Sloped corner radius fillers to reduce the risk of delamination in laminated stringer assemblies

A technology of inclination angle and radius, applied in the direction of thin material processing, aircraft parts, chords/stringers, etc., can solve the problem of adding extra weight to the aircraft, achieve the effect of large operating load and enhanced joint ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

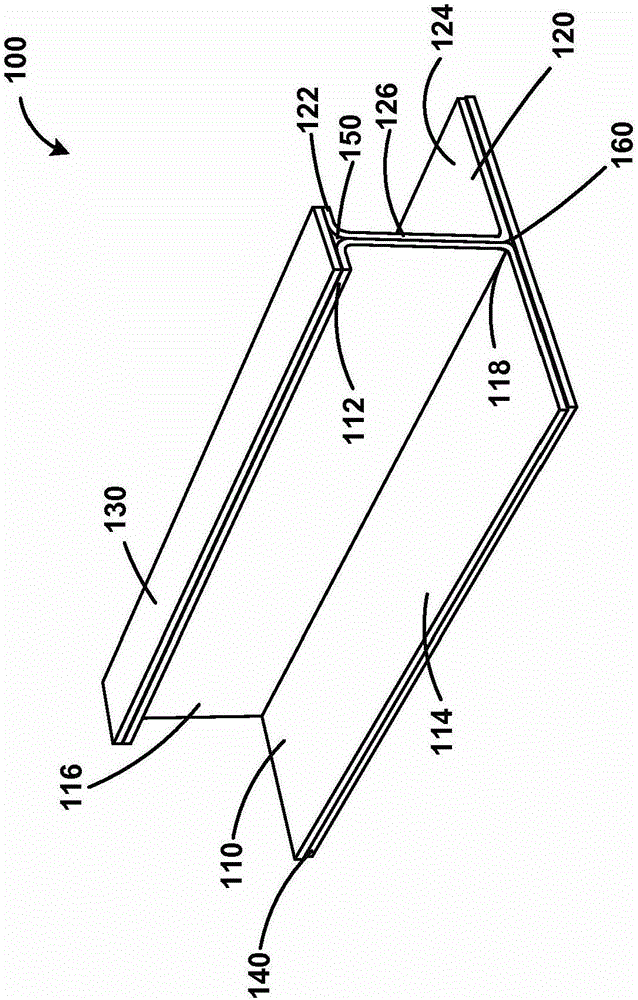

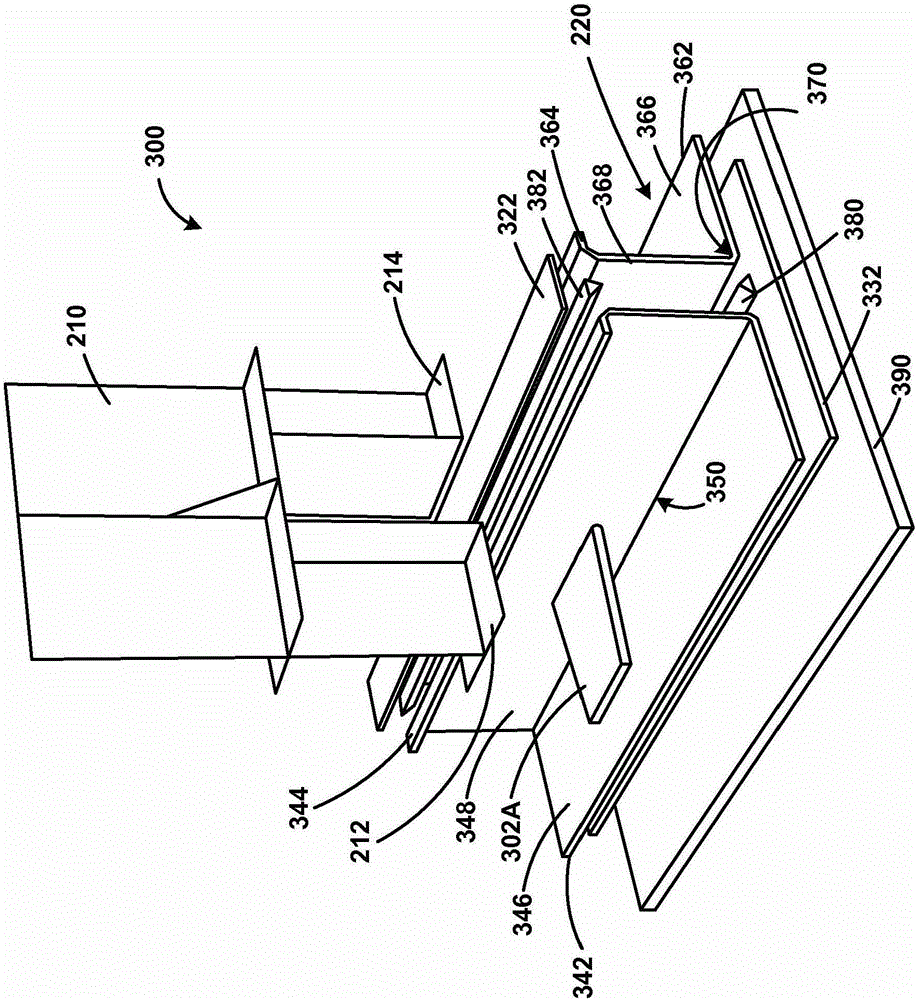

[0030] This article describes techniques for using oblique angle radius fillers to enhance joining capabilities and reduce the risk of delamination in stringers. By using the technology and concepts presented in this article, compared with the existing stringers using conventional rectangular