Patents

Literature

31results about How to "With anti-seepage function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

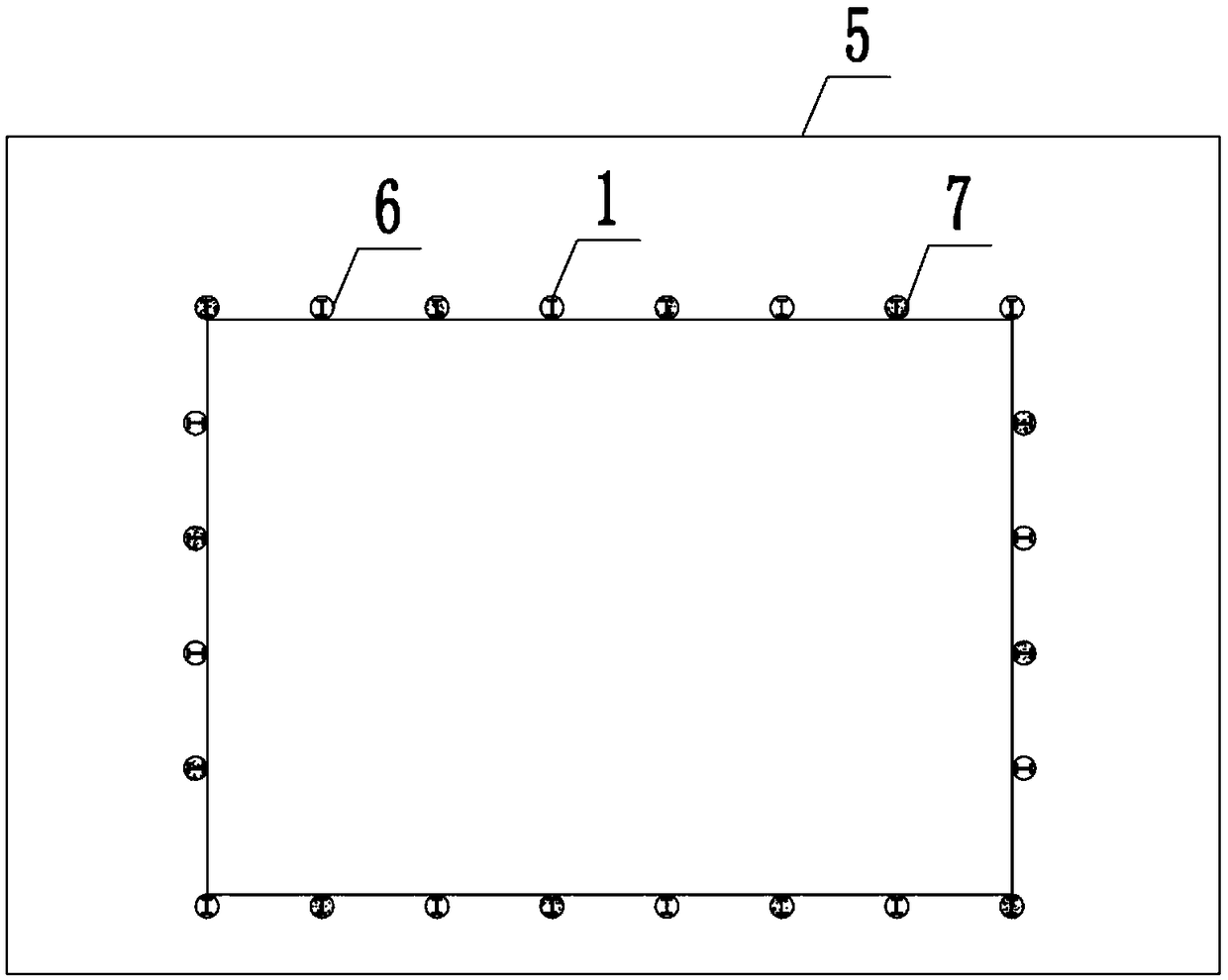

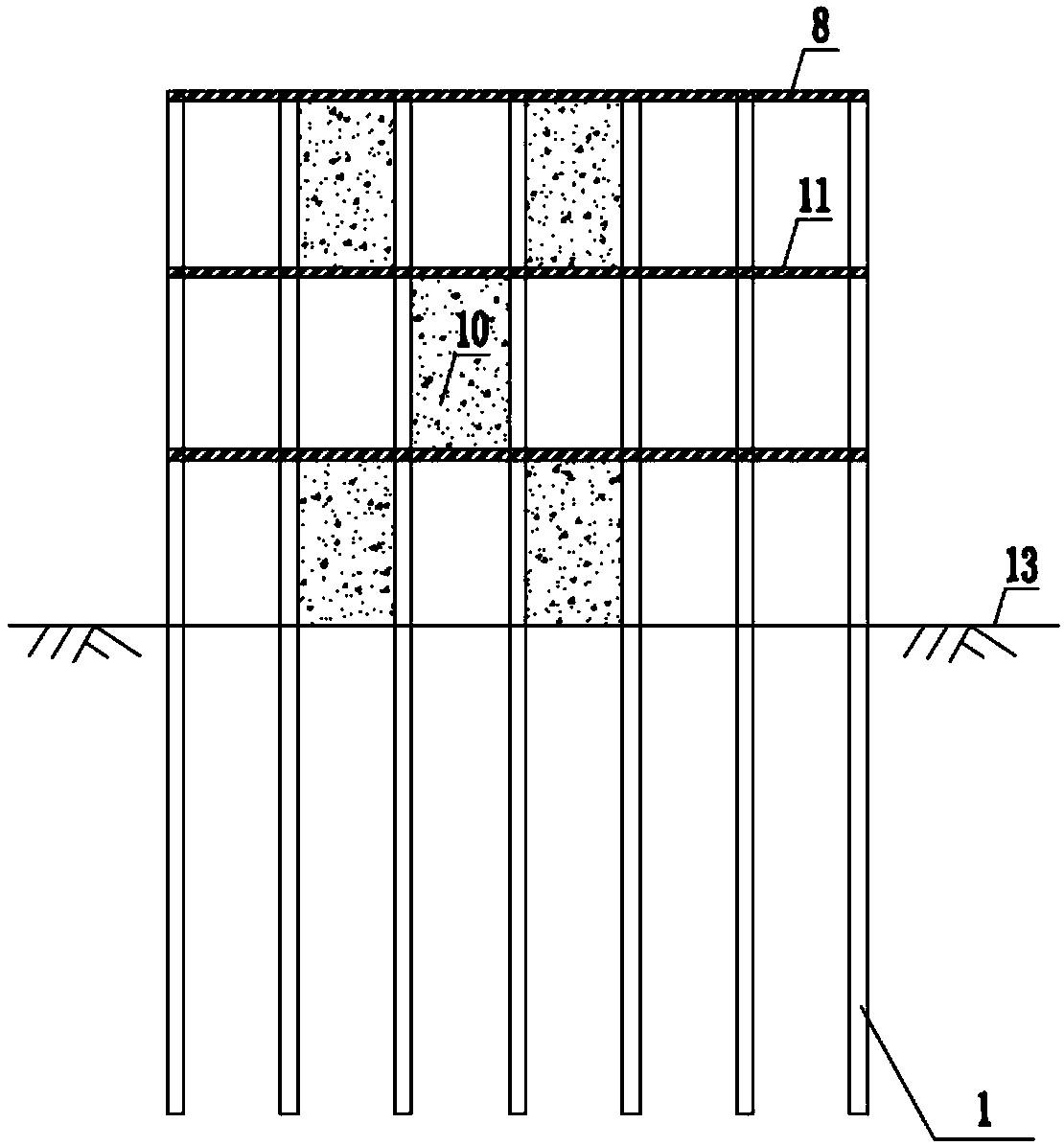

