Patents

Literature

42results about How to "Prevent fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microorganism fertilizer and its preparation method

The microbial organic fertilizer is prepared with brown sugar, fish meal, wheat bran, urea, KH2PO4, KNO3, and water in certain weight proportion, and through inoculating Saccharomyces cerevisiae and Bacillus subtilis and fermenting. It is one kind of multifunctional liquid organic fertilizer and may be applied to foliage or soil. It contains comprehensive nutrients and can raise the utilization of nitrogen fertilizer, phosphate fertilizer and potash fertilizer.

Owner:广东金饭碗环境科技有限公司

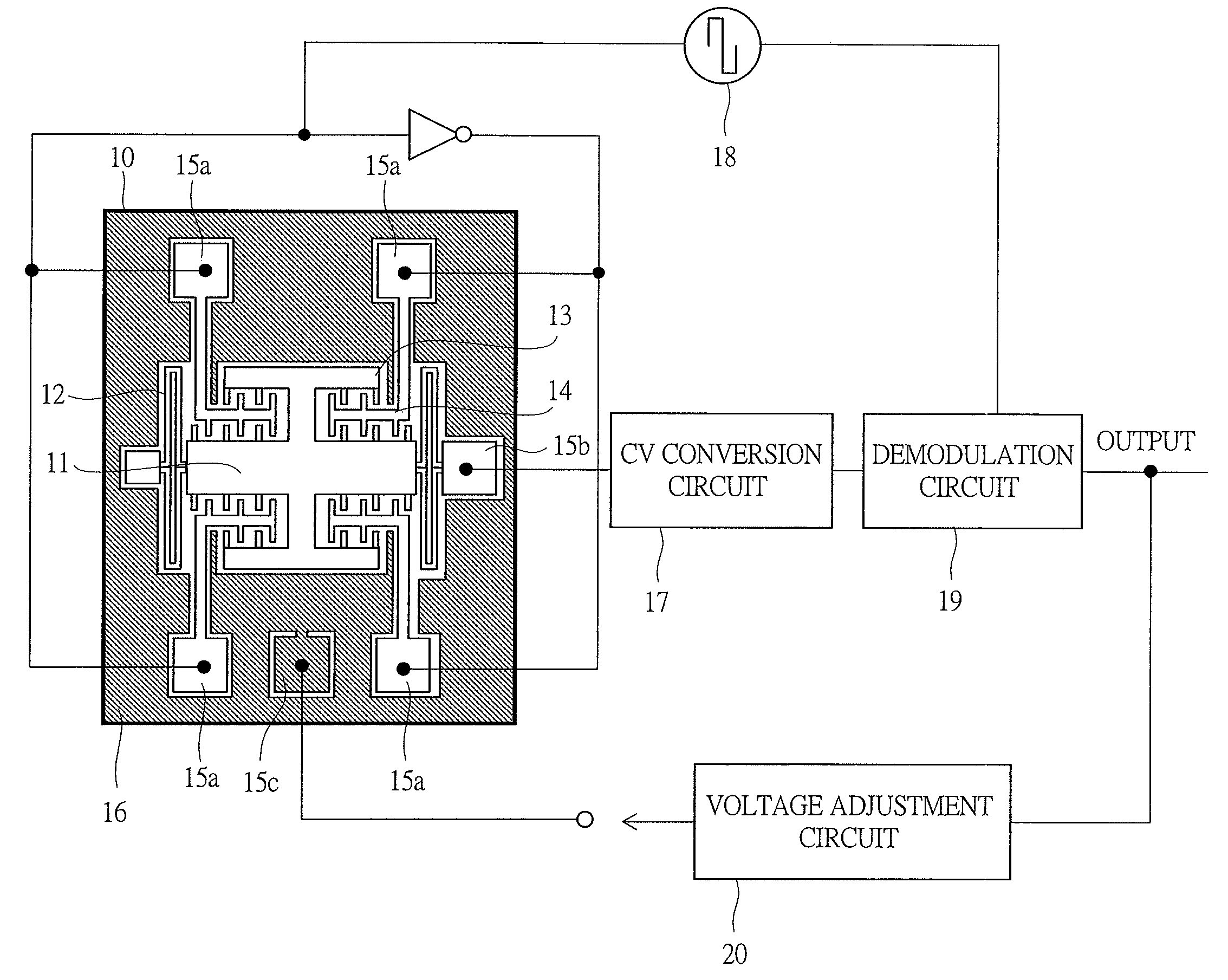

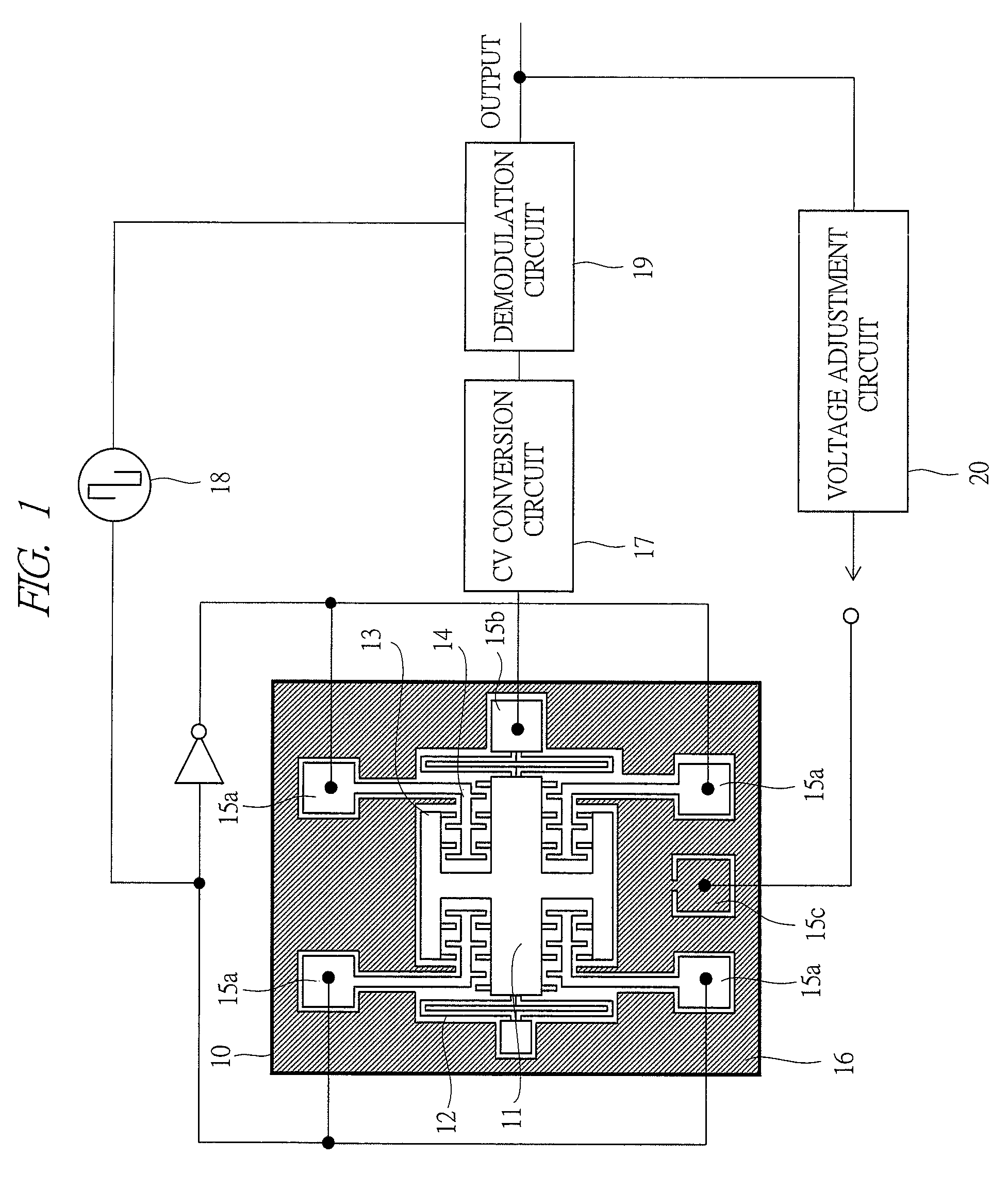

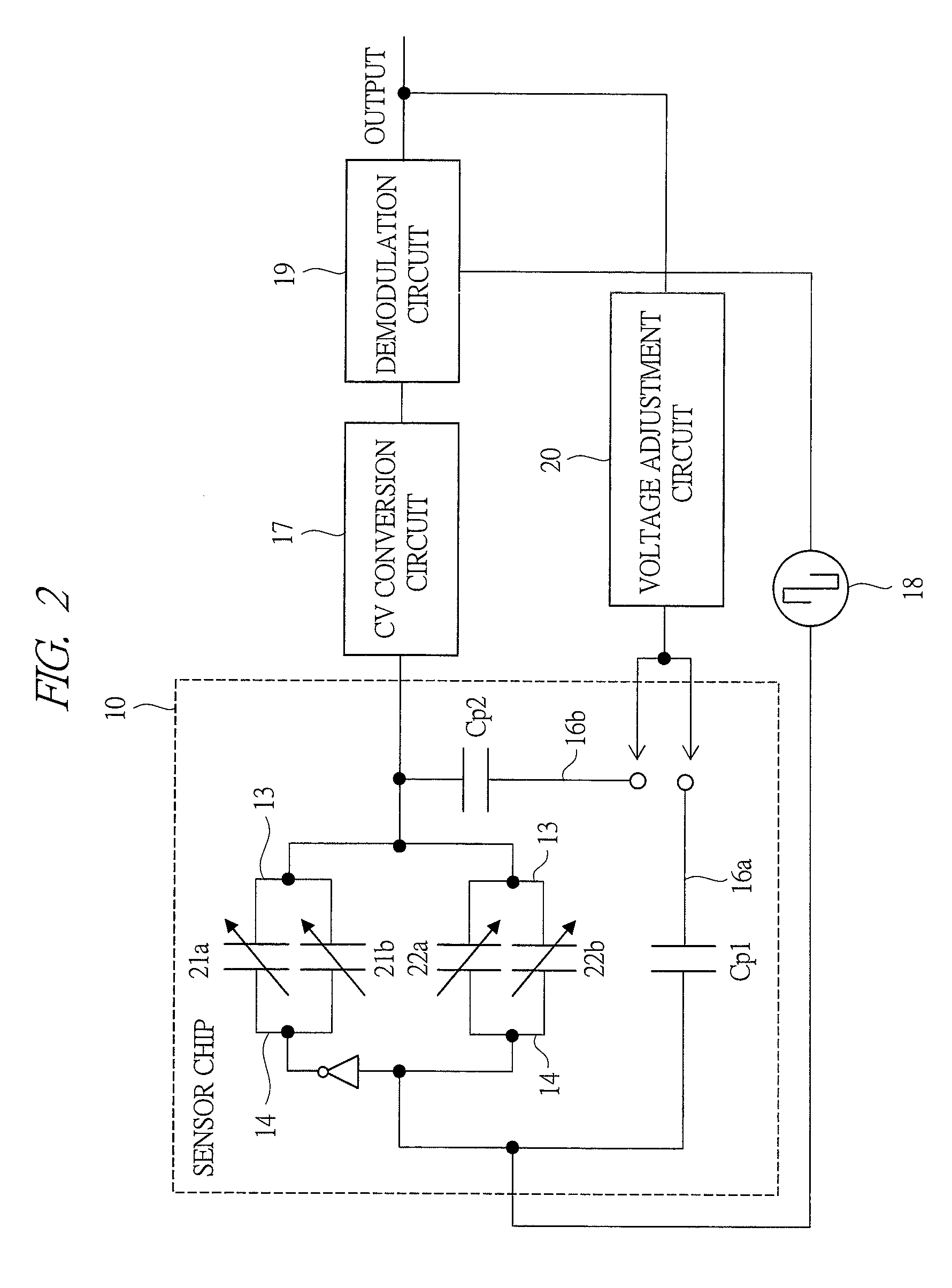

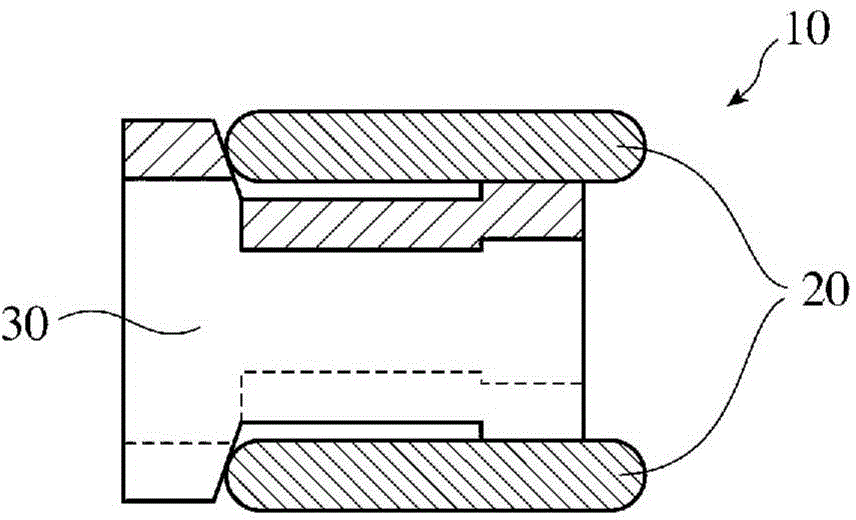

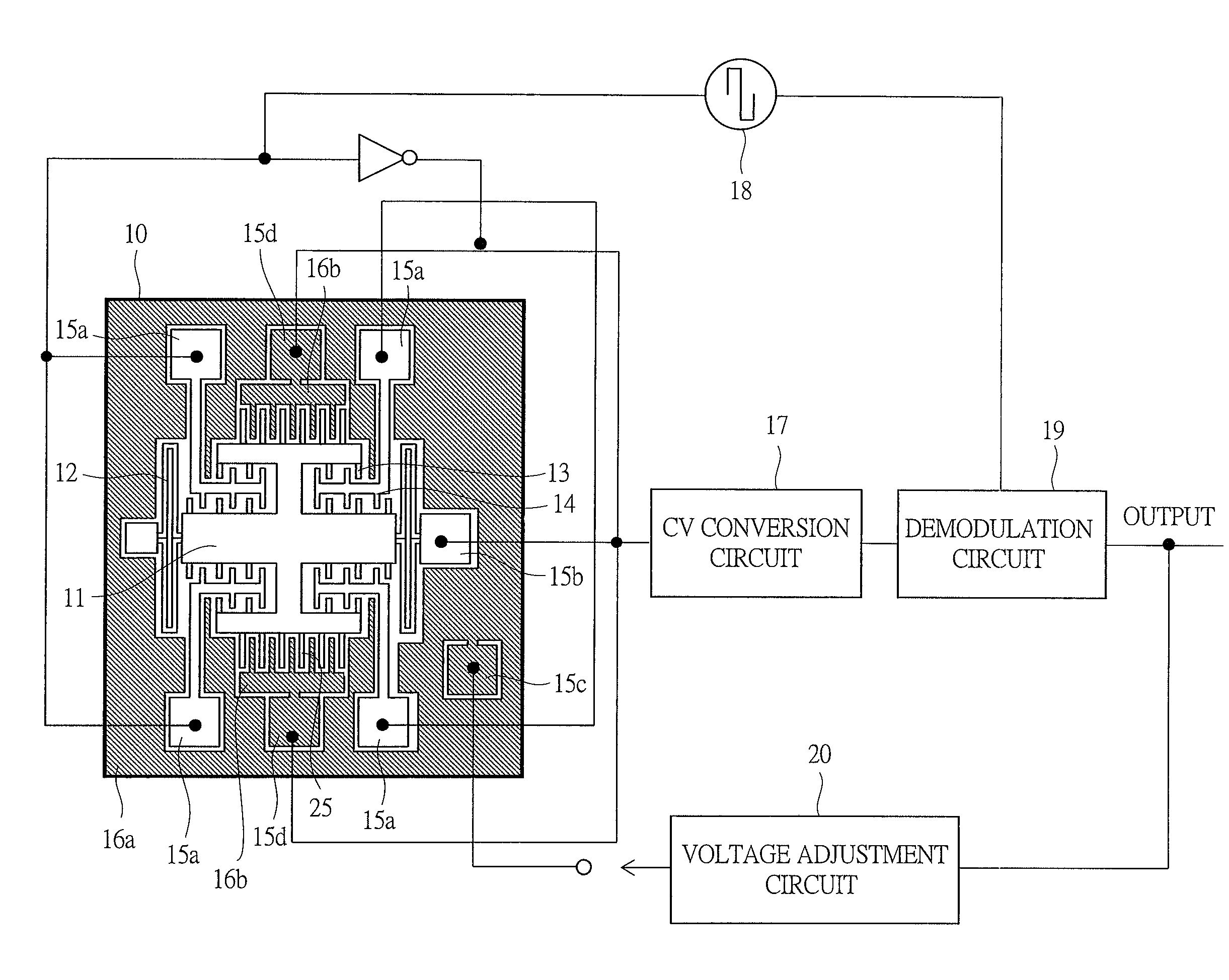

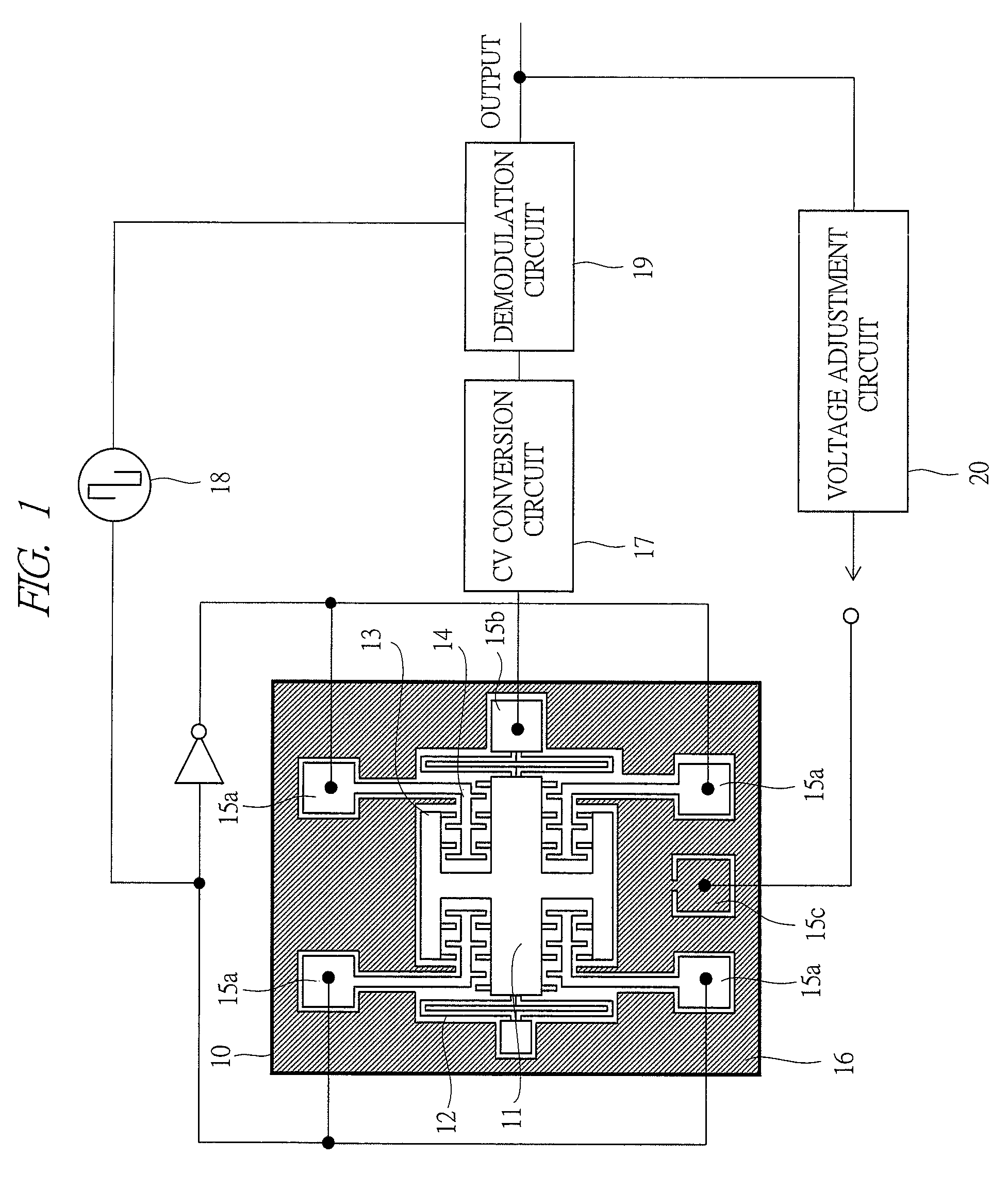

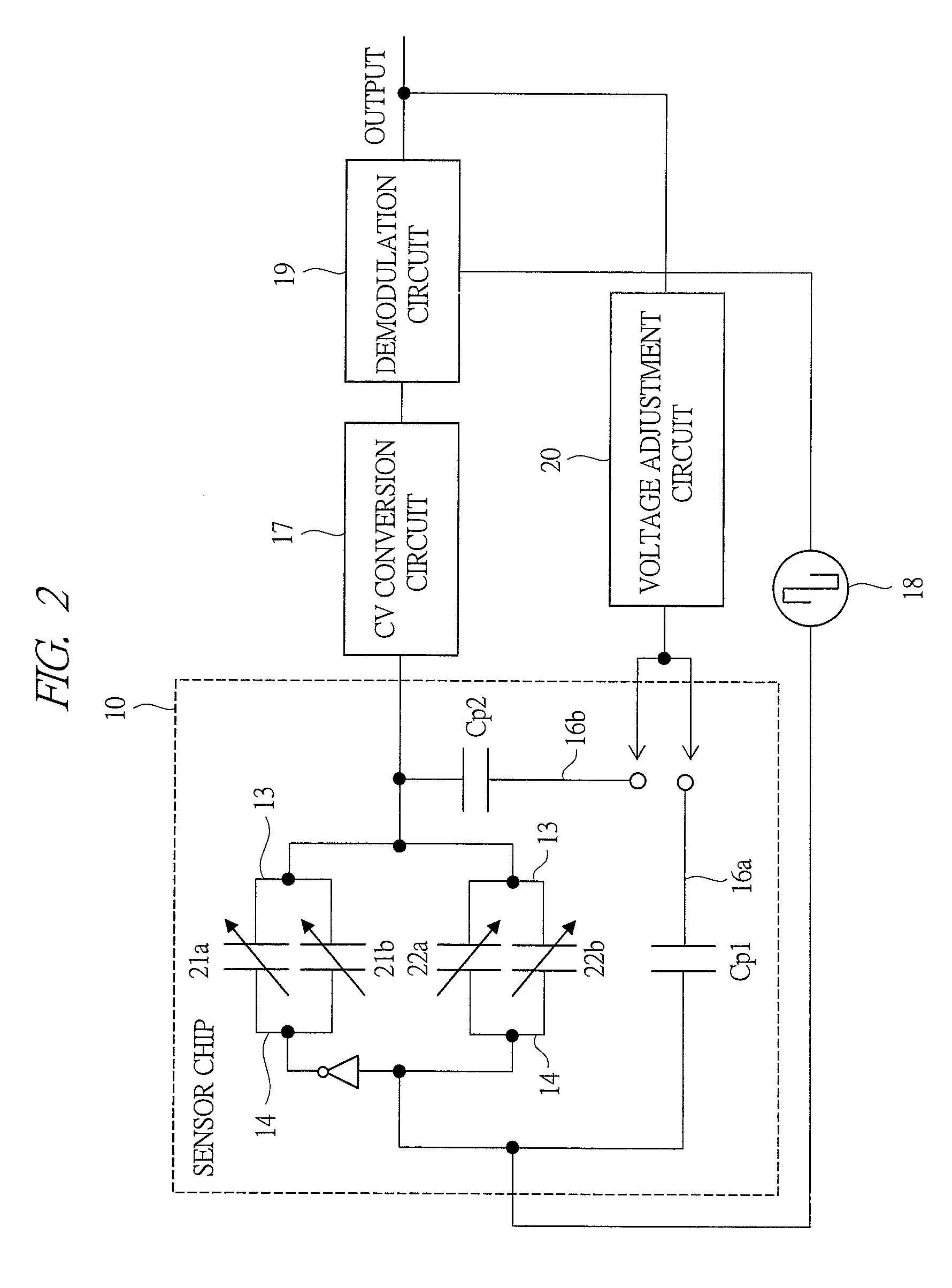

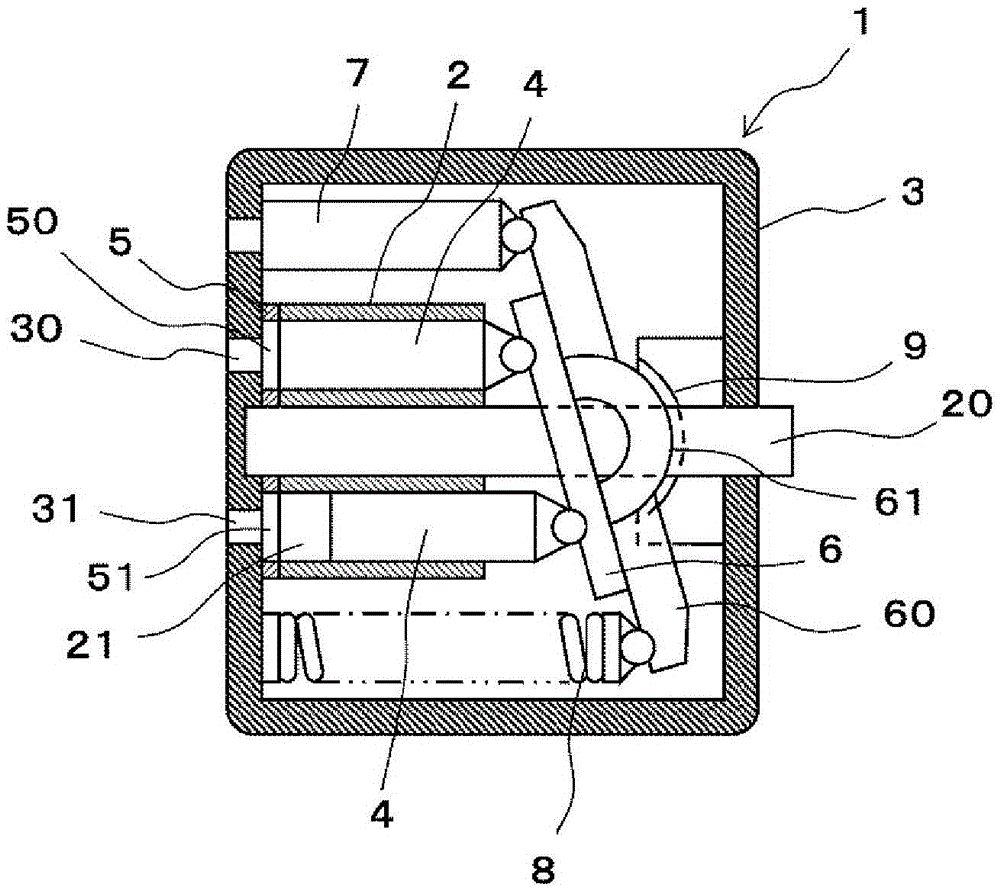

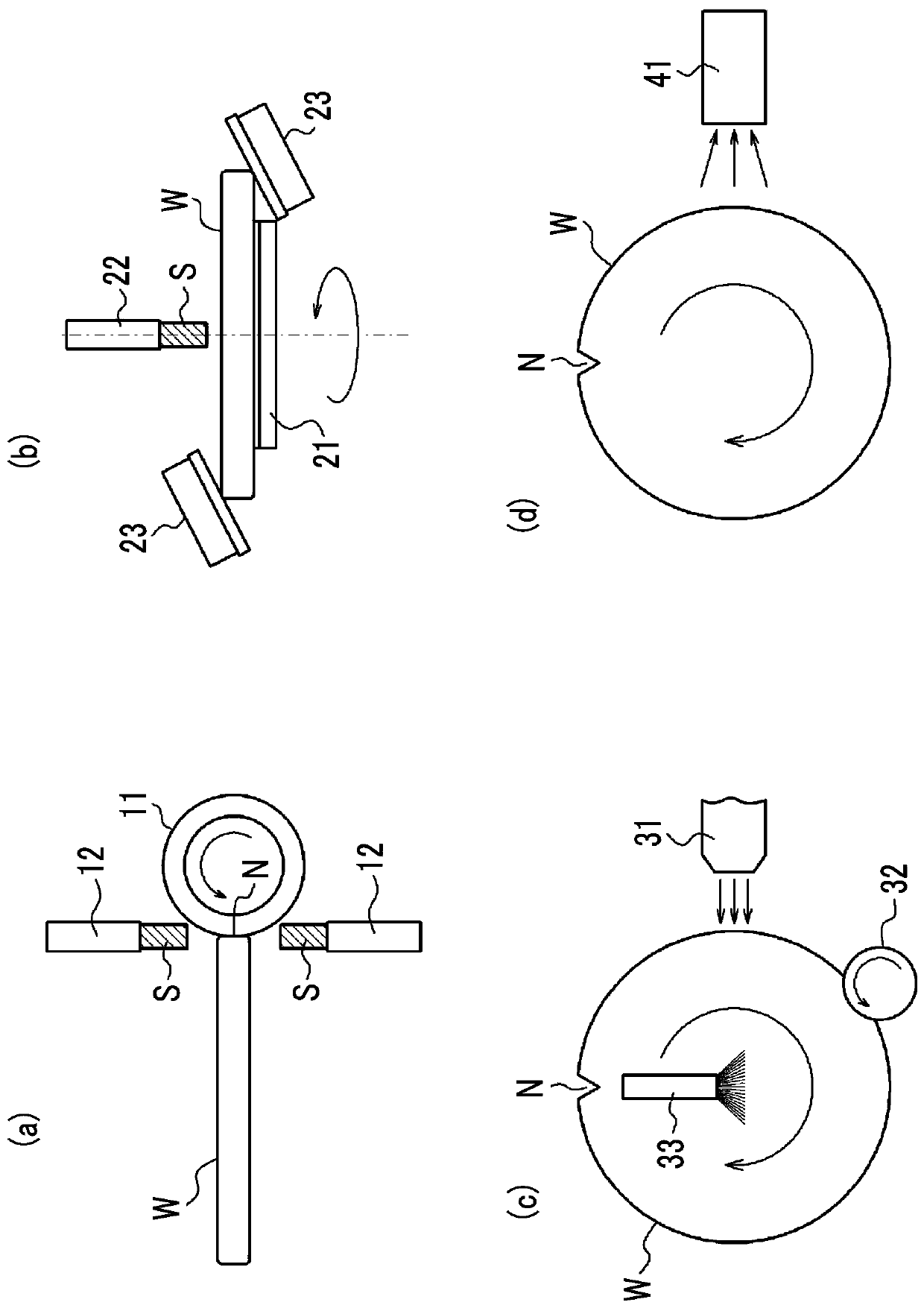

Inertial sensor

ActiveUS20090126491A1Prevent malfunctionSuppress fixationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceVoltage

Techniques capable of suppressing fixation between a movable electrode and a fixed electrode in an inertial sensor and preventing the inertial sensor from malfunctioning are provided. The movable electrode, the fixed electrode provided so as to face the movable electrode, a peripheral conductor facing both the movable electrode and the fixed electrode, and a demodulation circuit and a voltage adjustment circuit which adjust the electric potential of the peripheral conductor so that the electric potential of the peripheral conductor becomes the same as the electric potential of the movable electrode are provided, and a change in the capacitance between the movable electrode and the fixed electrode is detected.

Owner:HITACHI LTD

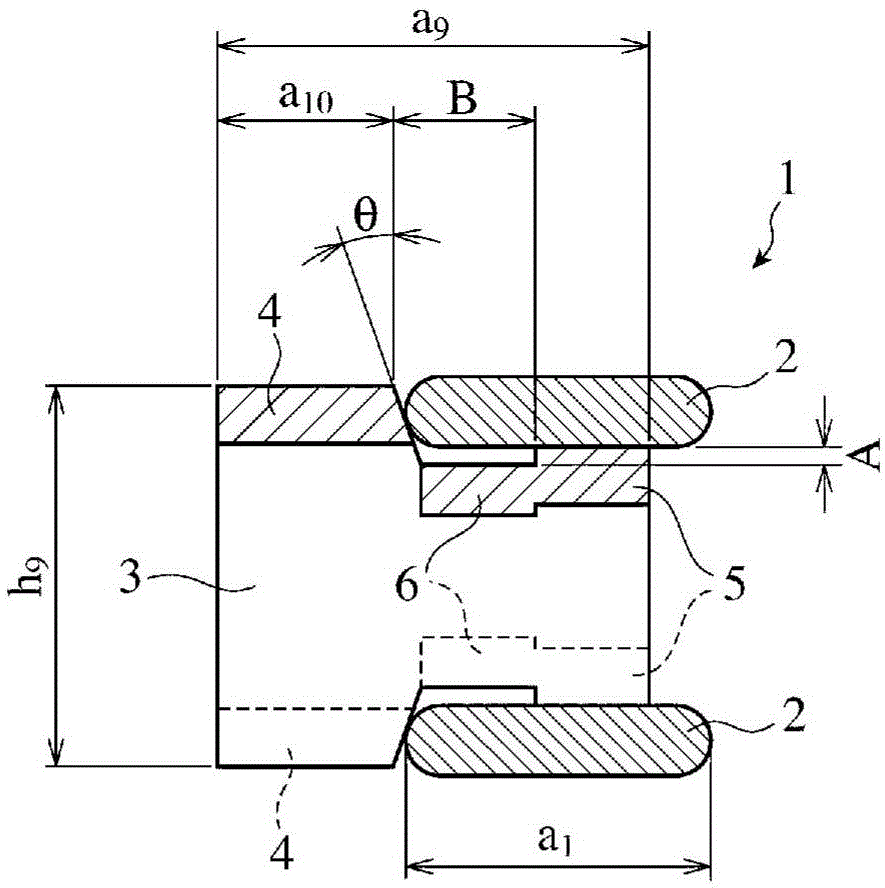

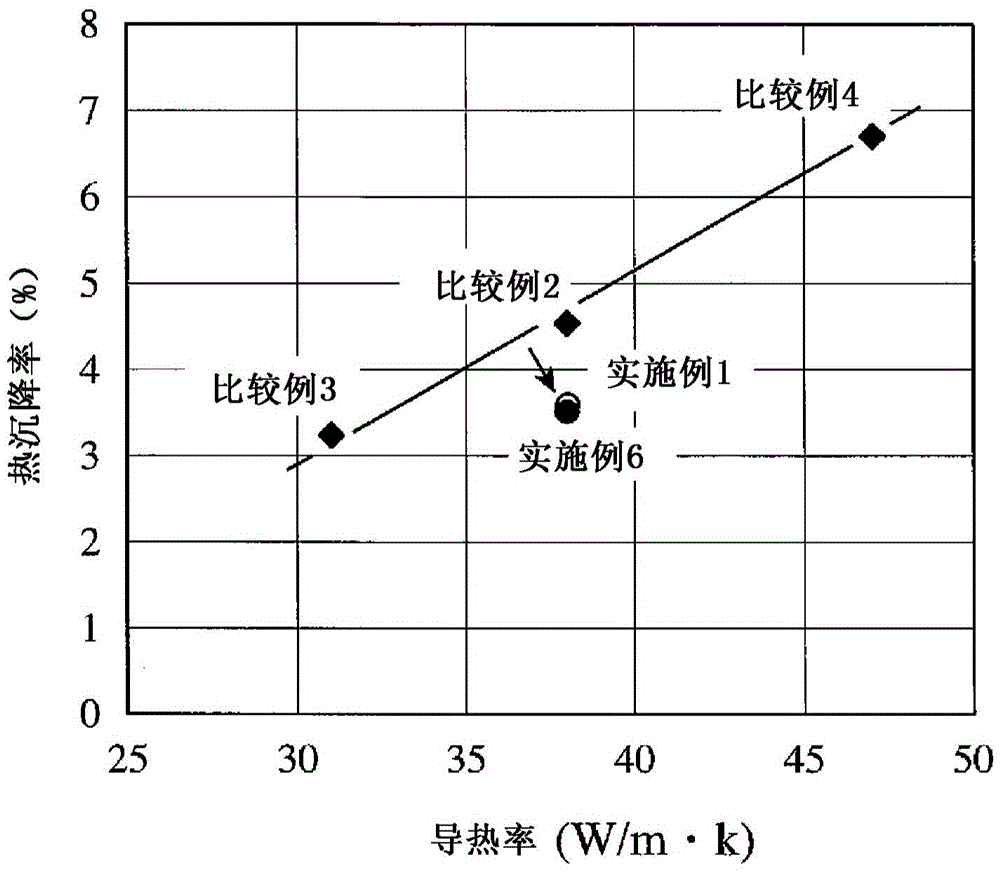

Combined oil-control ring

Provided is a combined oil-control ring which has excellent oil consumption characteristics, abrasive resistance and sludge resistance. The combined oil-control ring comprises a pair of circular ring shaped side rails with openings; and a wave-shaped separating outer tensioner ring clamped between the pair of circular ring shaped side rails and possessing ear parts for pressing inner peripheral surfaces of side rails in the inner periphery, wherein the thickness (a1) of the side riails is set to be 50-90% of a outer tensioner ring height (a9) of the separating outer tensioner ring, or the ear height (a10) of the ear of the separating outer tensioner ring is set to be 23-60% of the outer tensioner ring height (a9).

