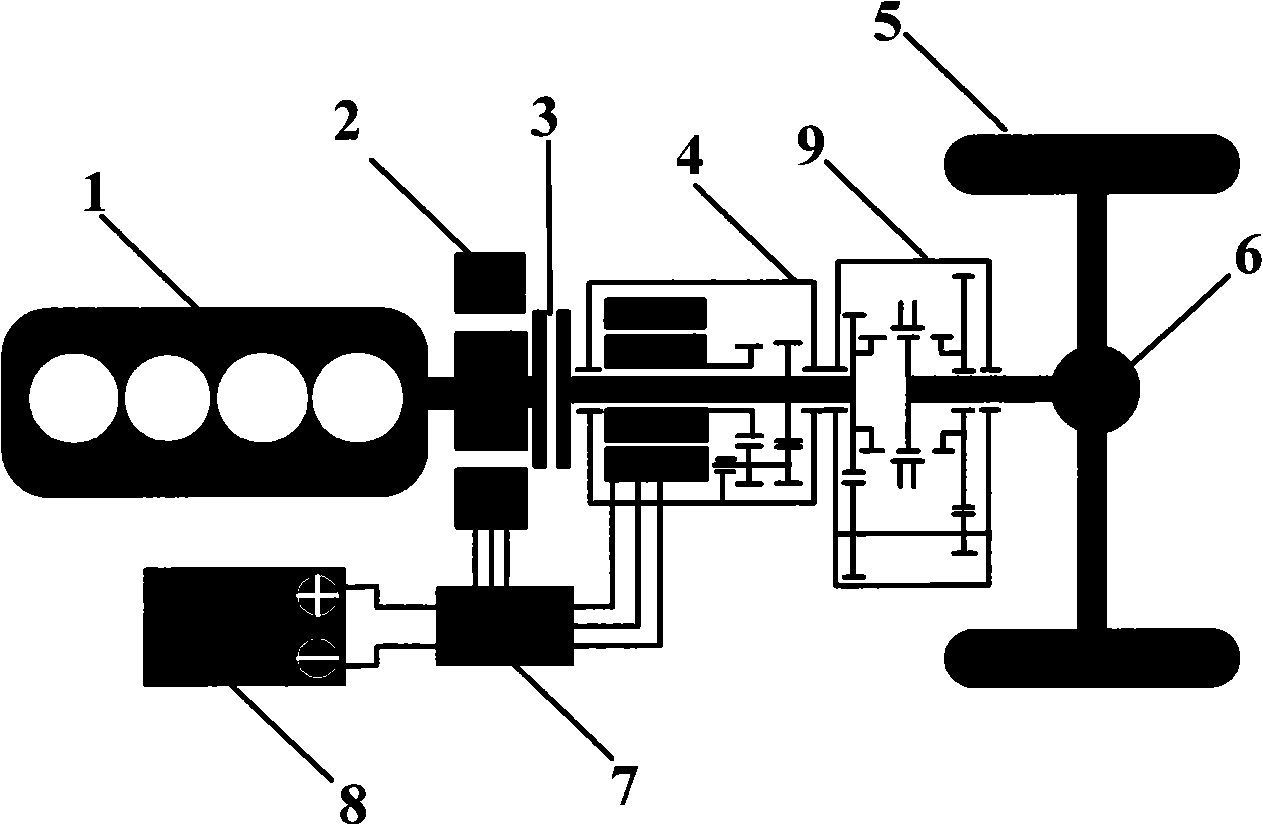

[0041] Such as figure 2 As shown, this embodiment is an optimized solution, and on the basis of Embodiment 1, it also includes a two-speed transmission 9, and the two-speed transmission 9 is arranged between the electromechanical coupling mechanism 4 and the final drive-differential 6 combined mechanism. The input shaft of the high-speed transmission 9 is connected with the reduction mechanism in the electromechanical coupling mechanism 4, and the output shaft of the two-speed transmission 9 is connected with the final drive-differential 7. Other component connections, working modes, and basic control strategies are the same as those in Embodiment 1, and will not be repeated here.

[0042] In this embodiment, due to the existence of the two-speed transmission mechanism, the speed change range is enlarged, and the requirement on the speed range of the driving motor is reduced, so that the speed change control is more flexible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com