Waste gas separation and treatment apparatus and control method therefor

A technology for separation treatment and exhaust gas, which is applied in separation methods, gas treatment, and separation of dispersed particles. It can solve problems such as difficult waste management, reduced durability, and reduced operating efficiency, and achieve improved treatment efficiency, improved operation rate, and Effect of preventing powder from solidifying or forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the exhaust gas sorting and separation treatment device 1 according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings. First of all, it should be noted that the same components or components in the drawings are denoted by the same reference numerals as far as possible. In order not to obscure the gist of the present invention, detailed descriptions related to related known functions or components are omitted when describing the present invention.

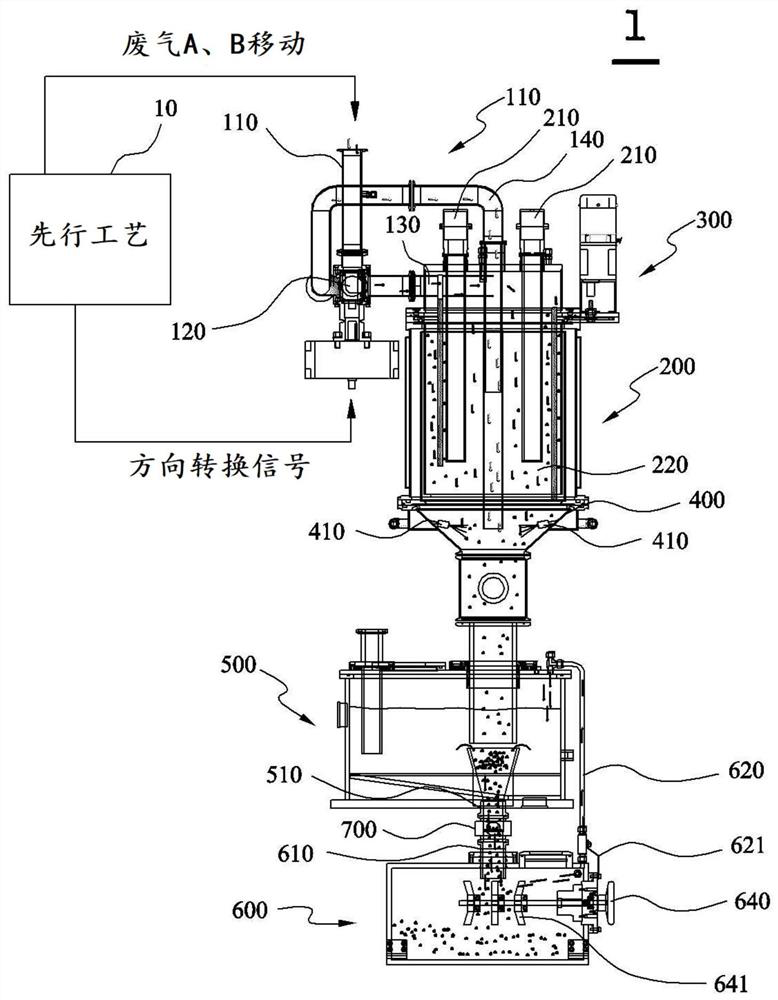

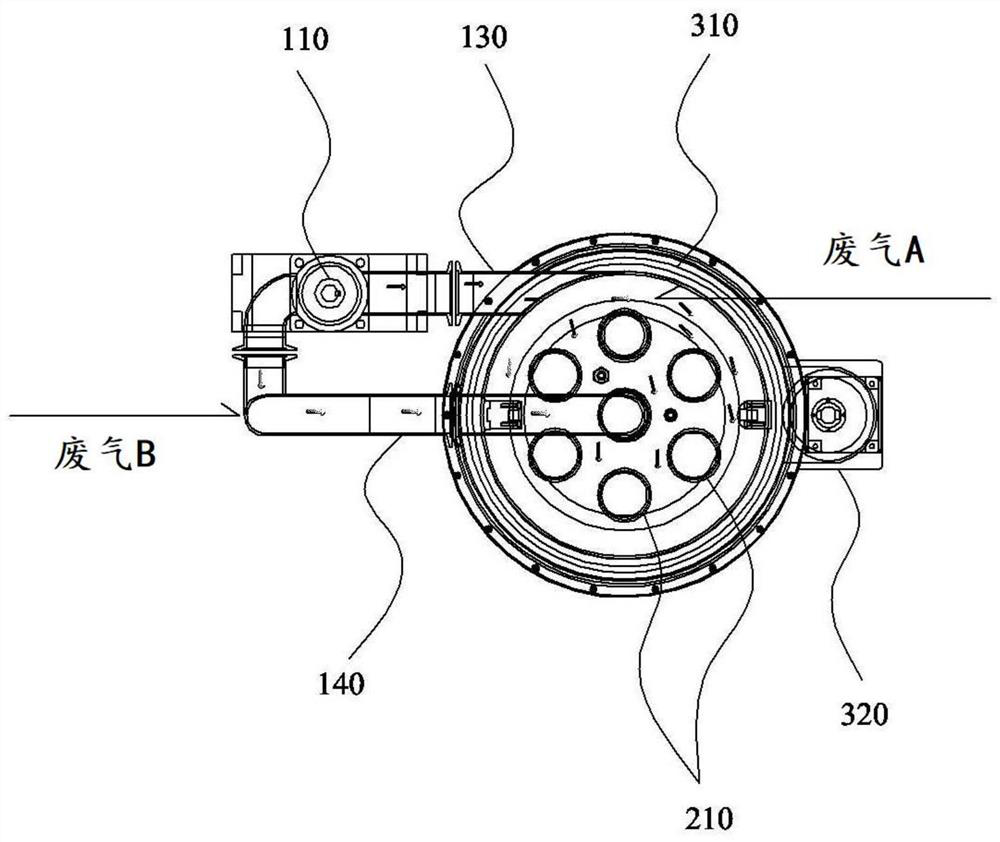

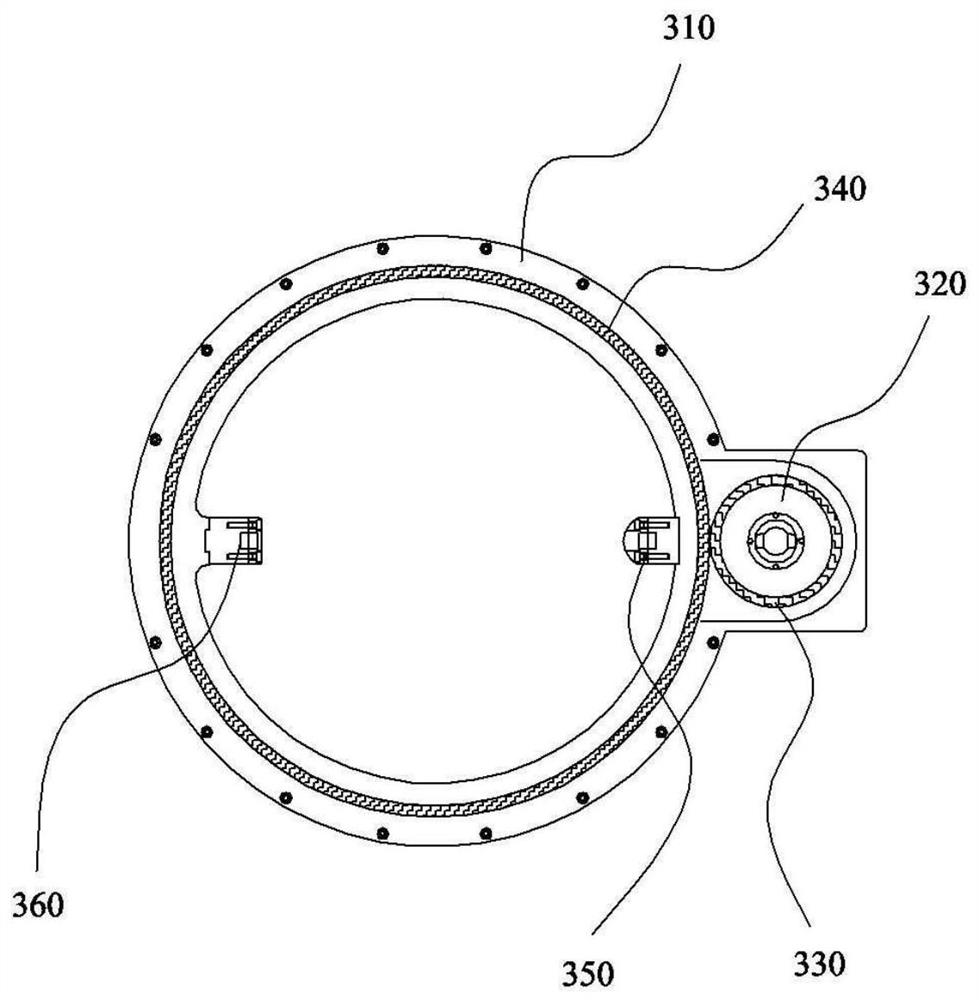

[0032] refer to figure 1 According to an embodiment of the present invention, the exhaust gas sorting and separation treatment device 1 is generally composed of an exhaust gas separation unit 100, a heating box unit 200, a scraper unit unit 300, a wet cleaning treatment unit 400, a first waste storage box 500 and a second waste disposal unit. Object storage box 600 forms.

[0033] First, the exhaust gas separation unit 100 will be described. Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com