Owner:RIKEN CO LTD

Inertial sensor

ActiveUS8096180B2Avoid fixationReduce the possibilityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceElectrical conductor

Owner:HITACHI LTD

Pressure ring

Provided is a pressure ring which suffers from little adhesion of a piston material. This pressure ring (11) is provided with an annular body (12) made of a steel material which consists of 0.45 to 0.55mass% C, 0.15 to 0.35mass% Si, 0.65 to 0.95mass% Mn, 0.80 to 1.10mass% Cr, at most 0.25mass% V, less than 0.010mass% P, and the balance Fe with unavoidable impurities.

Owner:RIKEN CO LTD

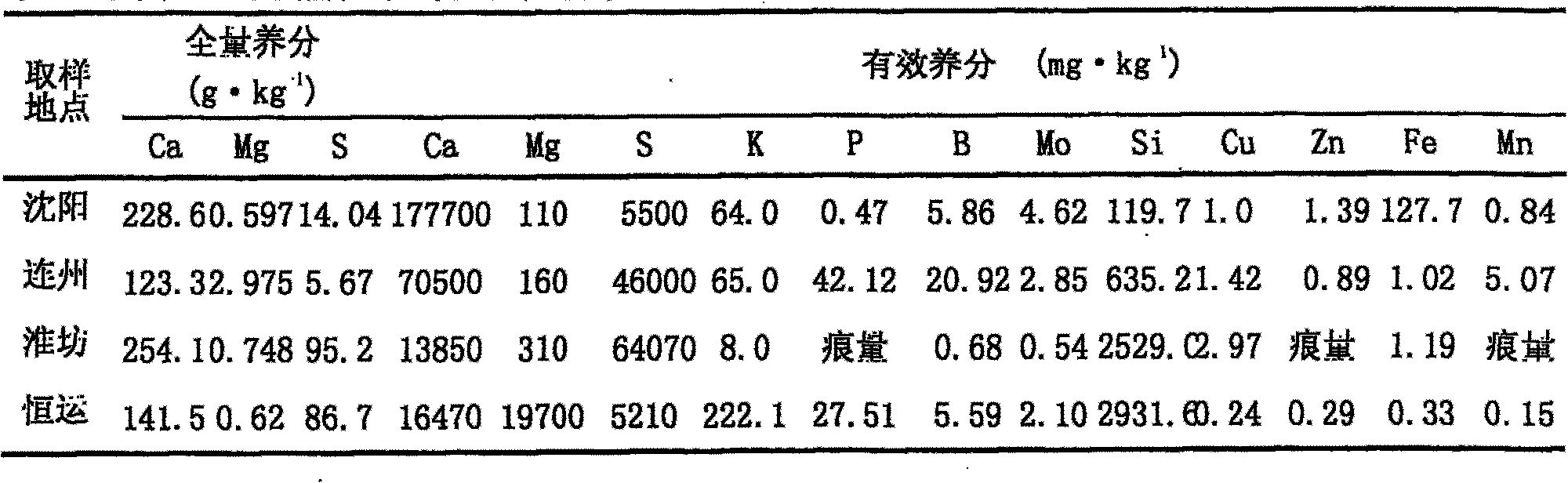

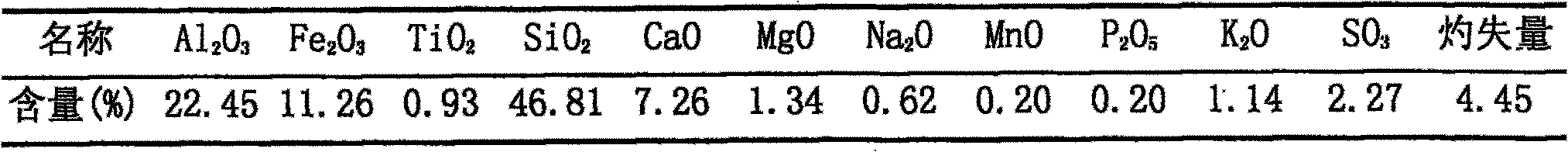

Acidity soil conditioner containing fire coal flue gas desulfurization solid waste material

InactiveCN1927999AImprove effectivenessImprove nutritional functionOrganic fertilisersSoil conditioning compositionsNitrateManganese

The present invention is one kind of acid soil amendment, which consists of coal burning fume desulfurizing solid waste in 83-97 wt% and humic acid in 3-17 wt%. The coal burning fume desulfurizing solid waste is formed through desulfurizing coal burning fume with lime suspension absorbing SO2. The acid soil amendment can complex or chelate Fe, Al and Mn elements of acid soil to regulate local concentration of active Fe, Al and Mn, raise the effectiveness and nourishing function of Ca, Mg, S, Si and B and raise activity of P, so as to raise the biomass and yield of crop and other plant and lower the content of nitrate in vegetable. The present invention utilizes coal burning fume desulfurizing solid waste effectively in agriculture.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

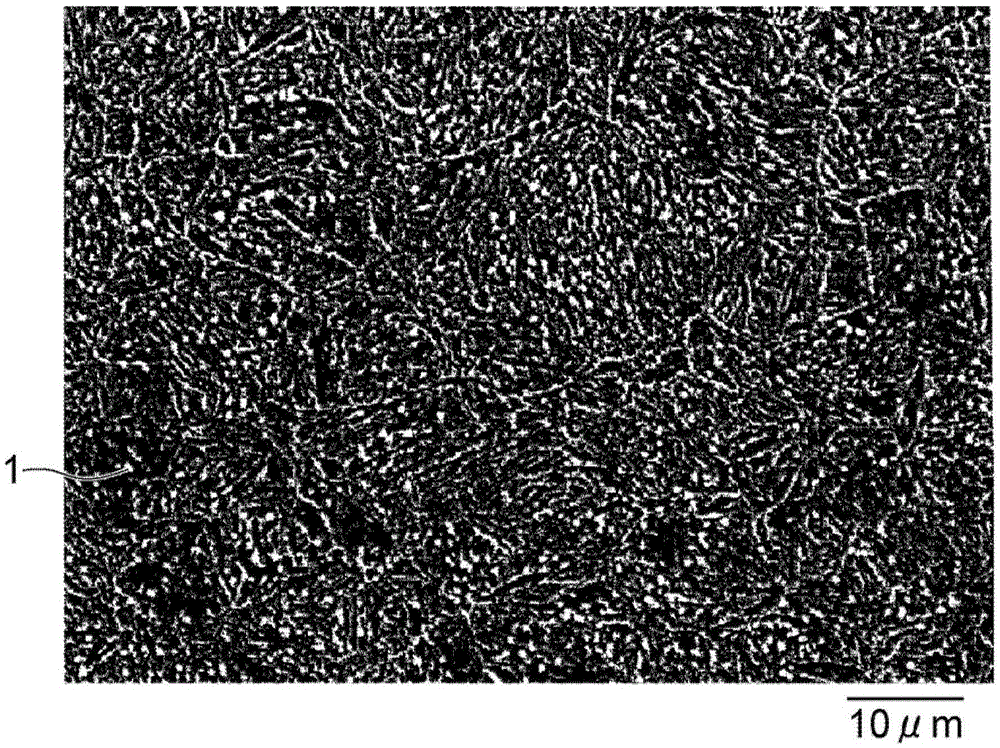

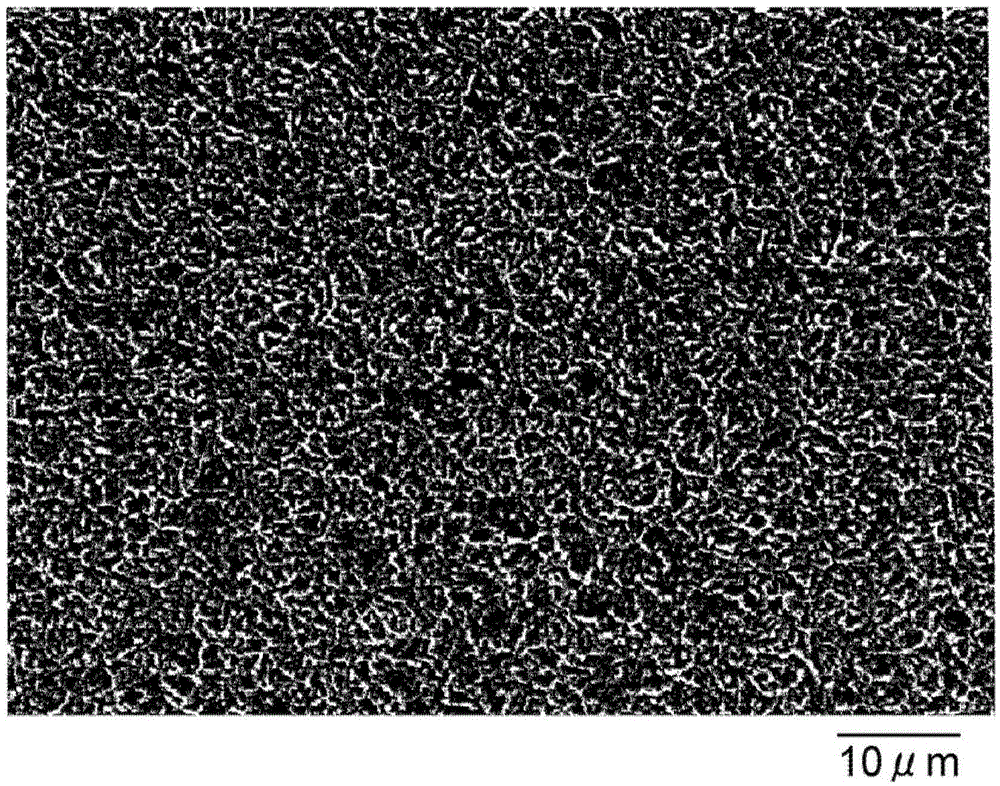

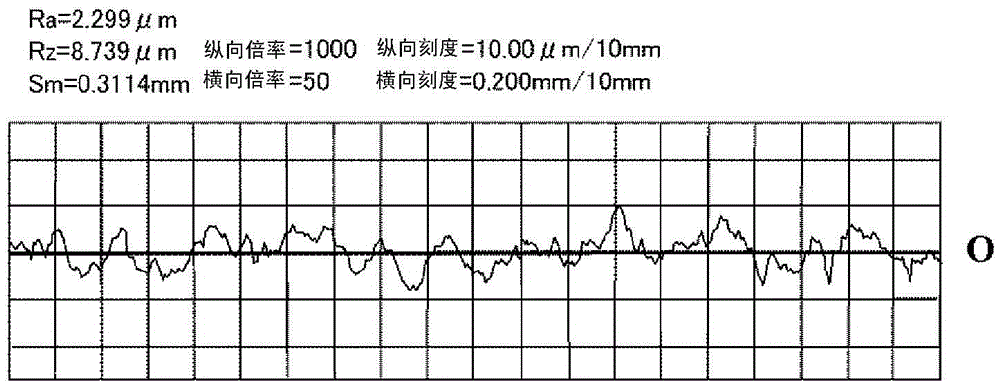

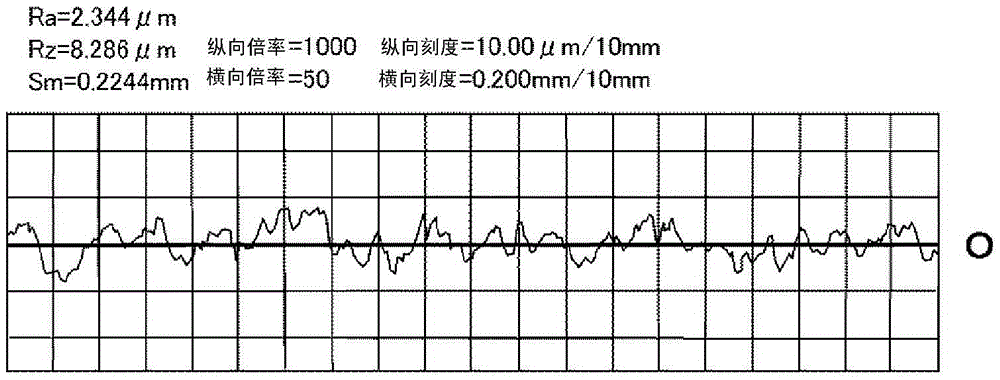

Sliding member

ActiveCN105579722AMaintain bumpy shapeGuaranteed wear resistanceShaftsBearing componentsHardnessWear resistance

Provided is a sliding member which has a hardness suitable for use under high-load conditions and which exhibits excellent abrasion resistance. A sliding member obtained by: shot-blasting the surface of a sliding layer, which is to support slidably an object to be slid; and then processing the resulting surface to form a sliding surface which has protrusions and recesses and which exhibits an arithmetic average roughness (Ra) of more than 0 to 2.0[mu]m, a ten-point average roughness (Rz) of more than 0 to 7.5[mu]m, and a surface hardness (Hv) of 150 to 250.

