Area contact truss strut joint

a strut joint and area contact technology, applied in the direction of girders, joists, trusses, etc., can solve the problems of reducing the overall stiffness and load carrying capacity of the truss, and achieve the effect of improving the overall stiffness of the truss and the load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

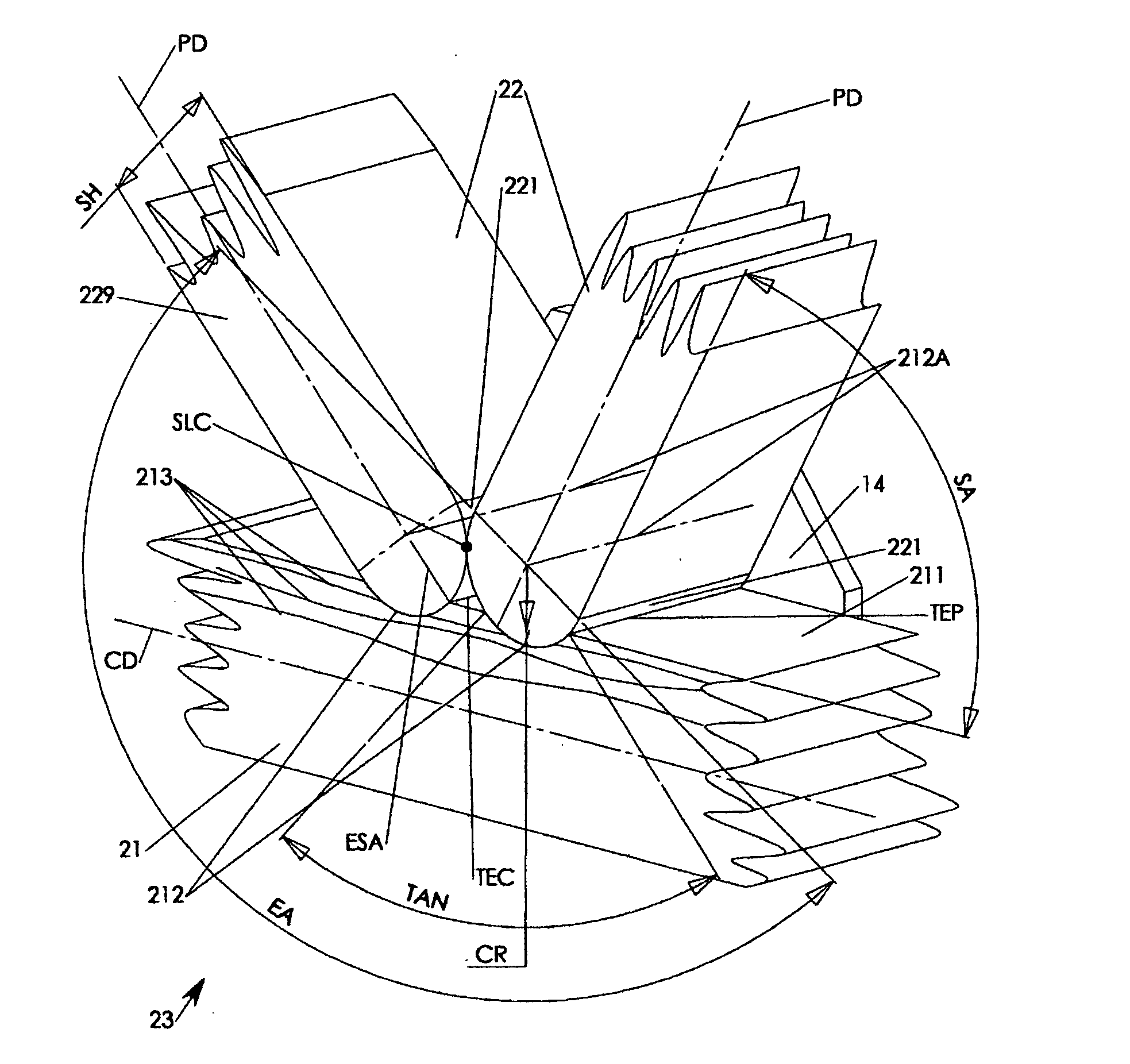

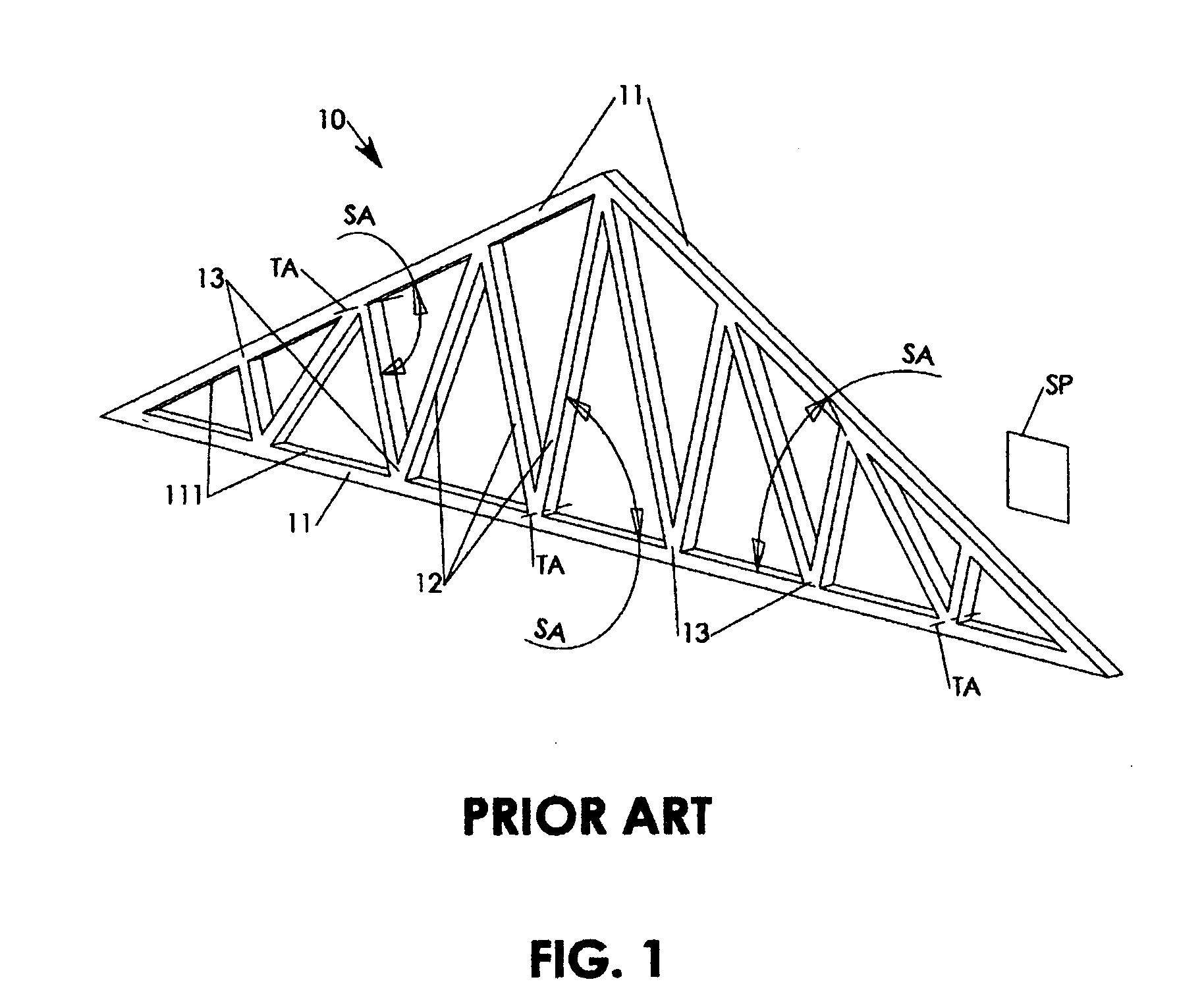

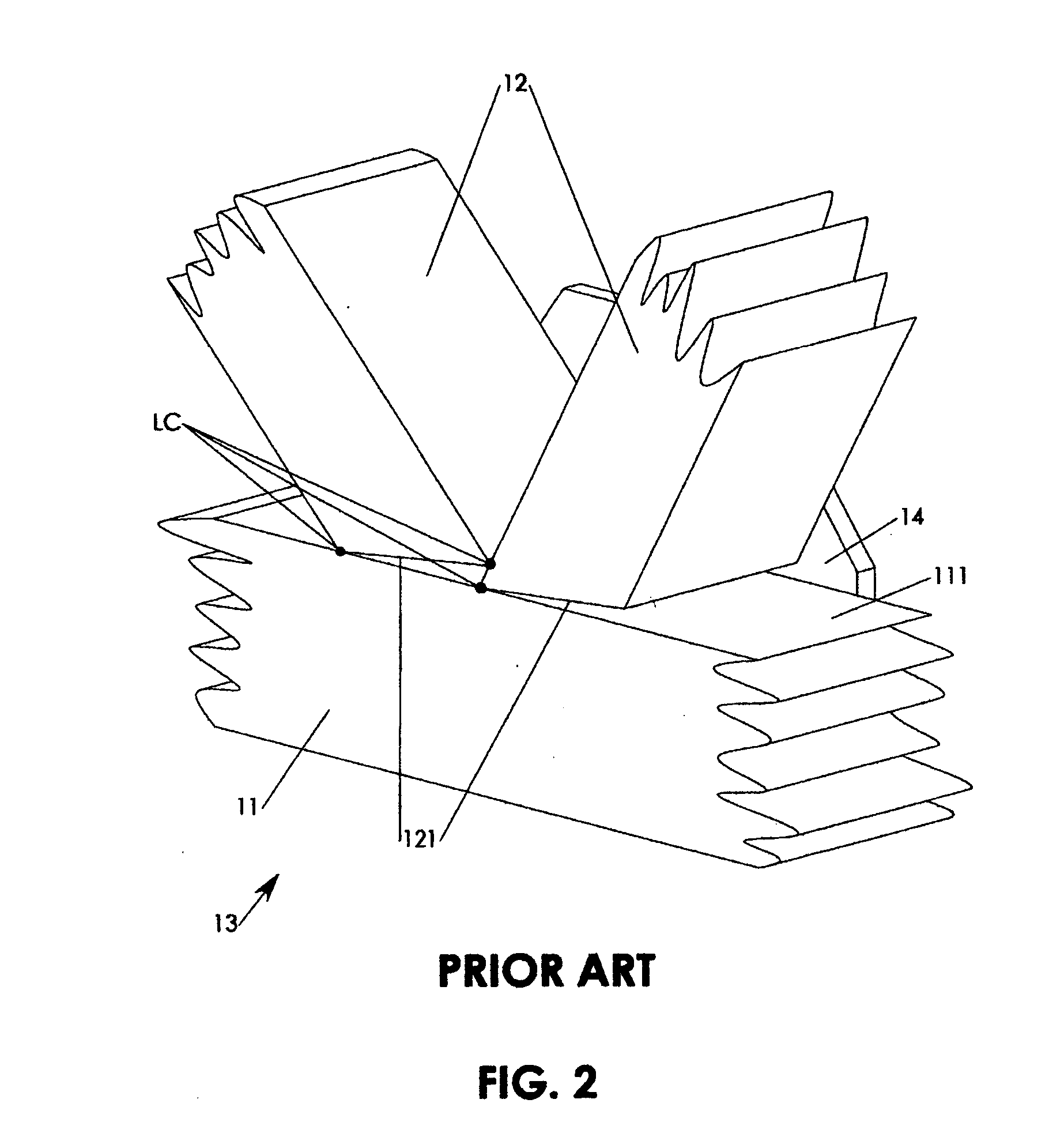

[0018] The present invention introduces improved strut joints 23 of FIGS. 4-7 with area contact at least in an interface between a chord trough 212 and a strut end surface 221 between the modified struts 22 and inner chord faces 211 of modified chords 21 as depicted in FIGS. 4, 5. Area contact may also extend directly between adjacent modified chord end surfaces 221 of a modified strut joint 23 as illustrated in FIGS. 6, 7.

[0019] Primary area contact is provided between at least rotationally symmetric strut end surfaces 221 and corresponding at least rotationally symmetric contact troughs 212. The contact troughs 212 are rotationally symmetric with respect to a trough axis 212A that is substantially perpendicular to the truss symmetry plane SP, a chord protrusion direction CD, a strut protrusion direction PD and parallel to the strut tilt axes TA. As a result, the struts 22 may be combined with the inner chord faces 211 in a primary area contact irrespective their strut joint angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com