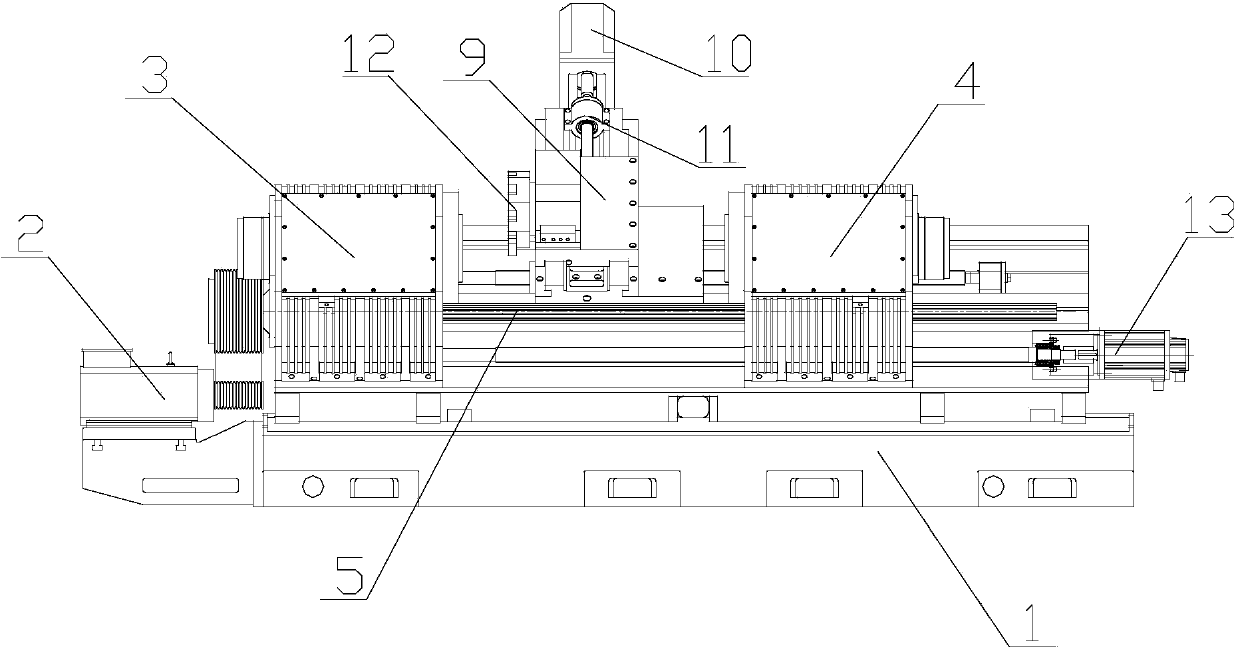

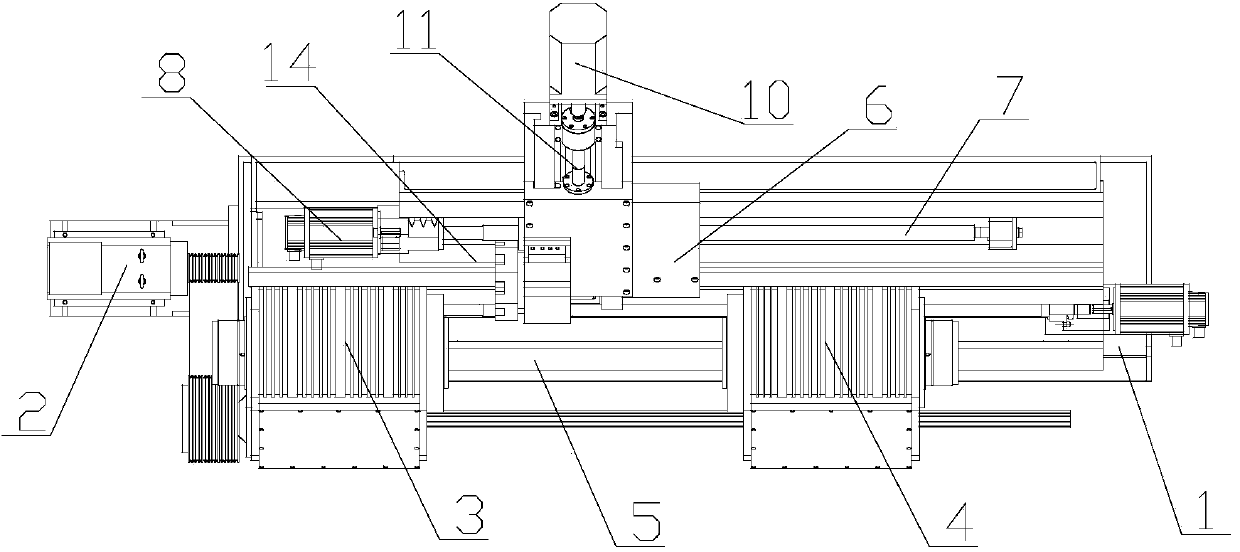

Synchronous double-spindle-box numerically controlled lathe

A CNC lathe and double-spindle technology, which is applied in the field of CNC machine tools, can solve the problems of inability to process long-axis workpieces at one time, low processing accuracy, and high labor intensity, and achieve long-term maintenance of guide rail accuracy, good accuracy retention, and automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] With reference to accompanying drawing, a kind of synchronous dual headstock numerical control lathe, it comprises bed, described bed side is provided with main motor, described bed end is provided with left headstock, right headstock, and A synchronous shaft is arranged between the left headstock and the right headstock, a bed saddle is arranged on the bed, a ball screw a is arranged on the bed saddle, and a servo drive motor a is arranged on one side of the bed saddle. The saddle is provided with a middle supporting board, a servo drive motor b is arranged on one side of the middle supporting board, a ball screw b is arranged inside the middle supporting board, and an electric knife is arranged on the middle supporting board tower.

[0016] The said right spindle box is provided with a servo drive motor c

[0017] The gears in the left headstock and the right headstock adopt the same gear ratio.

[0018] The moving surfaces of the saddles are all pasted with plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com