Owner:SENJU METAL IND CO LTD

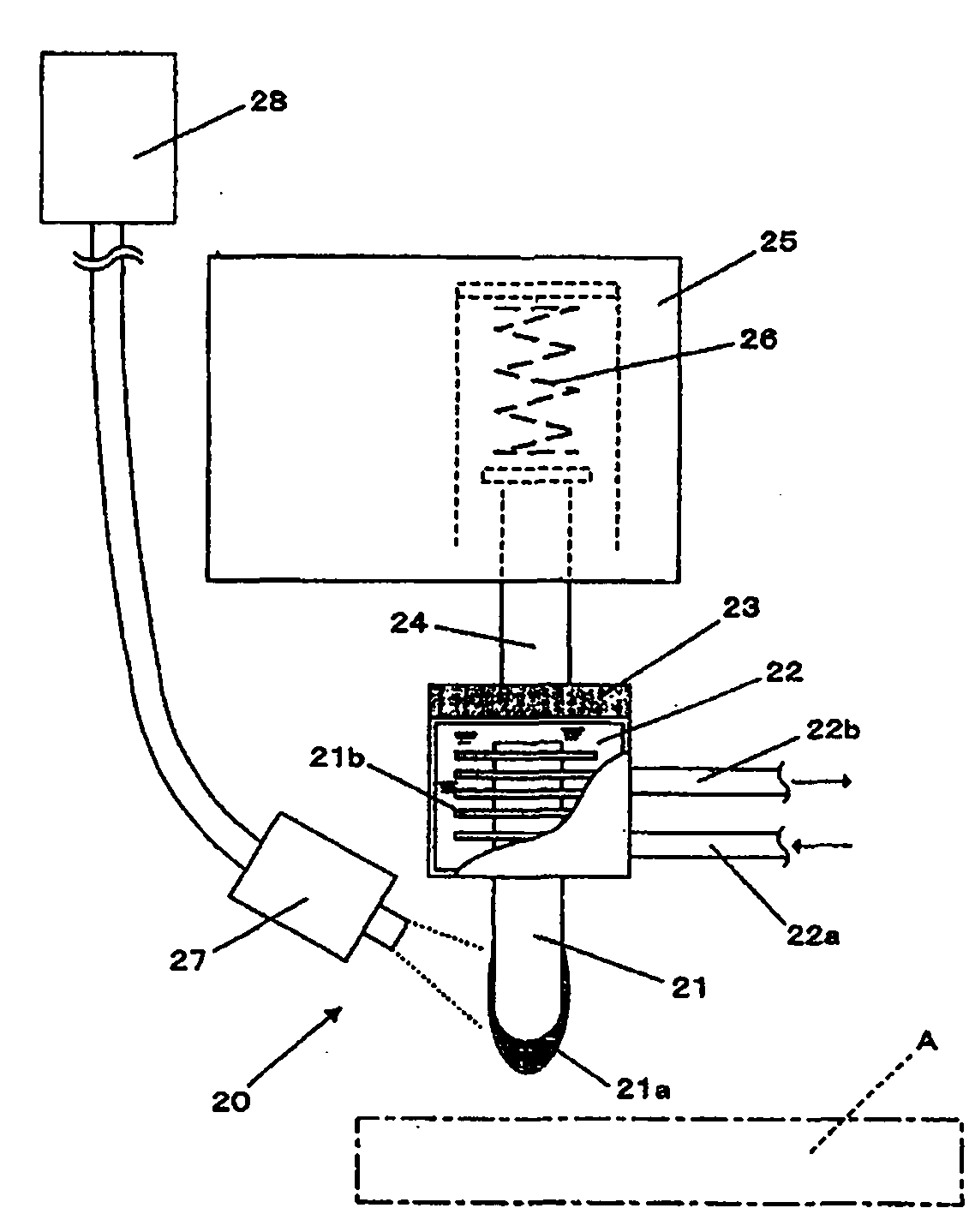

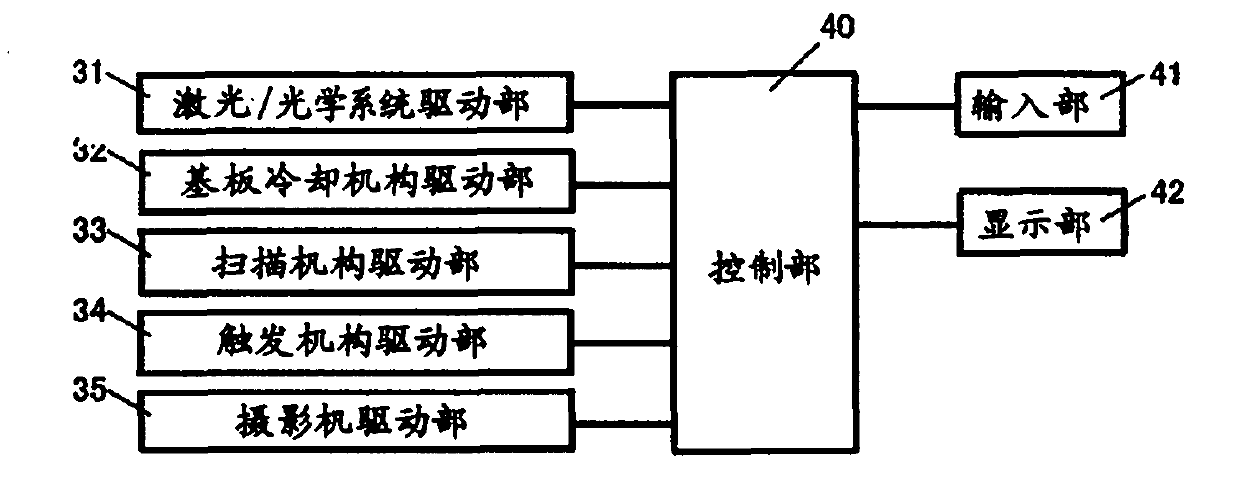

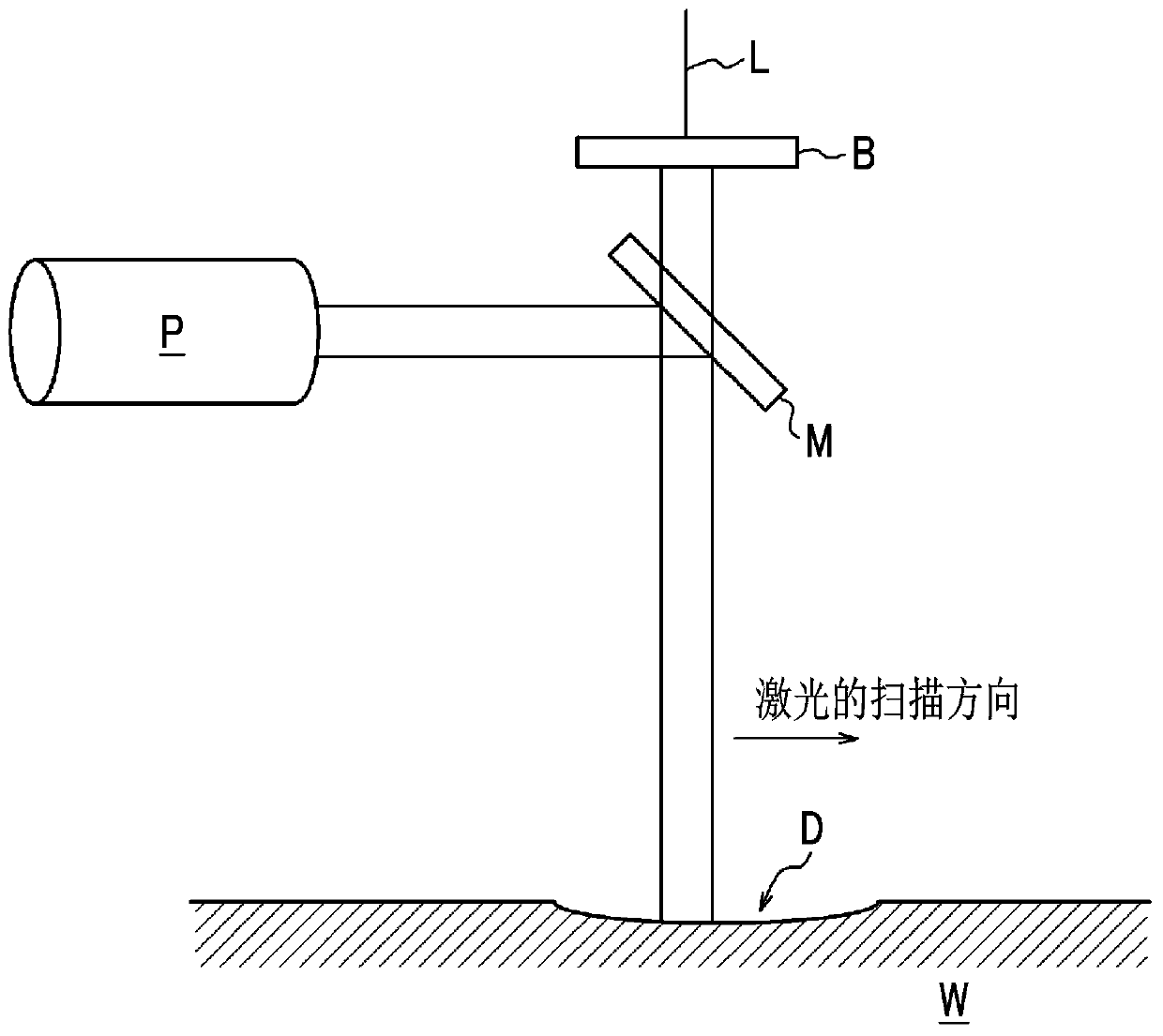

Laser working apparatus, and laser working method

InactiveCN102089115AImprove efficiencyHigh precisionSemiconductor/solid-state device manufacturingFine working devicesLight beamOptoelectronics

Provided are a laser working method and a laser working apparatus using a cooling method by a solid contact, which are freed from the problem of producing metal powder, the problem of sticking blots of a cooling member to a substrate, and the development of flaws by frictions. The laser working apparatus comprises a laser irradiation mechanism for forming a beam spot on a fragile material substrate, a substrate cooling mechanism for forming a cooling region, and a scanning mechanism for moving the beam spot and the cooling region relatively in the order of the beam spot and the cooling region along a scheduled working line set on the substrate. The substrate cooling mechanism includes a solid-phase coolant solidified by cooling a coolant material taking a gas or liquid phase at the ordinary temperature, and a push mechanism for causing the solid-phase coolant to contact the substrate.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Feed distributor

InactiveCN107646734AAvoid the hassle of needing frequent feedingAdjustable sizeAvicultureEngineeringDistributor

The invention relates to the field of animal husbandry equipment, in particular to a feed distributor. The feed distributor comprises a feed distributor body, and the feed distributor body comprises adischarge port, a discharge port adjusting device and two push plates; the discharge port is formed by two surrounding plates at the two sides in a defined mode; the push plates are fixedly arrangedat the two ends of the surrounding plates at the two sides respectively; the discharge port adjusting device is located at one end of the feed distributor body and comprises a discharge port adjustingplate and an operation plate, wherein the discharge port adjusting plate is tightly attached to the inner side of the surrounding plate at one side and slides vertically along the corresponding surrounding plate, the operation plate is fixedly installed on the corresponding surrounding plate and arranged in the mode of intersecting with the surrounding plate, the inner end of the operation plateis fixedly connected with the end of the discharge port adjusting plate, operation plate kidney-shaped holes are formed in the middle of the operation plate in the extending direction, operation plateadjusting bolts are fixedly installed on the surrounding plates and penetrate through the operation plate kidney-shaped holes. The feed distributor is simple in structure, convenient to use and capable of adjusting the size of the discharge port and preventing feed from caking.