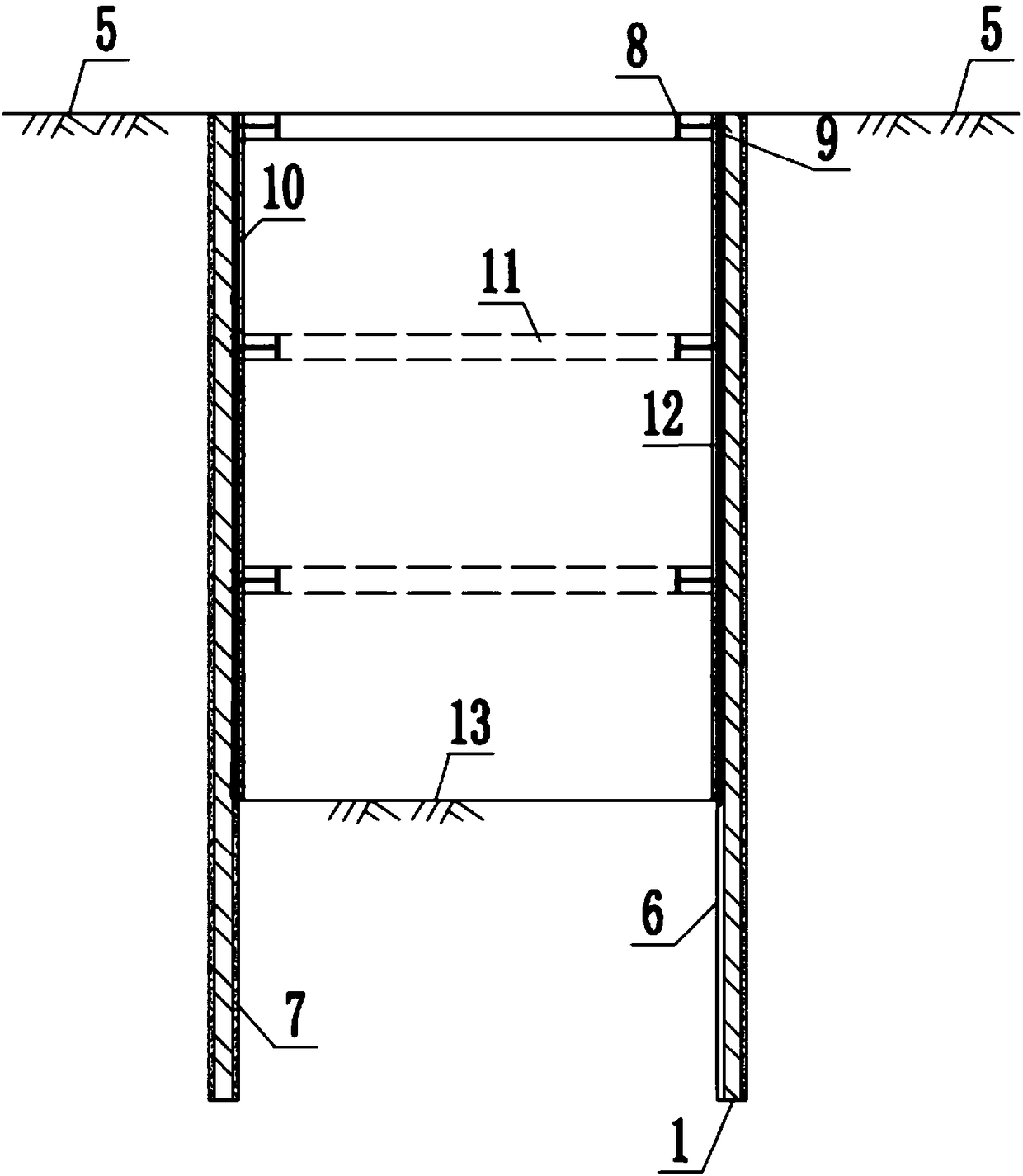

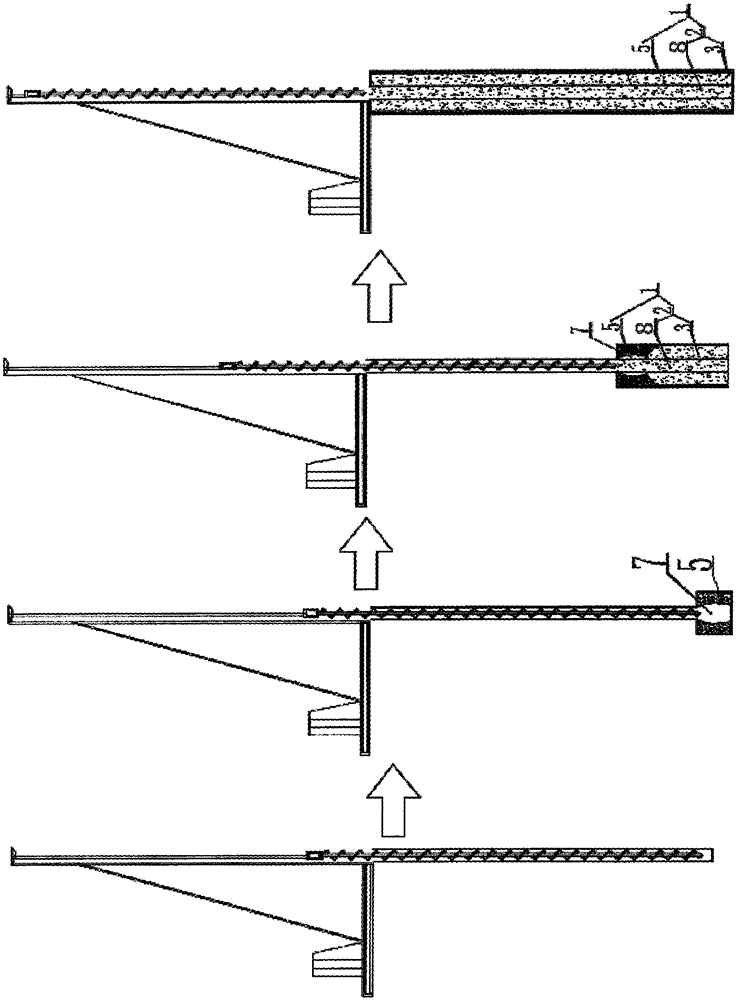

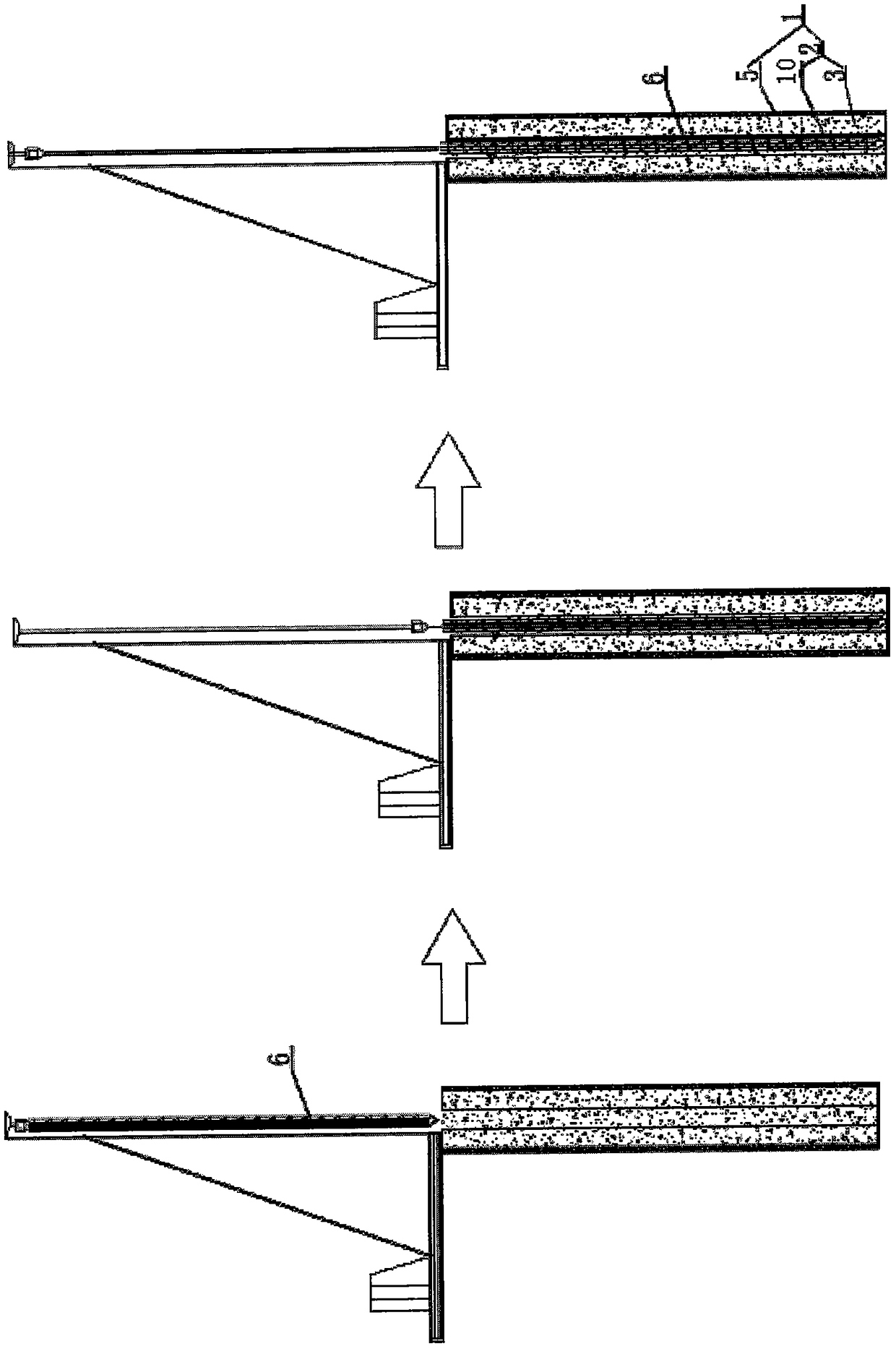

Design construction method of flexible compound fabricated recoverable rectangular working well supporting structure

InactiveCN109056746AMeet the positioning and installation accuracy requirementsAdvanced technologyExcavationsStructure systemHigh polymer

