Transmission radius variable cone disc-sprocket wheel transmission piece and engagement driving stepless speed transmission

A technology of sprocket transmission and cone disc, which is applied in transmission devices, belts/chains/gears, mechanical equipment, etc., and can solve problems such as low transmission efficiency, poor reliability, and limited transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

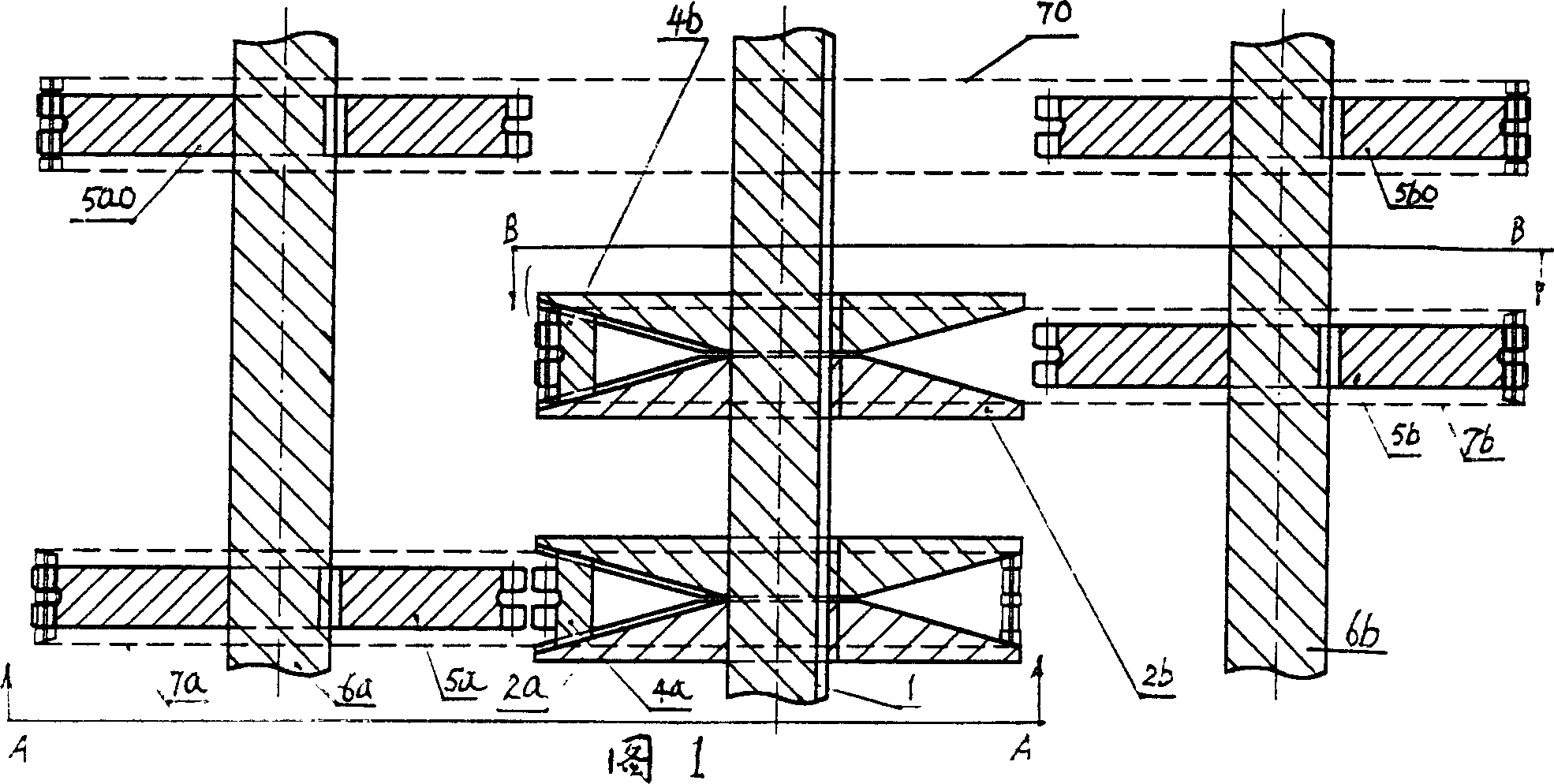

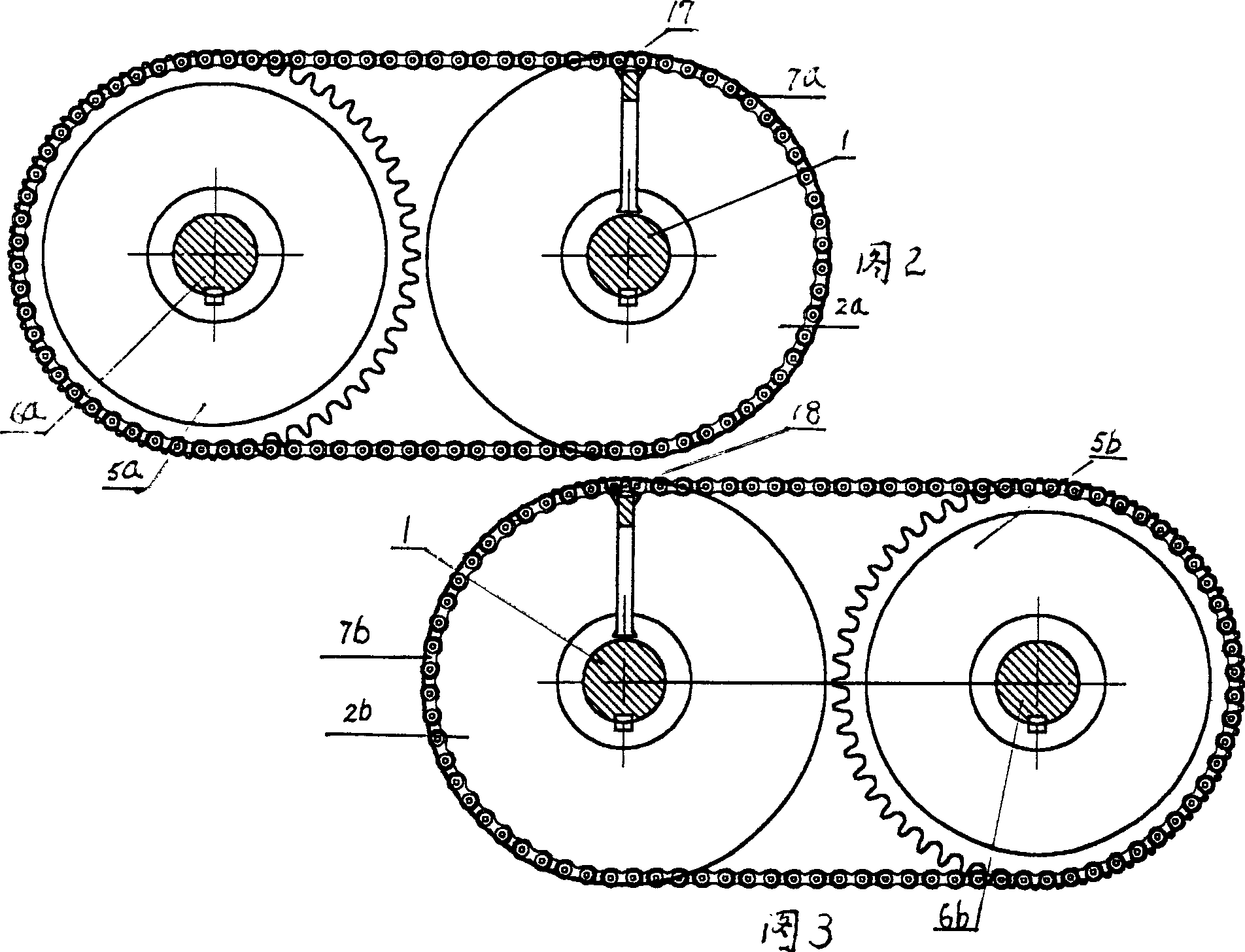

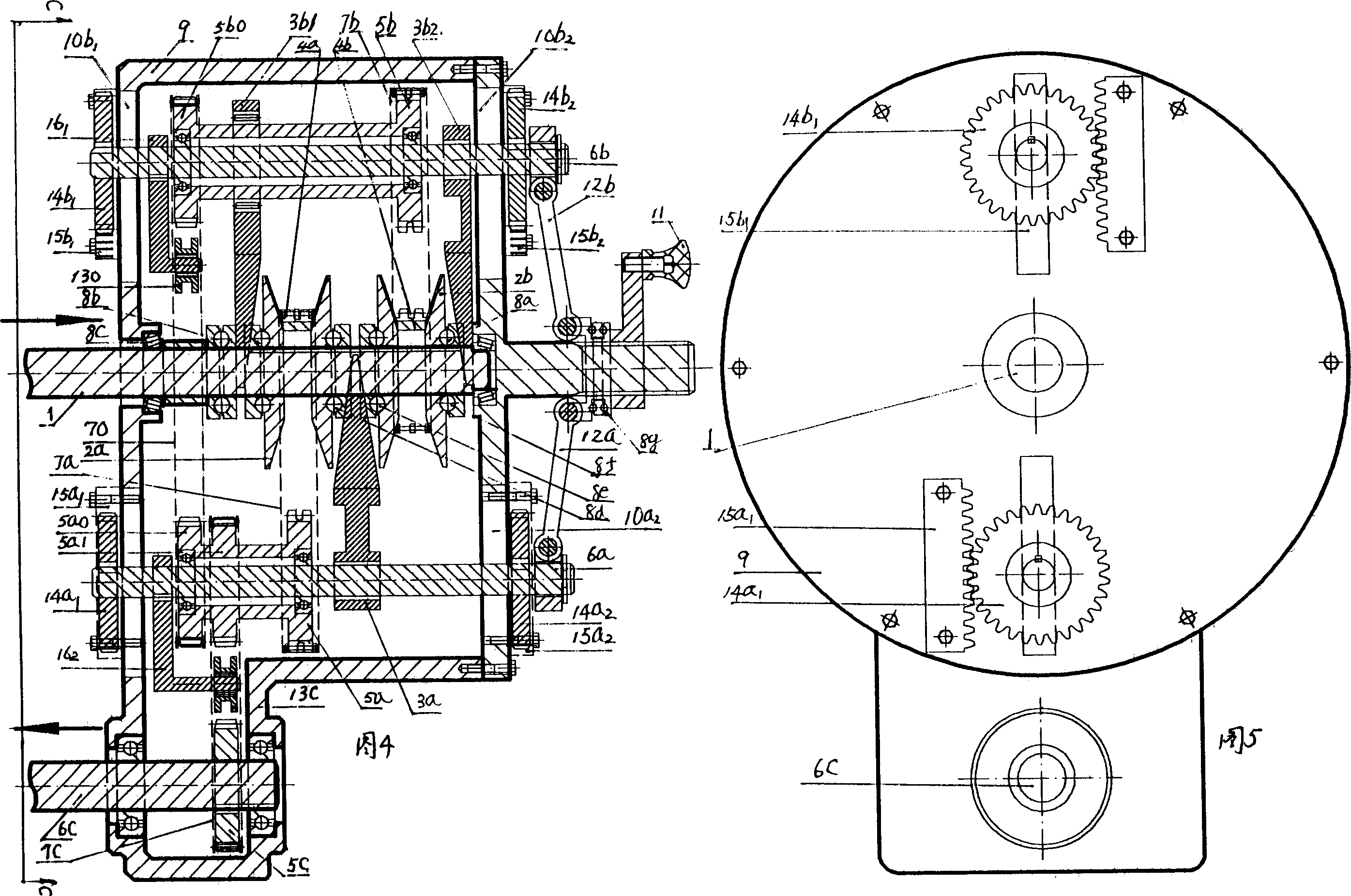

[0015] Now in conjunction with accompanying drawing 1~9 will illustrate working process:

[0016] (1) Working process of power transmission mechanism:

[0017] Taking Fig. 4 as an example, the power input shaft 1 drives the conical disks 2a-2b to rotate, and the conical disks 2a-2b, through the transmission chains 7a, 7b, drive the sprockets 5a, 5b to rotate, and the sprocket 5b is coaxially integrated with it. The sprocket 5b0 drives the sprocket 5a0 to rotate through the chain 70, and the coaxial sprocket 5a, 5a 1 、5a 2 by sprocket 5a 1 The chain 7c drives the sprocket 5c to rotate, and the sprocket 5 drives the power output shaft 6c to rotate to complete the power transmission process.

[0018] (2) Working process of variable speed control mechanism:

[0019] Turn the speed regulating handle 11 to axially move the end face bearing 8a for speed change, and make the shafts 6a, 6b in the chute 10a through the push-pull action of the speed change connecting rod 12a, 12b. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com