Owner:河北新裕德畜牧机械科技有限公司

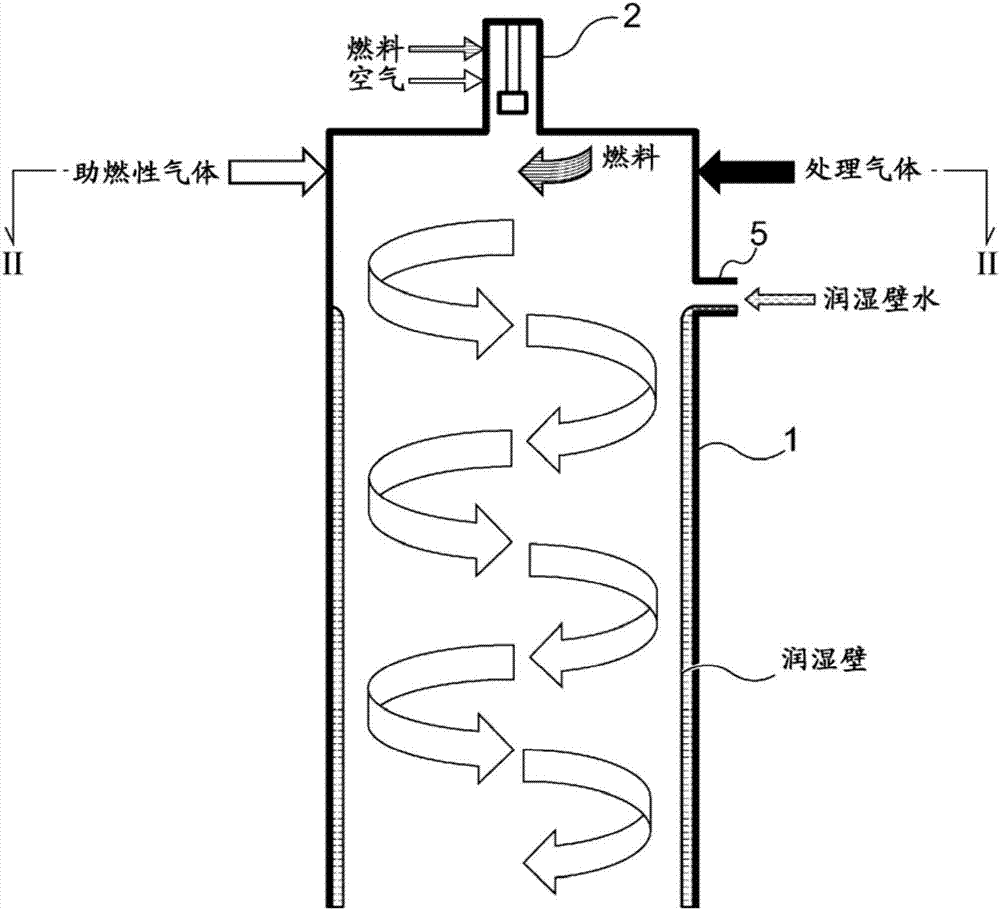

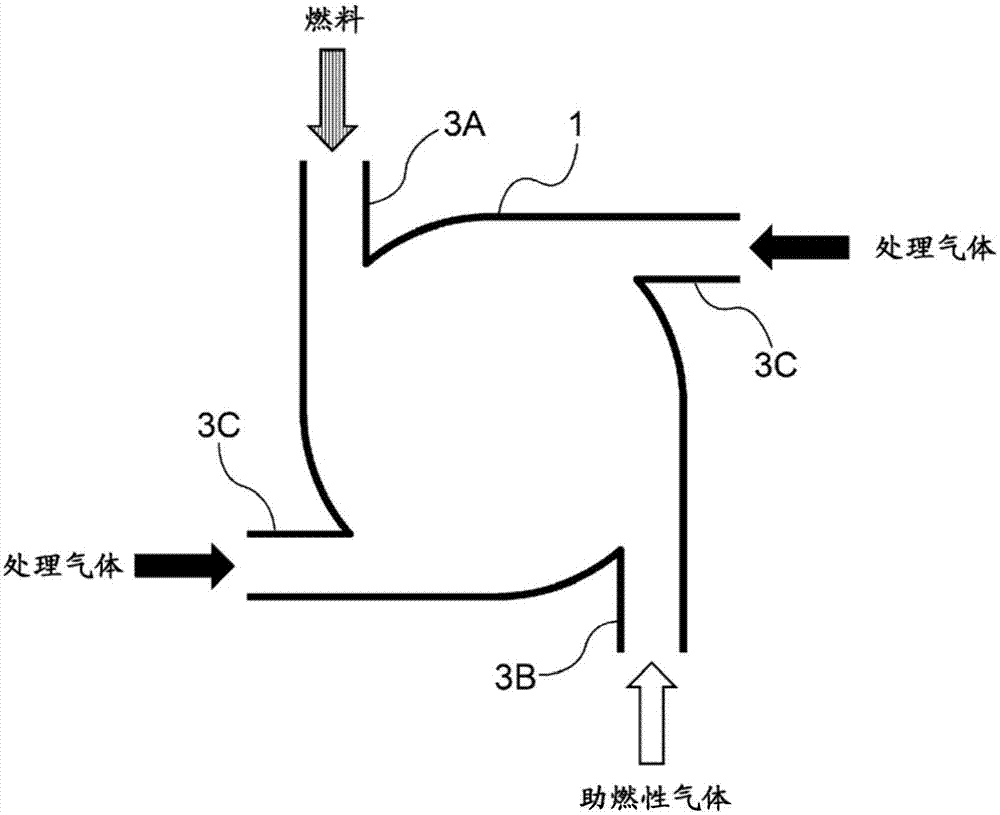

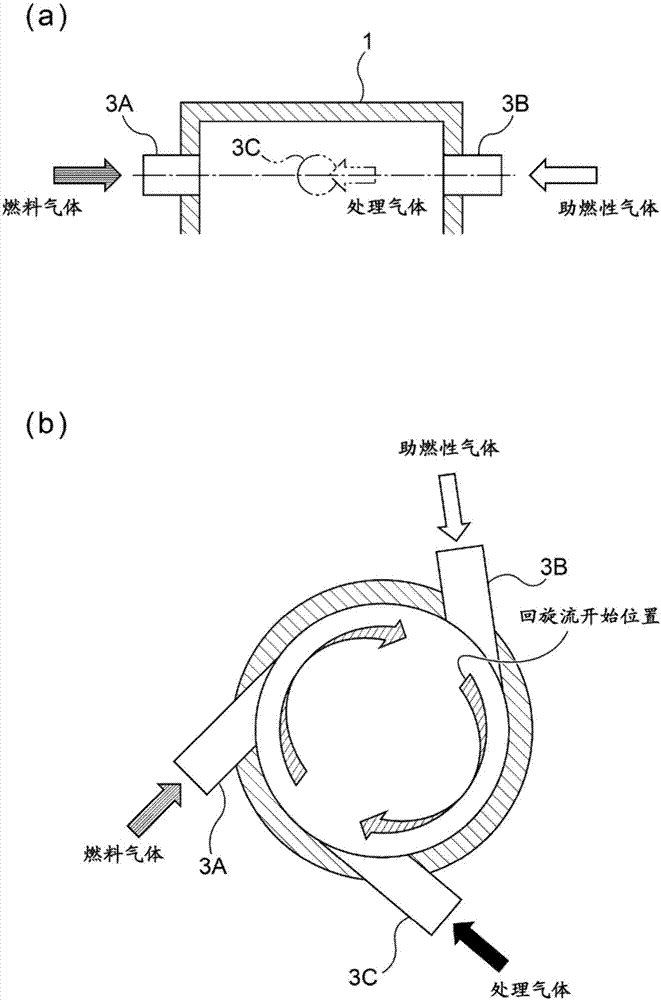

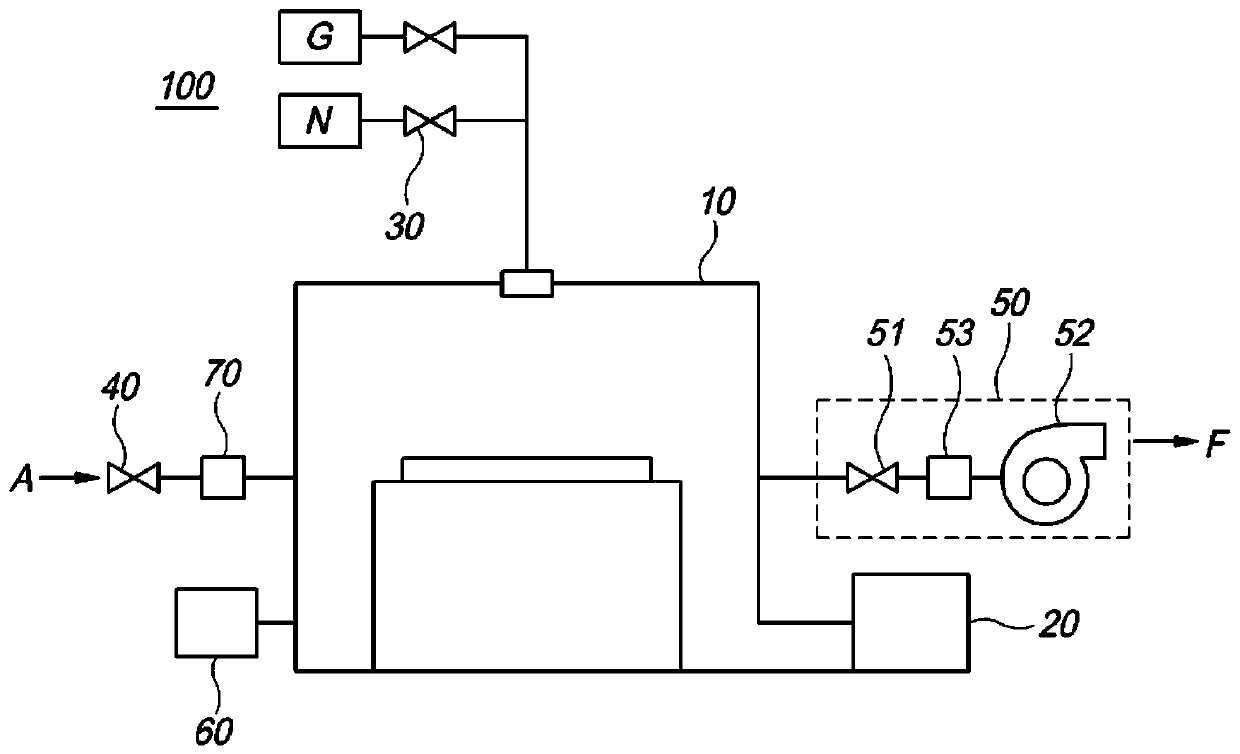

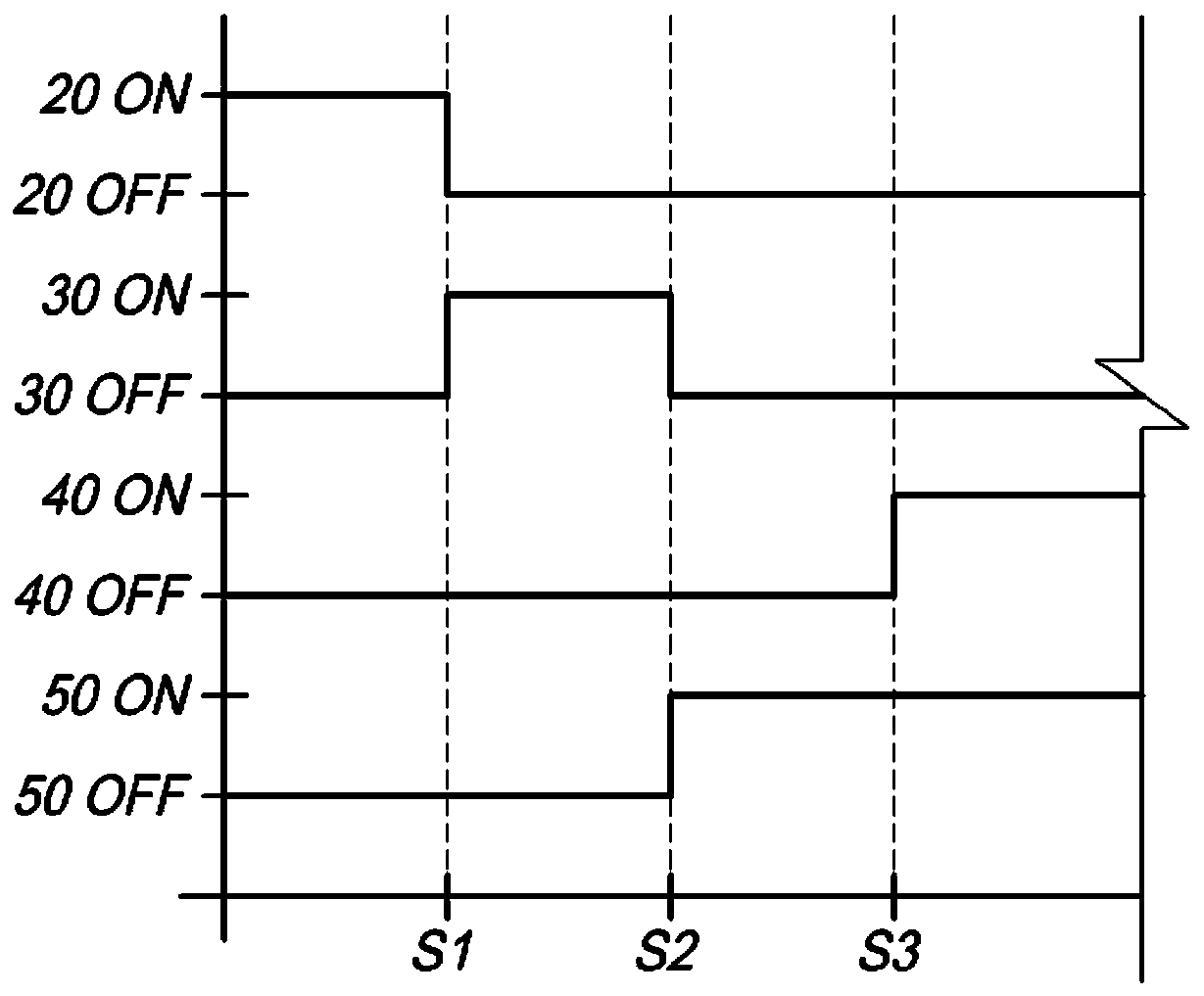

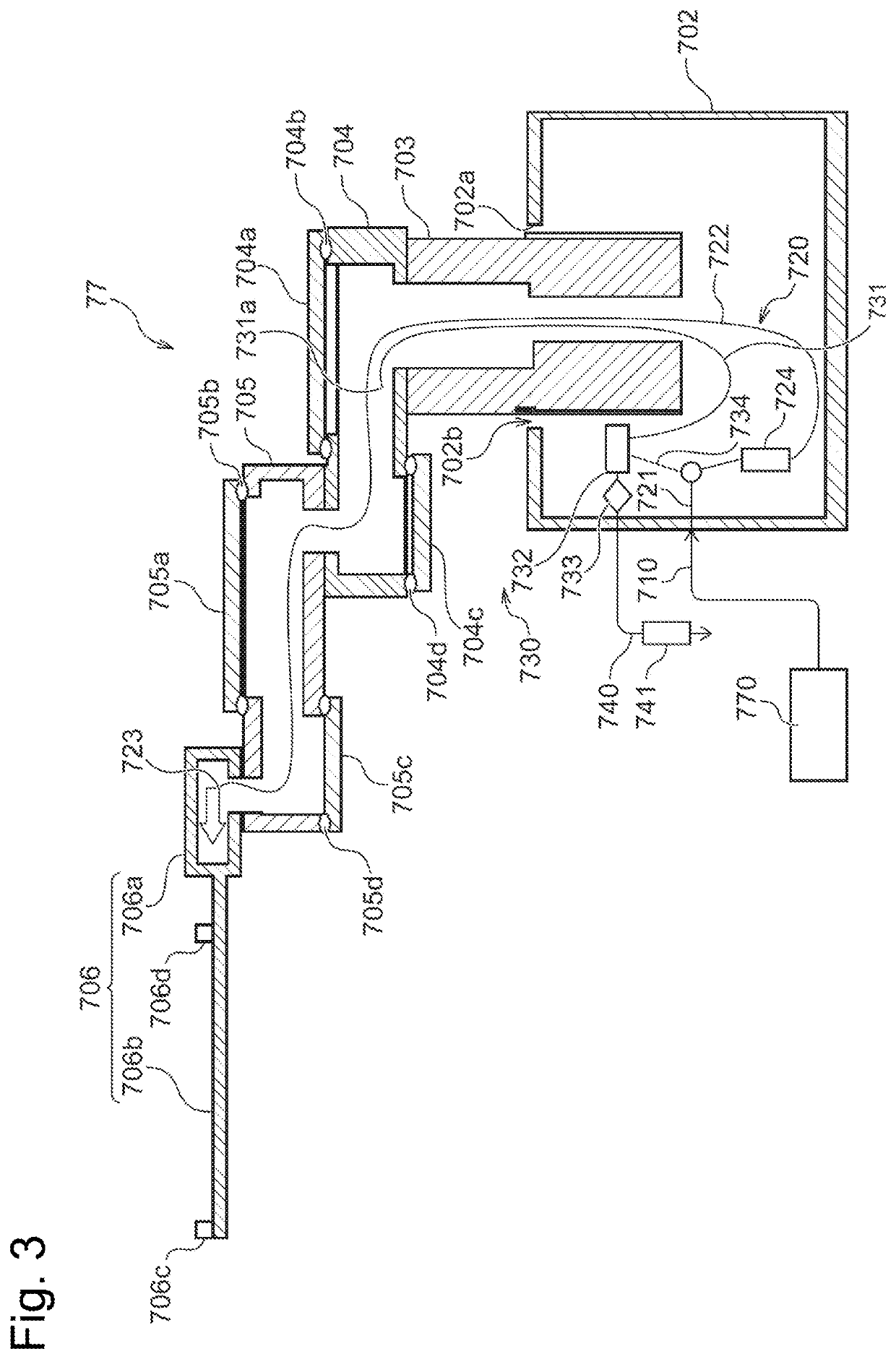

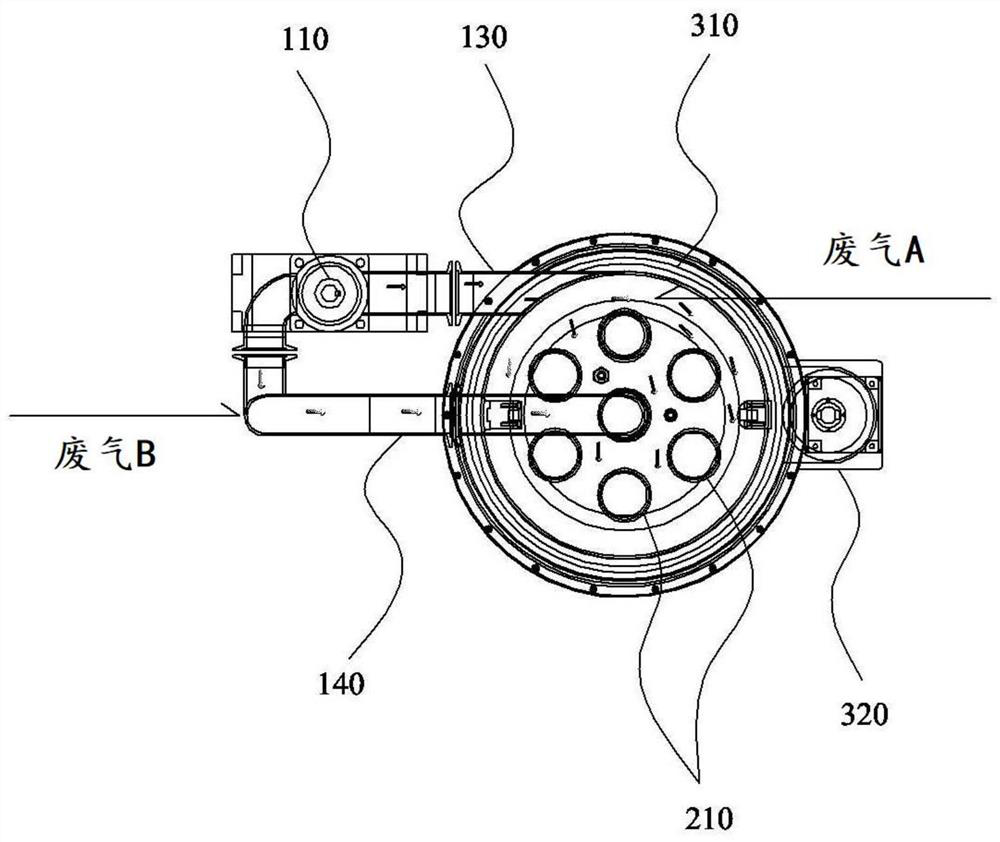

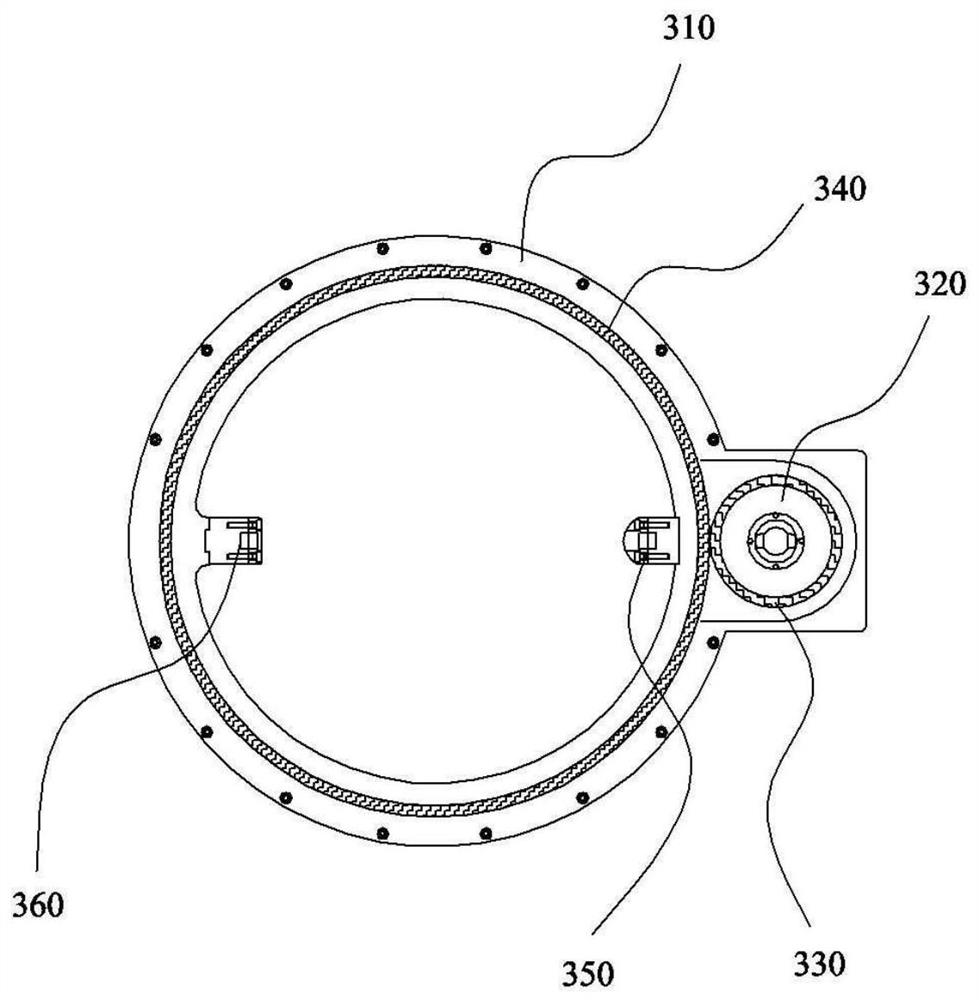

Exhaust-gas treatment apparatus

ActiveCN107429914AAvoid heat damageInhibitionGas treatmentExhaust apparatusCombustion chamberDevice material

The present invention pertains to an exhaust-gas treatment apparatus which burns and detoxifies the exhaust gas discharged from a manufacturing apparatus or the like that manufactures a semiconductor device, a liquid crystal, an LED or the like. In the exhaust-gas treatment apparatus which burns and detoxifies treatment gas, a cylindrical combustion chamber (1) burning the treatment gas is equipped with a combustion nozzle (3A), a susceptible gas nozzle (3B), and a treatment gas nozzle (3C) which inject fuel, susceptible gas, and treatment gas in the tangential direction of the inner peripheral surface of the combustion chamber (1). The combustion nozzle (3A), the susceptible gas nozzle (3B), and the treatment gas nozzle (3C) are located in the same plane perpendicular to the axis of the combustion chamber (1).

Owner:EBARA CORP

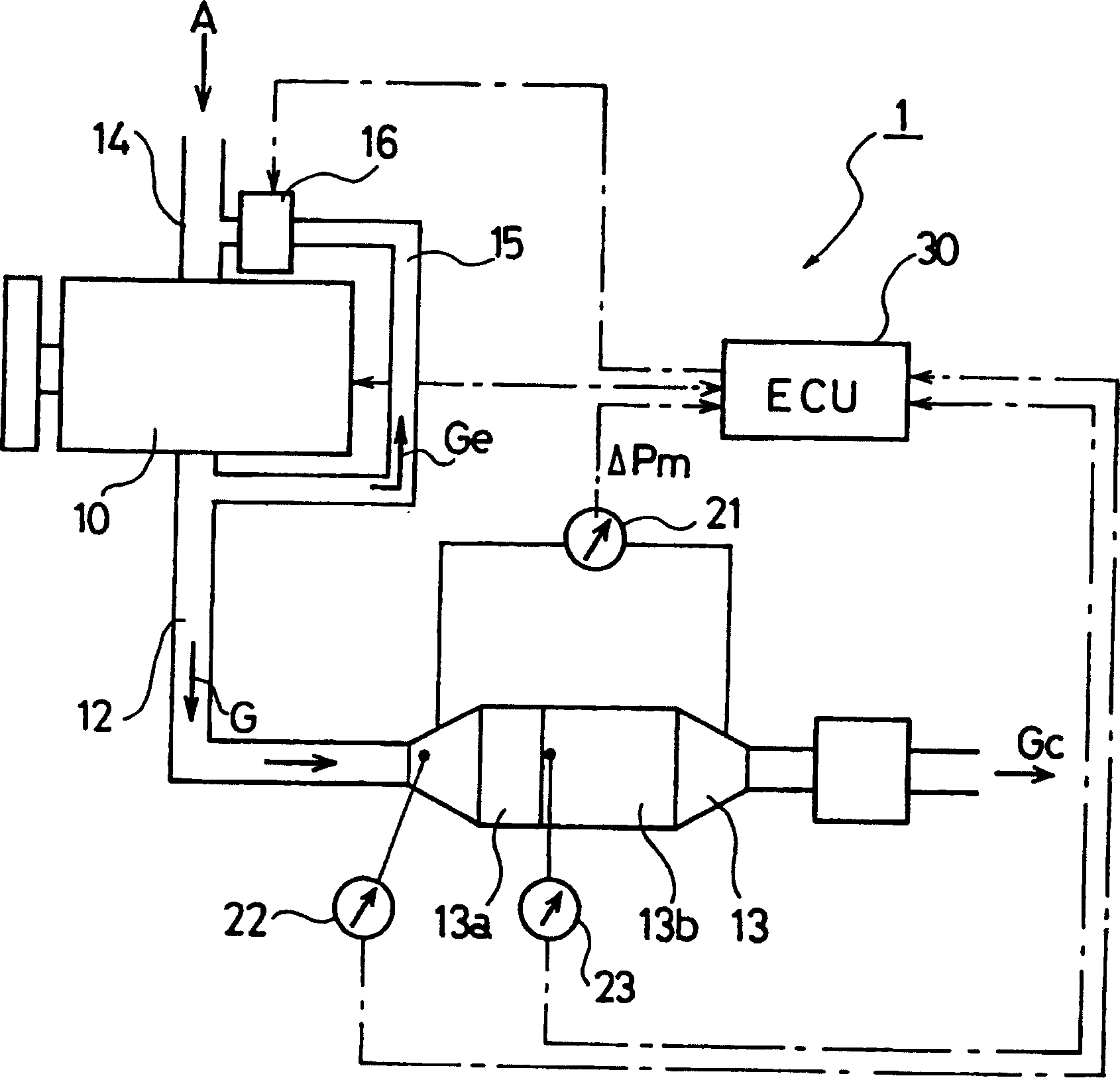

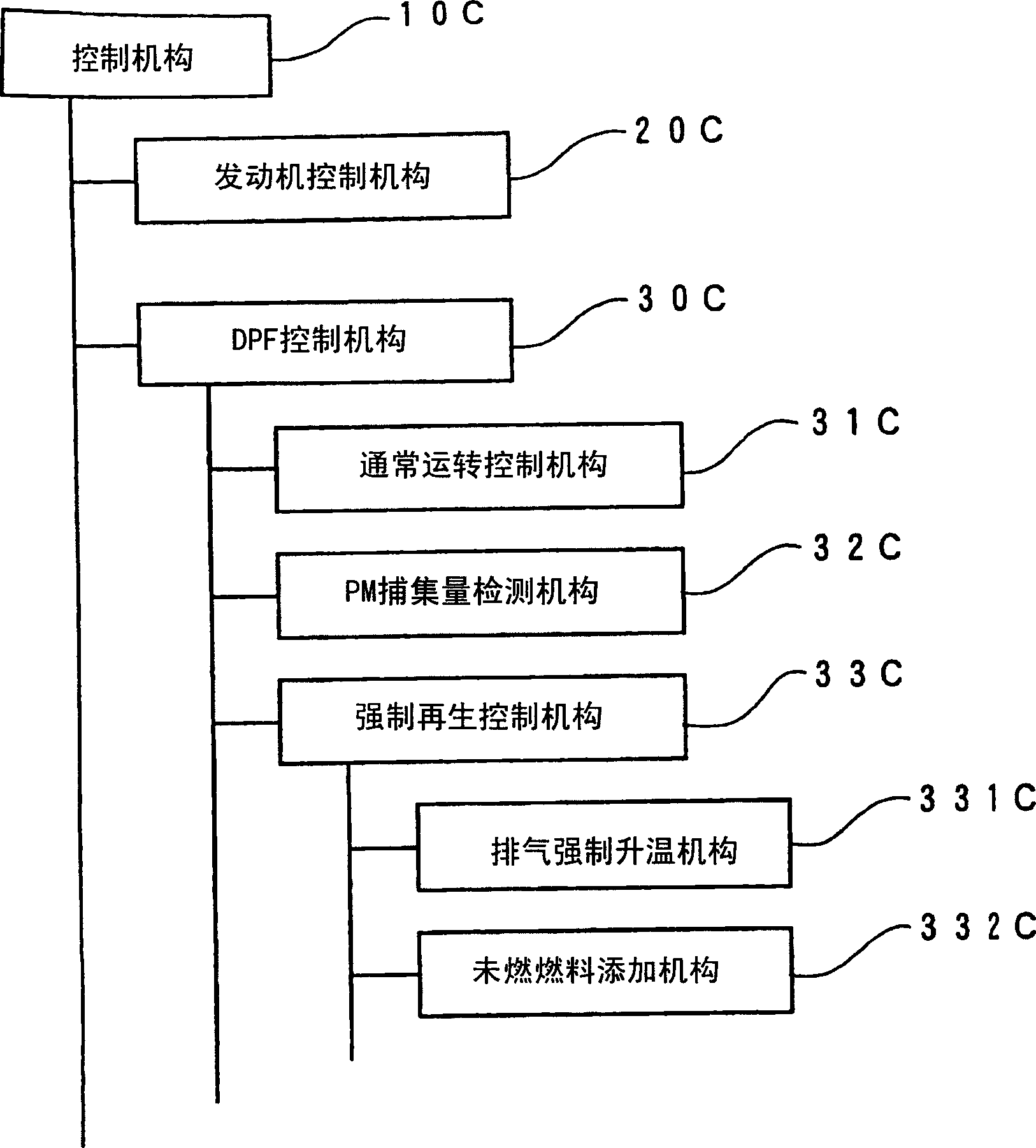

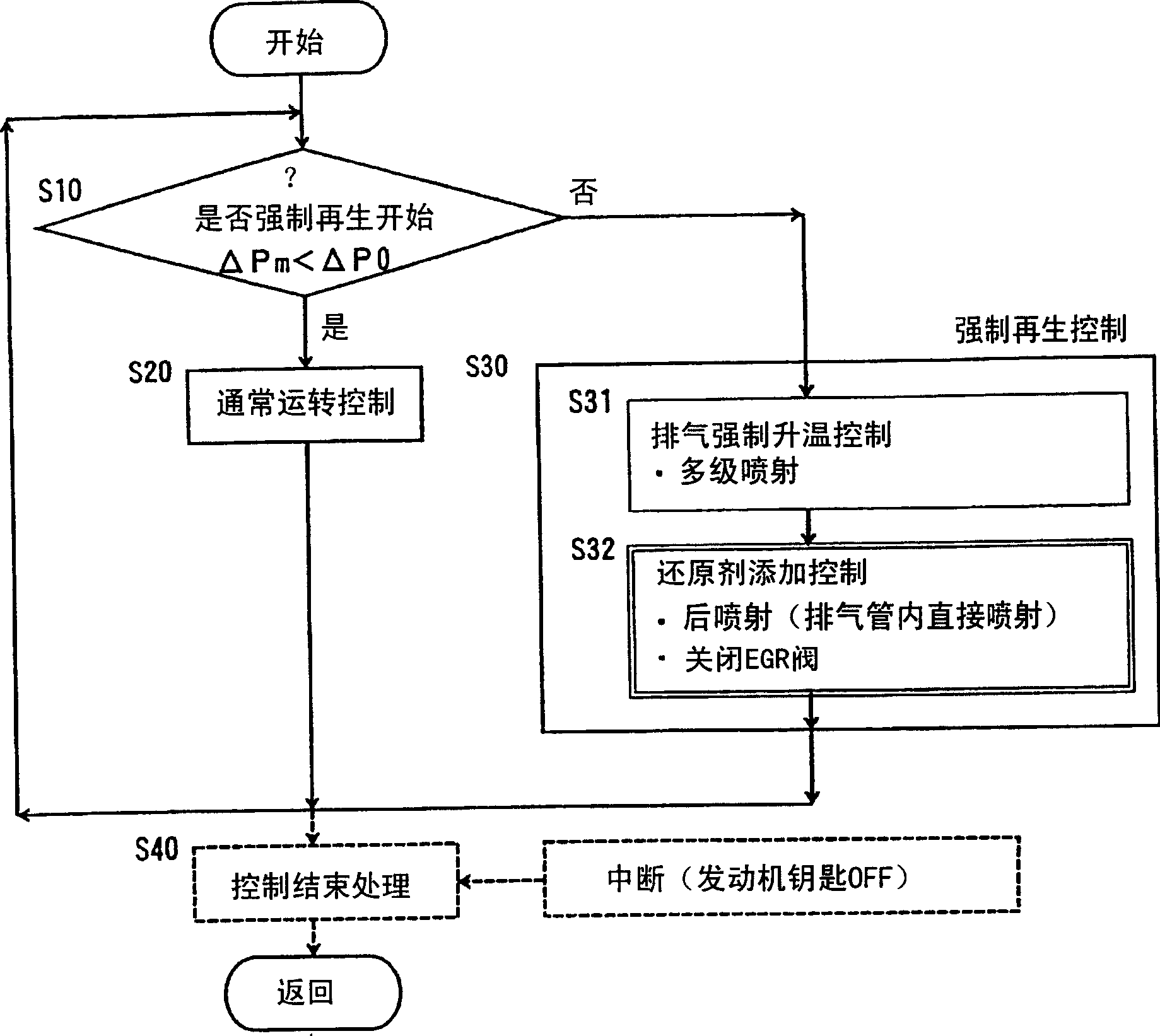

Control method for an exhaust gas purification system and an exhaust gas purification system

InactiveCN1690376AAvoid breakingAvoid occlusionElectrical controlNon-fuel substance addition to fuelControl systemInlet valve

This invention provides a method for controlling an exhaust emission control system and the exhaust emission control system capable of preventing damage of an engine caused by blockage of an EGR passage and adhesion of an intake valve or the like which occur due to imperfect combustion of unburned fuel or the like supplied to exhaust gas by preventing the blockage of the EGR passage, adhesion of the intake valve or the like in forced regeneration control of a continuous regeneration type DPF device. In the exhaust emission control system 1 having the continuous regeneration type DPF device 13 including a filter 13b collecting PM in exhaust gas G provided in an exhaust gas passage 12 of an internal combustion engine 10 equipped with an EGR system and supplying unburned fuel to the exhaust gas G flowing in the continuous regeneration type DPF device 13 at a time of forced regeneration for regenerating the filter 13b by forcedly burning PM collected by the filter 13b, circulation of EGR gas Ge to an intake air passage 14 side by the EGR system is stopped at a time of unburned fuel supply to the exhaust gas G in forced regeneration control.

