Frequency scanning signal analysis method based on atomic force microscopy technology and application thereof

A technique of atomic force microscopy and frequency signals, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as relying on experimental test results and unable to analyze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

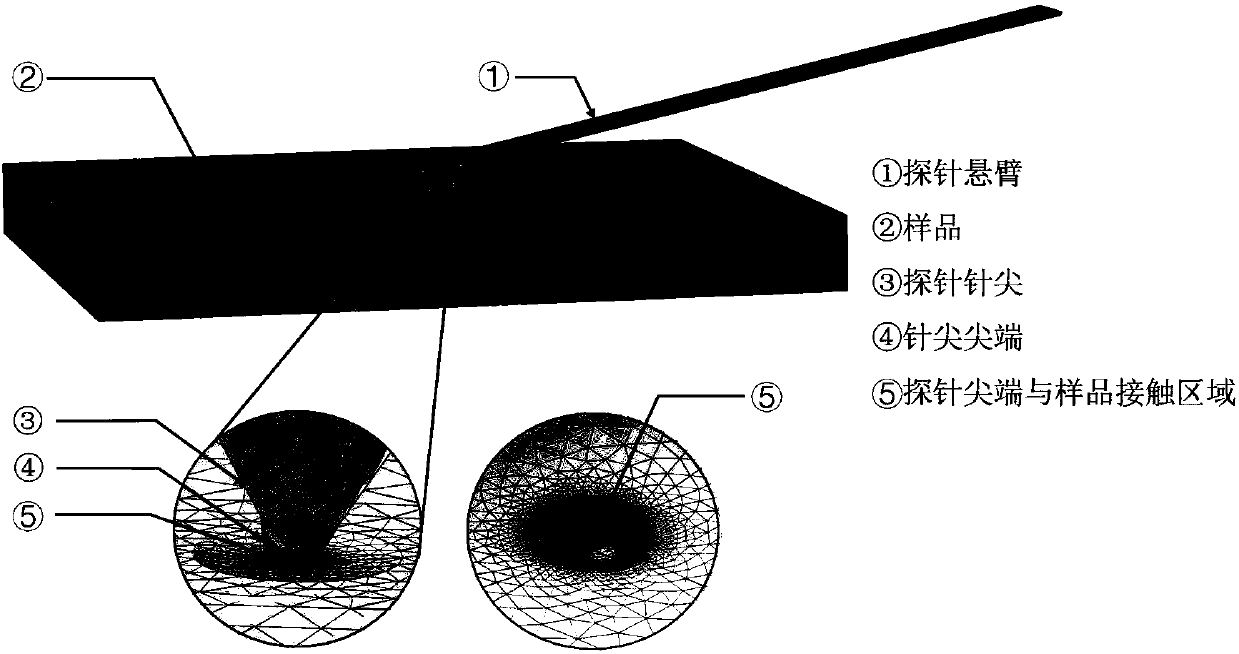

[0039] Finite element simulation of probe free resonance frequency:

