Magnetic material adhesive and preparation method thereof

A technology for adhesives and magnetic materials, applied in the directions of adhesives, non-polymer adhesive additives, non-polymeric organic compound adhesives, etc. Weakness and other problems, to achieve the effect of easy operation, fast bonding speed and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Put a-cyanoacrylate ethyl into a three-necked flask, then add 10% diallyl phthalate, 680ppm maleic anhydride, 800ppm modifier , 50ppm anionic polymerization inhibitor (sulfur dioxide: boron trifluoride complex = 1: 1) and 500ppm free radical polymerization inhibitor (hydroquinone: p-methoxyphenol = 5: 1) were stirred at 40°C until uniform.

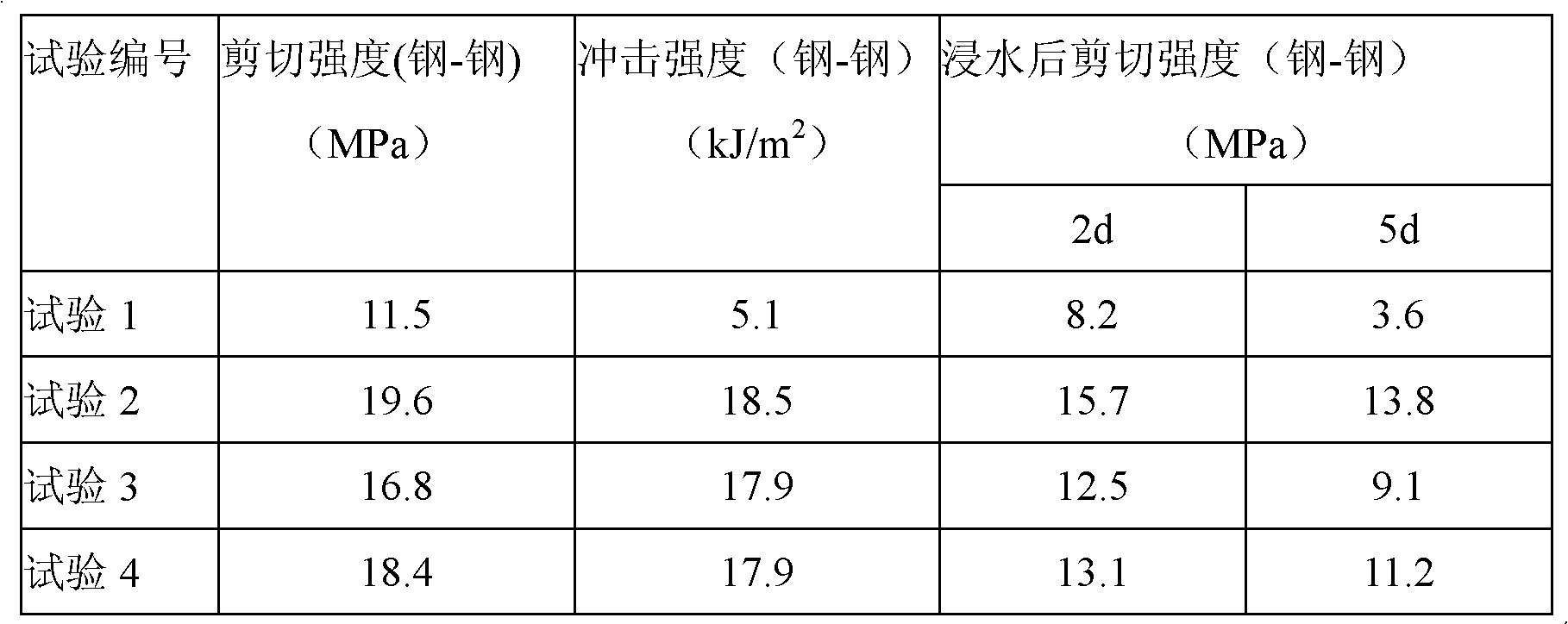

[0017] Measure shear strength, impact strength and water resistance (shear strength after immersion in water) data by embodiment 1 and see the following table:

[0018] Test 1: No Modifier

[0019] Test 2: 800ppm hydroxypropiolactone phthalate

[0020] Test 3: 800ppm pyrogallol

[0021] Test 4: 800ppm modifier (hydroxypropiolactone phthalate: bipyrogallol = 1:1 mixture)

[0022]

[0023] From the experimental data, it can be concluded that the strength, water resistance and impact strength of the adhesive with hydroxypropiolactone phthalate as the modifier are better than those of the other two groups.

Embodiment 2

[0025] Put α-ethyl cyanoacrylate into a three-necked flask, then add 10% diallyl phthalate, 680ppm maleic anhydride, modifier, 50 ppm anionic polymerization inhibitor (methanesulfonic acid) and 500 ppm free radical polymerization inhibitor (hydroquinone: p-methoxyphenol=5:1) were stirred at 60°C until uniform.