Owner:ISUZU MOTORS LTD

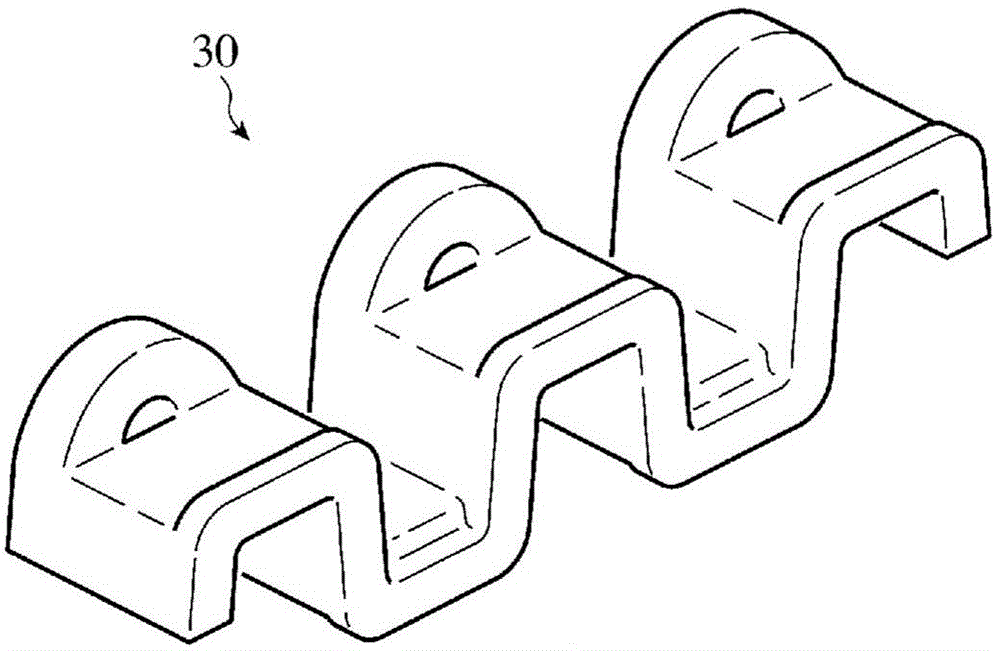

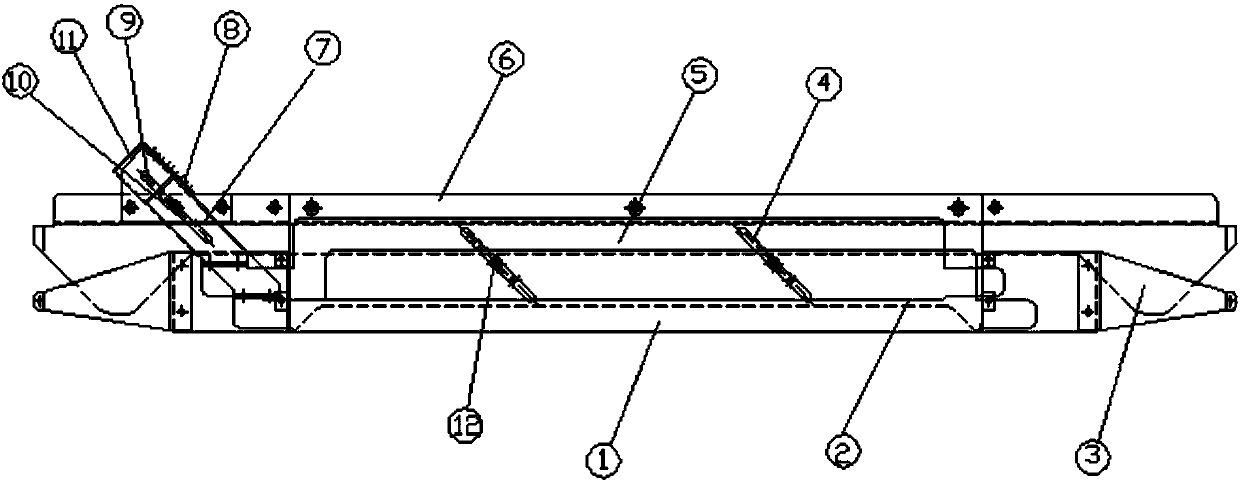

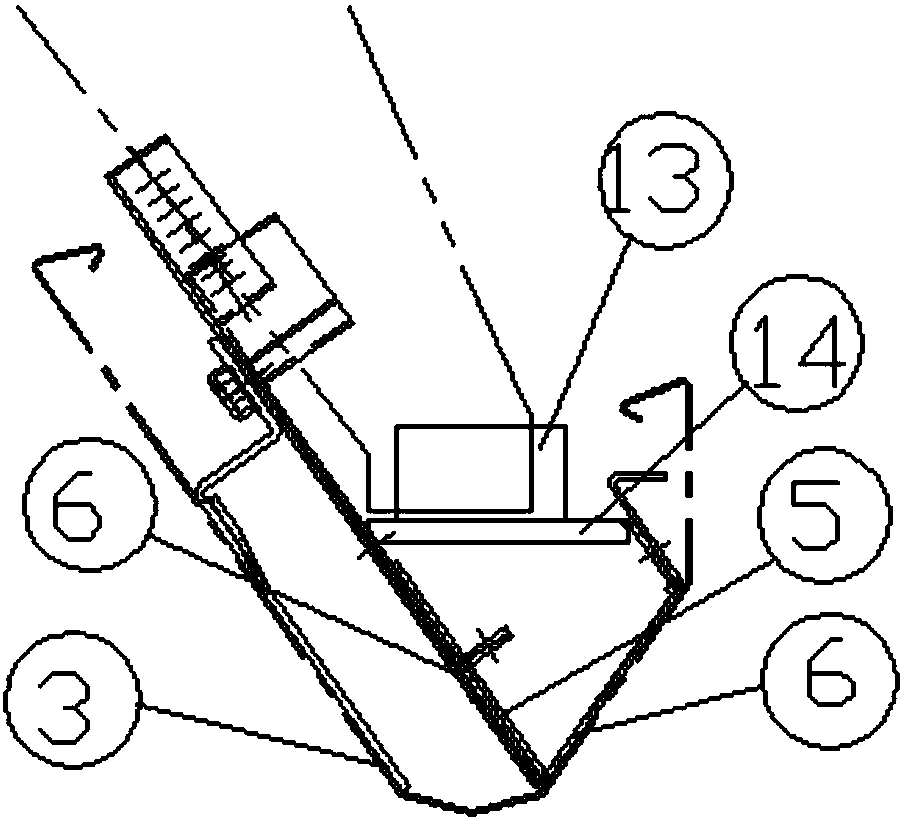

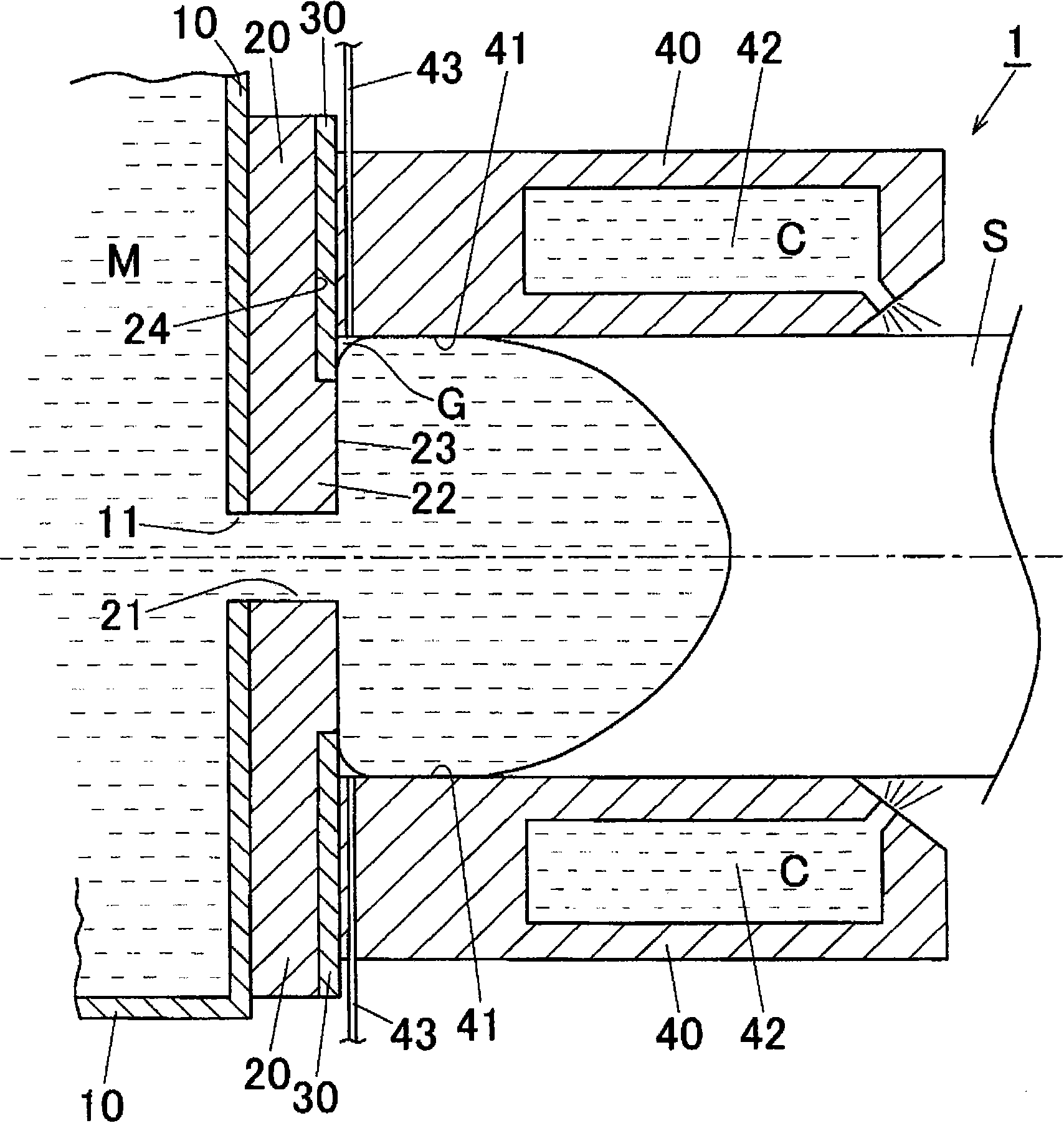

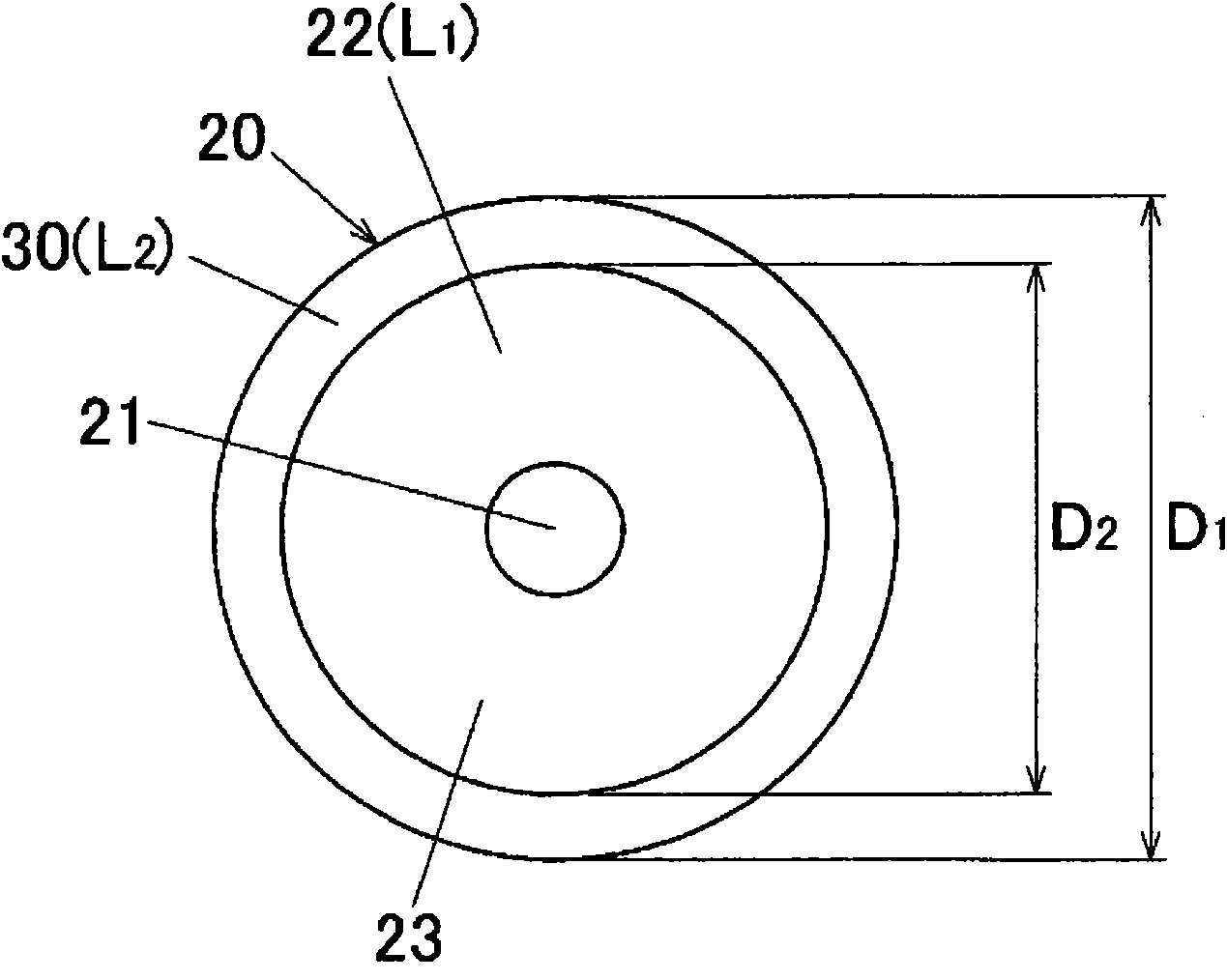

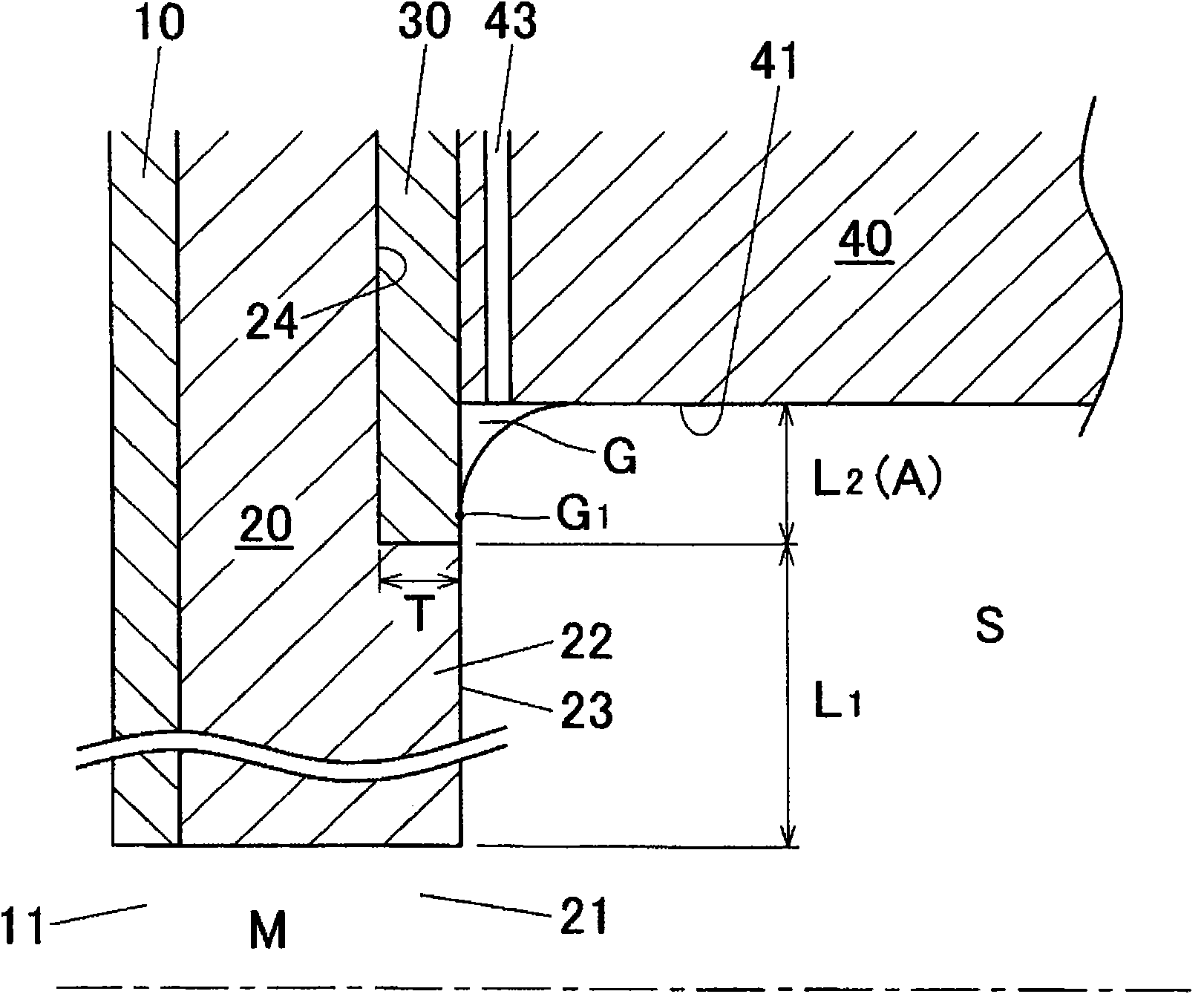

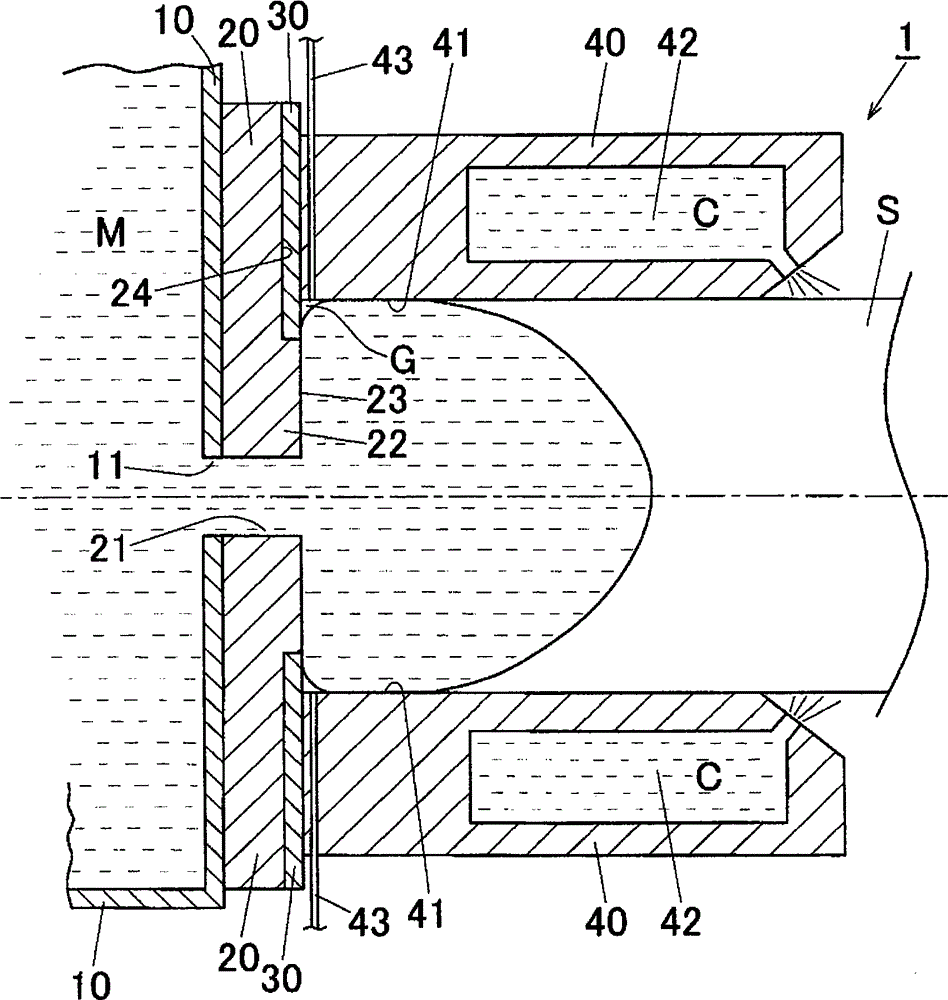

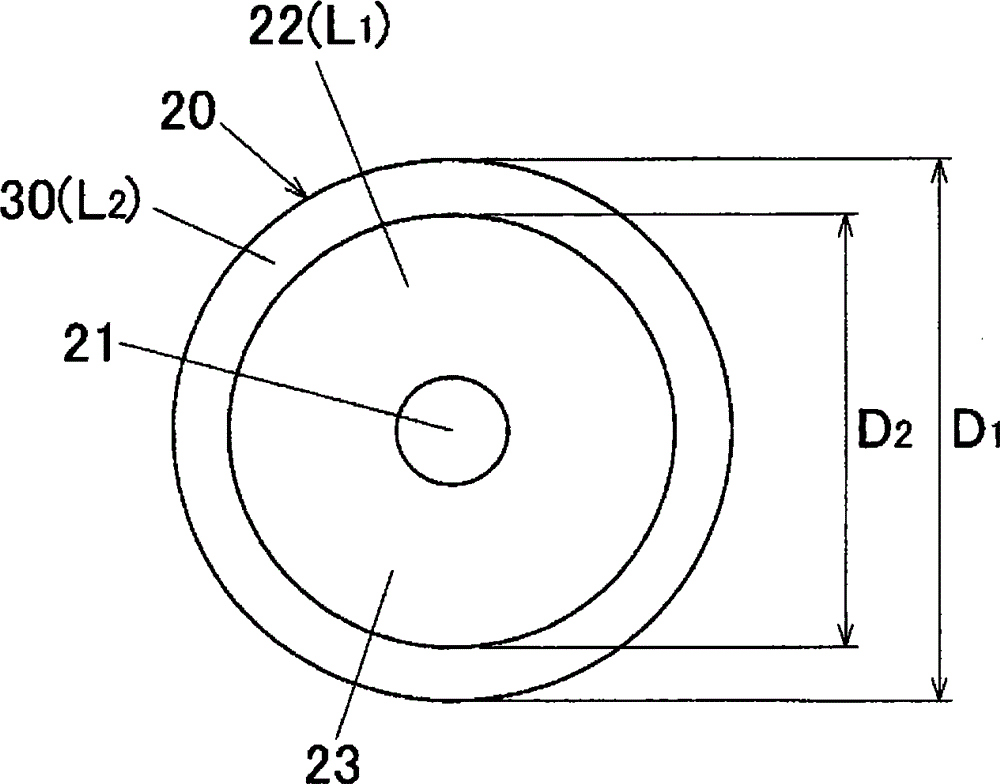

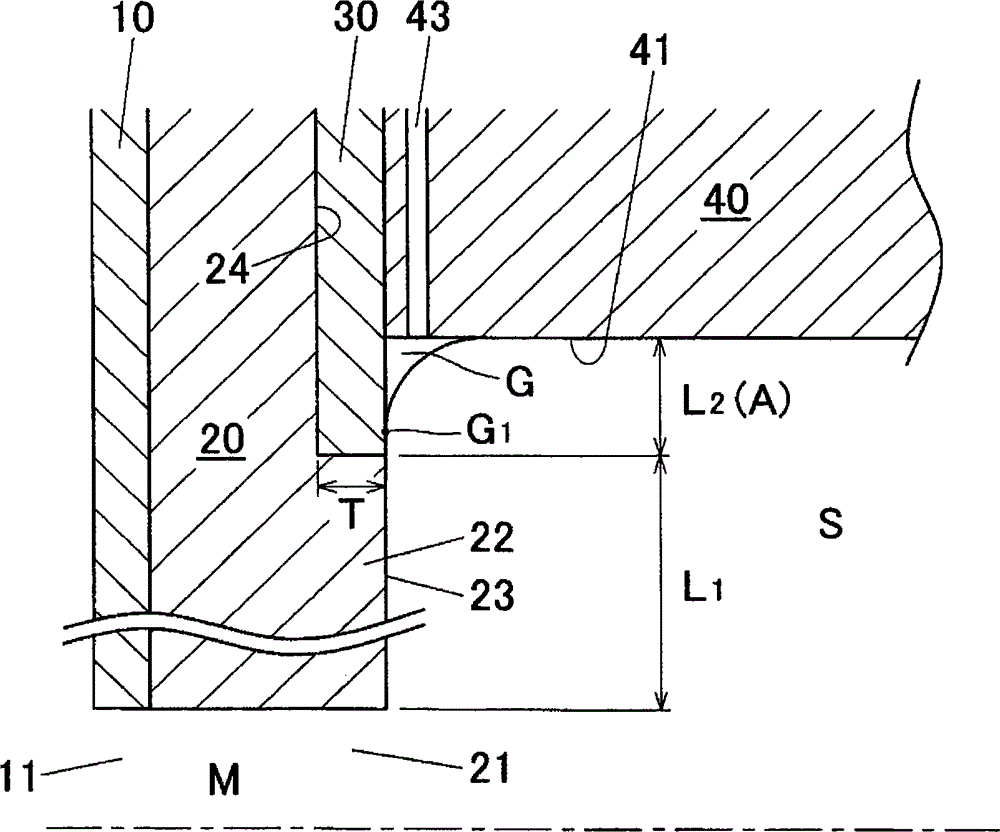

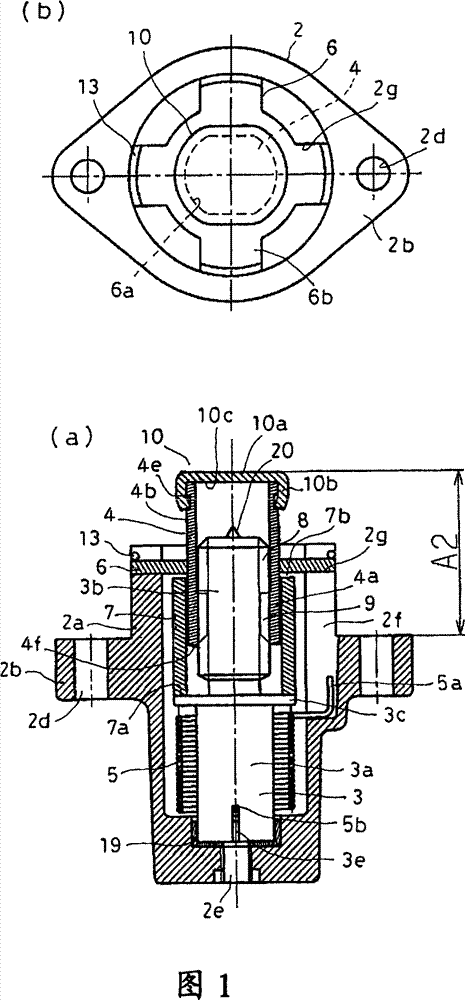

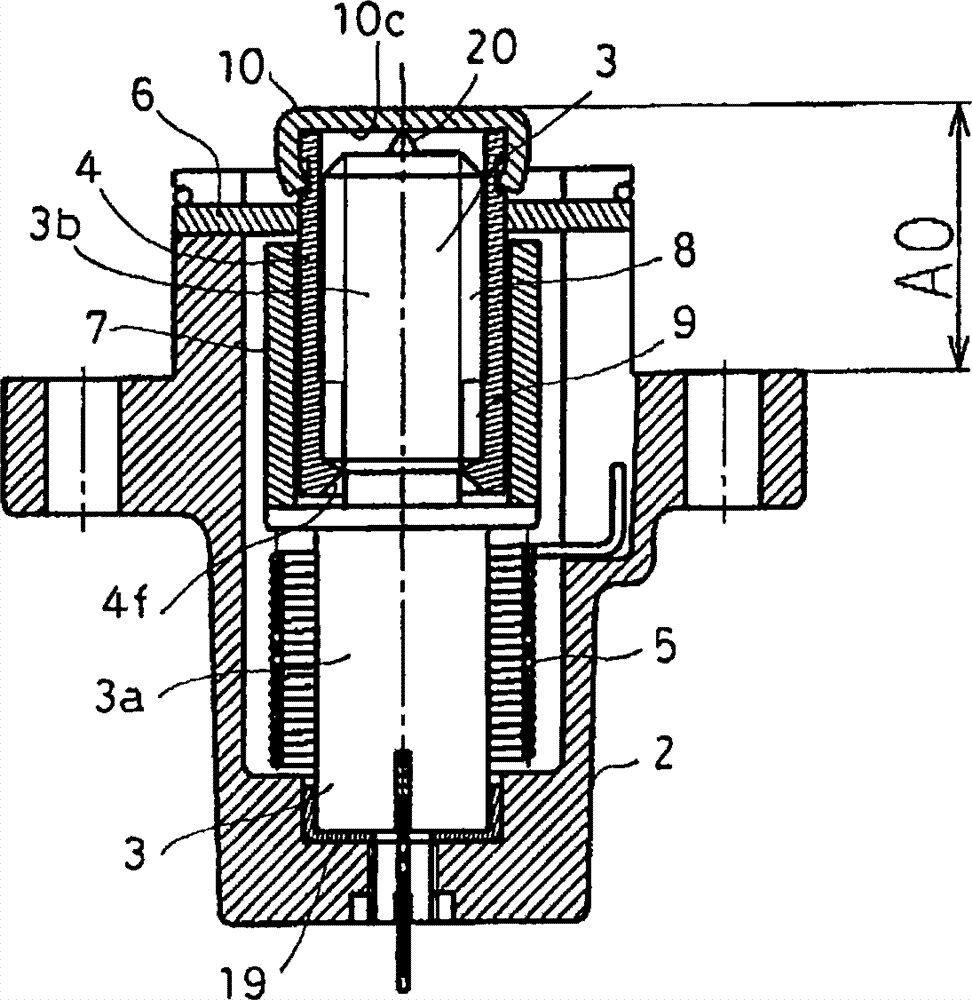

Continuous casting device and molten metal pouring nozzle

A continuous casting device in which an end surface of a molten metal pouring nozzle can achieve good lubricating ability without an increase in the amount of lubricating oil, so that the continuous casting device can cast ingots having good casting surface quality for a long period of time. The continuous casting device (1) has the molten metal pouring nozzle (20) provided between a molten metal receiving section (10) and a mold (40). The pouring nozzle (20) has a tubular body (22) having a molten metal path (21) and made from a fire-resistant substance. A self-lubricating annular member (30) is placed on a mold-side end surface (23) of the body (22) so as to surround the molten metal pouring path (21).

Owner:SHOWA DENKO KK

Continuous casting equipment and injection nozzles

The present invention provides a continuous casting device that imparts lubricity to the end face of a liquid injection nozzle without increasing the amount of lubricating oil, thereby enabling continuous casting of ingots with good surface quality for a long period of time. The continuous casting device of the present invention is a continuous casting device (1) in which a liquid injection nozzle (20) is arranged between a molten metal receiving part (10) and a casting mold (40). It is characterized in that the liquid injection nozzle (20) 20) It is provided with a cylindrical main body (22) having a liquid injection passage (21) and formed of a refractory material, and the end surface (23) of the main body (22) on the mold side is surrounded by the liquid injection passage (21). The method is equipped with a self-lubricating annular component (30).

Owner:RESONAC HOLDINGS CORPORATION

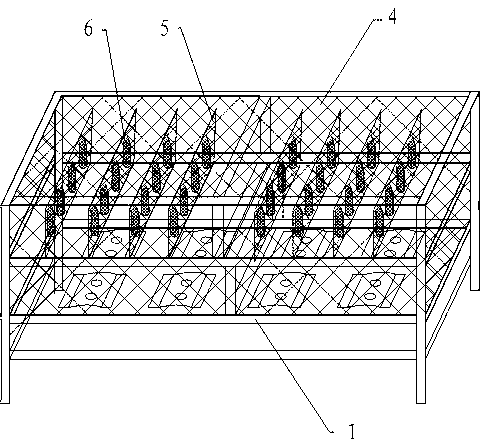

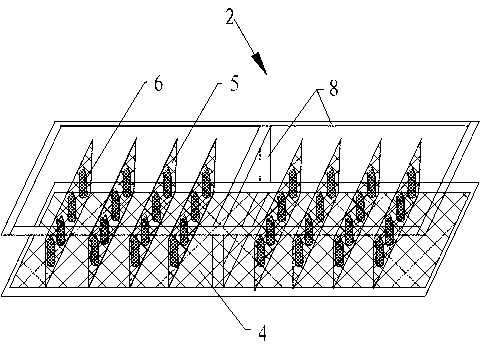

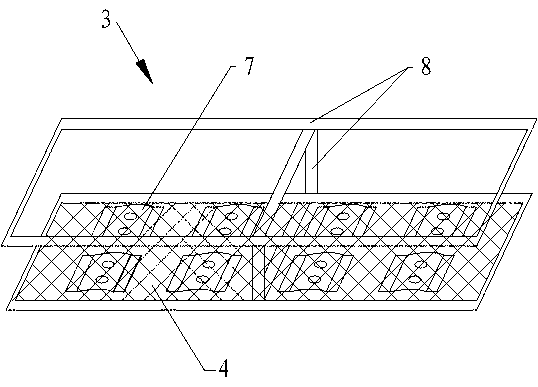

Seabed comprehensive cultivation device for stichopus japonicus and comb shells

ActiveCN103299928AIngenious designEasy to operateClimate change adaptationPisciculture and aquariaStichopusEcology

The invention provides a seabed comprehensive cultivation device for stichopus japonicus and comb shells, which comprises a stereoscopic support; at least two layers of cultivation areas are arranged at the upper part of the stereoscopic support; each cultivation is wrapped with a net; the cultivation area on the bottommost layer is used for cultivating stichopus japonicus, and a plurality of stichopus japonicus bunkers are fixedly arranged on the net at the bottom; the cultivation areas of the rest layers are used for cultivating comb shells; a plurality of longitudinal nets are fixedly arranged between the nets on two opposite side surfaces of the cultivation areas for cultivating comb shells; and a plurality of stereoscopic nets are arranged on each longitudinal net. The invention provides a comprehensive cultivation device suitable for multiple nutritive salt layers of seabed according to the biological and ecological characteristics of stichopus japonicus and comb shells, so that the growth of stichopus japonicus can be promoted, and the cultivation yield of a unit area of comb shells can be improved; the device has the characteristics of simplicity in operation and strong field operability; and complementarity of sea area and different ecological niches can be utilized fully, so that the cultivation yield can be improved, and the environment stress can be reduced.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Semiconductor processing device with cleaning function and cleaning method of semiconductor processing device using the same

ActiveCN110400736ASolve the problem of inhaling harmful substancesSolve the problem of sticking to the pumping pipeElectric discharge tubesHollow article cleaningInhalationCleaning methods

The present invention relates to a cleaning method of a semiconductor process device, including: a chamber providing a substrate processing space therein; a first gas exhaust unit exhausting process gas from the inside of the chamber; a first gas supply unit supplying inert gas into the chamber; a second gas supply unit supplying cleaning gas into the chamber and generating fume in the chamber; and a second gas exhaust unit exhausting the inert gas, the cleaning gas, the fume and mixed gas thereof from the inside of the chamber, wherein the second gas exhaust unit includes an inhalation fan controlling the displacement of the inert gas, the cleaning gas, the fume and the mixed gas thereof.

