A heavy-duty speed-regulating starting device and its control method

A technology of starting device and speed regulation, which is applied in the field of speed regulation and starting of heavy-duty scraper machine, heavy-duty speed-regulating starting device and its control, belt conveyor or other heavy-duty equipment, and can solve the problem of increasing connecting parts, The number of parts and the assembly process, the selected liquid-viscous device cannot meet the requirements, the clutch is difficult to adjust the torque and the sensitive speed regulation, etc., to achieve the effect of good cooling effect, sensitive speed regulation and simplified assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

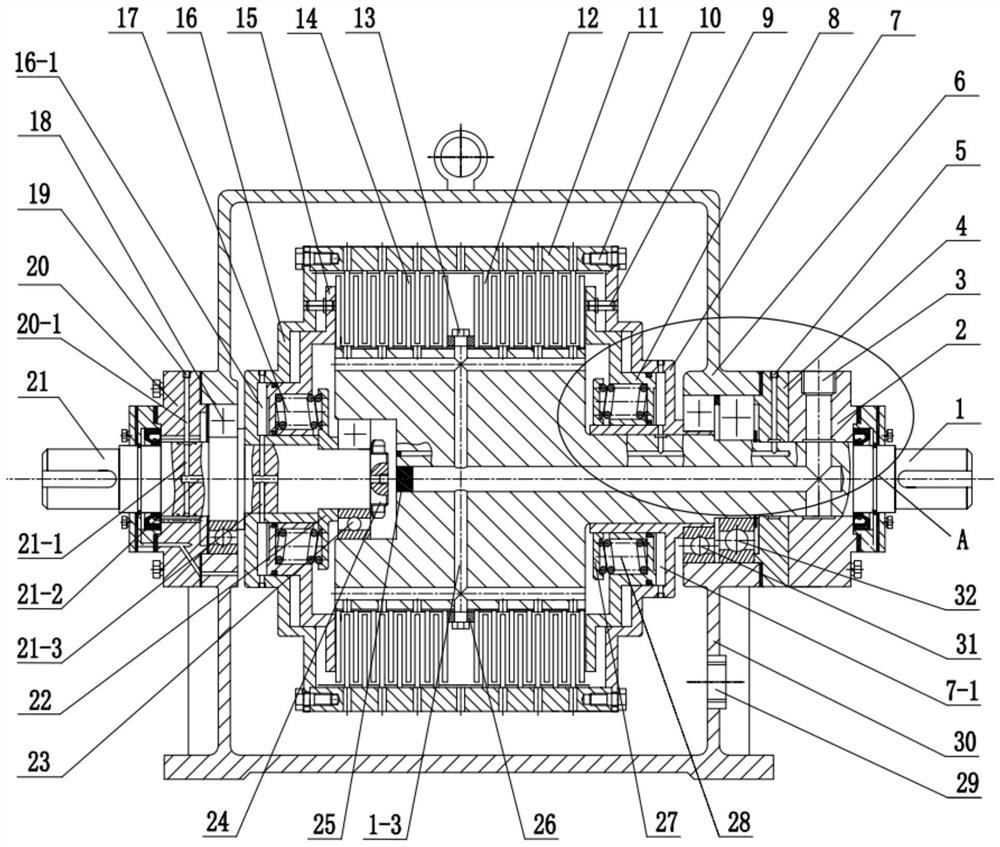

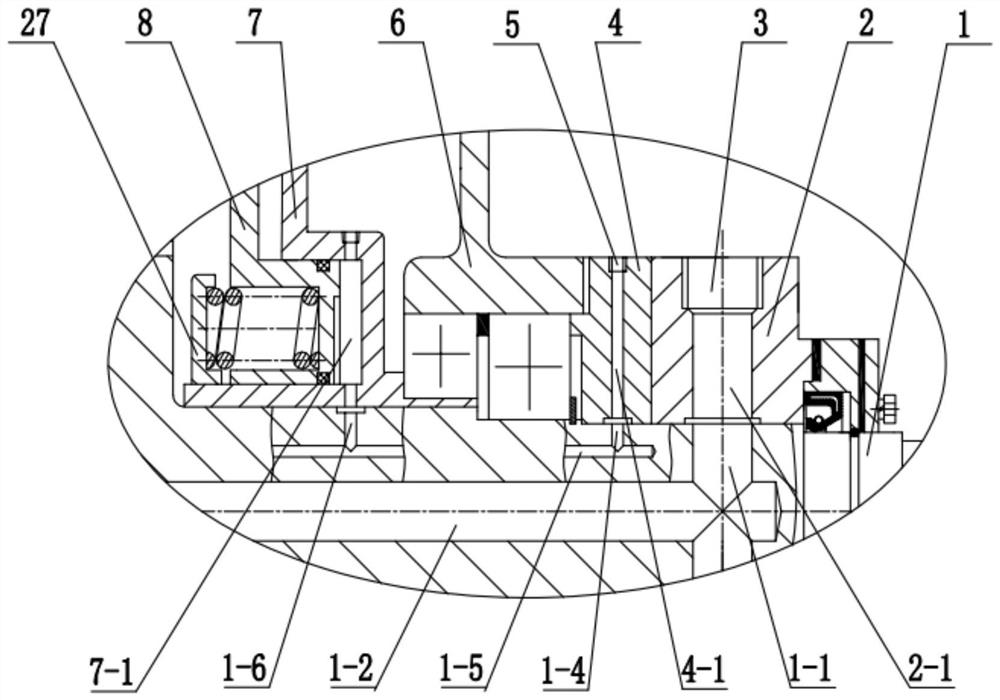

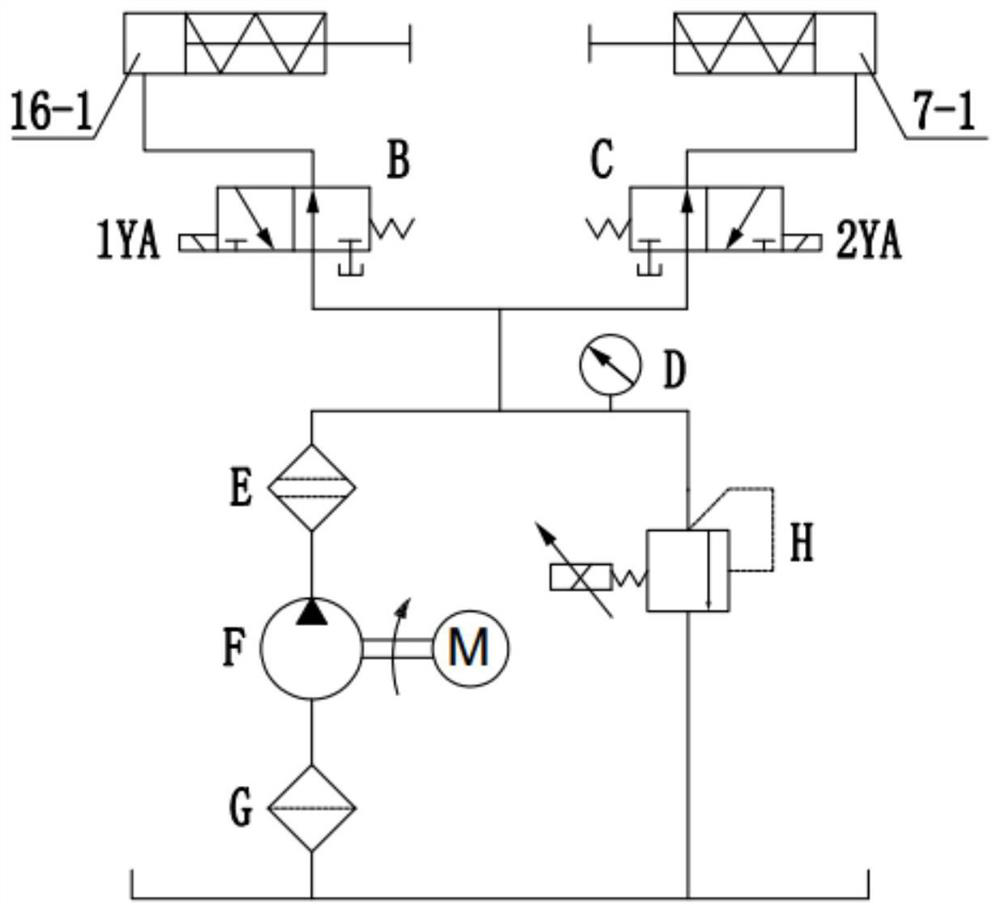

[0025] Embodiment 1: as Figure 1-5 As shown, this embodiment provides a heavy-duty speed-regulating starting device, including a box body, a control mechanism, a transmission mechanism, and a pressure oil control system. The box body includes an upper box body 6 and a lower box body 30. The transmission mechanism Correspondingly arranged inside the box, the transmission mechanism includes a driving shaft 1, a support disc 7, an active friction plate 14, a passive friction plate 12, a passive drum 11, a passive disc 16, and a passive shaft 21, and the right side of the box is sequentially The second drive shaft cover 4 corresponding to the drive shaft 1 and the first drive shaft cover 2 are provided. The left side of the box body is provided with a drive shaft cover 20 corresponding to the drive shaft 21. The upper box body 6. The lower box body 30, the second through cover 4 of the driving shaft, the first through cover 2 of the driving shaft, and the through cover 20 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com