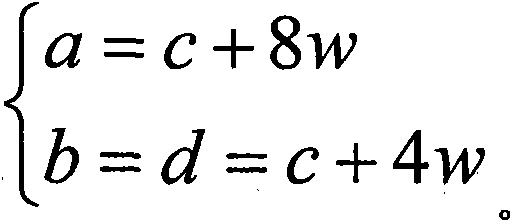

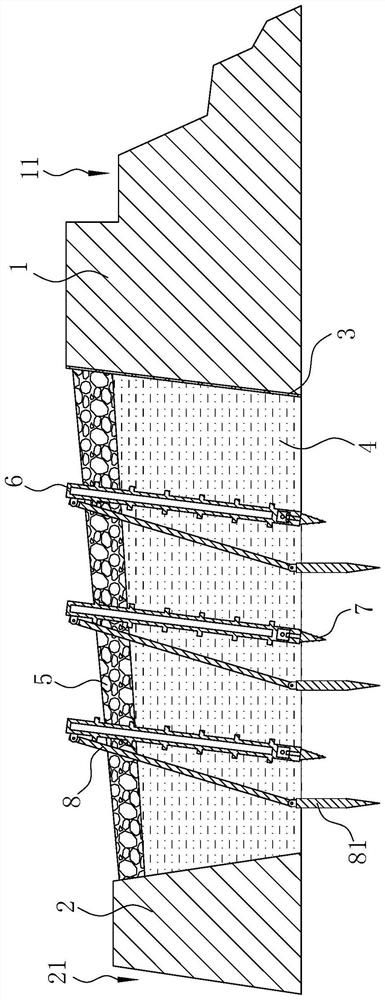

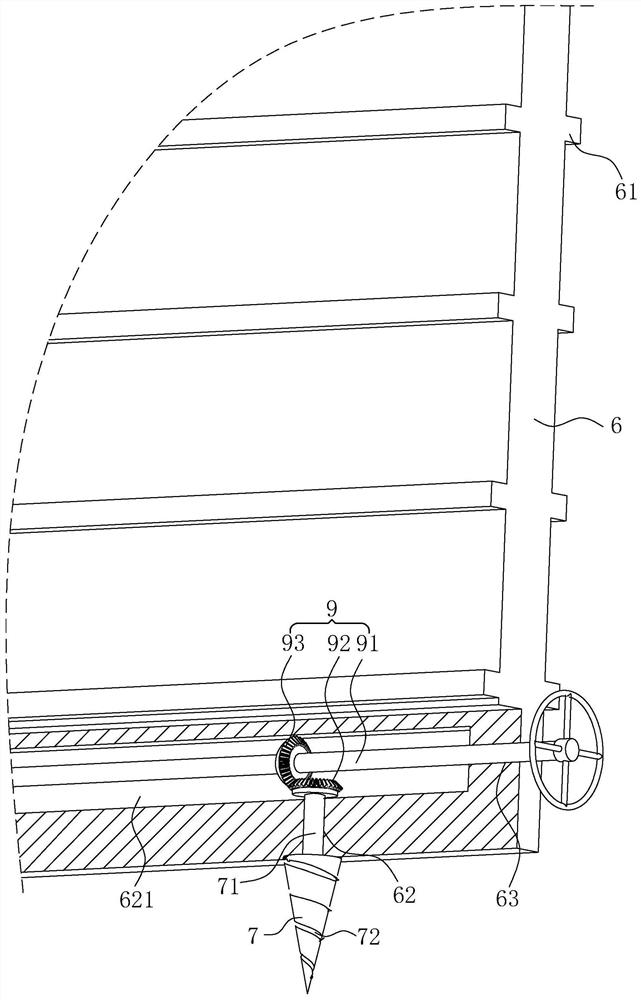

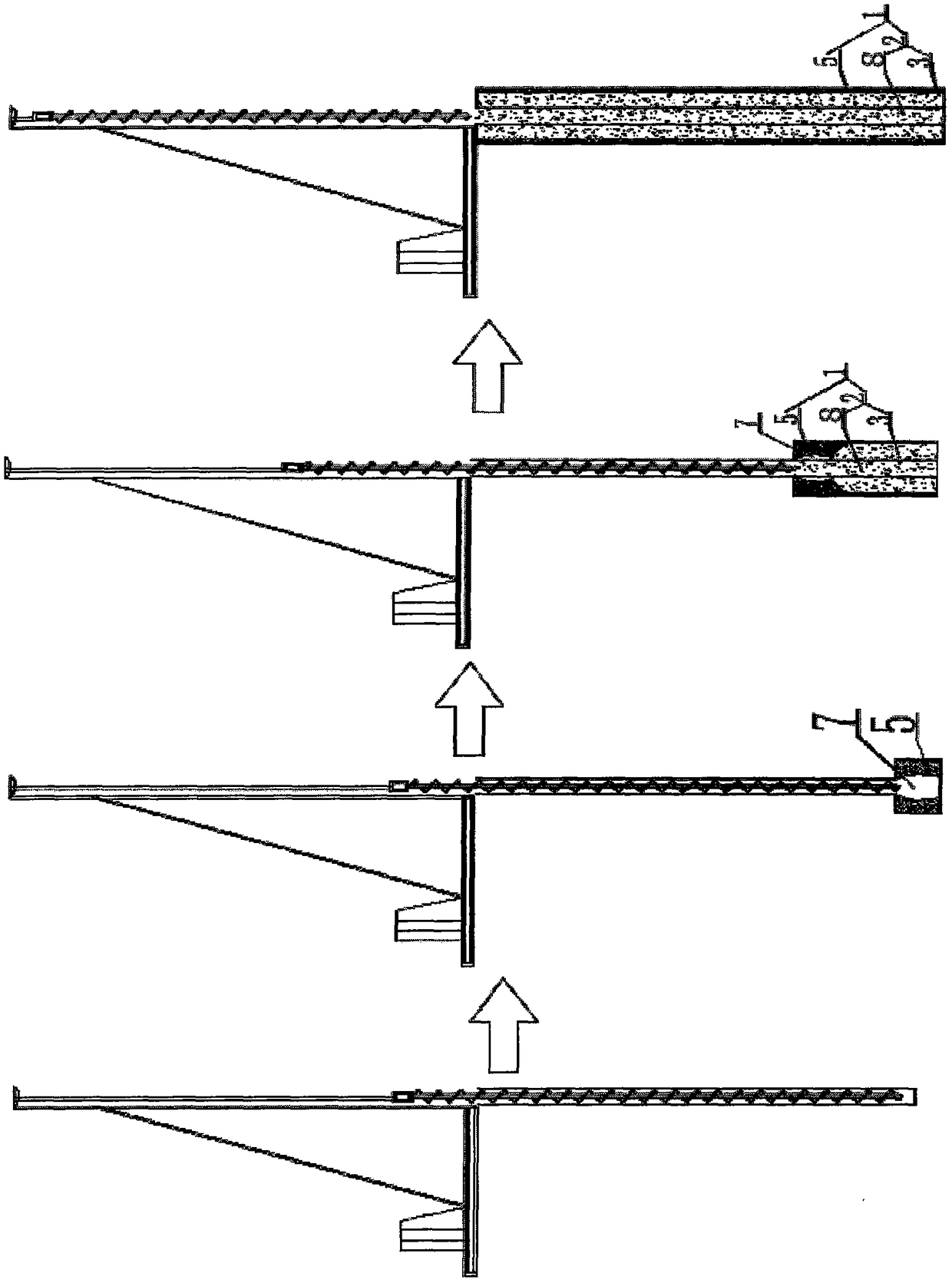

The invention relates to a standardized design construction method of a flexible compound fabricated recoverable rectangular working well supporting structure. The method comprises the following stepsthat (1) construction of minisize supporting piles is carried out; (2) construction of pile top crown beams; (3) a rectangular working well is excavated, panels and waist beams are installed, and high polymers are poured to side walls for sealing; (4) excavation is carried out layer by layer sequentially in the vertical direction, and the step (3) is carried out repeatedly till the design depth is met, that is, construction of the rectangular working well supporting structure is completed accordingly; and (5) after the supporting structure fulfills the usage function, the supporting structurerecovery work can be carried out as the backfilling work is started. Through standardized design construction of the established supporting structure system, one supporting structure can meet the construction requirement of most rectangular working wells in a region, the advantages of safety, reliability, quick and convenient construction, advanced technologies, high recoverability, superior economic indicators and the like are achieved, and the application and development prospects are considerable.

Owner:南方工程检测修复技术研究院

Forming construction method of long-spiral pore-forming pile-slab-pile supporting and anti-seepage continuous wall

PendingCN105464079AReduce investmentShear resistantArtificial islandsUnderwater structuresHigh pressureCement paste

The invention discloses a forming construction method of a long-spiral pore-forming pile-slab-pile supporting and anti-seepage continuous wall. The continuous wall is formed in a manner that a long-spiral drilling high-pressure jetting cemented soil composite concrete pile slab composite pile is taken as a construction main body and pile-slab-pile crossed construction and combination in different sequences is carried out. The forming construction method comprises the following steps that Step one, construction preparation is carried out; Step two, pile foundation construction and pore-forming are carried out, high-pressure jetting cement paste slab forming hole construction, and press grouting pile slab concrete construction are carried out, concrete is subjected to press grouting to reach the elevation of a pile top, then first plain concrete pile slab construction is accomplished; Step three, a second plain concrete pile slab is coaxially connected and constructed according to a designed pile space, and after second plain concrete pile slab construction is accomplished, the construction of a pile-slab-pile supporting and anti-seepage continuous wall structural unit is accomplished; and Step four, the pile slab construction of the next unit is carried out according to the operational procedures above, then the complete pile-slab-pile supporting and anti-seepage continuous wall is formed. According to the forming construction method of the long-spiral pore-forming pile-slab-pile supporting and anti-seepage continuous wall, stand-alone construction is realized, the equipment investment is low, the energy consumption is low, and the cost is saved.