Owner:GIGALANE CO LTD

Metal nitride and method for producing metal nitride

ActiveCN1993292APrevent fixationHigh yieldPolycrystalline material growthLaser detailsNitrogen sourceOxygen

The invention provides a process for producing efficiently high-quality metal nitrides (such as gallium nitride) which little contain impurities, particularly, a process for the production of metal nitrides which is characterized by using a container made of a nonoxide material. The employment of a nonoxide material as the material of the container to come into contact with a starting metal or a product metal nitride makes it possible to inhibit the reaction of the container with the starting metal or the product metal nitride, the adhesion of the metal or the metal nitride to the container, and the contamination of the metal nitride with oxygen resulting from the material of the container, thus permitting the production of highly crystalline high-quality metal nitrides. Further, the feeding of a nitrogen source gas in an amount larger than a certain level at a flow velocity higher than a certain level makes it possible to convert a starting metal into a nitride at an extremely high degree of conversion, thus enabling the production of a metal nitride having a theoretical metal / nitrogen ratio in a high yield with little unreacted starting metal. The obtained metal nitrides are little contaminated with oxygen and have theoretical metal / nitrogen ratios, thus being useful as the raw material for bulk crystal growth.

Owner:MITSUBISHI RAYON CO LTD

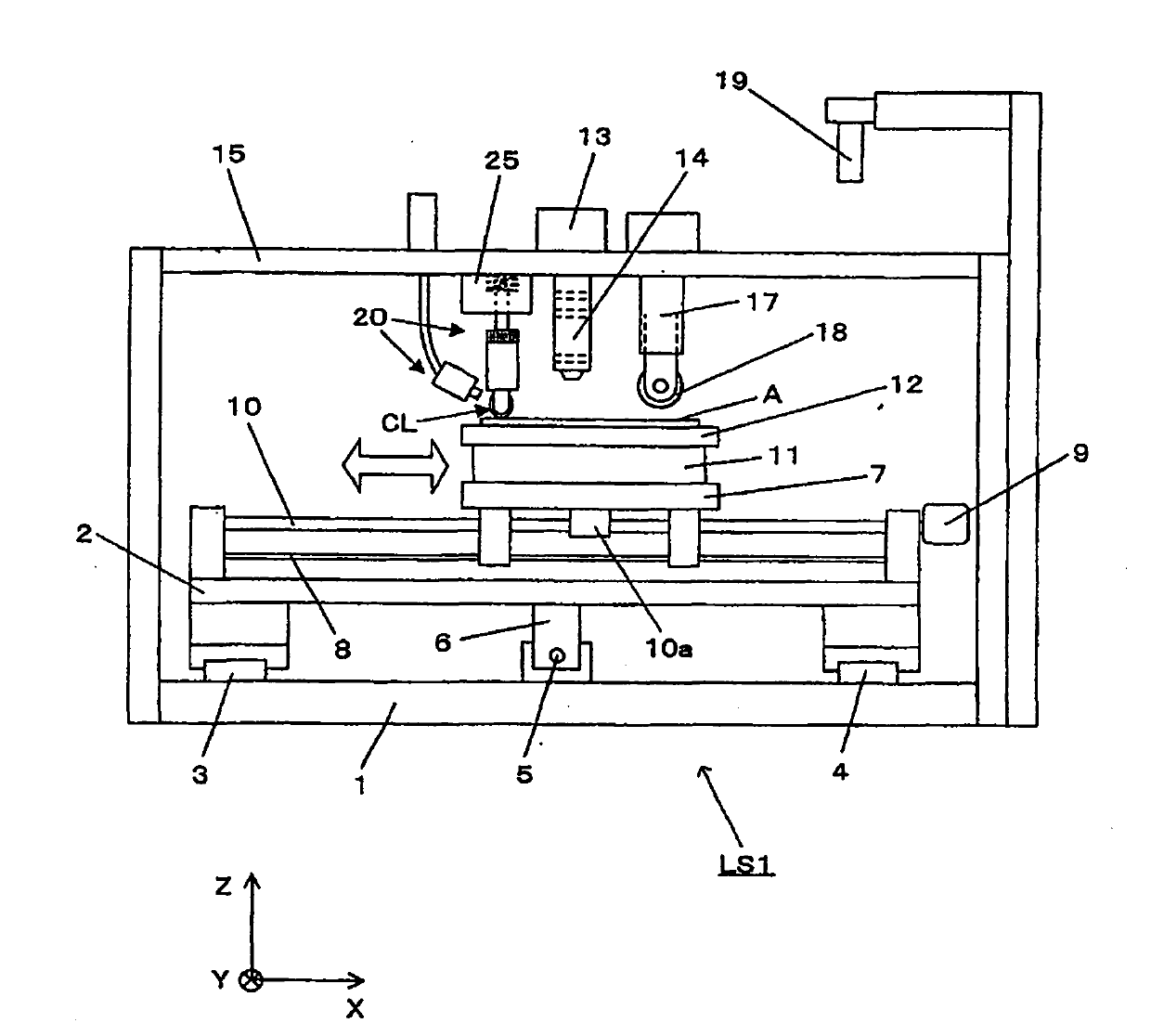

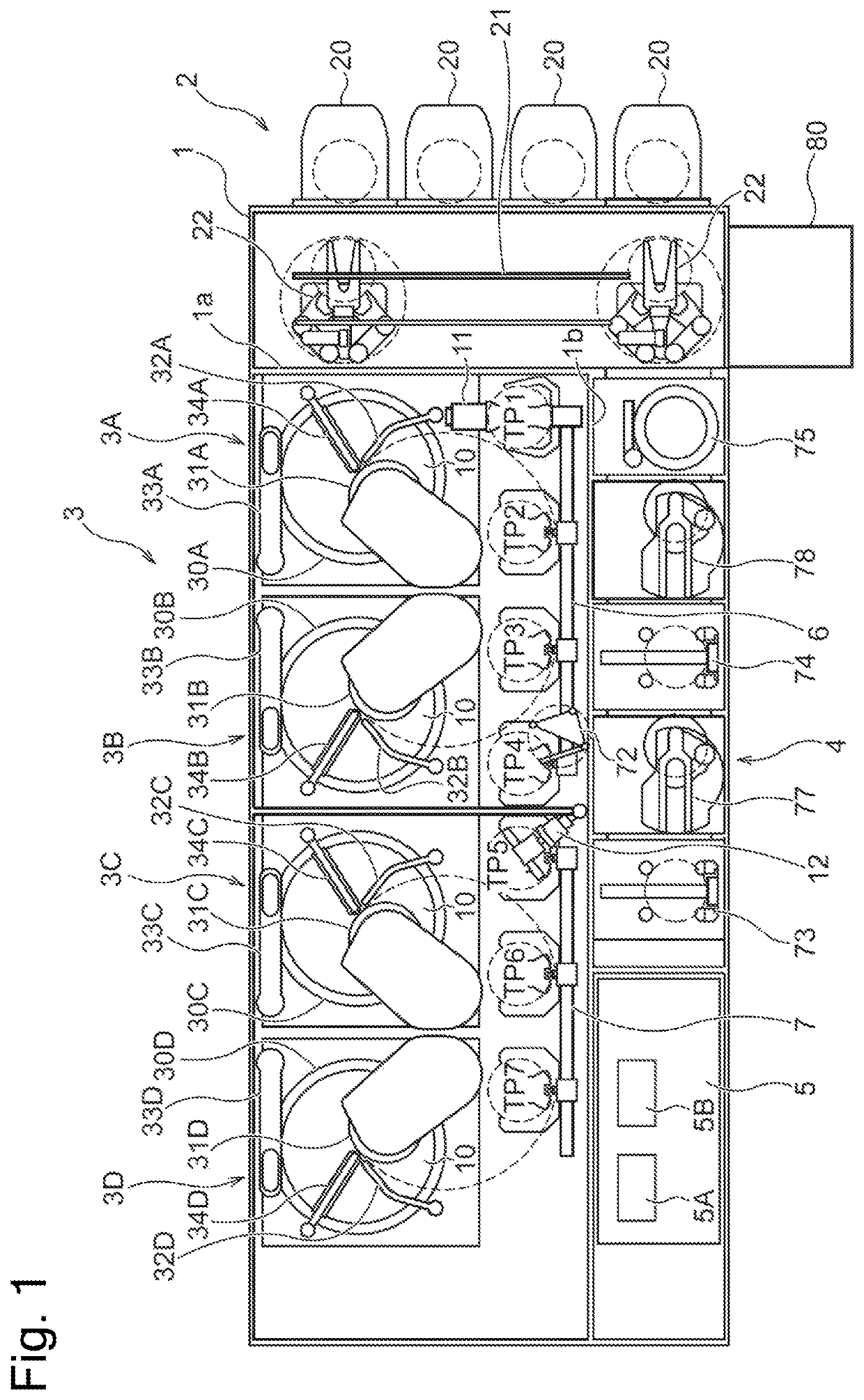

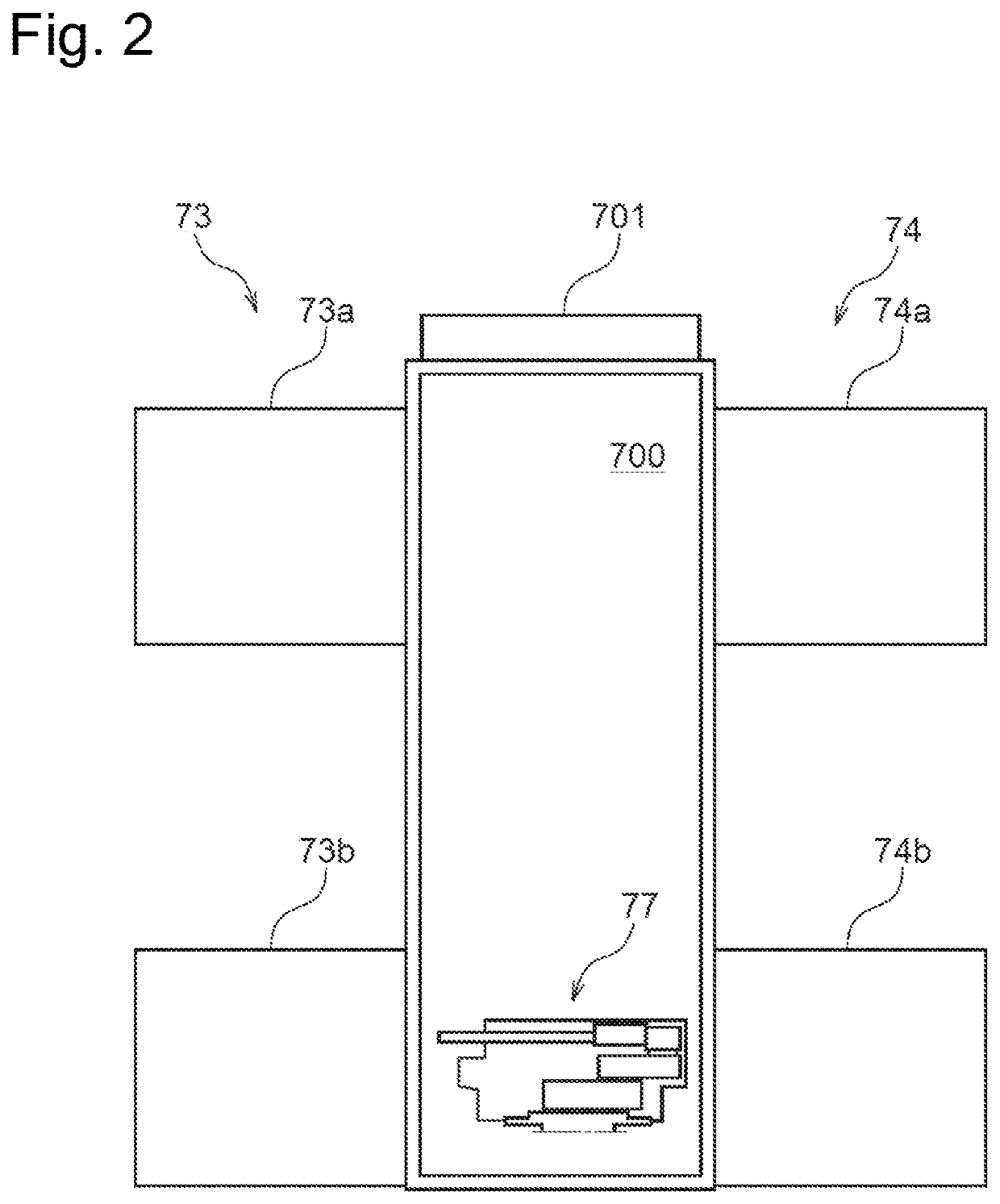

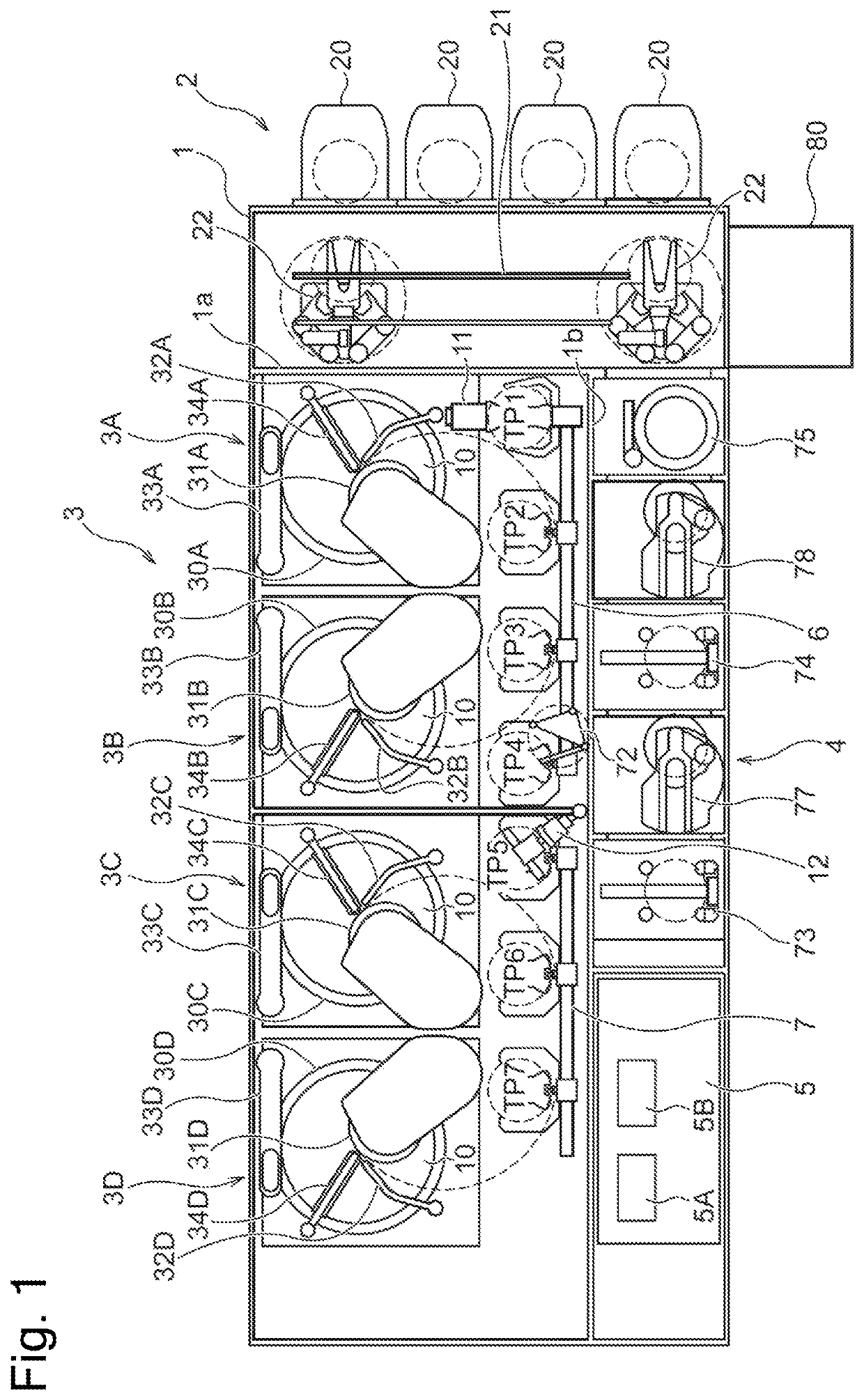

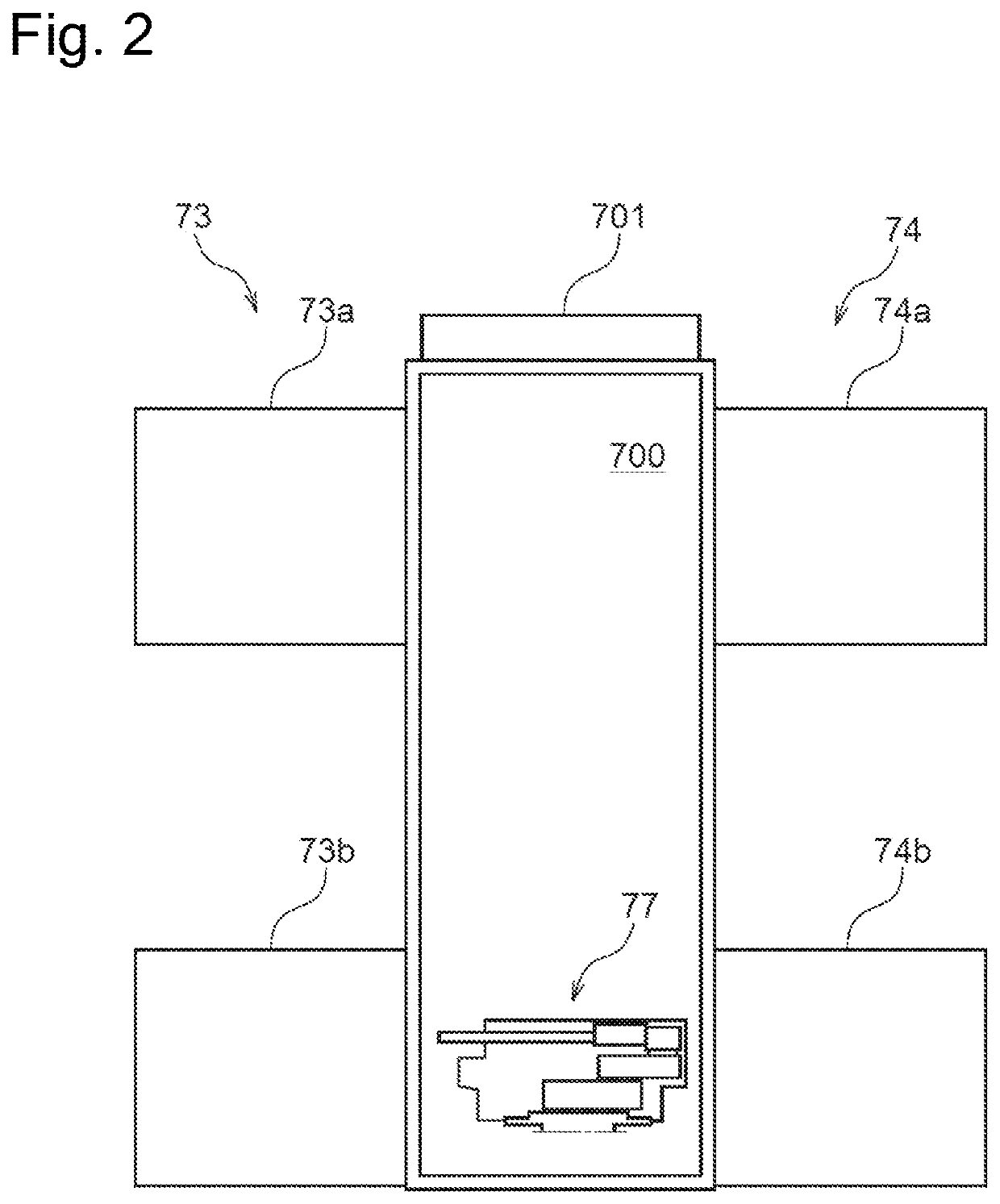

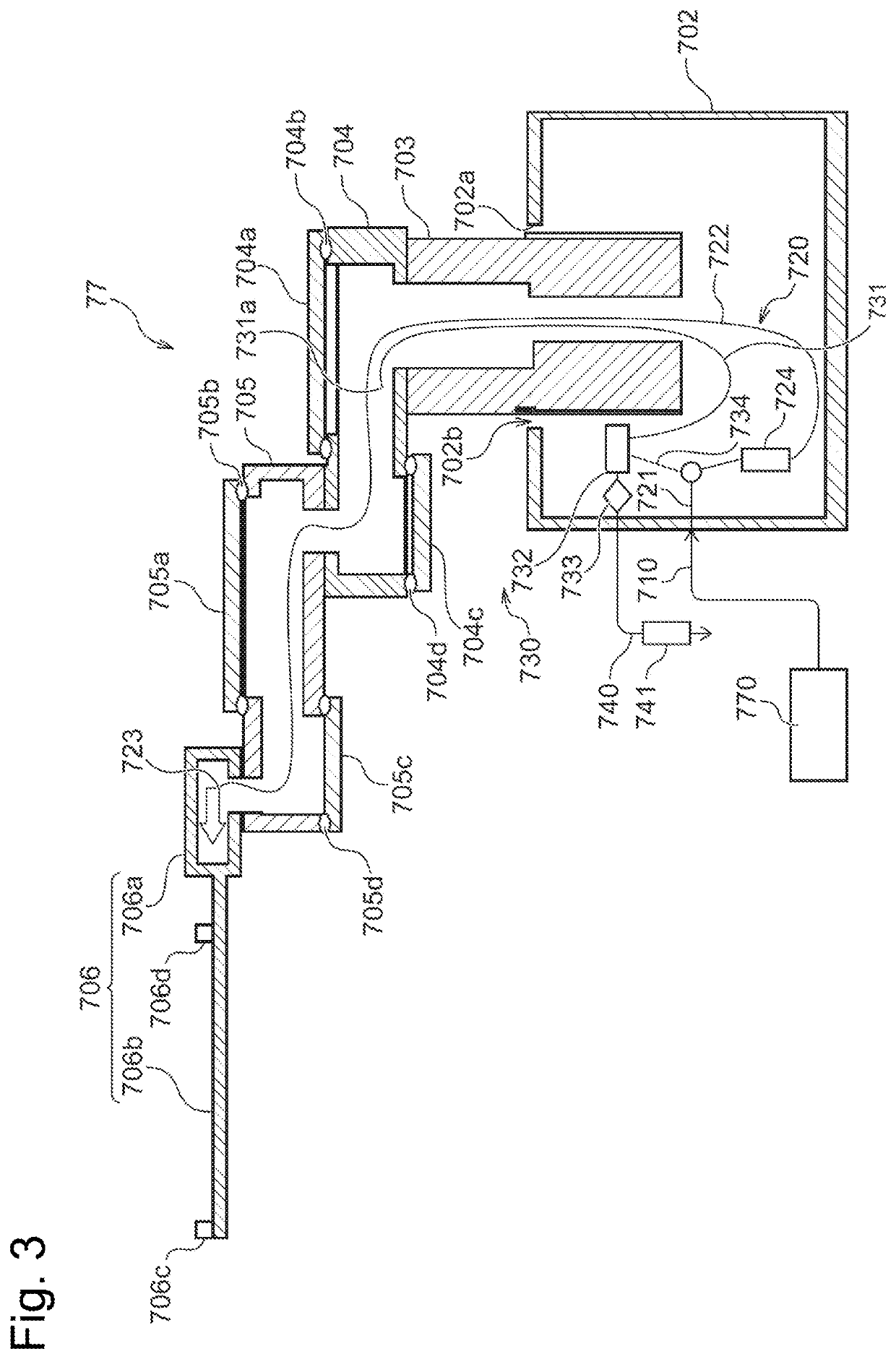

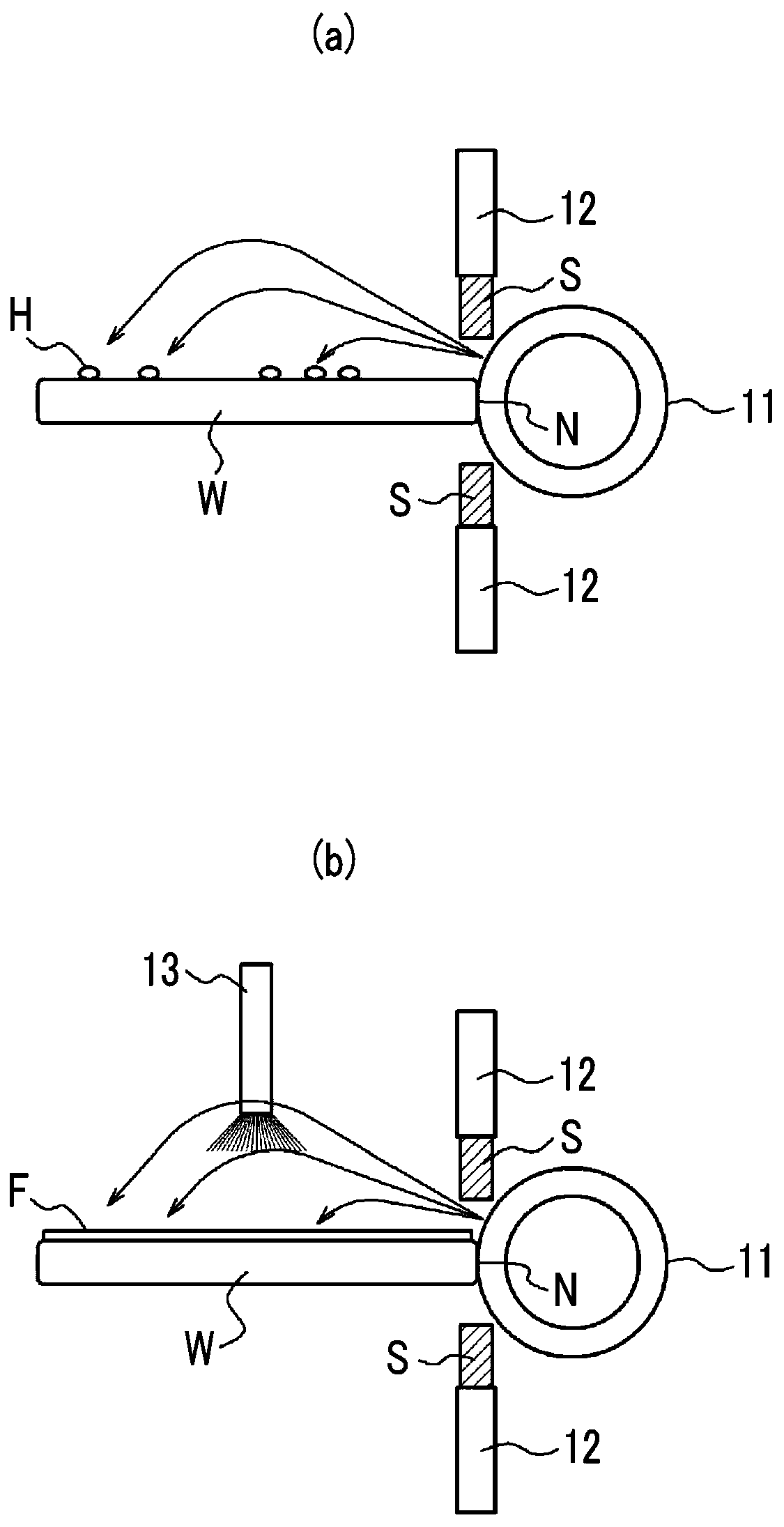

Carrier device, work processing apparatus, control method of carrier device and storage medium storing program

ActiveUS11380559B2Prevent fixationStable deliveryProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingInterior spaceDew

An object is to suppress dew condensation in a carrier device. There is provided a carrier device comprising a body; a rotational part provided to be rotatable relative to the body; an arm supported on the rotational part; an end effector provided in a leading end portion of the arm and configured to hold a work; a gas supply unit configured to supply a gas to an arm-side internal space provided in an arm-side base portion of the end effector and / or in the leading end portion of the arm; and an exhaust unit provided in a body-side internal space that communicates with the arm-side internal space and configured to discharge the gas in the arm-side internal space and / or in the body-side internal space.

