Numerically-controlled precise grinding polisher

A polishing machine, a precise technology, applied in grinding/polishing equipment, machine tools suitable for grinding workpiece planes, grinding machines, etc. , lack of precise control of speed, etc., to achieve the effect of stable speed regulation, wide speed change range and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

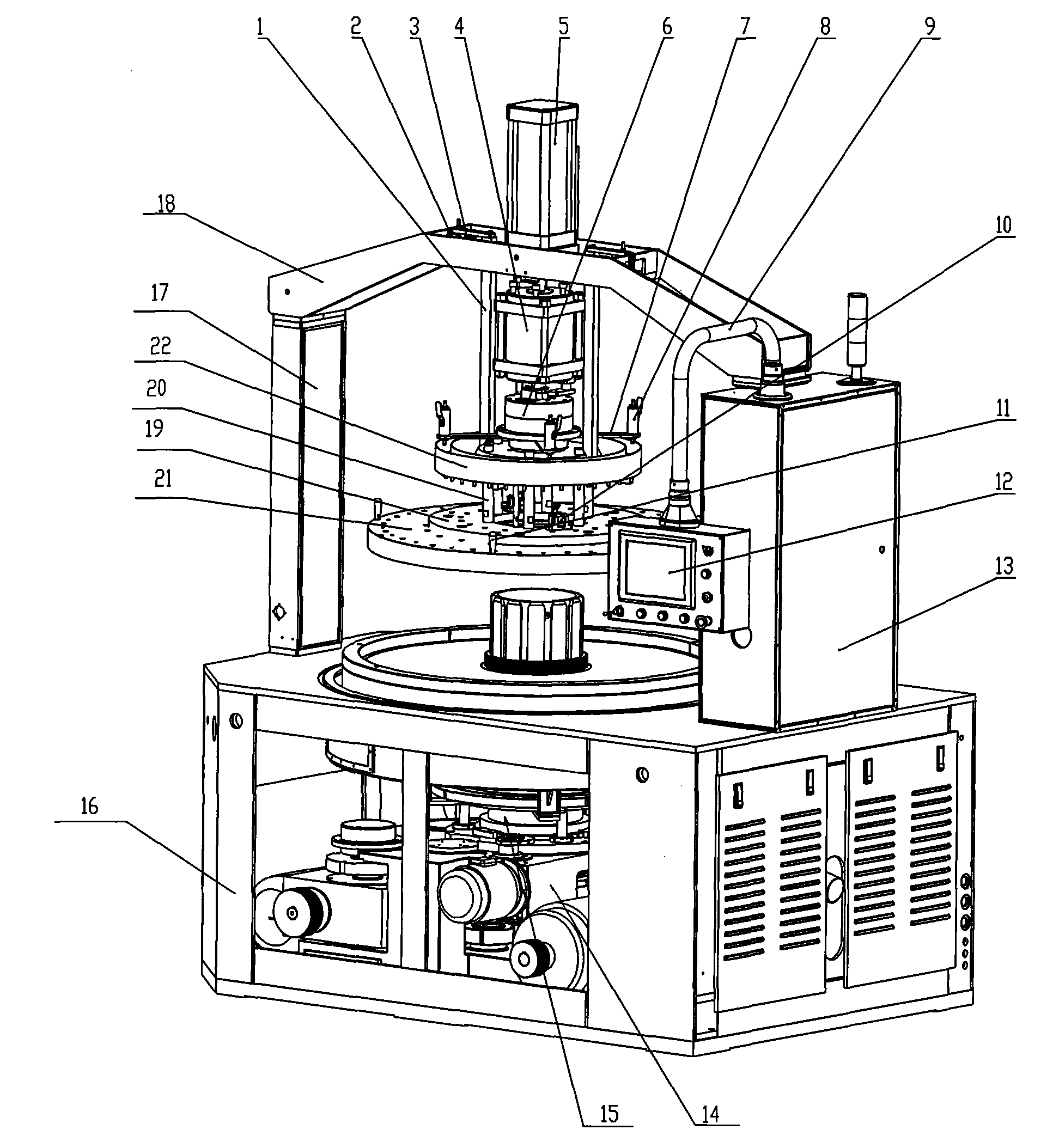

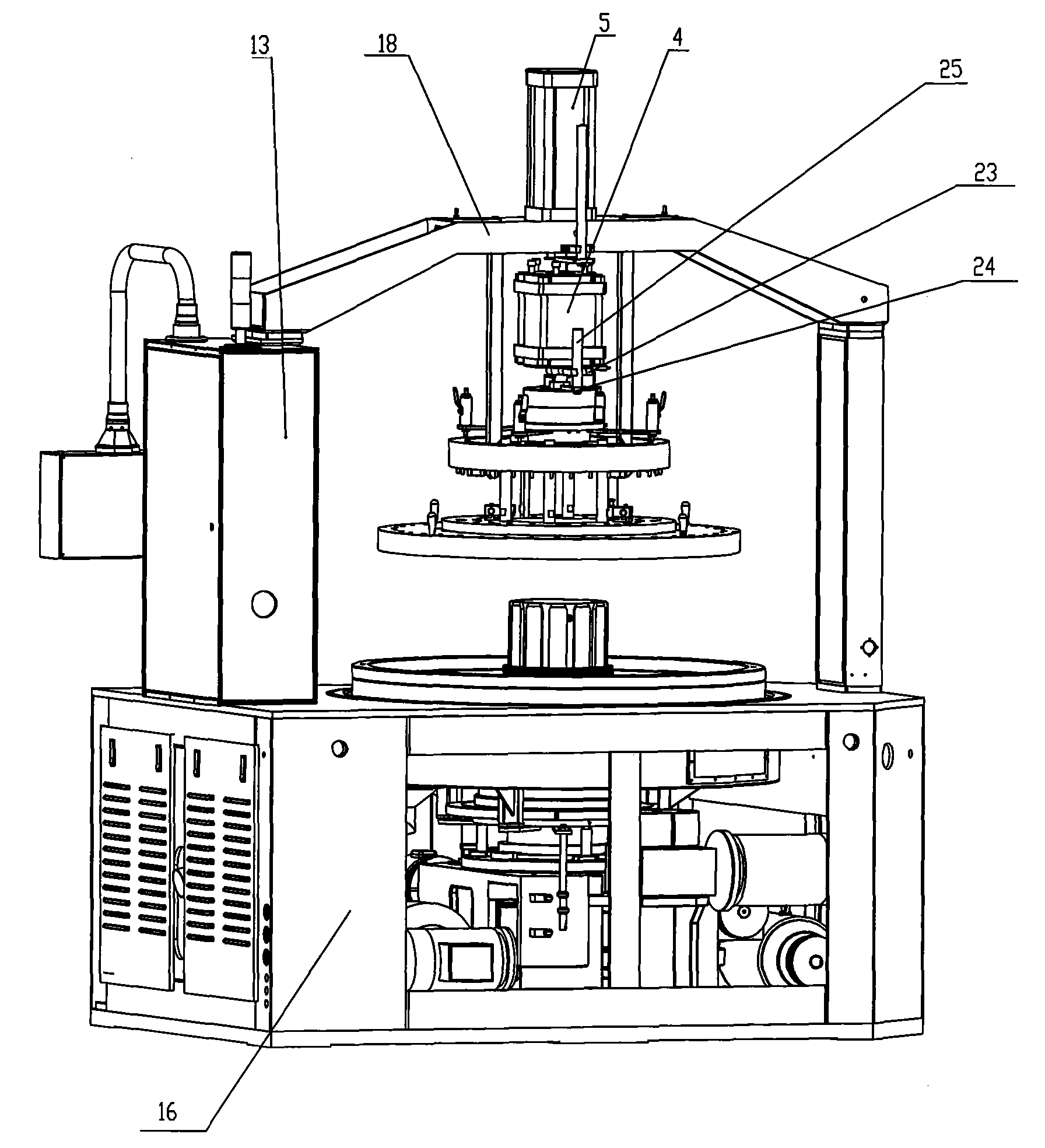

