Synchro clutch for washing machine

A technology for clutches and washing machines, applied in the field of transmission systems and synchronous clutches, to achieve the effect of simplifying transmission mechanisms and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

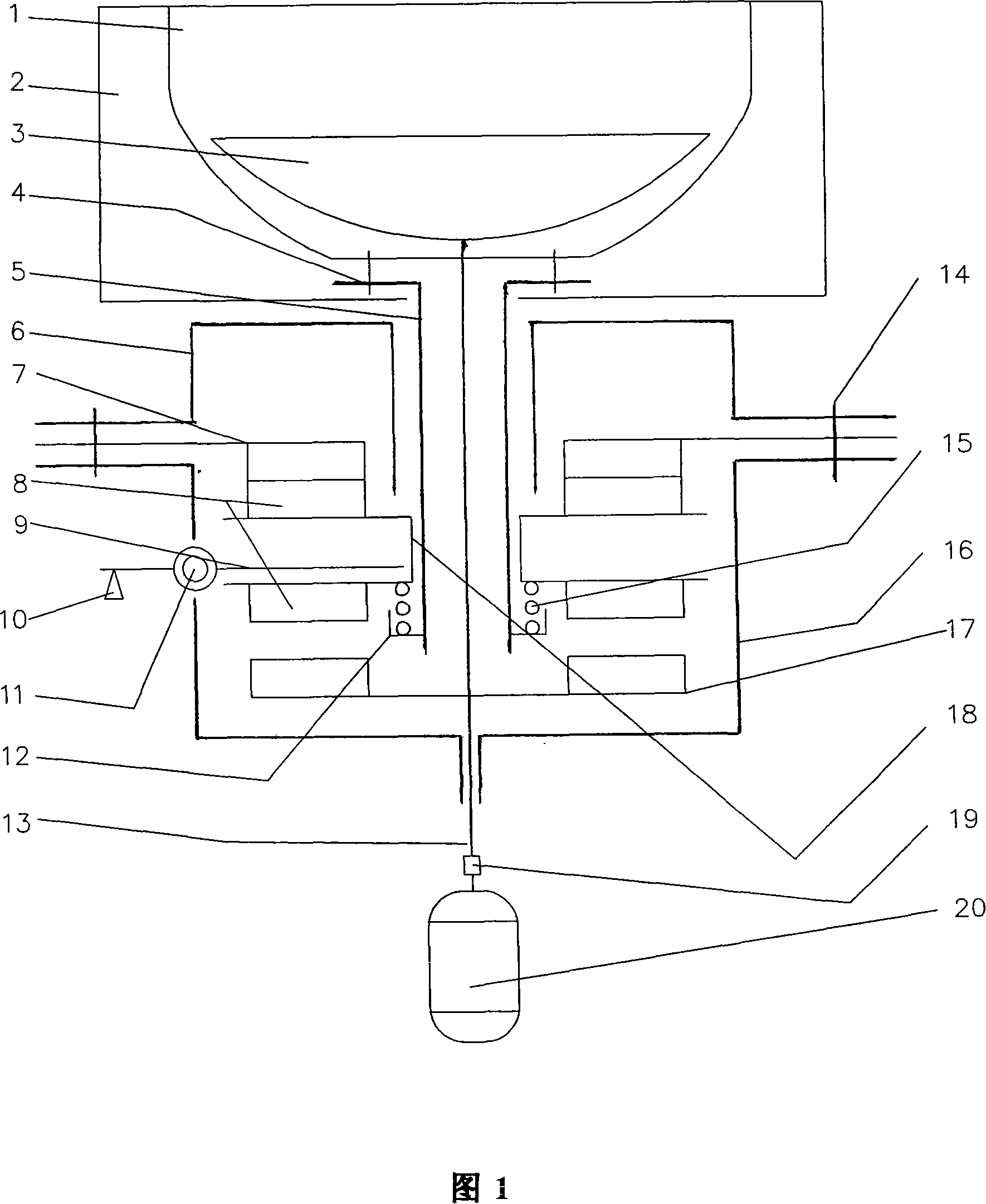

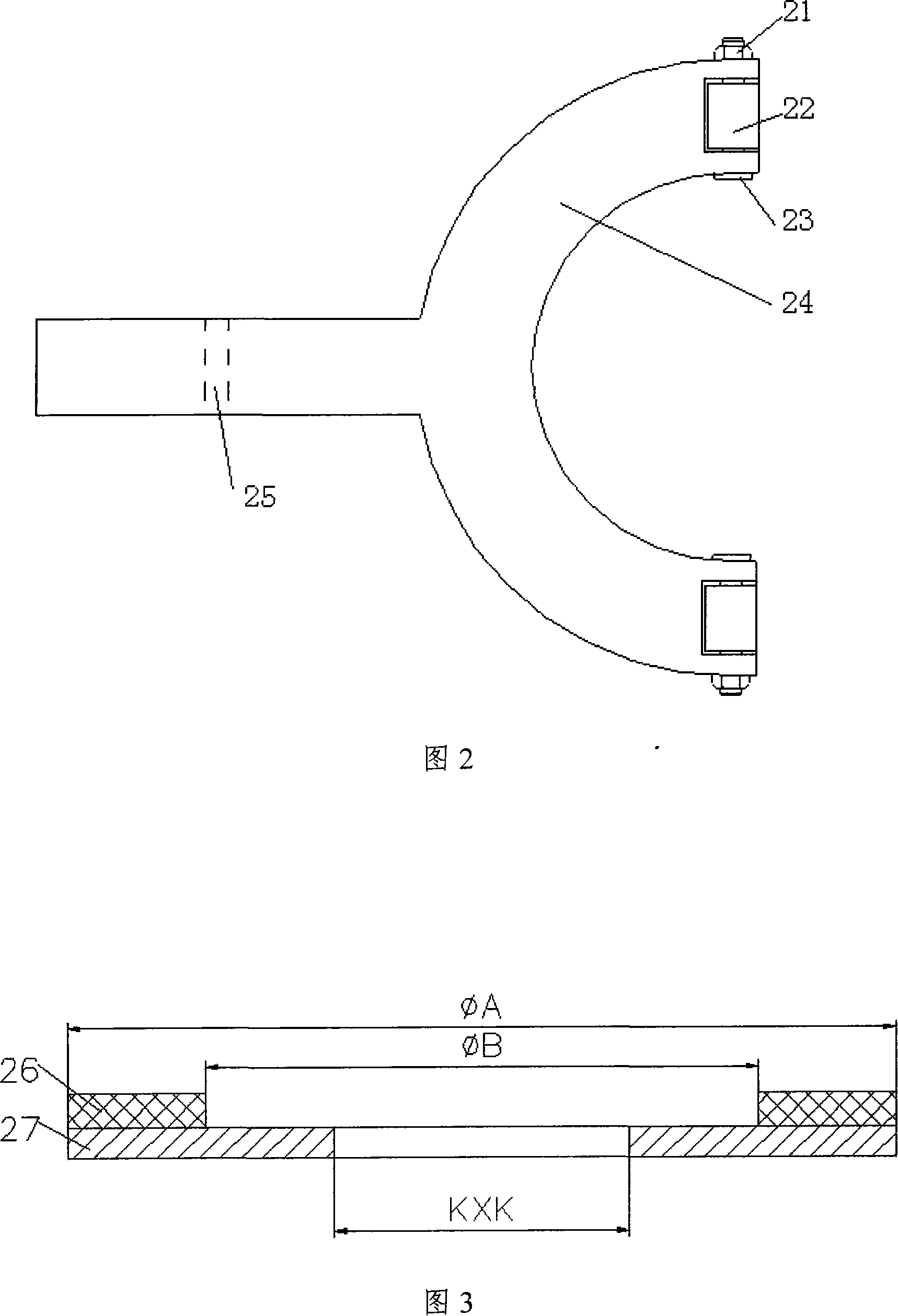

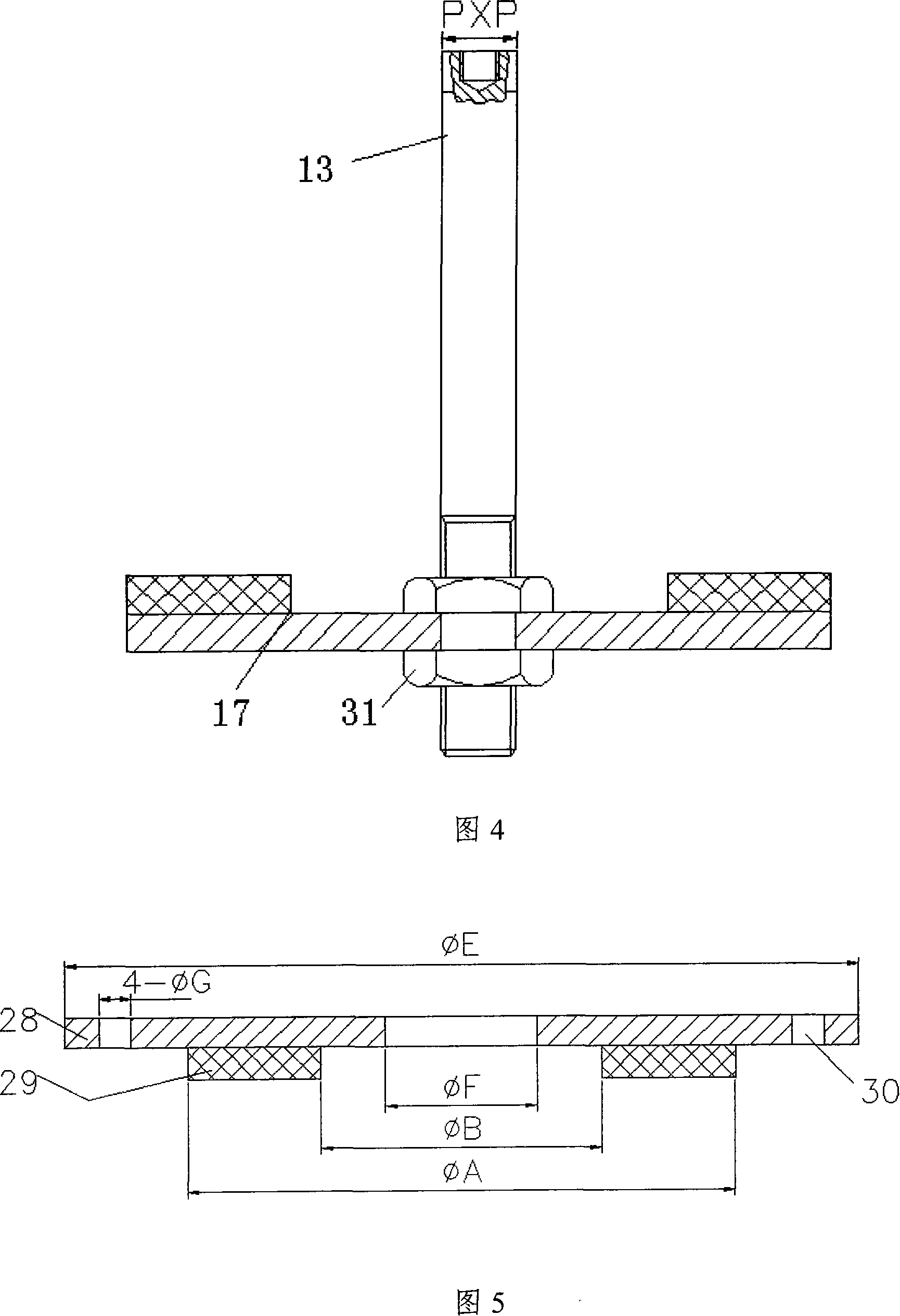

[0029] As shown in Fig. 1 to Fig. 8, the present invention is characterized in that in the upper casing 6 and the lower casing 16 that are covered together, from the bottom to the top of the lower casing 16, the bottom of the lower casing 16 is fixed on the The dehydration friction plate assembly 17 on the washing shaft 13 and the sliding sleeve 18 connected with the dehydration shaft 5 by splines are respectively fixed with a movable friction plate 8 on the upper and lower sides, and the sliding sleeve 18 is pressed against the compression spring 15 on the dehydration shaft 5. And the adjustment nut 12 threaded with the dehydration shaft 5 below it, the washing friction plate assembly 7 fixed at the junction of the upper housing 6 and the lower housing 16 and the washing friction plate 29 on it correspond to the movable friction plate 8, And the roller 22 (two) on the fork body 24 of the shift fork assembly 9 that links to each other with the drainage tractor 10 is against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com