Owner:EBARA CORP +1

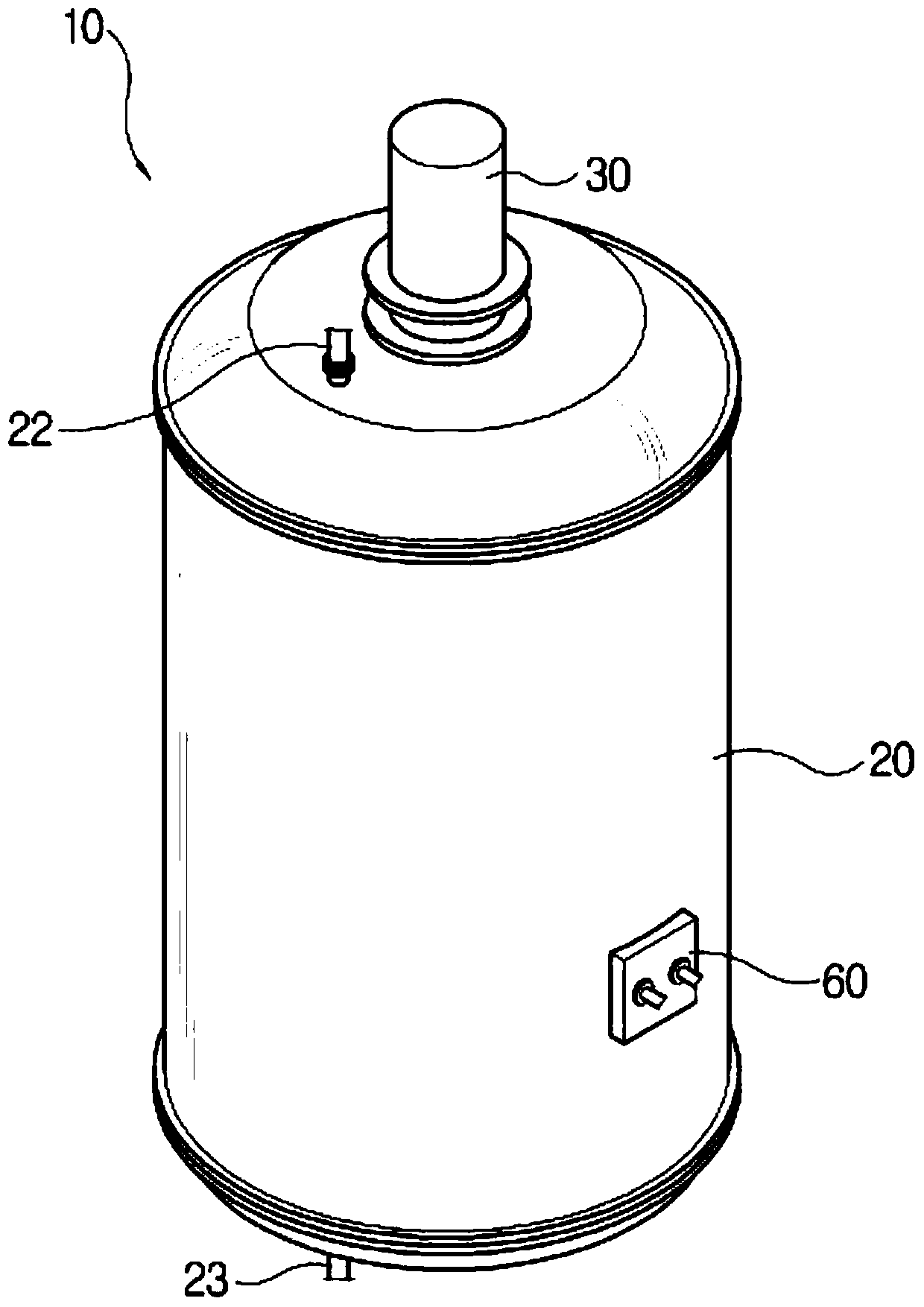

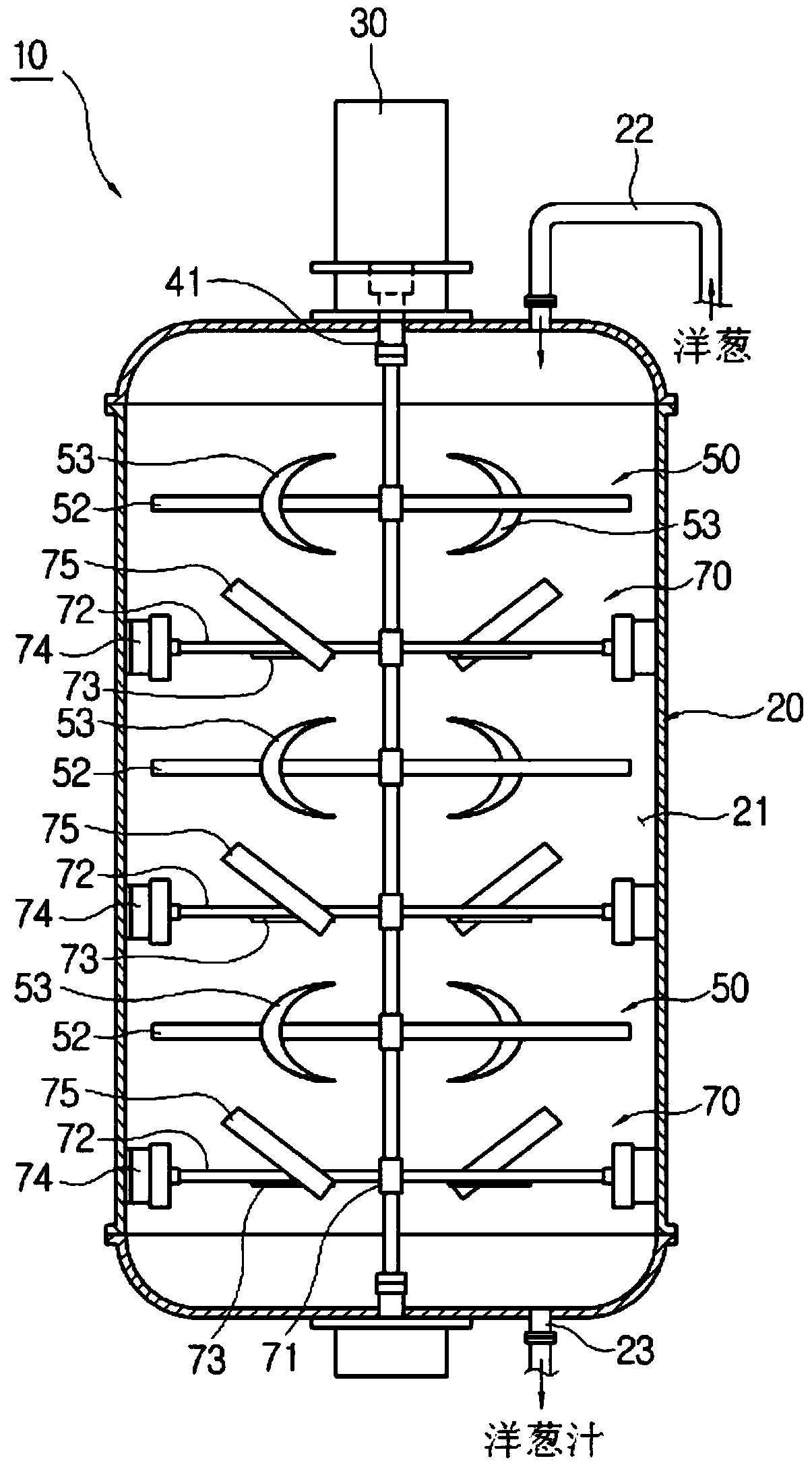

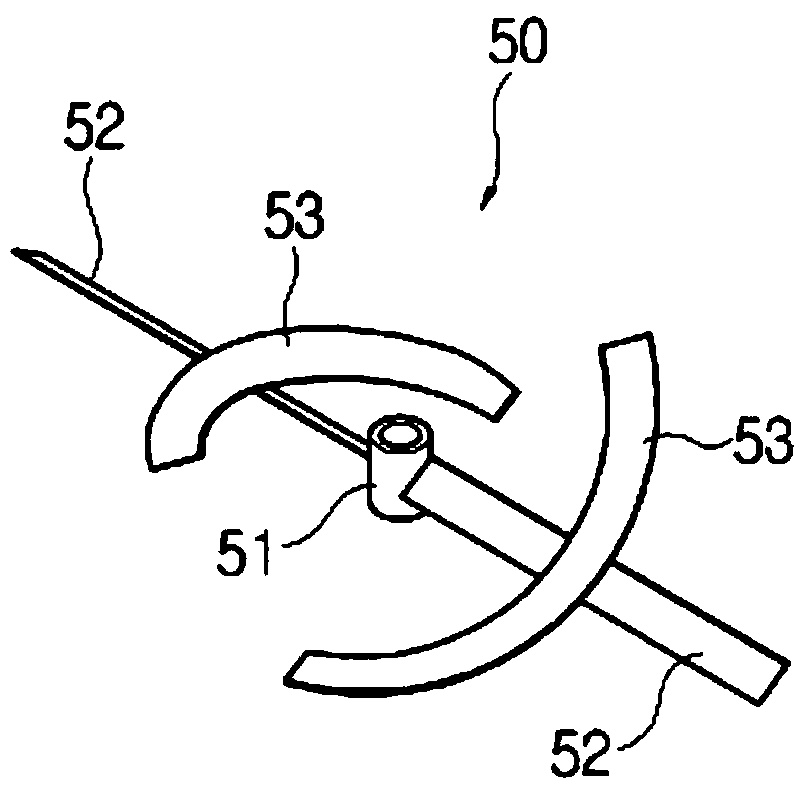

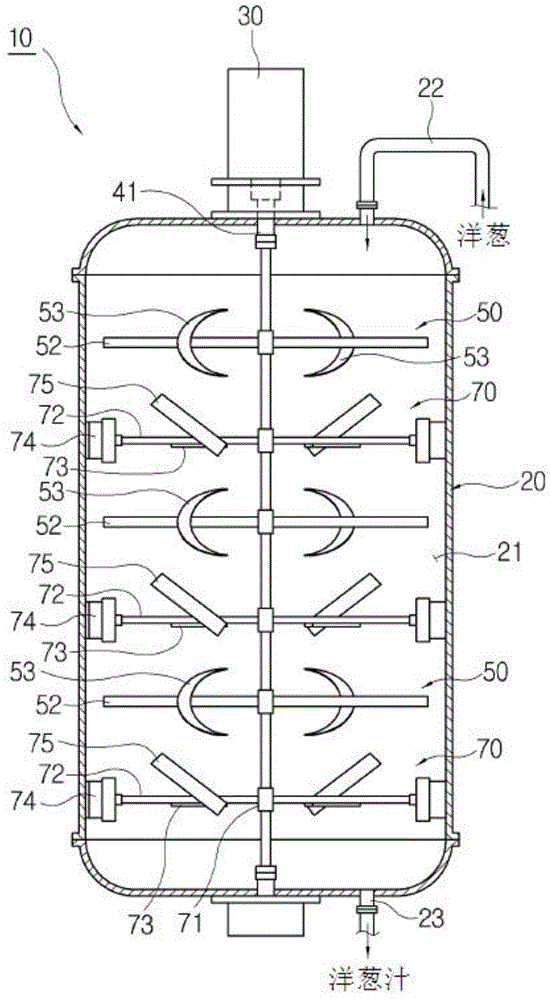

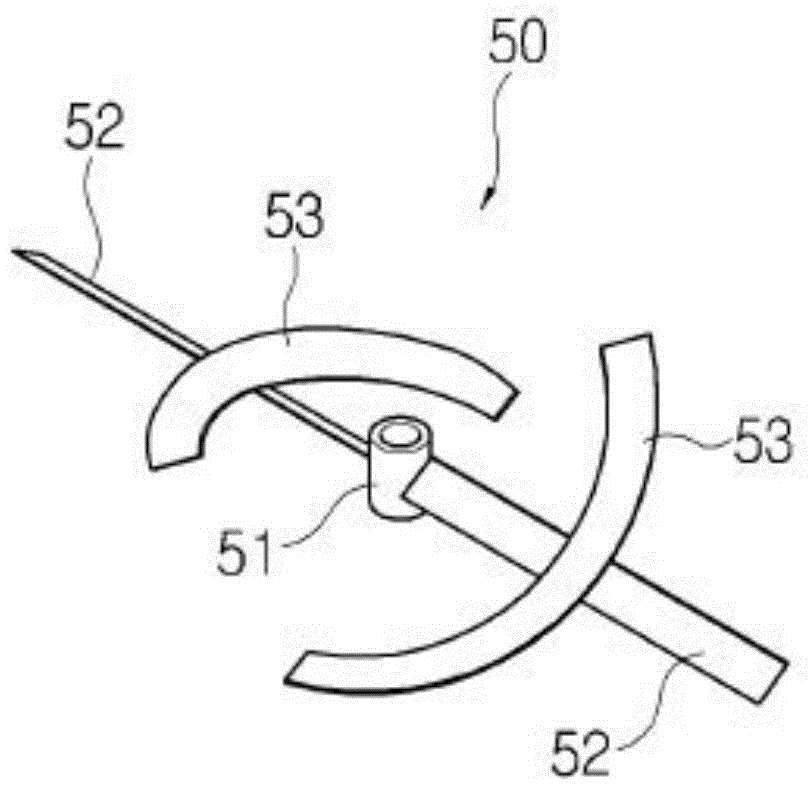

Onion Juice Extraction Device

InactiveCN105310082BHigh purityImprove productivityJuice extractionCooking vesselsDrive motorEngineering

Owner:WHANGTORANGYANGPAGEUB FARMING ASSOC

Carrier device, work processing apparatus, control method of carrier device and storage medium storing program

ActiveUS20200328096A1Prevent fixationStable deliveryProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingDewInterior space

An object is to suppress dew condensation in a carrier device. There is provided a carrier device comprising a body; a rotational part provided to be rotatable relative to the body; an arm supported on the rotational part; an end effector provided in a leading end portion of the arm and configured to hold a work; a gas supply unit configured to supply a gas to an arm-side internal space provided in an arm-side base portion of the end effector and / or in the leading end portion of the arm; and an exhaust unit provided in a body-side internal space that communicates with the arm-side internal space and configured to discharge the gas in the arm-side internal space and / or in the body-side internal space.

Owner:EBARA CORP +1

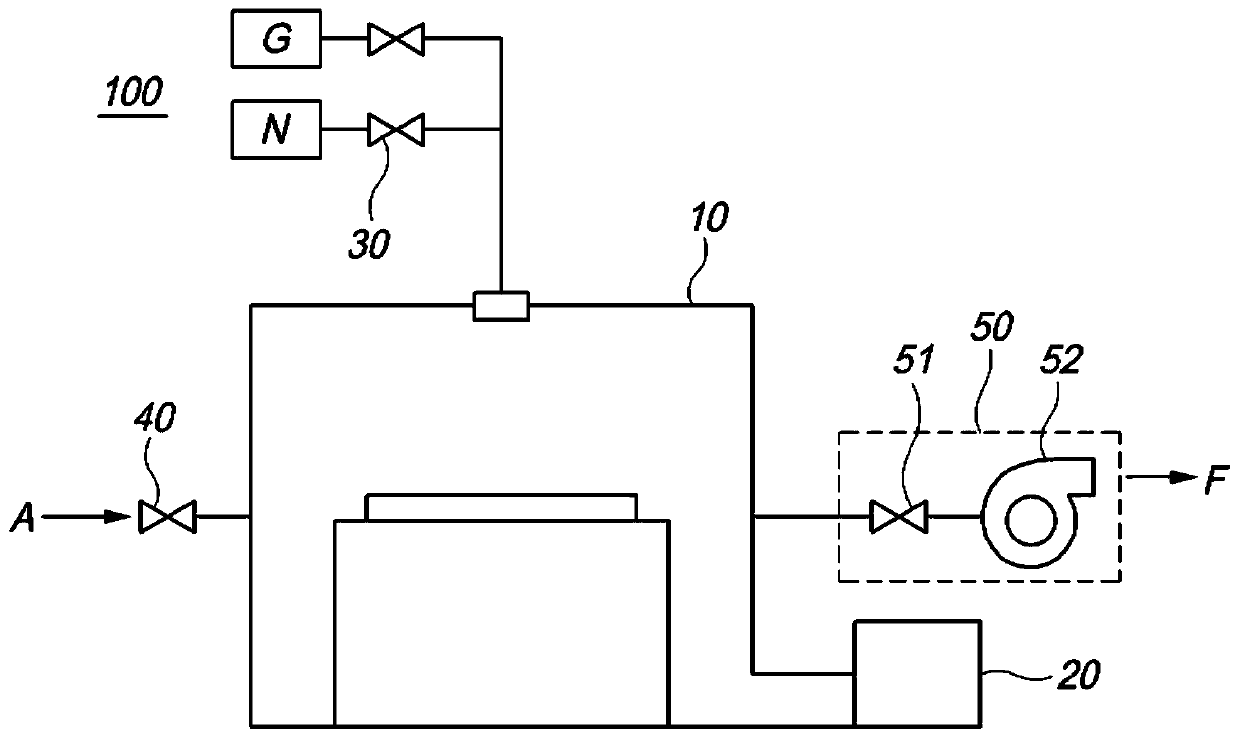

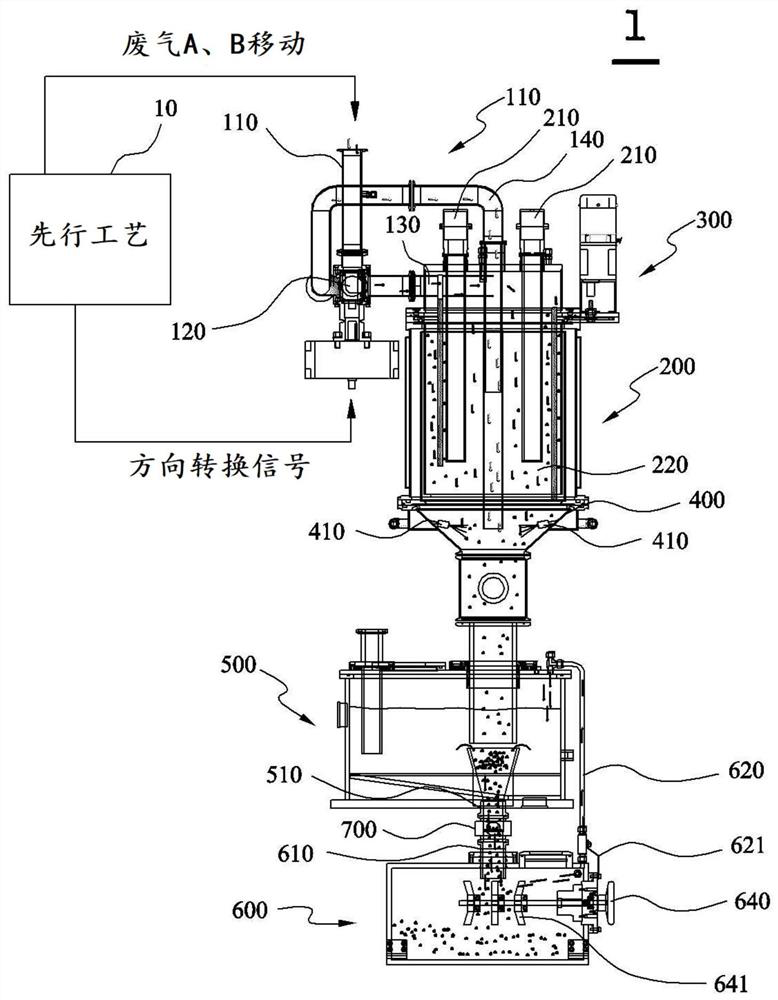

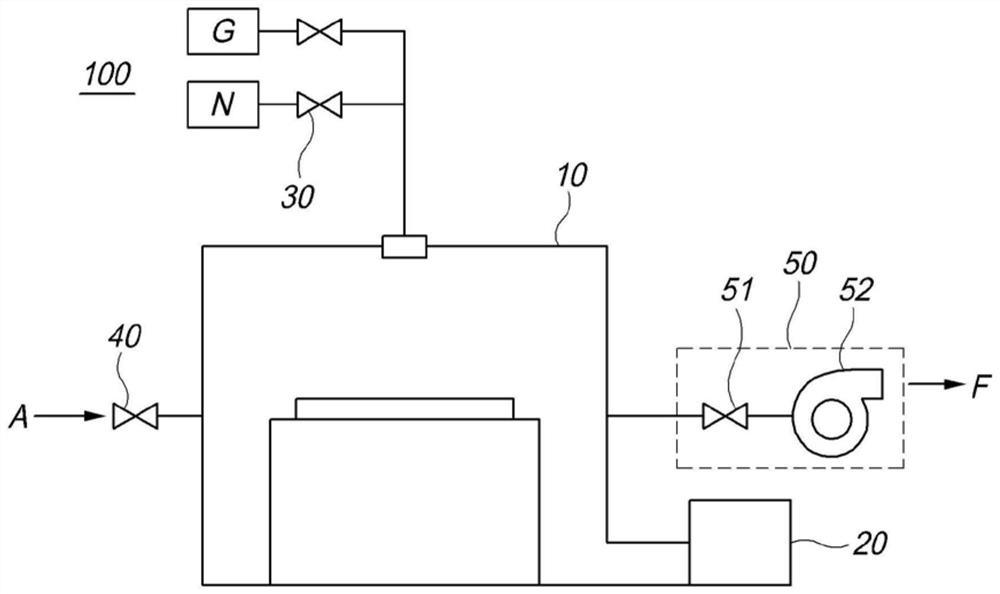

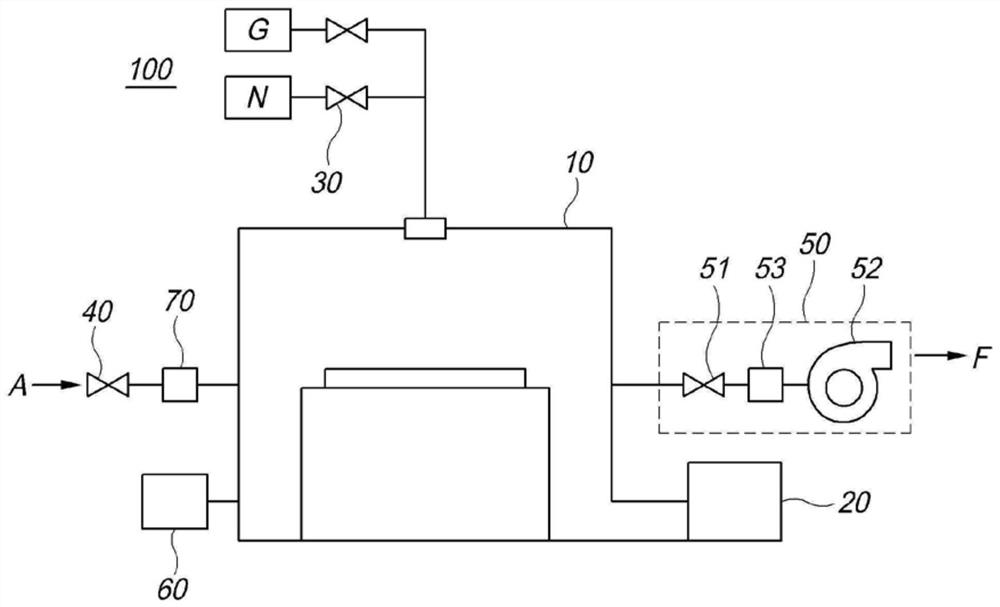

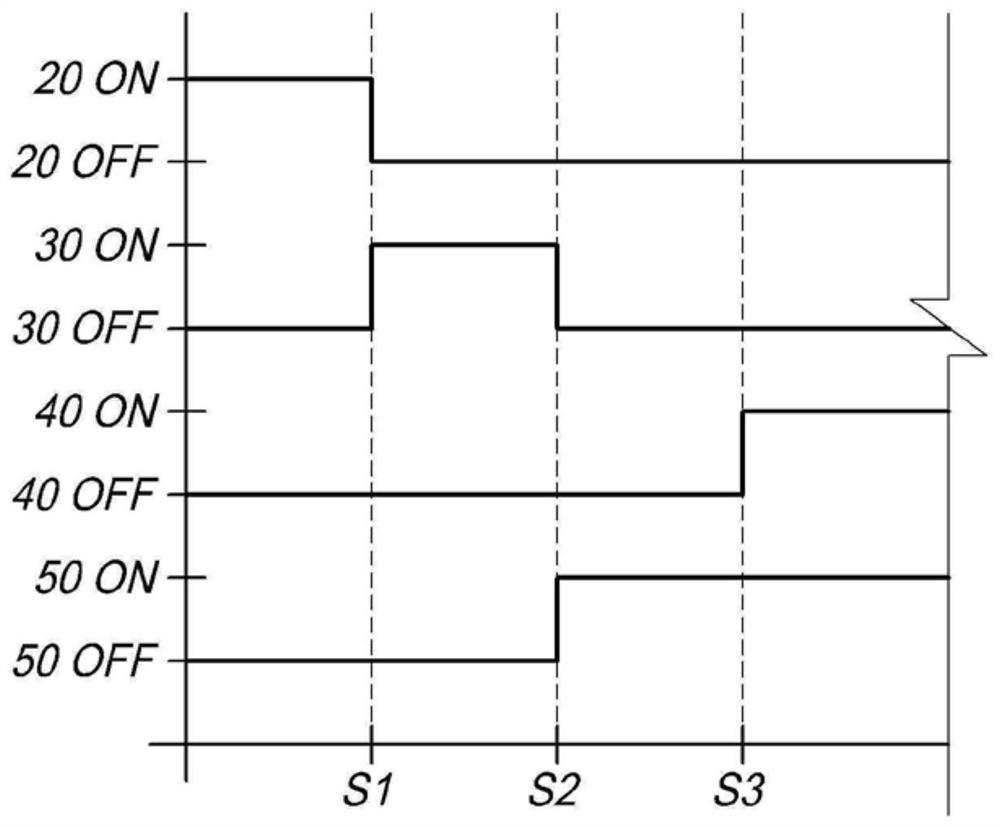

Waste gas separation and treatment apparatus and control method therefor

ActiveCN112739444AImprove operational efficiencyGuaranteed durabilityGas treatmentUsing liquid separation agentExhaust fumesProcess engineering

The present invention can separate waste gases according to whether they are corrosive or non-corrosive to perform pyrolysis treatment thereof individually, wherein powder fixed to a heating module and a chamber is removed to increase operation efficiency and equipment durability, and the collected powder can be externally discharged even during operation.