radius fillers, the stringer bar-shaped members can bear greater out-of-plane (lead) load by using inclined corner radius fillers, Without layering.

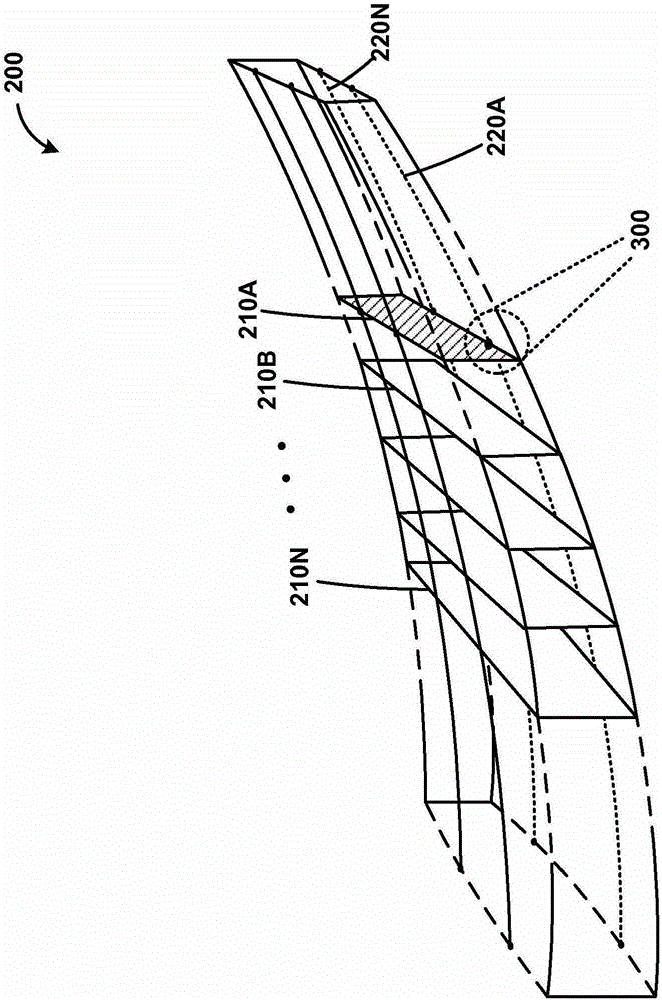

[0031] In the following specific embodiments, reference is made to the drawings that constitute a part of a specific embodiment or example and are shown in an illustrative manner. Referring now to the drawings, in which like reference numerals denote similar elements throughout several drawings, a technique for enhancing the joining ability and reducing the risk of delamination of the skin-stringer assembly using the inclined angle radius filler according to various embodiments will be described .

[0032] figure 2 A perspective view of a wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com