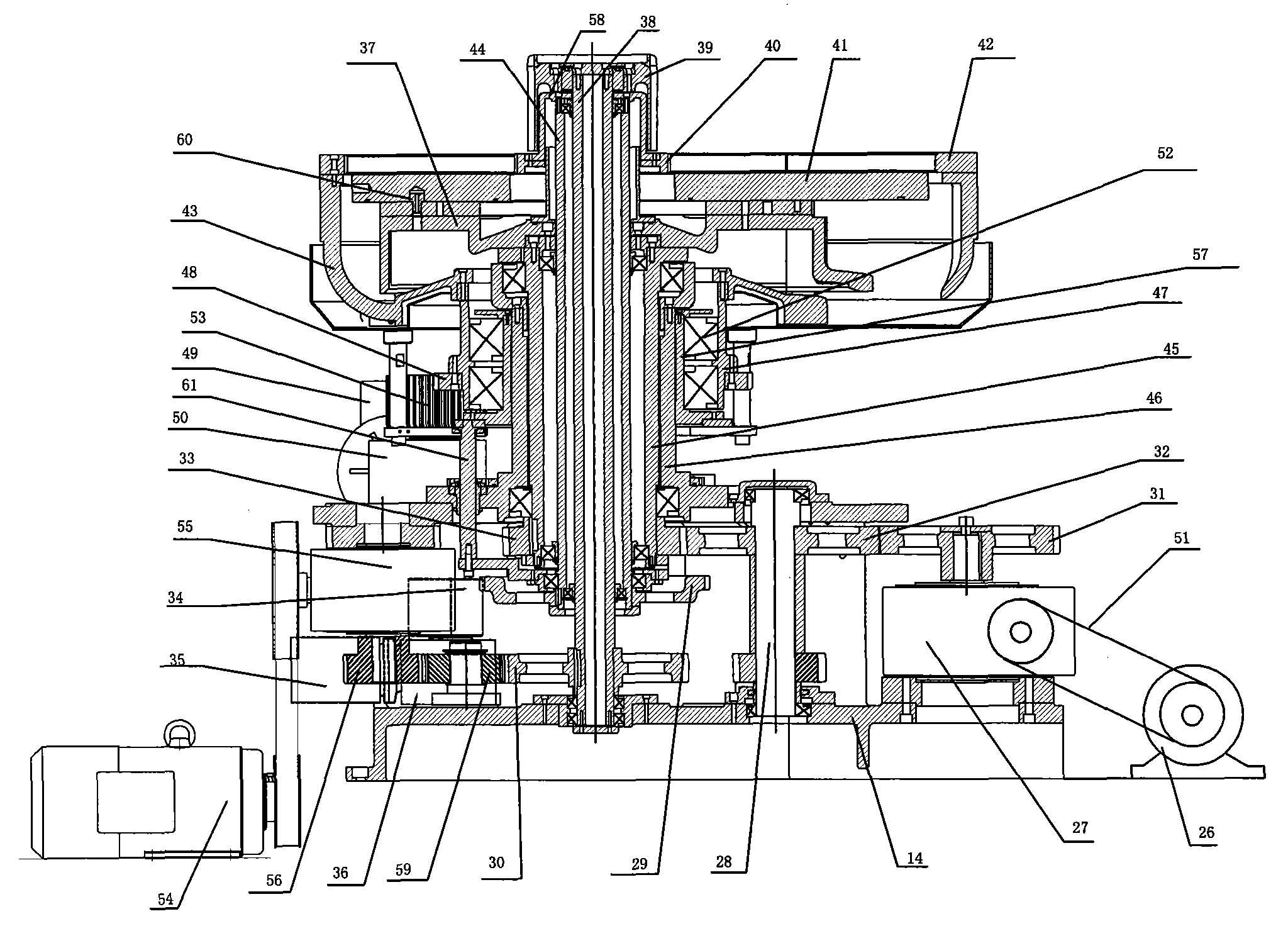

[0019] See figure 1 , 2 3. The numerically controlled precision grinding and polishing machine includes a welding box 16, one side of the welding box 16 is provided with a column 17, the other side of the welding box 16 is provided with an electrical cabinet 13, and the two ends of the beam 18 Fixedly installed on the column 17 and the electrical cabinet 13 respectively, the main support 14 in the welding box 16 is provided with a main shaft drive system 15, and the position corresponding to the main shaft drive system 15 is provided with an upper plate device on the beam 18, and the operation box 12 The supporting arm 9 of the operation box is arranged on the electrical cabinet 13, and it is characterized in that it also includes: the cylinder rod of the fast acting cylinder 5 of the upper plate device is fixedly installed in the center of the crossbeam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com