Owner:茶山有限公司 +1

Method for polishing silicon wafer and method for manufacturing silicon wafer

ActiveCN110291618APrevent fixationSuppression of small step-like defectsEdge grinding machinesPolycrystalline material growthWaferingSilicon

Provided are a method for polishing a silicon wafer and a method for manufacturing a silicon wafer which are capable of suppressing the occurrence of a step-shaped micro defect. This method for polishing a silicon wafer is characterized by being provided with: a double-sided polishing step for performing a polishing process on the front and rear surfaces of a silicon wafer; a notch part polishing step for polishing a chamfered section of a notch part of the silicon wafer after the double-sided polishing step; an outer peripheral chamfered section polishing step for polishing an outer peripheral chamfered section except for the chamfered section of the notch part after the notch polishing process; and a finish polishing step for finish polishing the front surface of the silicon wafer after the outer peripheral chamfered section polishing step, wherein the notch part polishing step is performed in a state in which the front surface is wet with water.

Owner:SUMCO CORP

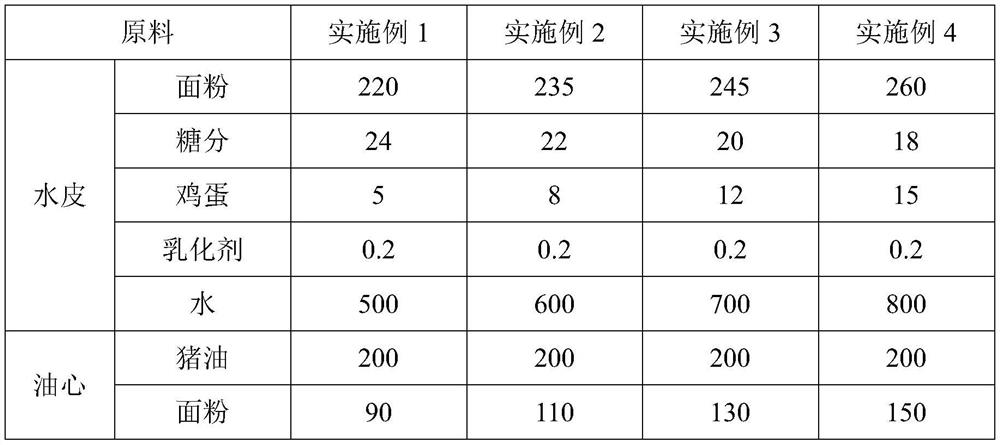

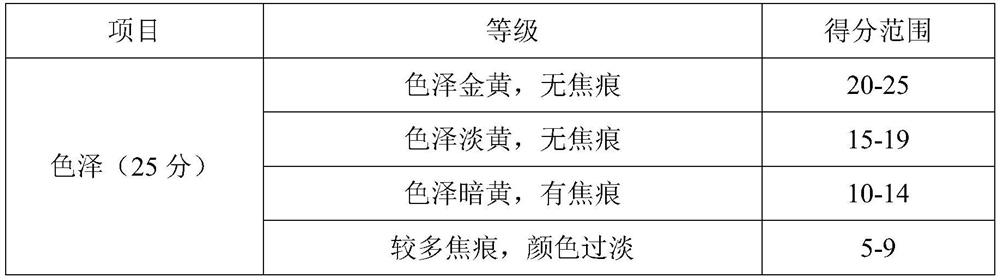

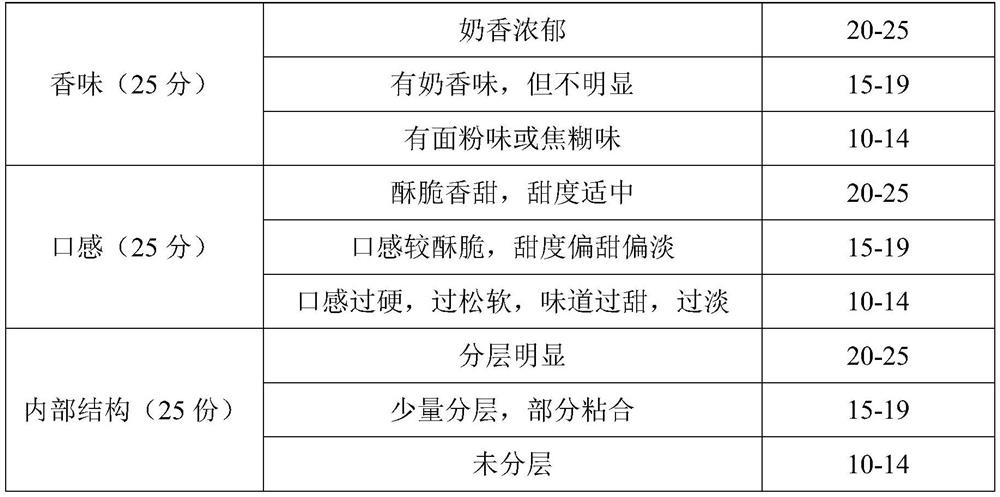

Egg tart skin and manufacturing process thereof

PendingCN114868780AEasy to shrinkGood colorDough treatmentBakery product preservationBiotechnologyMonoglyceride

The invention relates to the technical field of food, and particularly discloses an egg tart skin and a manufacturing process thereof, and the egg tart skin comprises the following raw materials in parts by weight: 50-60 parts of an oil core and 150-180 parts of a water skin; the water skin is prepared from the following raw materials in parts by weight: 220 to 260 parts of flour, 18 to 24 parts of sugar, 5 to 15 parts of eggs, 0.2 to 0.6 part of an emulsifying agent and 500 to 800 parts of water; the oil core comprises the following raw materials in parts by weight: 90-150 parts of flour and 200-260 parts of lard oil; the emulsifier comprises calcium lactate, sucrose fatty acid ester and distilled monoglyceride; the egg tart skin disclosed by the invention has a relatively good crisp mouth feel.

Owner:东莞市广隆食品有限公司

Onion juice extractor

InactiveCN105310082AHigh purityImprove productivityJuice extractionCooking vesselsDrive motorElectrical and Electronics engineering

The invention relates to an onion juice extractor which comprises: a case including an operation space therein; an insertion unit which has a washed onion is put thereto; a discharge port formed at a lower part and discharging onion juice extracted from an onion to the outside; a driving motor installed in an upper center of the case; a rotation shaft which is positioned in an inner center of the case and includes an upper connection unit connected to the driving motor wherein the upper connection unit protrudes outside; a first pulverizing unit which is installed in the rotation shaft at specific intervals in a vertical direction and pulverizes an onion while interlocked when the rotation shaft is operated; and a steam supply unit which is installed in one side of the case and supplies steam inside the case.

Owner:WHANGTORANGYANGPAGEUB FARMING ASSOC

Acidity soil conditioner containing fire coal flue gas desulfurization solid waste material

InactiveCN100556987CImprove effectivenessImprove nutritional functionOrganic fertilisersSoil conditioning compositionsNitrateManganese

The present invention is one kind of acid soil amendment, which consists of coal burning fume desulfurizing solid waste in 83-97 wt% and humic acid in 3-17 wt%. The coal burning fume desulfurizing solid waste is formed through desulfurizing coal burning fume with lime suspension absorbing SO2. The acid soil amendment can complex or chelate Fe, Al and Mn elements of acid soil to regulate local concentration of active Fe, Al and Mn, raise the effectiveness and nourishing function of Ca, Mg, S, Si and B and raise activity of P, so as to raise the biomass and yield of crop and other plant and lower the content of nitrate in vegetable. The present invention utilizes coal burning fume desulfurizing solid waste effectively in agriculture.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

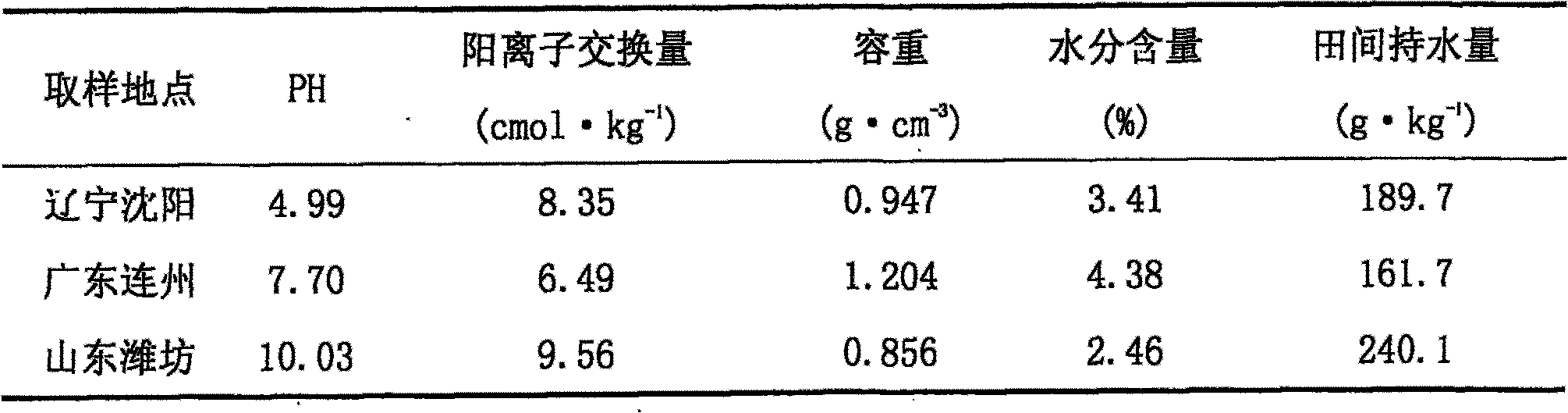

Environment-friendly tire molding device

InactiveCN108202488APrevent fixationReduce operating proceduresTyresDirt cleaningEngineeringGrinding wheel

The invention provides an environment-friendly tire molding device. According to the technical scheme, a conventional mode of a tire molding device is changed, and an enclosed cabin is used as a machining environment; and a heater and a mold are arranged in the cabin, and the molding of a tire is realized by hot pressing under the action of the high temperature mold. At the same time, a rotating grinding wheel is arranged beside the mold, and the grinding wheel is used for grinding the tire immediately after the molding of the tire, thereby shortening the operating process. In addition, an airsuction pipe for exhausting is disposed in the enclosed cabin to form a negative pressure environment in the cabin, and harmful gas generated by the hot pressing of rubber and dust particles generated by grinding are discharged through the air suction pipe; and since the outer end of the air suction pipe is provided with a gas filter, the environmental protection property of the tire molding process is greatly improved. In addition, in order to avoid dust adhering to the inner wall of the cabin during long-term operation, a cabin wall vibrator is arranged on the supporting columns to preventthe dust from sticking by vibration.

Owner:天津乐驰百盈科技发展有限公司

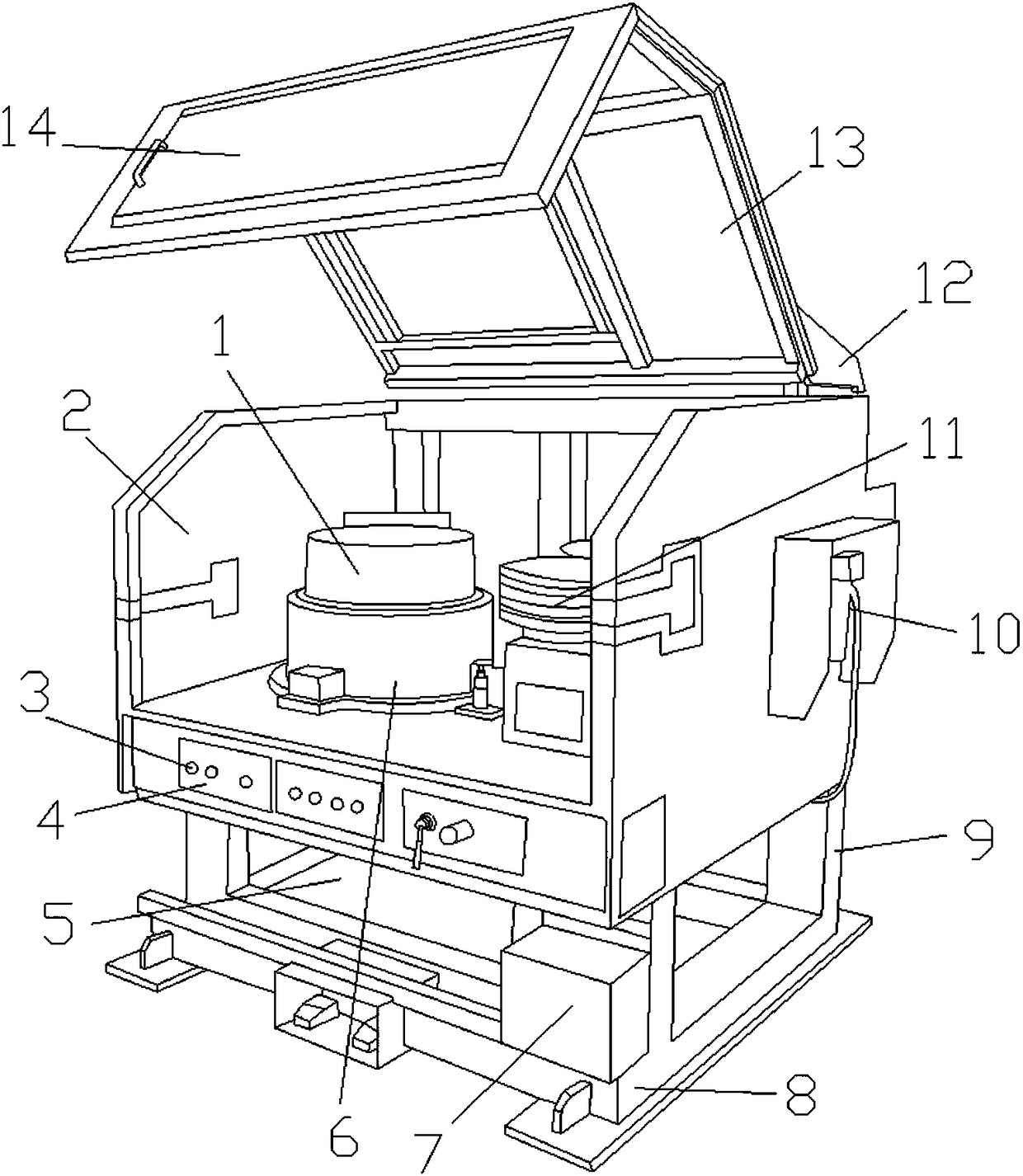

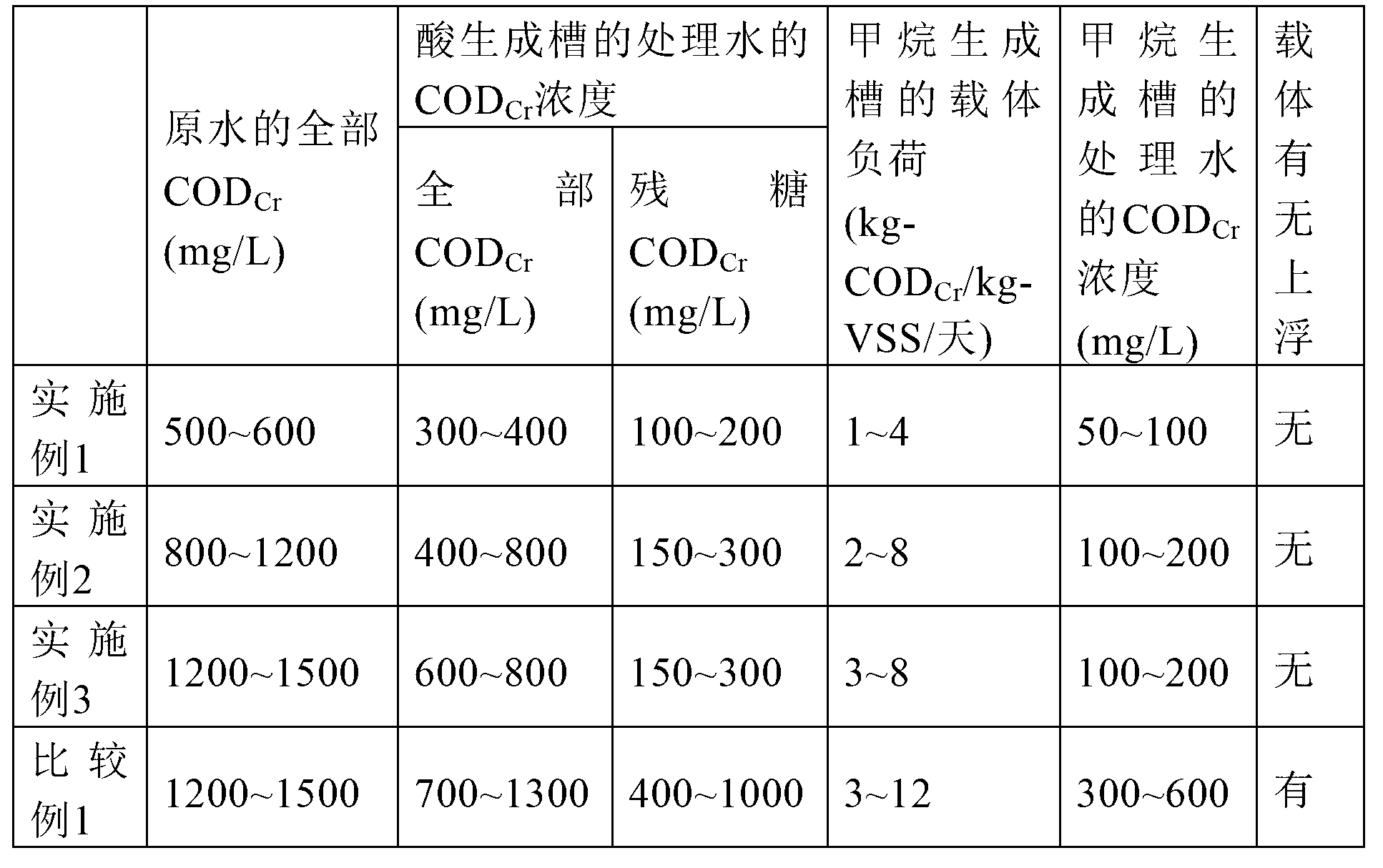

Anaerobic treatment method

ActiveCN103228581APrevent dysfunctionEfficient anaerobic treatmentWater treatment parameter controlBiological treatment regulationMicroorganismOrganic acid

Owner:KURITA WATER INDUSTRIES LTD

Tamp pad

InactiveCN1227959CAvoid accumulationSolve the accumulationRotary pressesOther printing apparatusEngineering

Owner:TELEFON AB LM ERICSSON (PUBL)

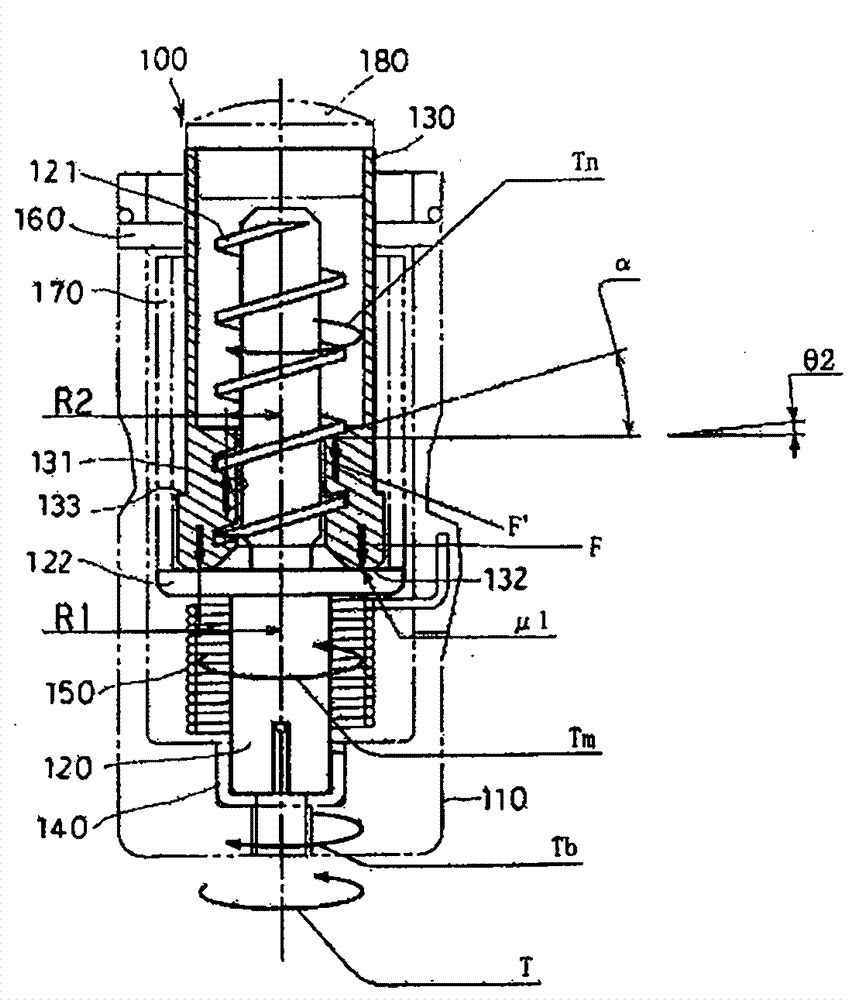

Tensioner

A tensioner in which sticking between a rotation member and a drive member when the tensioner is in a fully retracted state is prevented by using a simple mechanism, thereby ensuring reduced man-hour for control in assembling the tensioner and enabling the tensioner to function when it is abnormally operated. A pair of shaft members (3, 4) is threaded to each other by thread sections (8, 9), and one (3) of the shaft members (3, 4) is rotatingly urged by a spring (5) and driven by rotational force transmitted from the one shaft member (3) with the other shaft member (4) restrained from rotating. A contact section (20) is formed at that portion of the shaft members (3,4) which is other than that of the thread sections (8, 9), and the contact section (20) come into contact with the other shaft member (4) when it is moved in the direction opposite the drive direction. The contact section (20) is set to satisfy the expression of R1 / R2 < -tan(µ2 - a) / µ1, where R1 is a contact radius caused by contact, R2 the effective diameter of the thread sections (8, 9), µ1 the coefficient of friction of the contact section (20), µ2 the coefficient of friction of the thread sections (8, 9), and a the lead angle of the thread faces of the thread sections (8,9).

Owner:NHK SPRING CO LTD

Semiconductor process equipment with cleaning function and cleaning method thereof

ActiveCN110400736BFully removedIncrease temperatureElectric discharge tubesHollow article cleaningThermodynamicsProcess equipment

Owner:GIGALANE CO LTD

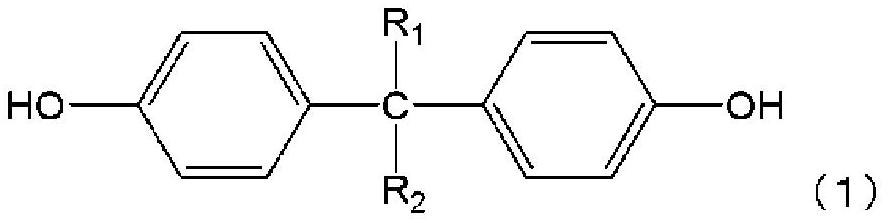

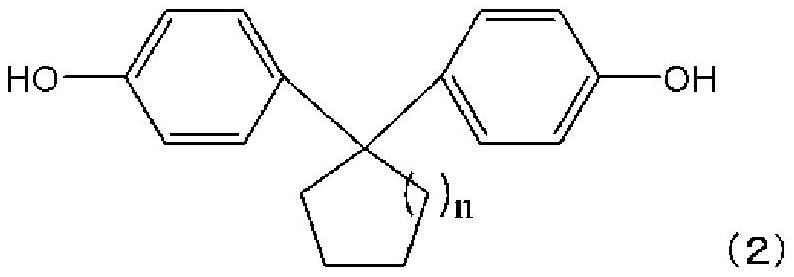

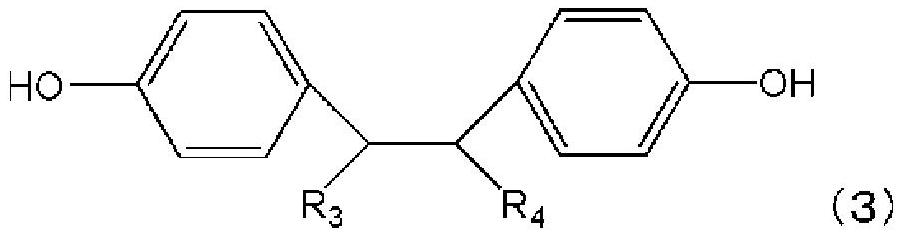

Rubber composition containing butyl rubber, resol type phenol-formaldehyde co-condensed resin, and phenol

Provided are: a rubber composition containing a butyl rubber, a resol type phenol-formaldehyde co-condensed resin, and a phenol, wherein the rubber composition contains, as the phenol, at least one phenol chosen from the group consisting of phenols represented by general formulas (1), (2), (3) and (4); a production method therefor; and a resin mixture containing a resol type phenol-formaldehyde co-condensed resin, and at least one phenol chosen from the group consisting of phenols represented by general formulas (1), (2), (3) and (4).

Owner:TAOKA CHEM COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com