Heatproof corrosion-resistant cable material for urban rail transport and preparation method thereof

An anti-corrosion technology for urban rail transit, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor heat resistance and corrosion resistance, short service life, loss of life and property, etc., and achieve good heat resistance , good wear resistance, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

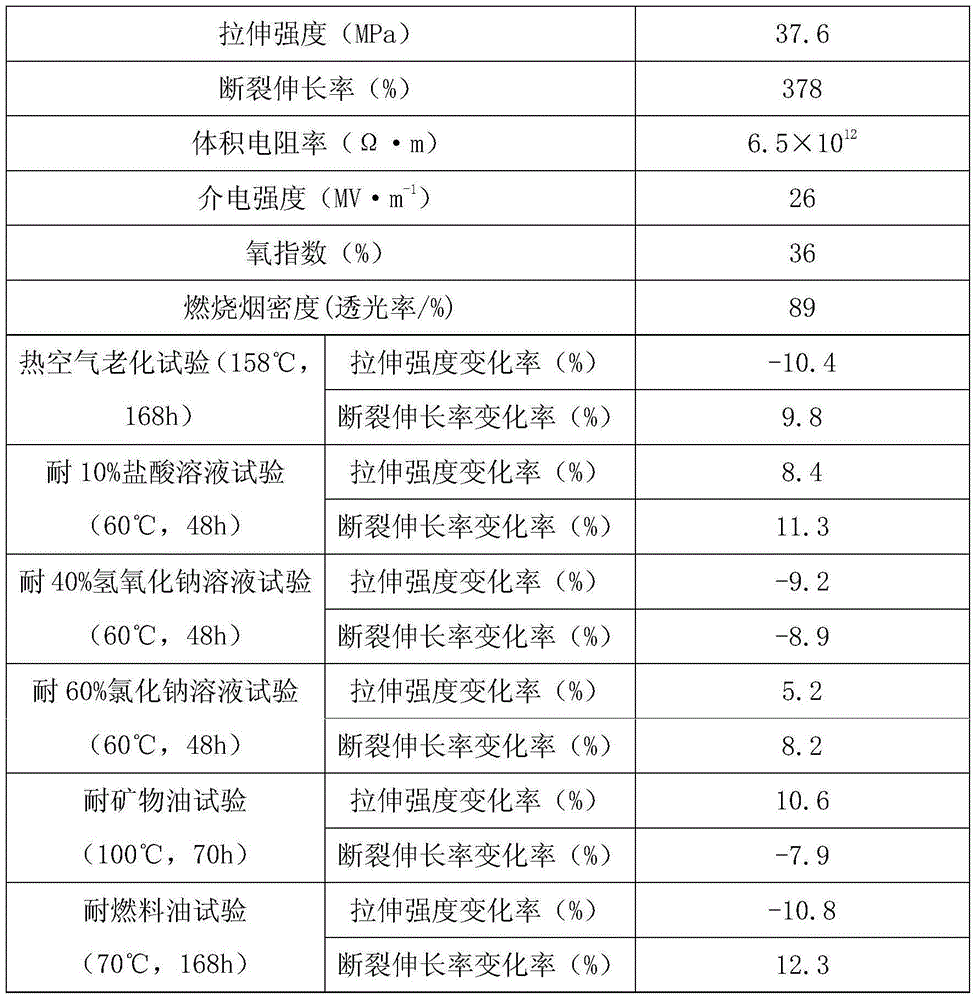

[0015] A heat-resistant and corrosion-resistant cable material for urban rail transit, made of the following raw materials in weight (kg): polytetrafluoroethylene 42, liquid crystal polymer 27, polyaryl sulfone 19, nano-zeolite molecular sieve 13, hexaphenoxy ring Triphosphazene 8, diethylene glycol dibenzoate 7, microcrystalline paraffin 4.5, hollow glass microspheres 12, composite flame retardant 16, melamine cyanurate 6, tri(n-butyl thioglycolic acid) Esters) antimony 2.5, 2-octyldodecanol 2, diallyl phthalate 12, stearoylbenzoylmethane 2.5, 6-ethoxy-2,2,4-trimethyl-1 ,2-dihydroquinoline 1.5;

[0016] The preparation method of described composite flame retardant is as follows:

[0017] (1) Take palygorskite, attapulgite and barium metaborate in a ratio of 5:4:3 by mass, mix uniformly, pulverize, pass through a 120 mesh sieve, and then ball mill at 750r / min for 0.5h;

[0018] (2) Add water and stir the powder obtained by the above ball milling to prepare a suspension with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com