Environment-friendly tire molding device

An environmentally friendly technology for tire building, applied in the field of tire manufacturing, can solve the problems of tire building equipment pollution and seriousness, and achieve the effects of avoiding dust fixation, low cost, and improving environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

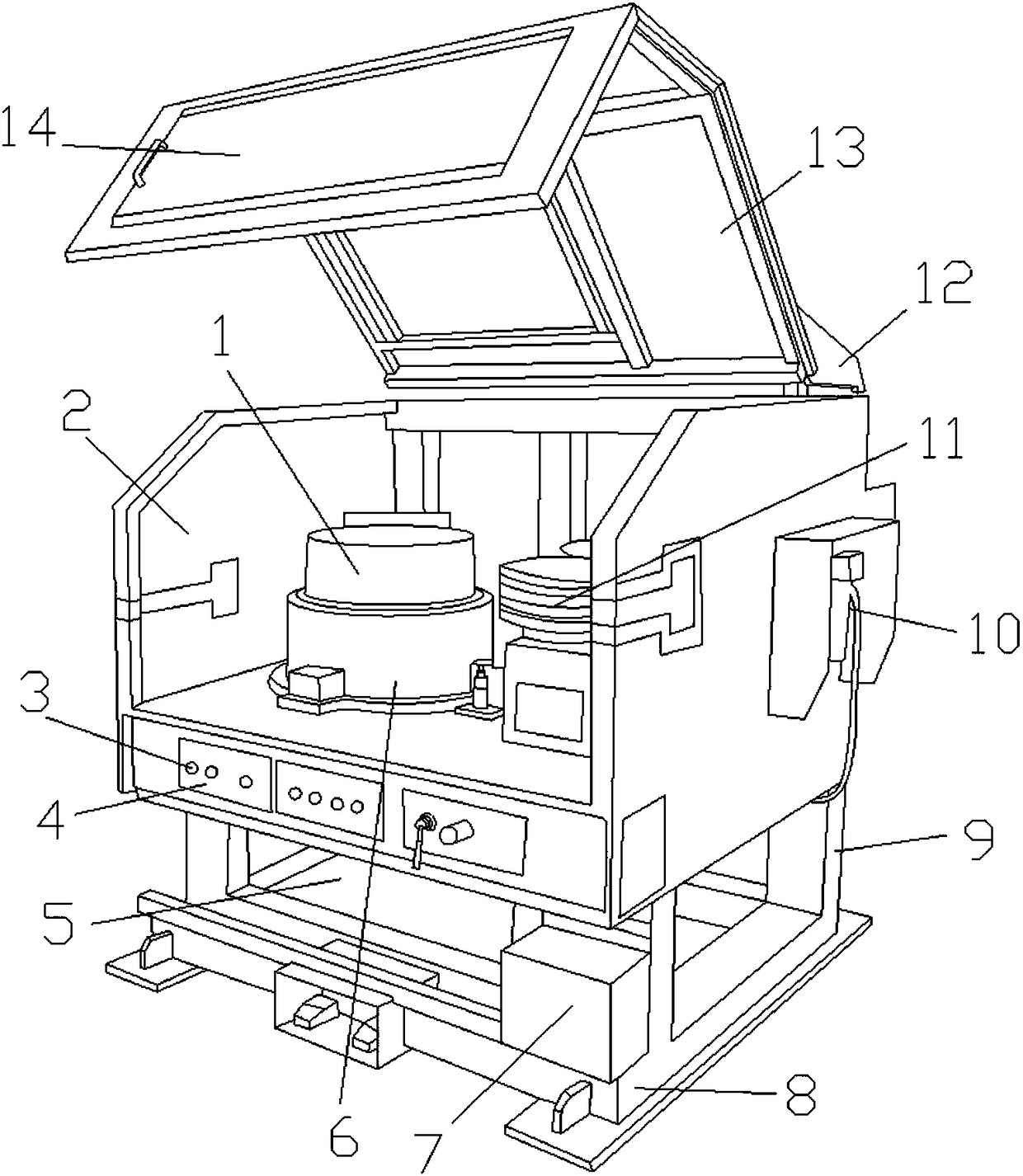

[0019] An environment-friendly tire building device, including a mold 1, a cabin body 2, a control button 3, a control panel 4, a collection tray 5, an electric heater 6, a bin wall vibrator 7, a base 8, a pillar 9, an air suction pipe 10, Grinding wheel 11, protruding strip 12, upper cover 13, window 14, wherein the base 8 is fixed on the ground, the pillar 9 is fixedly connected to the base 8, the cabin body 2 is fixedly connected to the top of the pillar 9, and the collecting tray 5 is fixedly connected to the base 8 On the upper surface of the cabin body 2, the collection tray 5 is located below the cabin body 2, the bin wall vibrator 7 is fixedly connected to the pillar 9, a control panel 4 is arranged on the outer wall of the cabin body 2, and a control panel 4 is provided on the control panel 4. The button 3 and the electric heater 6 are fixedly connected to the inside of the cabin body 2, the mold 1 is fixedly connected to the electric heater 6, and the inside of the ca...

Embodiment 2

[0026] An environment-friendly tire building device, including a mold 1, a cabin body 2, a control button 3, a control panel 4, a collection tray 5, an electric heater 6, a bin wall vibrator 7, a base 8, a pillar 9, an air suction pipe 10, Grinding wheel 11, protruding strip 12, upper cover 13, window 14, wherein the base 8 is fixed on the ground, the pillar 9 is fixedly connected to the base 8, the cabin body 2 is fixedly connected to the top of the pillar 9, and the collecting tray 5 is fixedly connected to the base 8 On the upper surface of the cabin body 2, the collection tray 5 is located below the cabin body 2, the bin wall vibrator 7 is fixedly connected to the pillar 9, a control panel 4 is arranged on the outer wall of the cabin body 2, and a control panel 4 is provided on the control panel 4. The button 3 and the electric heater 6 are fixedly connected to the inside of the cabin body 2, the mold 1 is fixedly connected to the electric heater 6, and the inside of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com