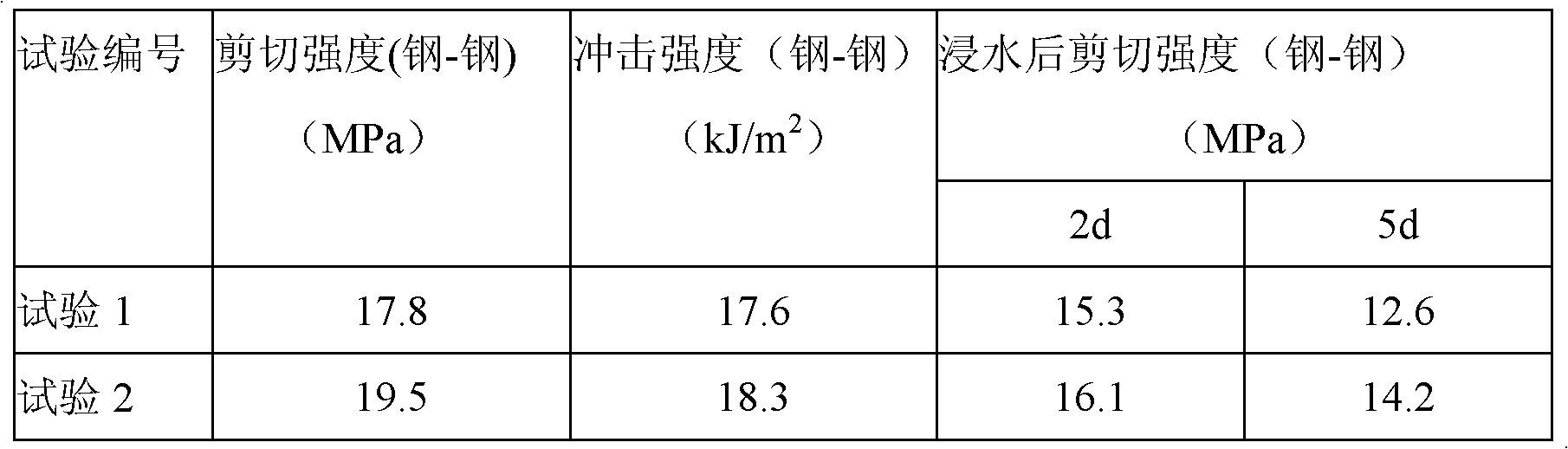

[0026] Measure shear strength, impact strength and water resistance (shear strength after immersion in water) data by embodiment 2 and see the following table:

[0027] Test 1: 300ppm hydroxypropiolactone phthalate

[0028] Test 2: 800ppm hydroxypropiolactone phthalate

[0029] Test 3: 1000ppm hydroxypropiolactone phthalate

[0030]

[0031]

[0032] It can be concluded from the experimental data that the strength, water resistance and impact strength of the adhesive are better when the amount of phthalate hydroxypropiolactone salt is 800 ppm.

Embodiment 3

[0034] Put a-cyanoacrylate ethyl into a three-necked flask, then add 10% diallyl phthalate, 680ppm maleic anhydride, 800ppm modifier (hydroxypropiolactone phthalate), anionic polymerization inhibitor and 500ppm free radical polymerization inhibitor (hydroquinone: p-methoxyphenol=5:1) were stirred at 50°C until uniform.

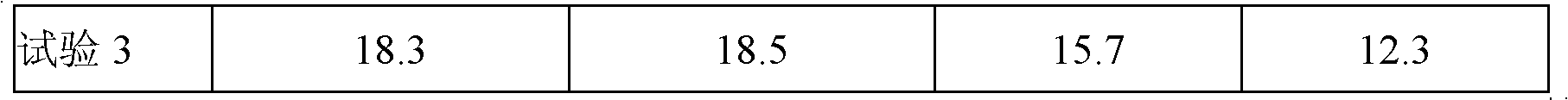

[0035] Measure shear strength, impact strength and water resistance (shear strength after immersion in water) data by embodiment 3 and see the following table:

[0036] Test 1: 50ppm sulfur dioxide

[0037] Test 2: 50ppm boron trifluoride complex

[0038] Test 3: 50ppm p-toluenesulfonic acid

[0039] Test 4: 50ppm anionic polymerization inhibitor (sulfur dioxide: methanesulfonic acid = 2:1 mixture)

[0040]

[0041] From the experimental data, it can be concluded that the strength, water resistance and impact strength of the adhesive are better when the anionic polymerization inhibitor adopts 50ppm p-toluenesulfonic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com