Spatial swing cam type stepless variable drive

A continuously variable speed, swinging cam technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of high manufacturing cost, complex structure, huge size, etc., achieve simple and compact structure, stable speed change transmission, vibration reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

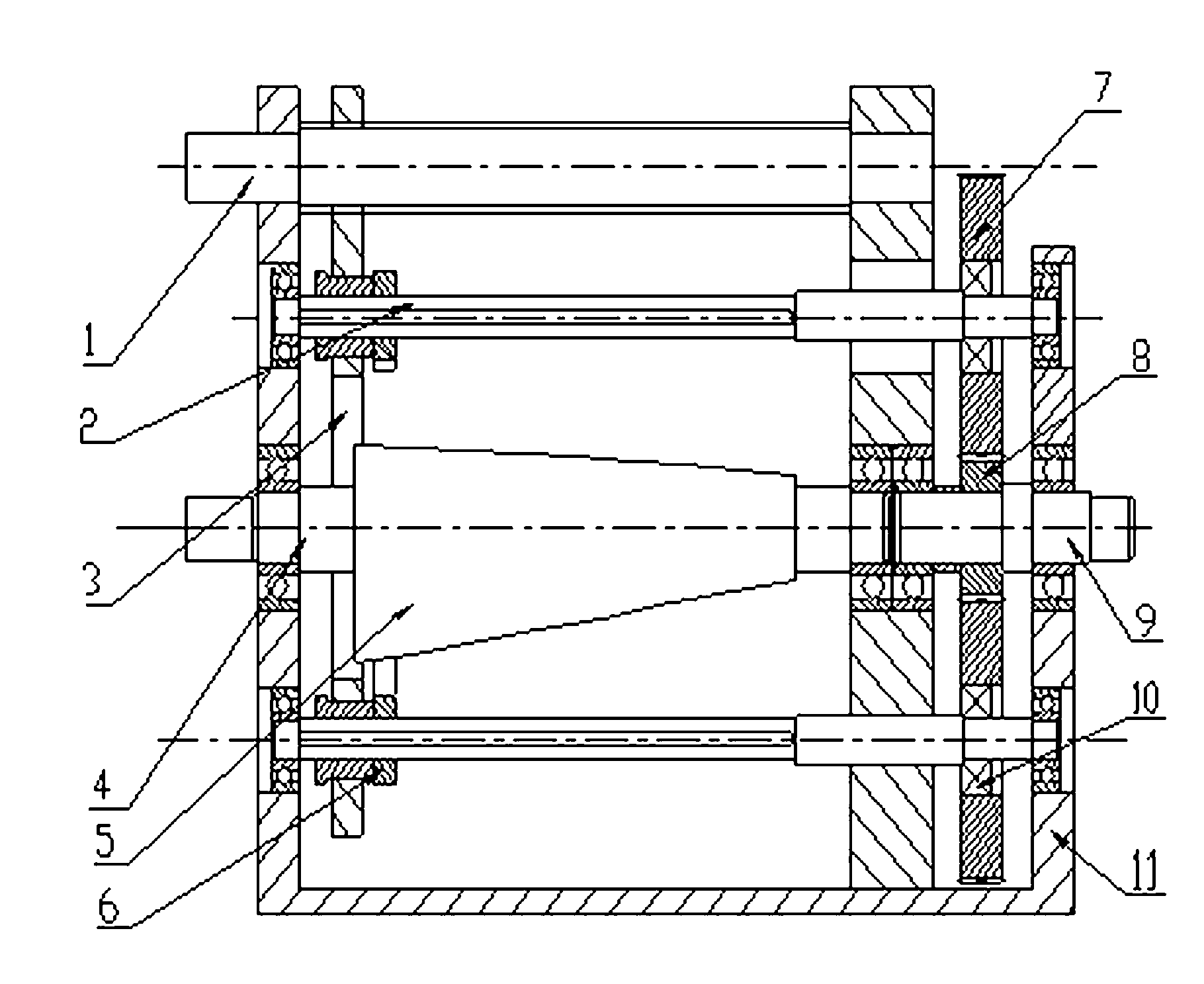

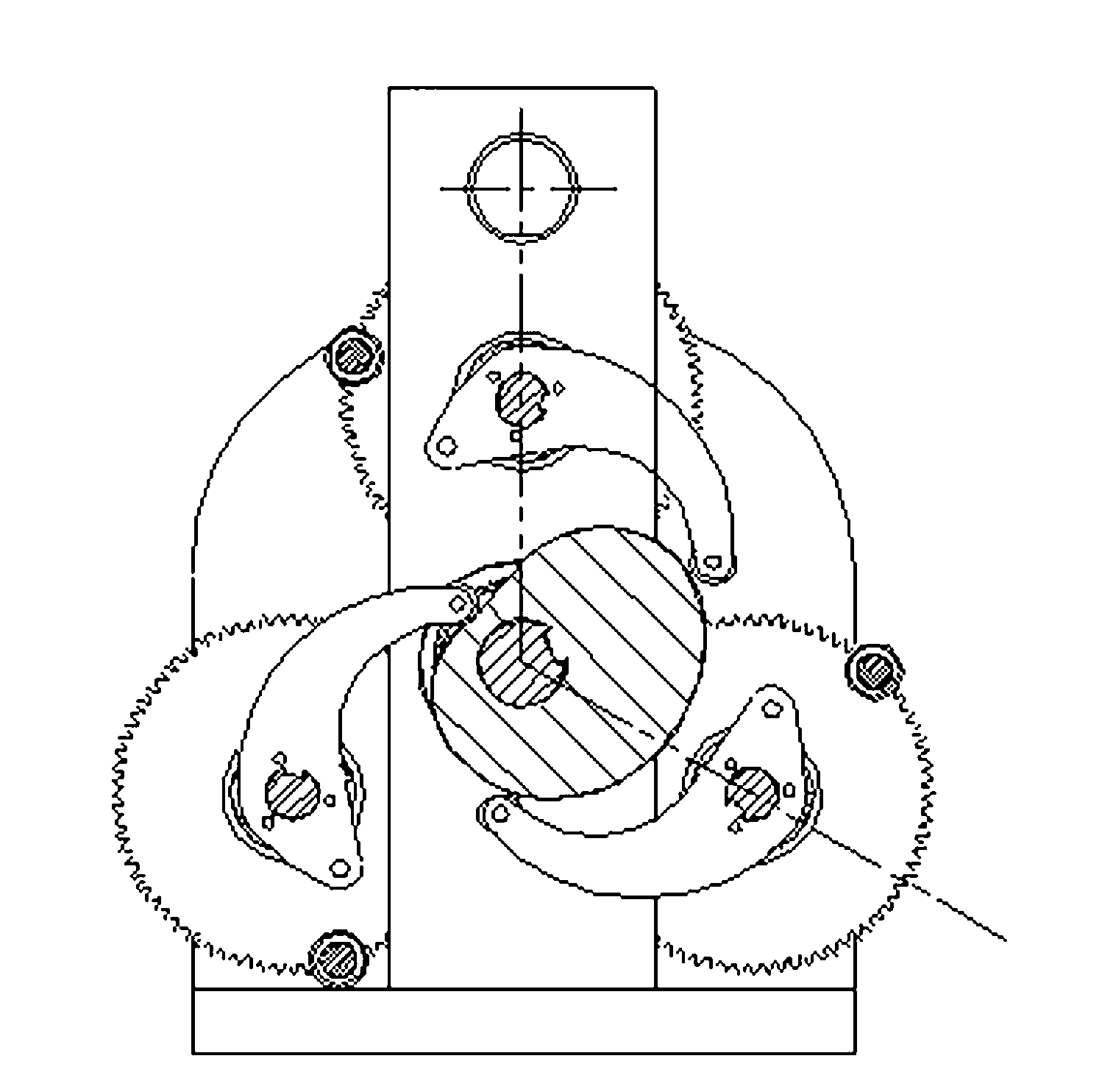

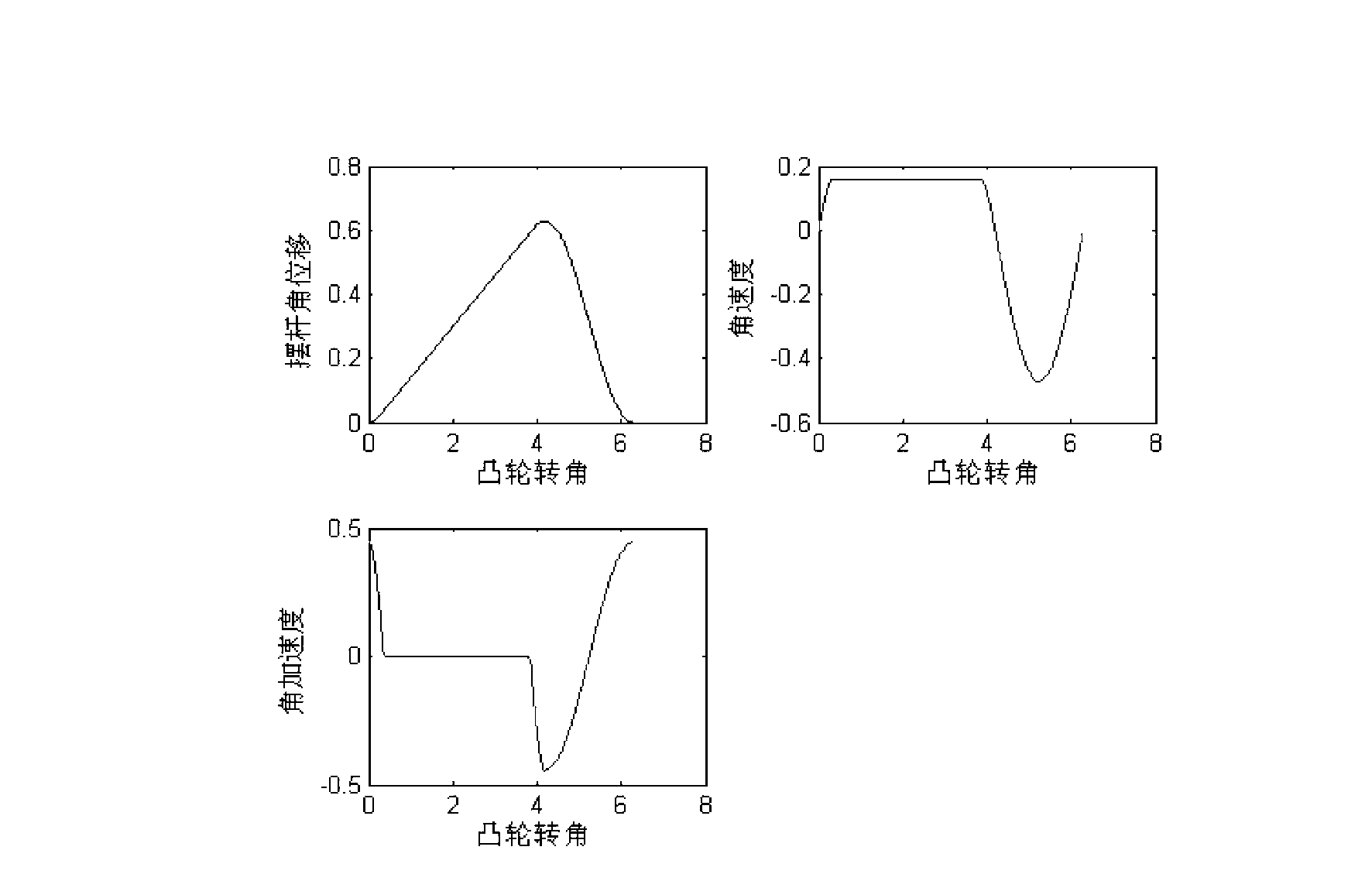

[0012] attached figure 1 , 2 Shown is a preferred embodiment of the present invention. In this embodiment, the space oscillating cam stage speed change transmission device of the present invention comprises a frame 11, an input shaft 4, an output shaft 9, a gear train composed of gears 7 and 8, an overrunning clutch 10, a space cam 5, a speed regulating The mechanism, the slide plate 3, the input shaft 4 and the output shaft 9 are respectively rotatably installed on the frame, and the two shafts are on the same axis. The space cam is fixed on the input shaft 4, and the space cam has the same base circle in the axial direction, and the swing stroke of the space cam increases monotonously from zero to one side of the frame axially (such as Figure 4 shown), the cross-sectional profile of the space cam is designed according to the rule that the thrust motion is a constant speed motion (such as Figure 5 As shown), a slide plate 3 is set on the outer edge of the space cam, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com