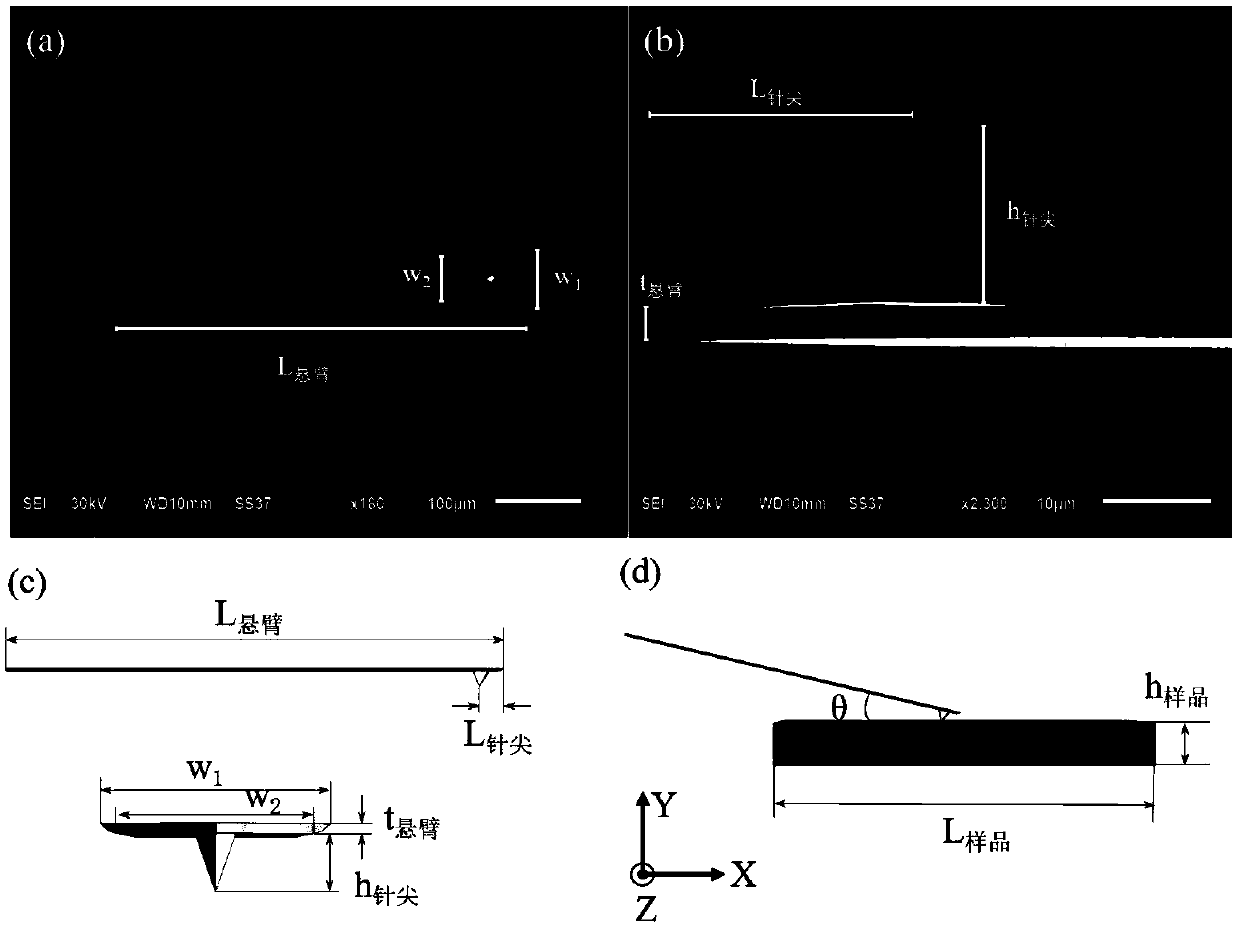

[0040] (1) Calibration of AFM probe geometry

[0041] The AFM probe selects a commercial atomic force microscope conductive probe (model: Econo-SCM-PIC, manufacturer: Asylum Research) made of single crystal silicon, and uses a scanning electron microscope to observe and photograph the morphology of the atomic force microscope conductive probe. figure 2 (a)-(b) are the topography images of the AFM conductive probe observed by the scanning electron microscope, and the geometric dimensions of the probe are calibrated. The main geometric dimensions are: L 针尖 =23.922±1μm, h 针尖 =14.35±1μm, t 悬臂 =2.586±0.2μm, L 悬臂 =480.5±2μm, w 1 =58.33±1μm, w 2 =46.33±1μm, r 针尖 = 20nm.

[0042] (2) Optimization of AFM probe geometry

[0043] Such as figure 2 (c) Establish the finite element model of the probe, and optimize the geometric size of the AFM probe calibrated in step ① as the initial value through the AFM fre...

Embodiment 2

[0050] Probe-piezoelectric sample Pb(Zr 0.2 , Ti 0.8 )O 3 Finite element simulation of the contact resonance frequency of the joint body model.

[0051] figure 2 (d) is the AFM probe and piezoelectric sample Pb(Zr 0.2 , Ti 0.8 )O 3 (hereinafter referred to as PZT) schematic diagram of the contact geometry model. The specific process of the finite element simulation of the free vibration of the AFM probe and the resonant frequency of the AFM probe and the PZT joint model is as follows.

