Predication method for layered threshold value load under transverse impact of laminated board

A technology of layered threshold and lateral impact, applied in the direction of using one impact force to test the strength of materials, can solve the problem of low prediction accuracy, and achieve the effect of improving the prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] There is a composite laminate material, the equivalent elastic modulus of the material system E=1.77×10 11 Pa, equivalent Poisson's ratio μ=0.34.

[0029] The reference test piece number is T0, thickness h 0 =0.00846m, its response can be regarded as the impact response of the half-space plate when it is impacted.

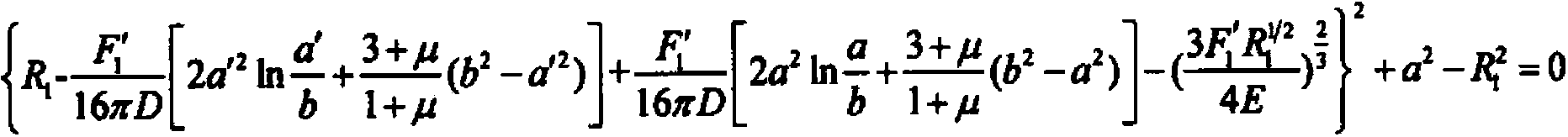

[0030] The test piece to calculate the impact delamination threshold load is T1, the equivalent radius of T1 is b=0.09m, and the thickness is h 1 =0.003m, equivalent bending stiffness D=161N.m. its radius R 1 = Delamination threshold load F under the action of 0.008m impact head 1 The calculation process of is as follows.

[0031] Use a radius of R 0 = 0.0127m punch impacts T0, and the delamination threshold load is 18932N.

[0032] Using the formula (1), the delamination strength S of this material is calculated as 3.54×10 8 Pa.

[0033] The approximate value F′ of the stratified threshold load of T1 is calculated using formula (2) 1 =3173N.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com