Owner:李金良

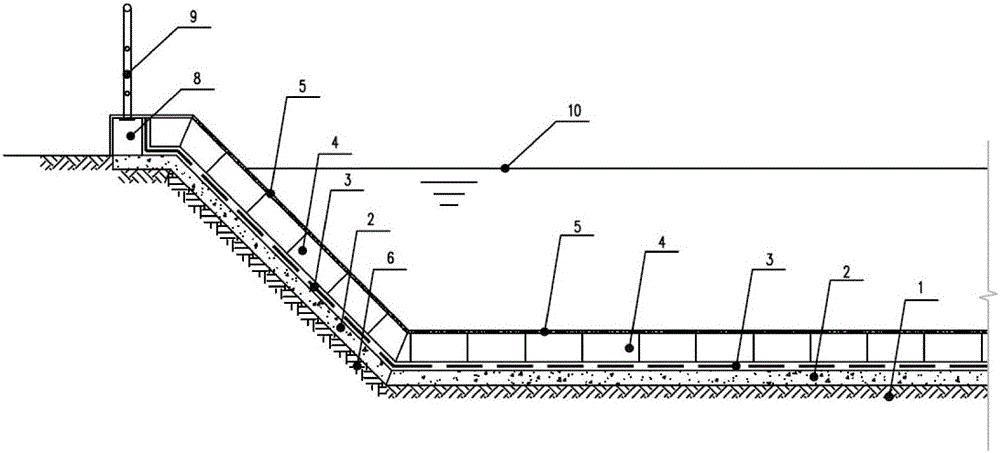

Seepage-proof modification method for sewage storage pools of large-scale livestock and poultry farms

ActiveCN104314164ASave one-time investment costsWith anti-seepage functionSewerage structuresProtective foundationReinforced concreteWater table

The invention discloses a seepage-proof modification method for sewage storage pools of large-scale livestock and poultry farms. The pool bottom and pool walls are constructed synchronously by means of the once-forming construction process, and a seepage-proof structure employs a modification process which integrates a plain concrete cushion layer, an HPDE (high-density polyethylene) seepage-proof film and a concrete block pressure cover. Pool wall modification of the pool walls includes: modifying an all-soil storage pool, adding the plain concrete cushion layer to a compacted foundation soil layer of an original pool wall, adhering the HPDE seepage-proof film, and paving a layer of concrete blocks. Modification of a storage pool with a soil bottom and retaining walls around includes: roughening contact surfaces of original reinforced concrete retaining walls, adhering the HPDE seepage-proof films, and paving a layer of concrete blocks. Pool bottom modification includes: digging to an old soil layer, adding a plain concrete cushion layer, laying an HPDE seepage-proof film, and paving a layer of concrete blocks. The seepage-proof modification method has the advantages that seepage-proof effects can meet seepage-proof requirements of the reinforced concrete pools, the seepage-proof films can be protected effectively to prevent the problem of 'bumps' caused by rise of groundwater level, and service lives of the seepage-proof films can be prolonged greatly.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

