Planetary gear continuously variable transmission

A technology of continuously variable transmission and planetary gear, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of insensitive speed regulation, and achieve the effect of simple structure, simple principle and wide speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

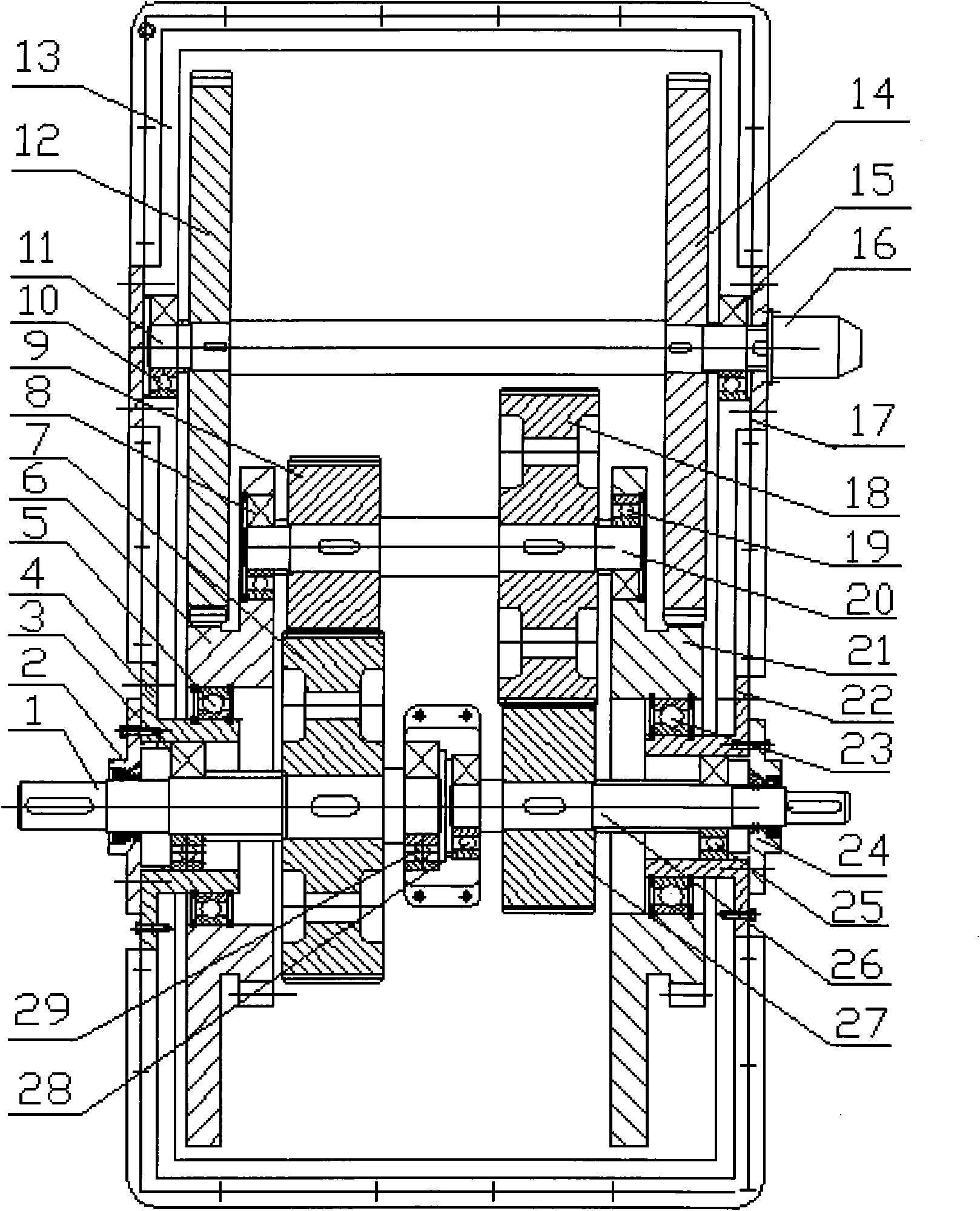

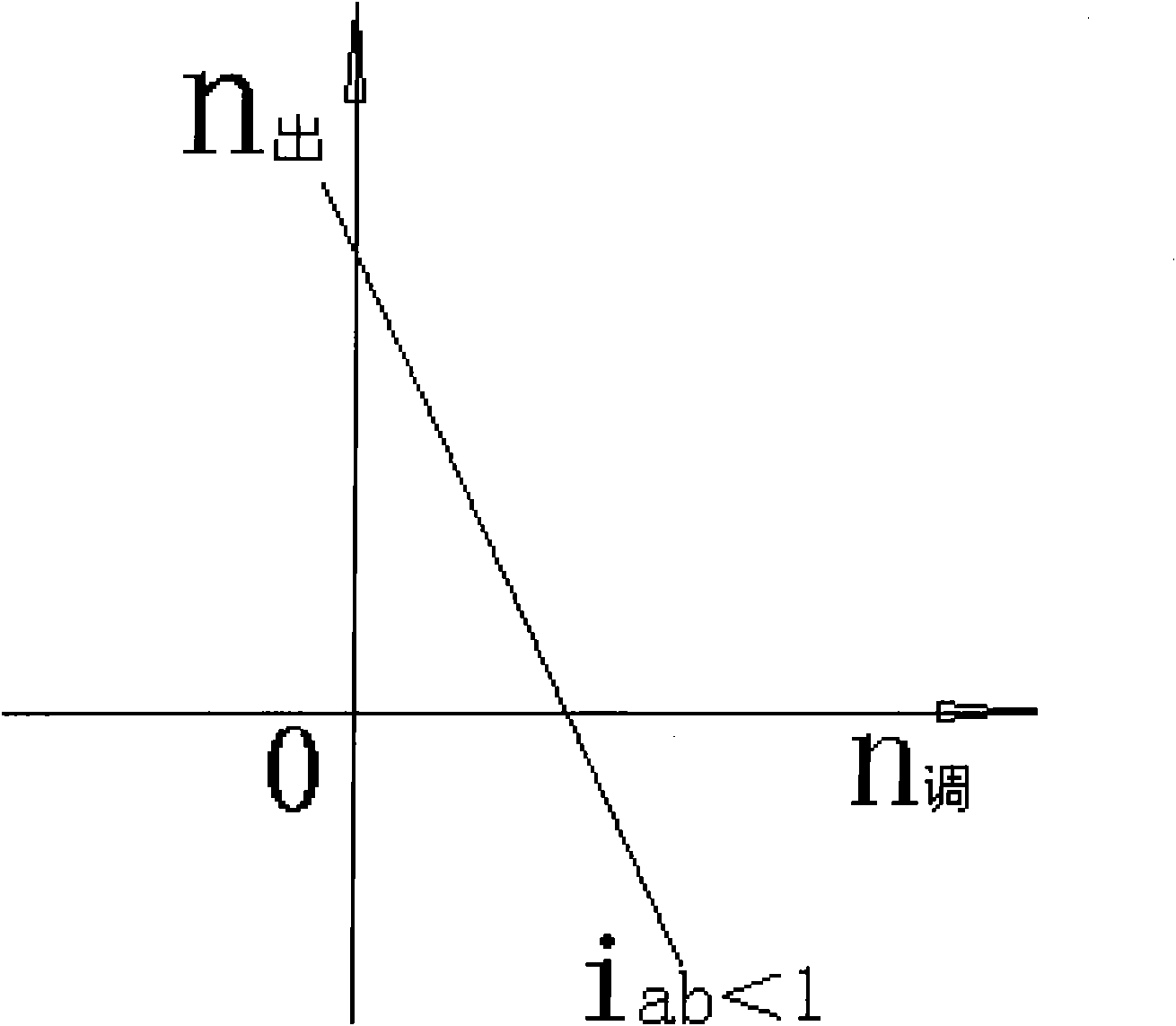

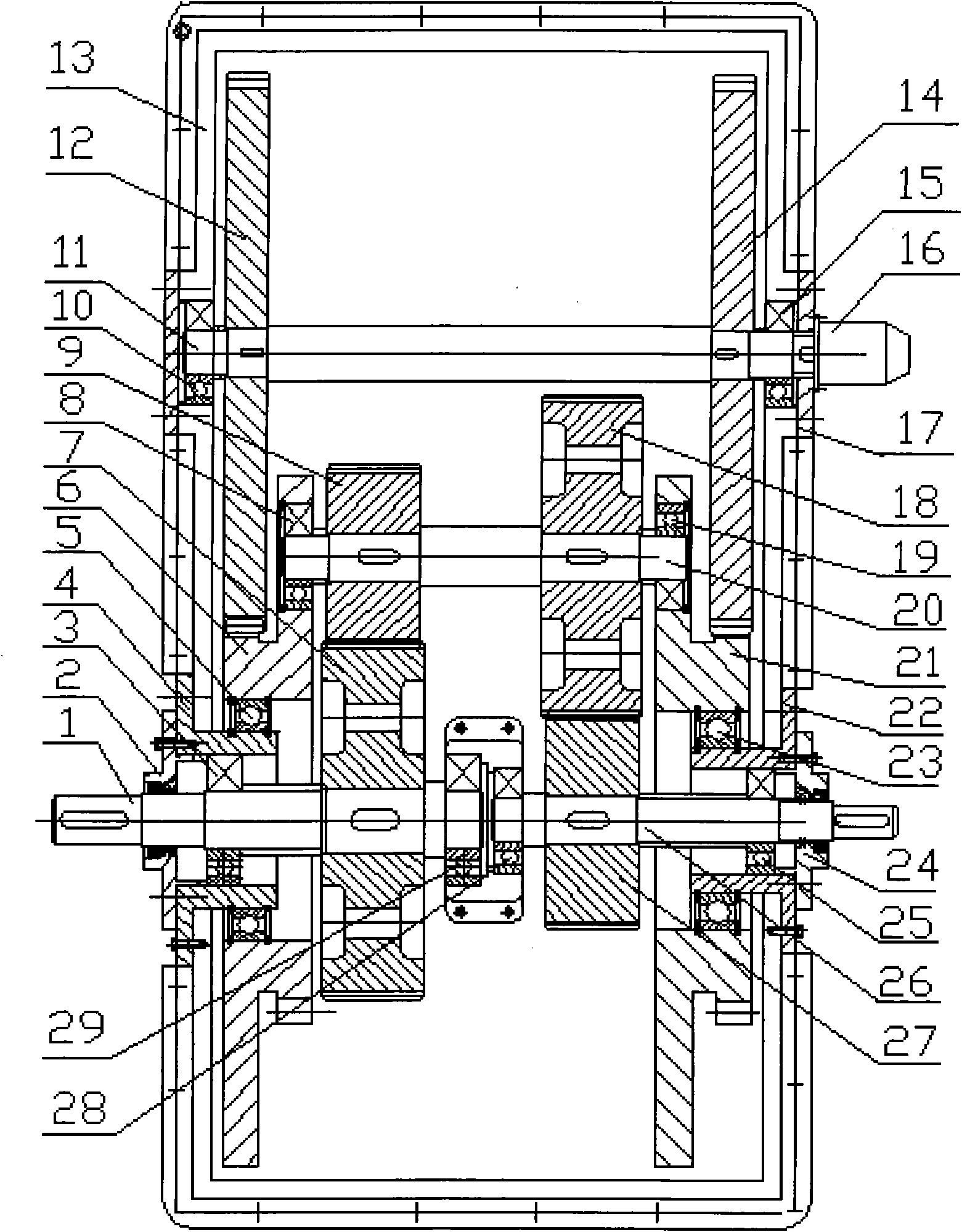

[0019] Such as figure 1 A planetary gear continuously variable transmission is shown, in which the planetary gear train belongs to the WW type external meshing double planetary gear train, the input speed is the speed of the center wheel I 7, and the number of revolutions of the input shaft 1 is n 入 =1500r / min, the stepless speed regulating device 16 adopts the frequency conversion motor, the rotating speed is 0~3000r / min, through the fixed ratio transmission, the gear ratio of the speed regulating gear and the tie rod is 60:47, the rotating speed of the tie rod can be reduced to 0~2350r / min; the output speed is center wheel II 27 speed. The tooth shape of the planetary gear and the center wheel adopts the involute tooth shape, and adopts iab出 =3n 入 -2n 调 . no 入 =1500r / min, when n 出 = 0, n 调 =1.5n 入 , when n 调 = 0, n 出 =3n 入 , when n 出 =n 入 when n 调 =n 入 , when n 出 =-n 入 / 10, n 调 =1.55n 入 . Realize the stepless speed change of the output speed from -150 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com