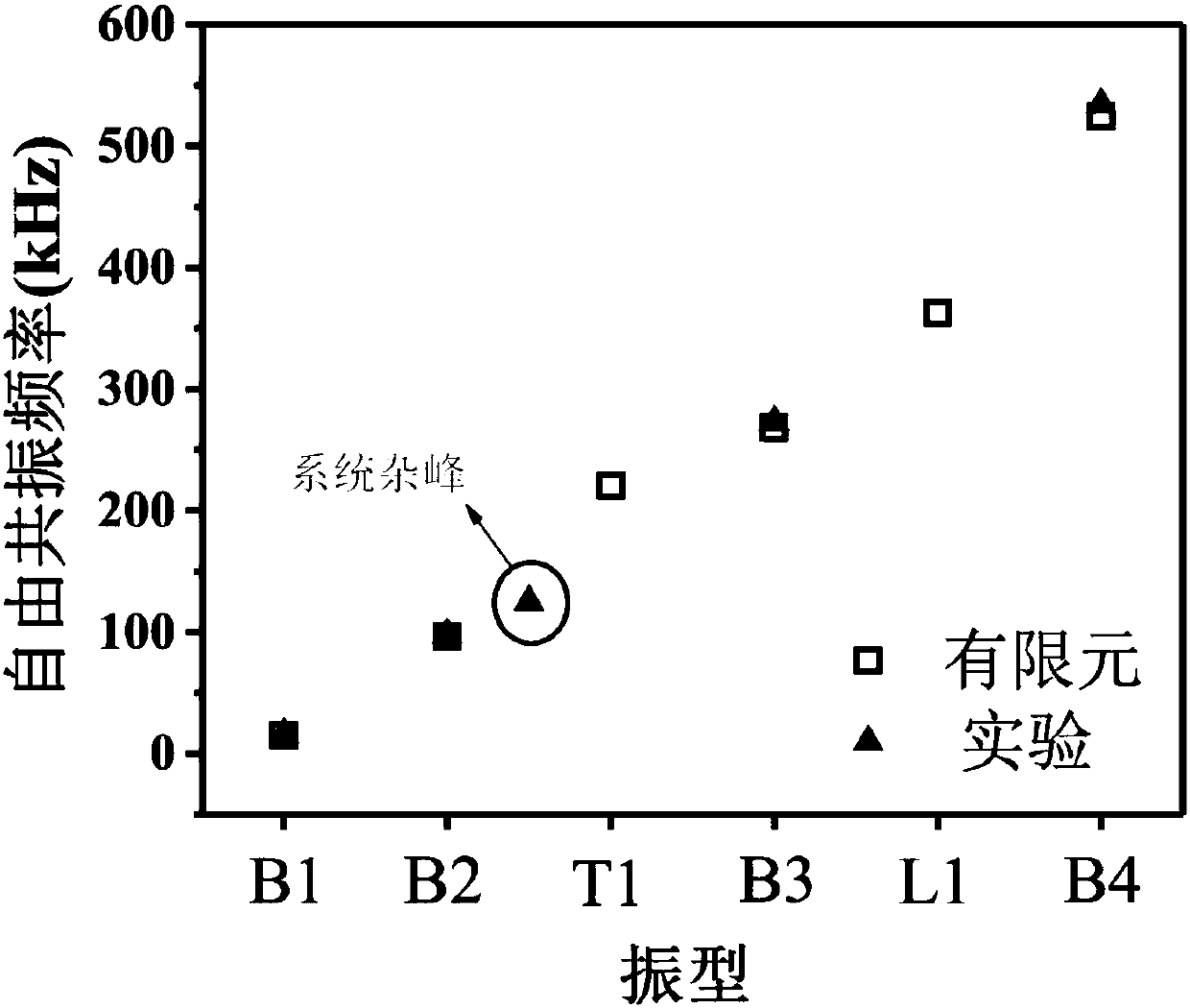

[0052] (1) AFM probe free resonance finite element simulation

[0053] The AFM probe selected here is the same as that in Example 1, and the material parameters of the AFM probe in Example 1 and the optimized probe geometry are adopted.

[0054] see image 3 , image 3 It is a comparison chart of the AFM probe free resonance frequency results obtained from the test of the AFM probe under thermal vibration and the finite element calculation. In the thermal vibration test results, B ...

Embodiment 3

[0070] Finite Element Simulation of Contact Resonance Frequency of AFM Probe and Fused Silica Combination Model of Pure Elastic Sample

[0071] (1) Calibration of AFM probe geometry

[0072] The AFM probe is a commercial atomic force microscope conductive probe (model: Nanosensors, NanoWorld Services, Switzerland) made of single crystal silicon, and the morphology of the atomic force microscope conductive probe is observed and photographed by a scanning electron microscope, and the geometry of the probe is Size for calibration: L 悬臂 = 235.2 μm, t = 6.6 μm, h 针尖 = 11.672 μm, w 1 =54.2μm, w 2 = 18.8 μm, r 针尖 = 25nm.

[0073] (2) Setting AFM probe material parameters

[0074] Considering that the material of the selected AFM probe is cubic single crystal silicon, the anisotropy of the elastic properties of the cantilever caused by the different crystal axis orientations of the cubic single crystal silicon makes the cantilever long axis direction, width direction and upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com