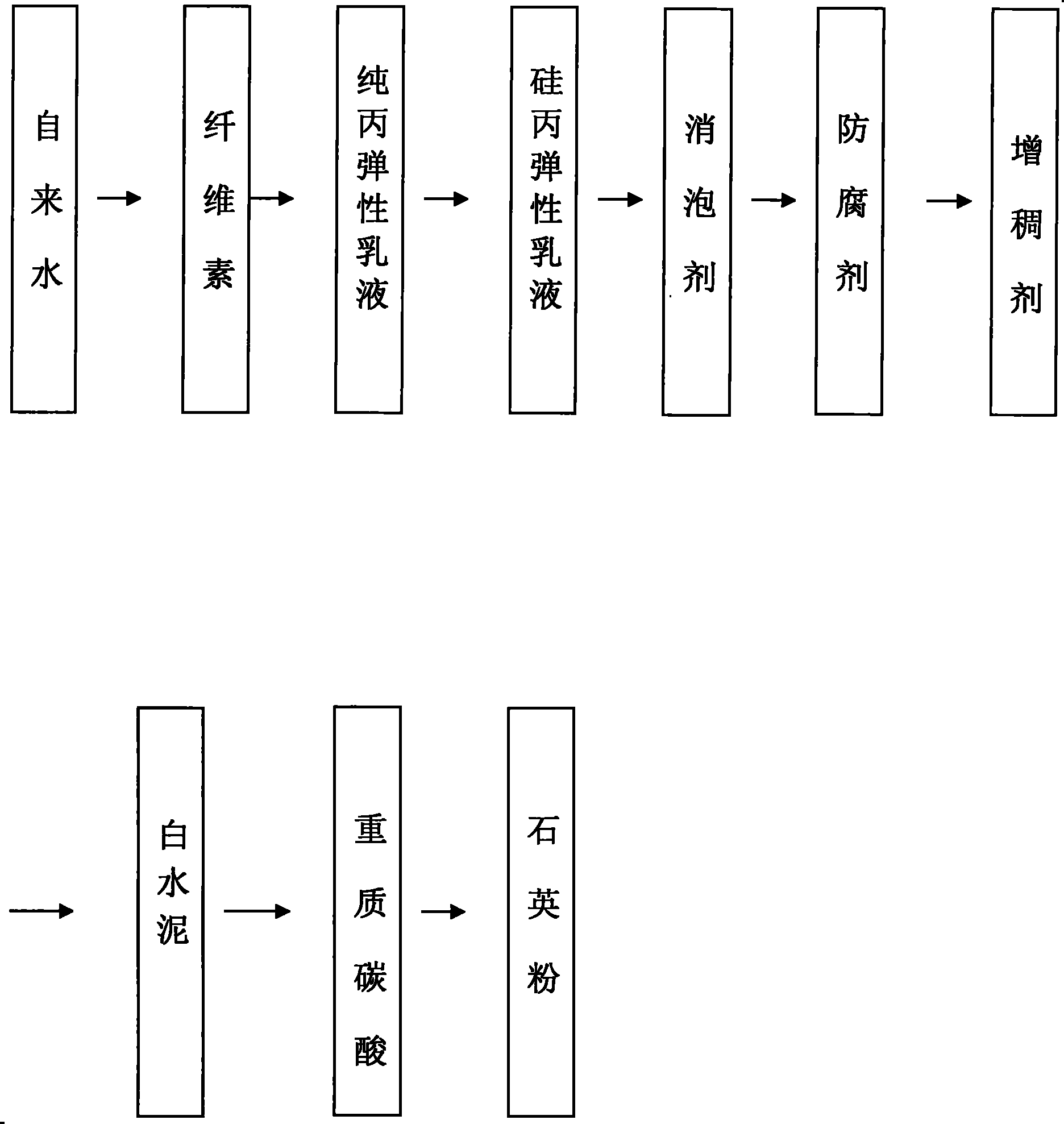

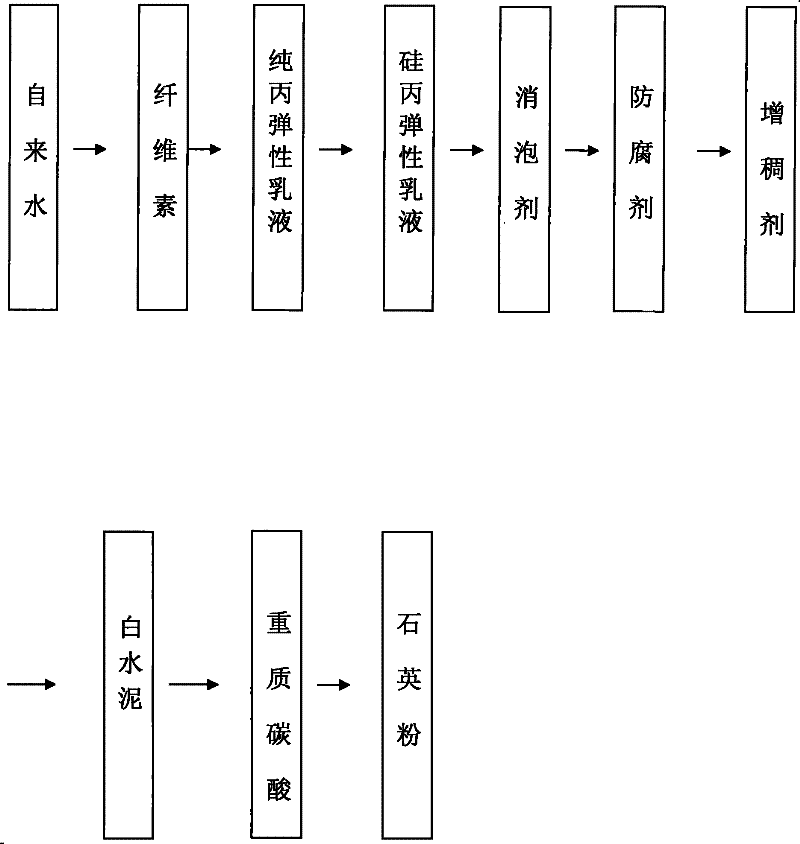

Production method of multifunctional outer-wall crack-resisting putty

ActiveCN101805535AImprove crack resistanceComply with building material standardsFilling pastesCelluloseEmulsion

The invention provides a production method of multifunctional outer-wall crack-resisting putty which is prepared from the following components in parts by weight. The production method comprises the following steps of: taking 13-17 parts of tap water, 0.18-0.22 part of cellulose, 9-11 parts of pure-acrylic elastic emulsion, 18-22 parts of silicon-acrylic elastic emulsion, 0.2-0.3 part of defoamer, 1-2 parts of preservative, 0.8-1.2 parts of thickener, 28-32 parts of white cement, 6-9 parts of heavy calcium carbonate and 15-19 parts of quartz powder, wherein the optimal preparation is 15 parts of tap water, 0.2 part of cellulose, 10 parts of pure-acrylic elastic emulsion, 20 parts of silicon-acrylic elastic emulsion, 0.3 part of defoamer, 1.5 parts of preservative, 1.0 part of thickener, 30 parts of white cement, 8 parts of heavy calcium carbonate and 17 parts of quartz powder; sequentially putting the tap water, the cellulose, the silicon-acrylic elastic emulsion, the pure-acrylic elastic emulsion, the defoamer, the preservative and the thickener into a reaction kettle, fully stirring for 13-17 minutes, adding the white cement, the heavy calcium carbonate and the quartz powder, stirring for 40-50 minutes until the mixture is mixed evenly, waiting for 10 minutes, and visually inspecting the required viscosity and using, wherein the particle size of the selected heavy calcium carbonate is 750-800 meshes, and the particle size of the quartz powder is 260-300 meshes.

