Semiconductor processing device with cleaning function and cleaning method of semiconductor processing device using the same

A process equipment and semiconductor technology, applied in cleaning methods and appliances, semiconductor/solid-state device manufacturing, cleaning hollow objects, etc., can solve problems such as inhalation of harmful substances by workers, corrosion of pump parts, failure of semiconductor process equipment, etc., to achieve a solution Reduced performance or frequent malfunctions, effects of preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

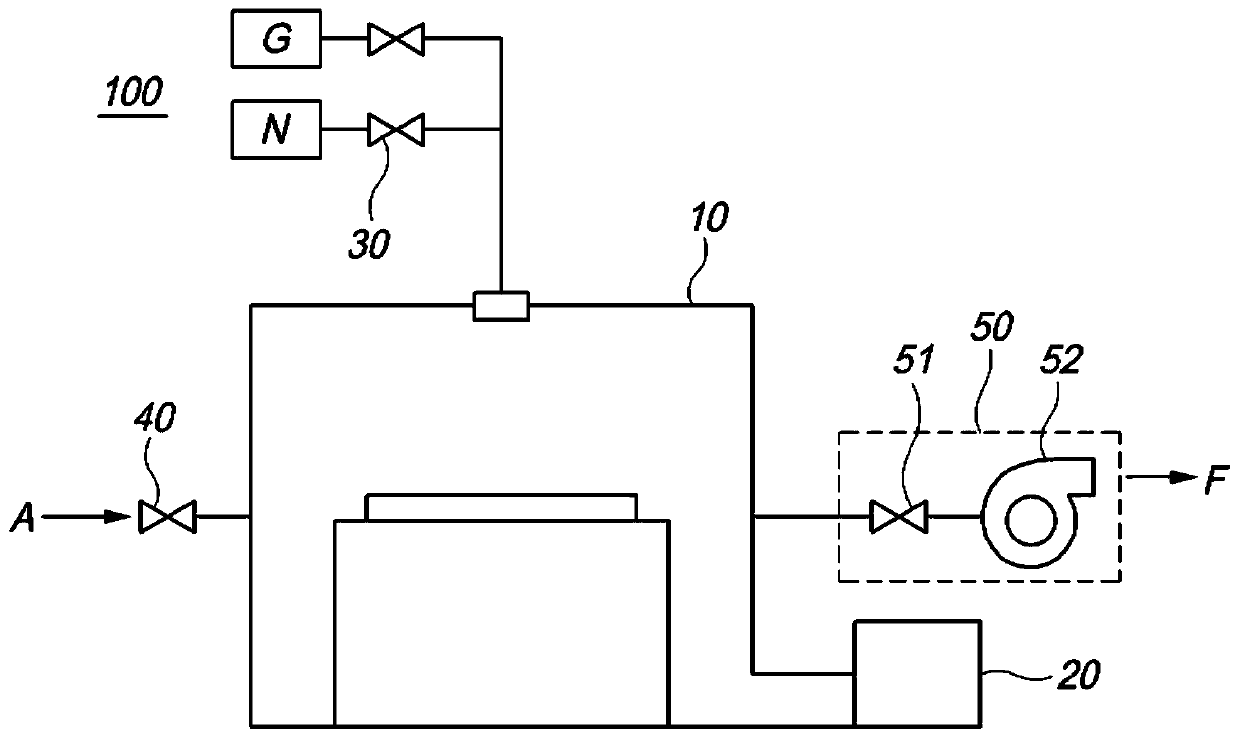

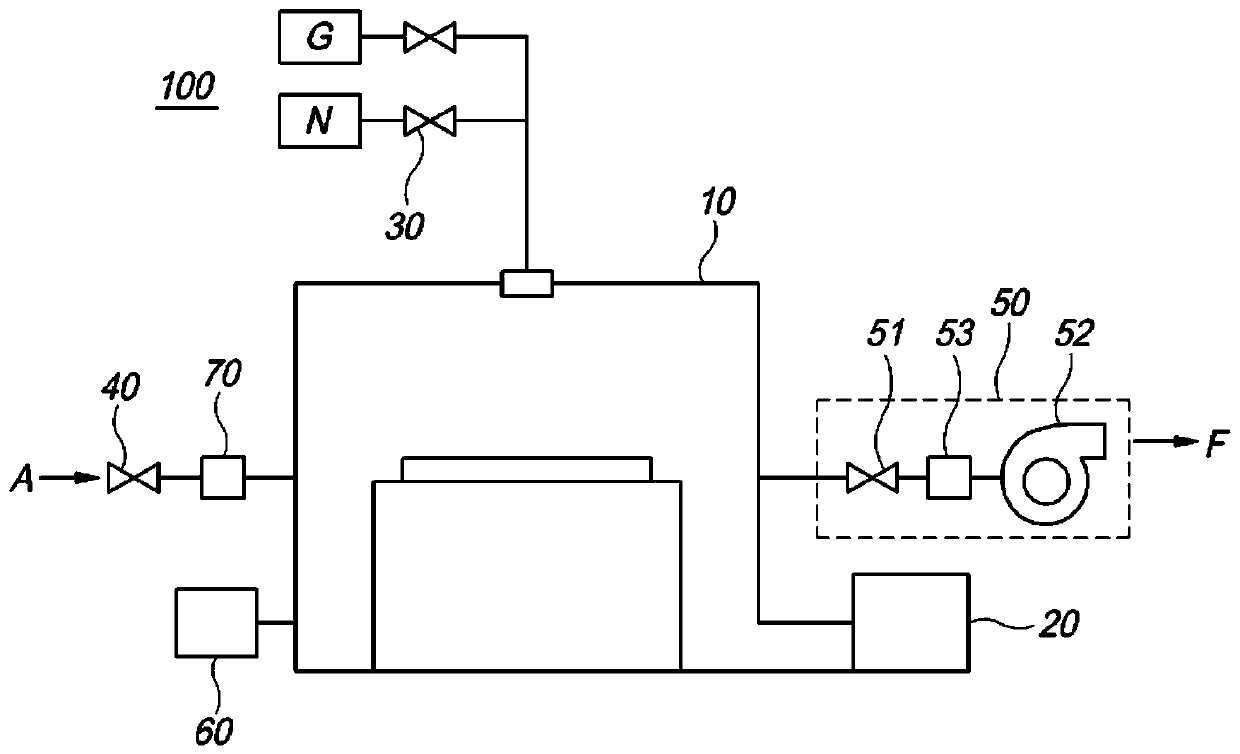

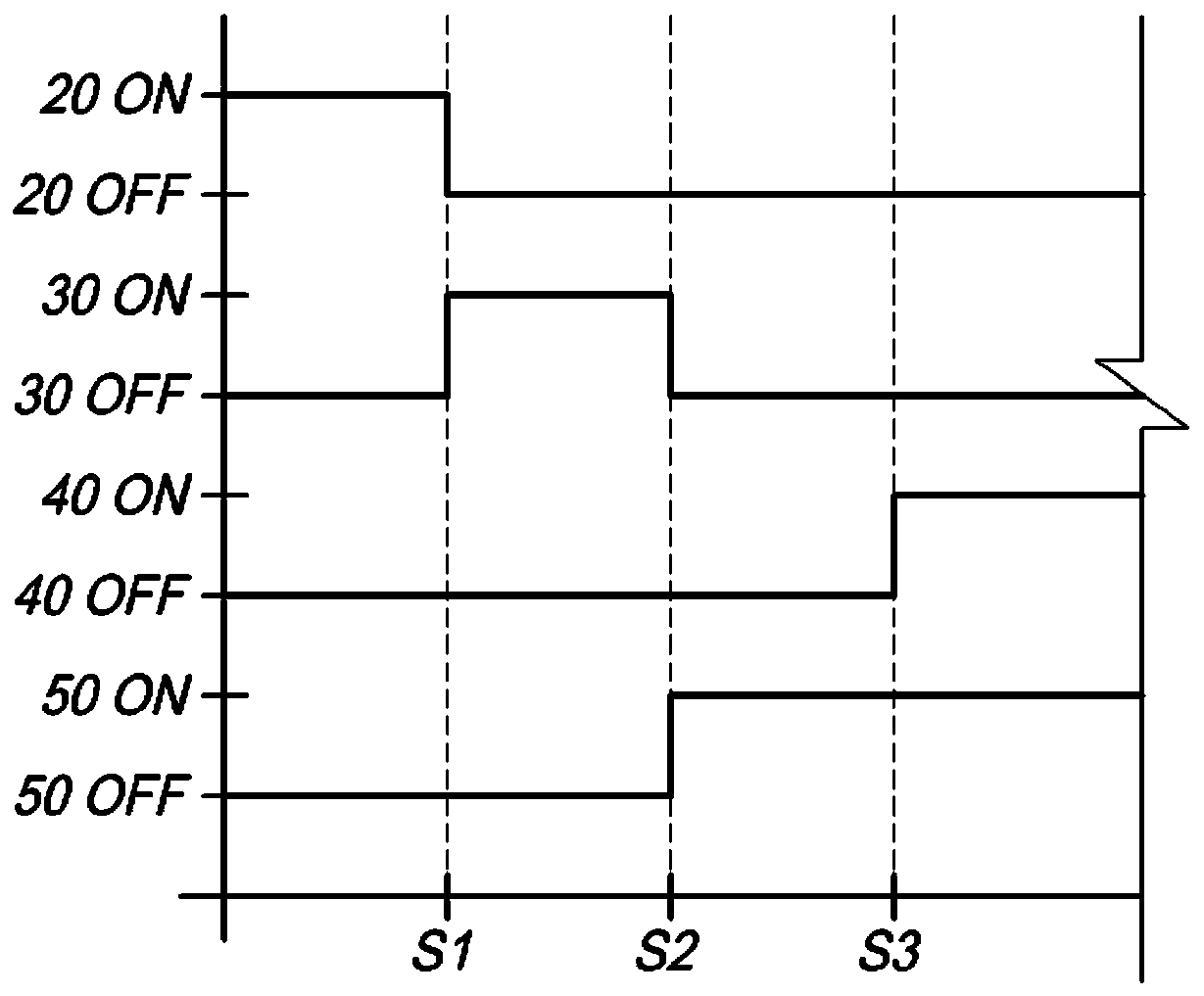

[0041] Hereinafter, with reference to the accompanying drawings, the semiconductor process equipment with cleaning function and the cleaning method of the semiconductor process equipment utilizing the cleaning function according to the present invention will be described in detail.

[0042] Generally, in order to etch a thin film formed on a substrate, chlorine (Cl)-based (Cl 2 / Ar, Cl 2 / N 2 , Cl 2 / He, Cl 2 / BCl 3 / Ar, BCl 3 / Ar, BrCl 3 、SiCl 4 / Ar, CCl 2 f 2 / H 2 / Ar, etc.) gas is used as the process gas. When the etching process is repeatedly performed using such a process gas, reaction by-products are generated inside the chamber. The reaction by-products are deposited inside the chamber and act as a source of contamination to the substrate in subsequent processes, so in order to remove them, the chamber needs to be cleaned periodically. As a method of cleaning the chamber, there is a method in which a worker opens the chamber lid to clean the inside of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com