Infinitely variable transmission for planetary gear

A technology of infinitely variable transmission and planetary gear, applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., it can solve the problems of heavy load of the speed control device, and the power transmission is not as good as the gear transmission, etc., and achieves high overload capacity and weight. Light, wide speed range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

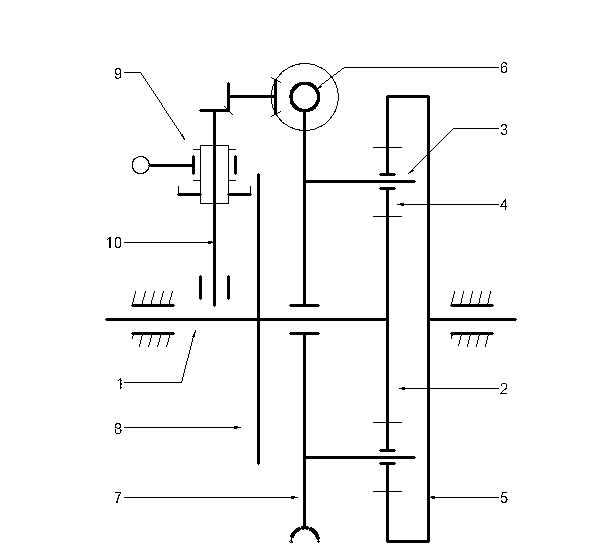

[0027] Such as figure 1 As shown, the drive shaft 1, the central gear 2, and the transmission disc 8 are fixedly connected; the planetary gear shaft 3 and the worm wheel 7 are fixedly connected, and the worm wheel 7 acts as a support for the planetary gear; the friction wheel 9 includes a guide sleeve and a wheel fixed on the guide sleeve The friction wheel and the control rod can slide on the guide rod 10 and rotate synchronously with the guide rod 10; the guide rod 10 drives the worm 6 through the transition of the bevel gear. The friction wheel 9 is tightly pressed on the disc surface of the transmission disc 8, and rotates together with the transmission disc 8; the speed changes accordingly when sliding on the guide rod 10; the worm wheel 7 is driven to rotate through the guide rod 10 and the worm 6, and the planetary gear shaft 3 revolutions; at the same time, the planetary gear 4 rotates, transmits the power from the sun gear 2, and drives the driven wheel 5 to rotate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com