Continuous casting device and molten metal pouring nozzle

A continuous casting and liquid injection technology, which is applied in the field of continuous casting equipment, can solve the problems of increased cutting amount on the surface of the ingot and rupture of the ingot, and achieve the effect of preventing the fixation of the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

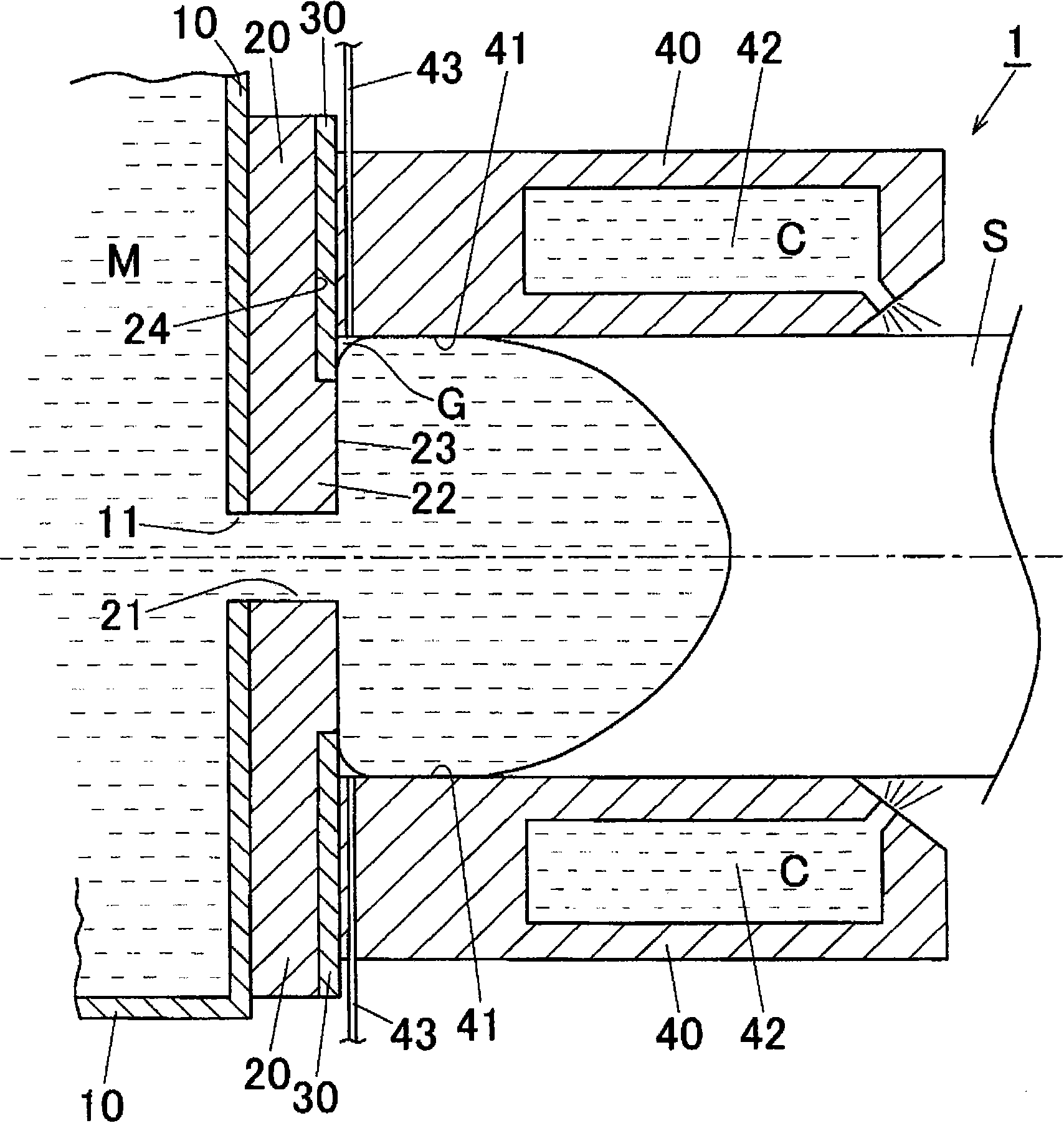

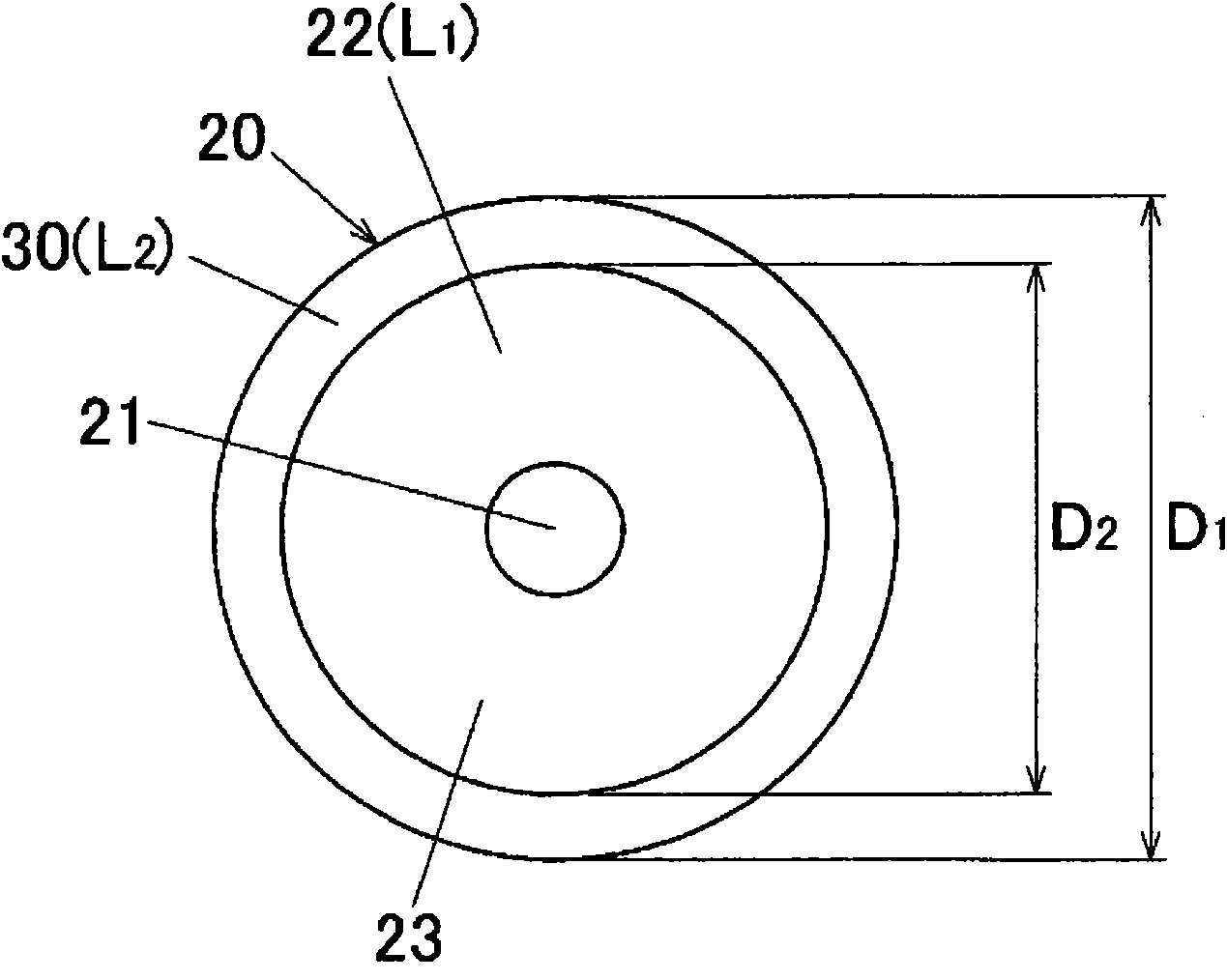

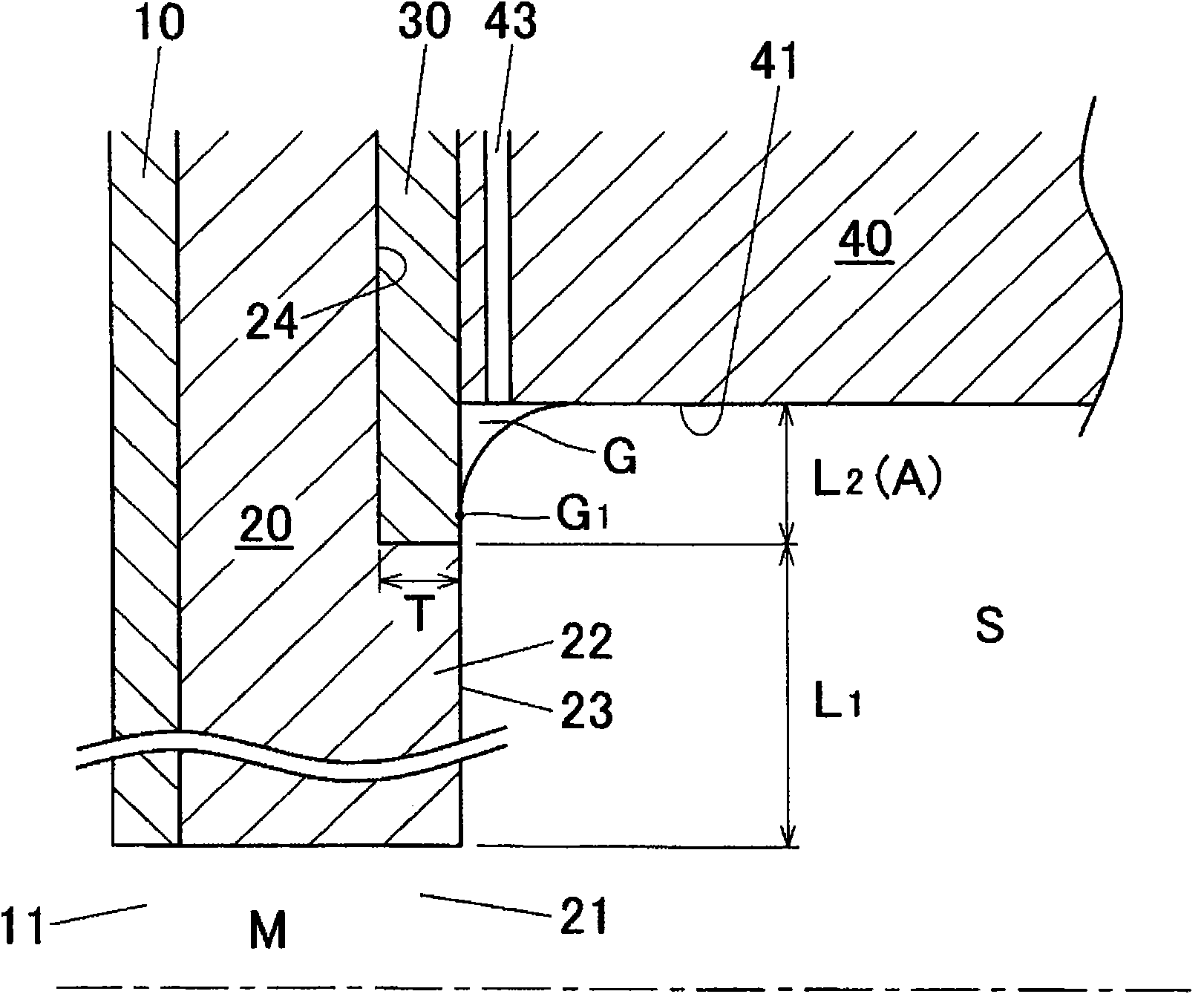

[0070] as reference figure 1 , Figure 2A , Figure 2B In this way, on the mold-side end surface 23 of the main body portion 22 of the injection nozzle 20, a graphite ring-shaped member 30 with a thickness T of 3 mm is arranged so that the protrusion A from the periphery of the forming hole 41 of the mold 40 is 3 mm or more. 2.2mm. In addition, the lubricating oil supply pipe 43 is opened in the forming hole 41 of the mold 40 to utilize the lubricating oil supplied to the mold 40 . Lubricating oil was supplied in the amount shown in Table 2.

Embodiment 3、4

[0072] as reference Figure 5 In this way, a sleeve 25 made of silicon nitride with a thickness of 1 mm is attached to the liquid injection passage 21 of the liquid injection nozzle 20, so that the vaporized lubricating oil does not leak from the liquid injection passage 21. The other configurations are the same as in Embodiment 1. , 2 are the same.

Embodiment 5、6

[0074] as reference Figure 6 In this way, the sleeve 45 made of graphite is caulked into the peripheral wall of the forming hole 41 of the mold 40 to facilitate the sliding of the ingot S in the mold 40 . The other constitutions are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com