Exhaust-gas treatment apparatus

A waste gas treatment device and a gas treatment technology, which are applied in gas treatment, exhaust devices, noise reduction devices, etc., can solve the problems of low decomposition performance of refractory gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

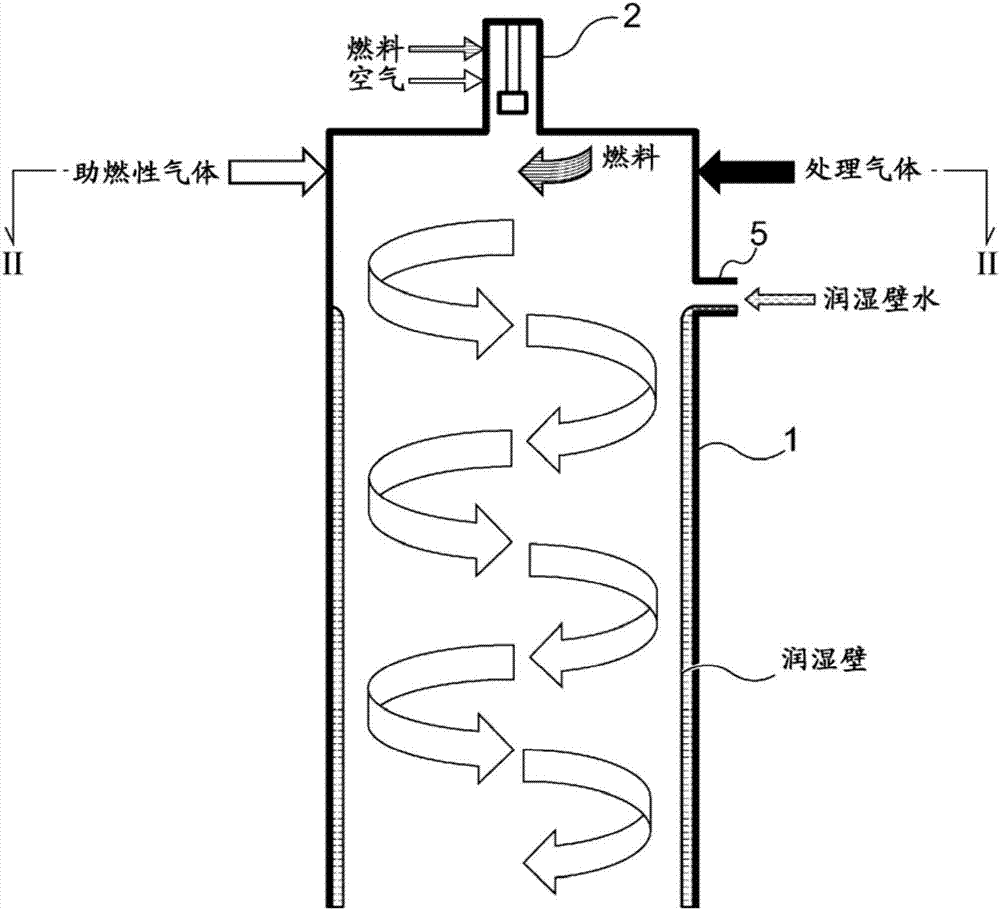

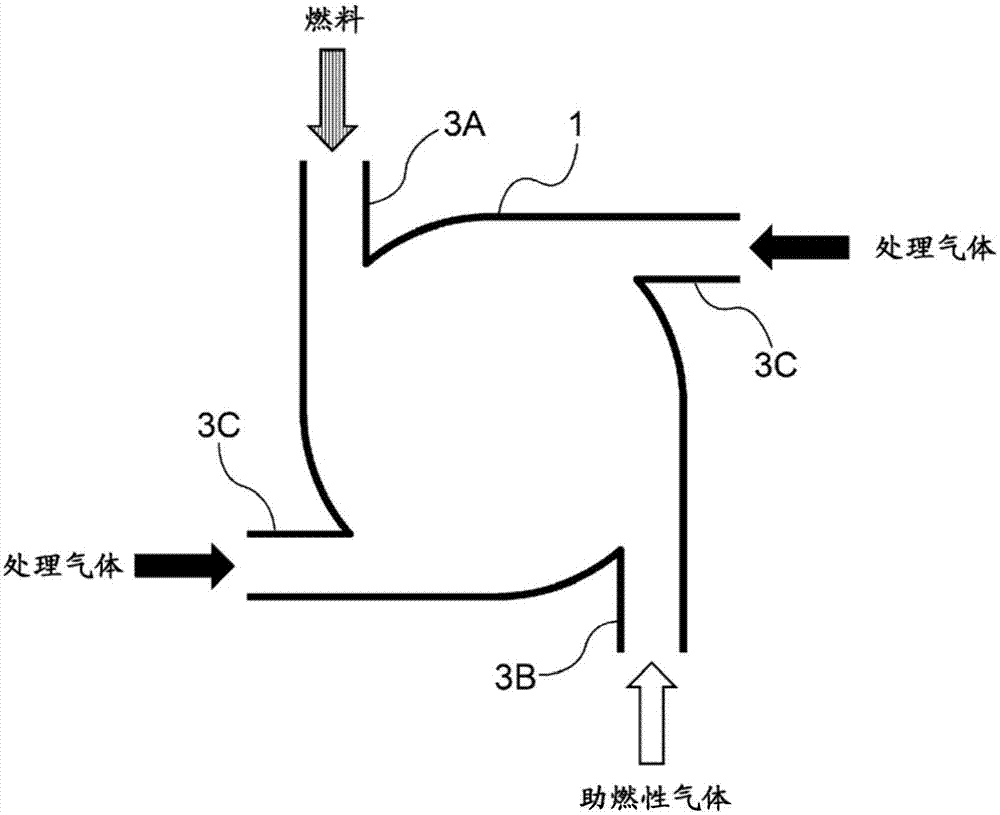

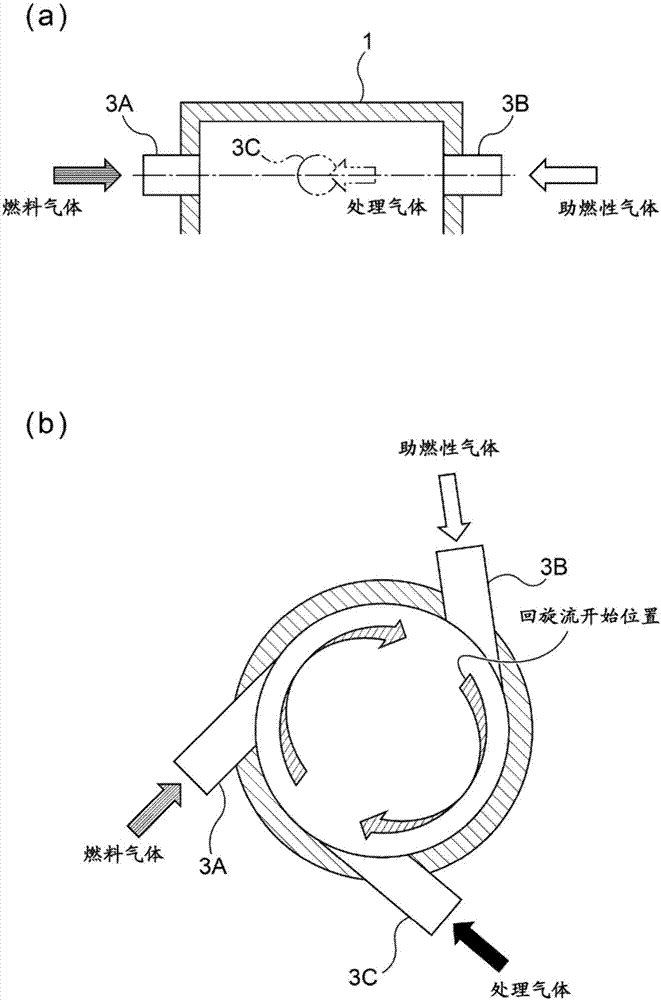

[0052] Below, refer to Figure 1 to Figure 6 Embodiments of the exhaust gas treatment device according to the present invention will be described. exist Figure 1 to Figure 6 In , the same reference numerals are attached to the same or corresponding constituent elements, and overlapping descriptions are omitted.

[0053] figure 1 It is a schematic sectional view which shows the structural example of the combustion chamber of the exhaust gas processing apparatus of this invention. The combustion chamber 1 is configured as a cylindrical container-shaped combustion chamber with one end (the upper end in the illustrated example) closed and the other end (the lower end in the illustrated example) opened. In the cylindrical container-shaped combustion chamber 1, fuel (fuel gas), combustion-supporting gas (oxygen-containing gas), and process gas (exhaust gas) are injected near the closed end. A pilot burner 2 for ignition is provided at the closed end of the combustion chamber 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com