Laser working apparatus, and laser working method

A laser processing method and laser processing technology, which can be used in fine working devices, stone processing equipment, laser welding equipment, etc., and can solve problems such as insufficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] (Embodiment 1)

[0065] Hereinafter, embodiments of the present invention will be described based on the drawings.

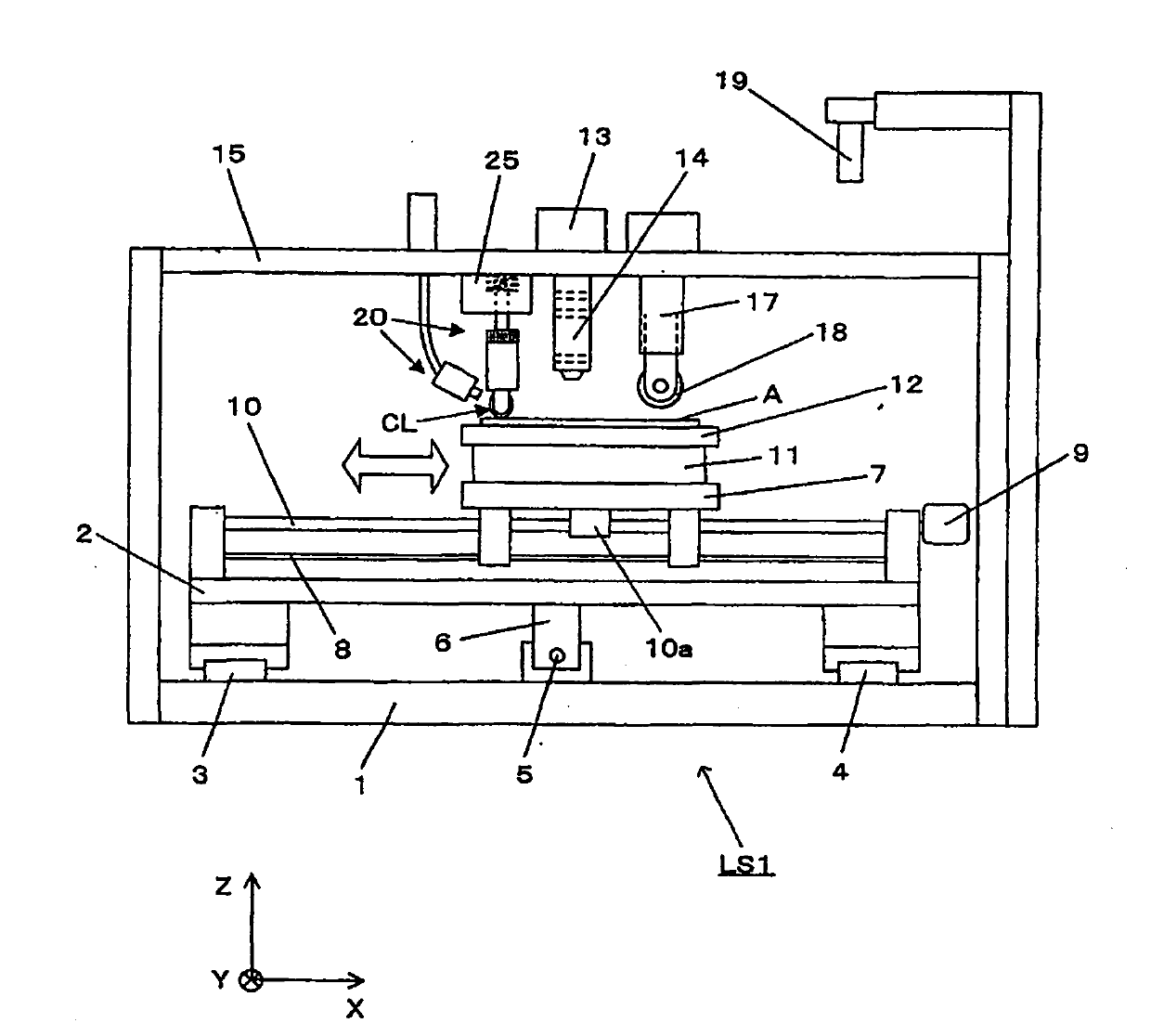

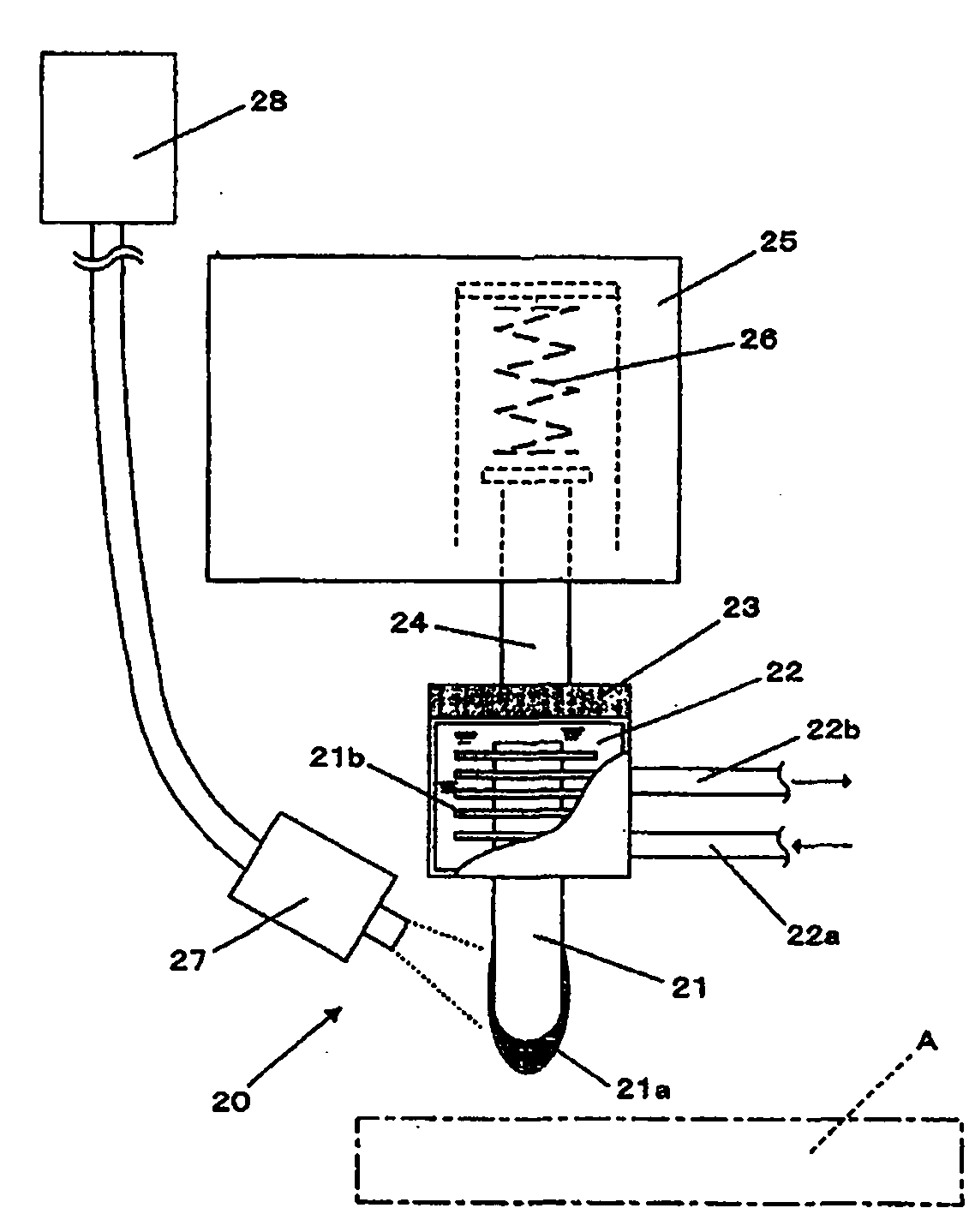

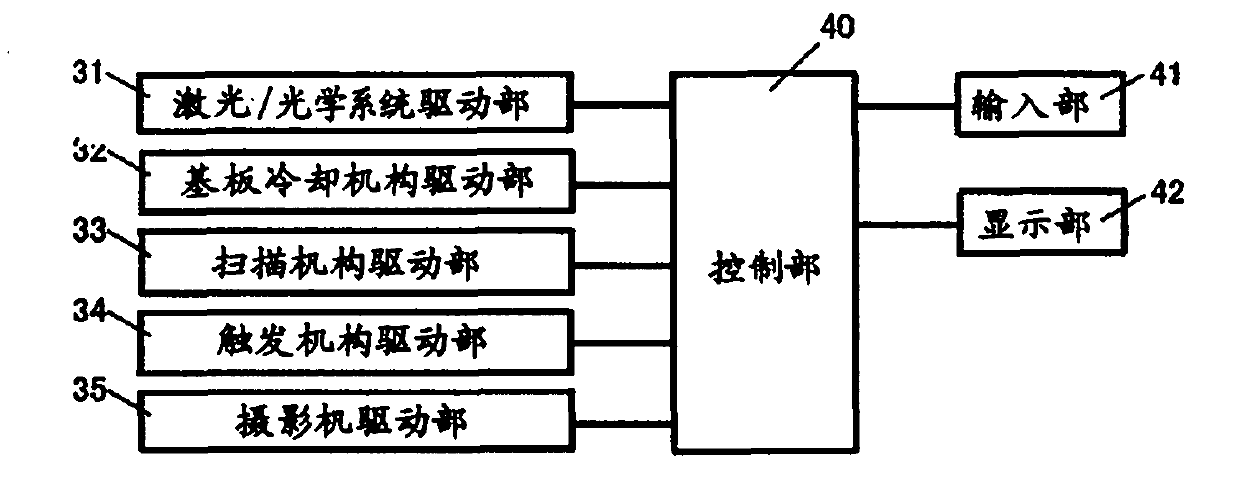

[0066] figure 1 It is an overall configuration diagram of a substrate processing apparatus LS1 capable of implementing the processing method of the present invention. figure 2 It is a partial configuration diagram showing the configuration of a substrate cooling mechanism that is a part of the substrate processing apparatus LS1.

[0067] In the present embodiment, although a processed glass substrate is taken as an example, the same applies to substrates made of brittle materials such as silicon substrates. Also, although it is described that ice is used as the solid-phase refrigerant, other solid-phase refrigerants (liquid alcohol is used in the case of solid alcohol, and liquefied carbon dioxide gas is used in the case of dry ice) are also the same.

[0068] First, the overall configuration of the substrate processing apparatus LS1 will be described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com