Owner:新疆亚克希姆建材有限公司 +1

Seepage-resistant tunnel fireproof paint

InactiveCN103641497AMake up for the defect of poor waterproof functionSimple construction operationSlagCarvacryl acetate

A disclosed seepage-resistant tunnel fireproof paint is prepared by stirring the following raw materials in parts by weight: 100-105 parts of fireproof cement, 20-30 parts of portland blast furnace slag cement, 30-35 parts of acrylate polymer emulsion, 10-15 parts of vinyl acetate resin emulsion, 5-7 parts of aluminium hydroxide, 10-15 parts of perlite, 4-8 parts of fly ash, 3-4 parts of ammonium bichromate, 2-6 parts of light calcium carbonate, 10-16 parts of polypropylene short fiber, 2-6 parts of carboxymethyl cellulose, 7-9 parts of diatomite, 4-9 parts of vermiculite, 3-8 parts of ammonium polyphosphate, 5-8 parts of potter's clay and 3-5 parts of pentaerythritol. The product provided by the invention not only has good fireproof performance, but also has water seepage resistant performance, and thus makes up the disadvantage the conventional fireproof paints are bad in waterproof performance; and the fireproof paint is green, environment-friendly, strong in caking property, easy to construct and operate and excellent in comprehensive performance, and is suitable for the fields such as traffic tunnels, people's air defence buildings, underground buildings and the like.

Owner:江苏博思源防火材料科技有限公司

Method for eliminating efflorescence of magnesium oxychloride wall through magnesium sulfate

InactiveCN105884320AImproves strength and stabilityOvercome porositySolid waste managementSaw dustPerlite

The invention provides a method for eliminating efflorescence of a magnesium oxychloride wall through magnesium sulfate. The wall without efflorescence is prepared from raw materials in parts by weight as follows: 50-70 parts of a magnesium sulfate aqueous solution, 30-40 parts of magnesium oxide, 3-4 parts of a modifying agent, 0.2-0.3 parts of fly ash, 0.8-1.4 parts of surface-modified whiskers, 0.6-0.8 parts of polypropylene fibers, 0.3-0.4 parts of quartz sand, 0.6-1.2 parts of saw dust, 1-2 parts of straw and 2-4 pats of perlite. According to the wall preparation process, magnesium oxide and magnesium sulfate are taken as main raw materials, the main defect that a wall prepared from magnesium and magnesium chloride is prone to moisture absorption and efflorescence is overcome, and the prepared wall has the excellent performance of high strength, heat resistance, water resistance, thermal insulation, acid-base resistance, good surface smoothness and no efflorescence.

Owner:广东晶盈环保建材实业有限公司

Anti-bleeding, anticoagulated colloid for textile decoration printing and preparation thereof

InactiveCN101139801BImprove print outline definitionWith anti-seepage functionDyeing processTextile printerPolymer science

The invention provides a water-tight anticoagulant, which mainly comprises the raw materials that: 2-Acrylamido-2-methylpropanesulfonic, Benzenesulfonic acid, 4-ethenyl-, sodium, Methacrylic acid, propenoic acid, aqueous ammonia, Sorbitan MOnooleate, Polyoxyethylene nonyl phenyl ether, Diallyl phthalate and Styrene / alpha-methylstyrene linear body and etc. The water-tight anticoagulant is fabricated through the three steps of techniques of neutralization, emulsification and polymerization. The invention is a water-tight anticoagulant for textile material printing, and the adding volume is below 0.5 percent in printing paste or dyeing paste, so that water-tight coagulation prevention function can be fulfilled, and distinct and elegant printing patterns can be gained in dye printing paint printing. Meanwhile, the invention also has the advantages of perfect levelling power, dispersion and migration prevention, etc.

Owner:LIAONING FIXED STAR FINE CHEM

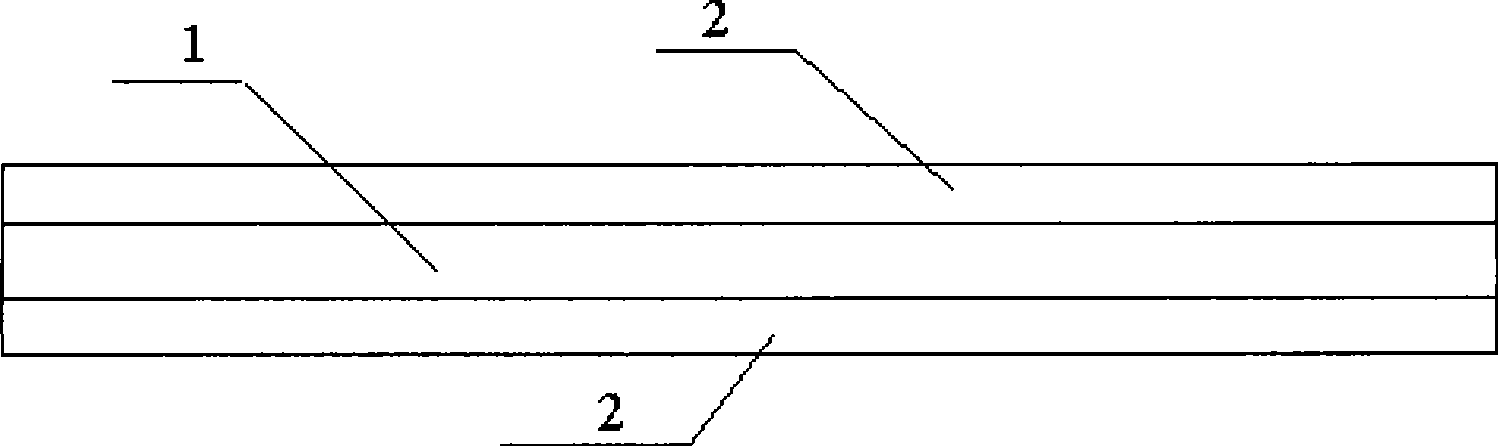

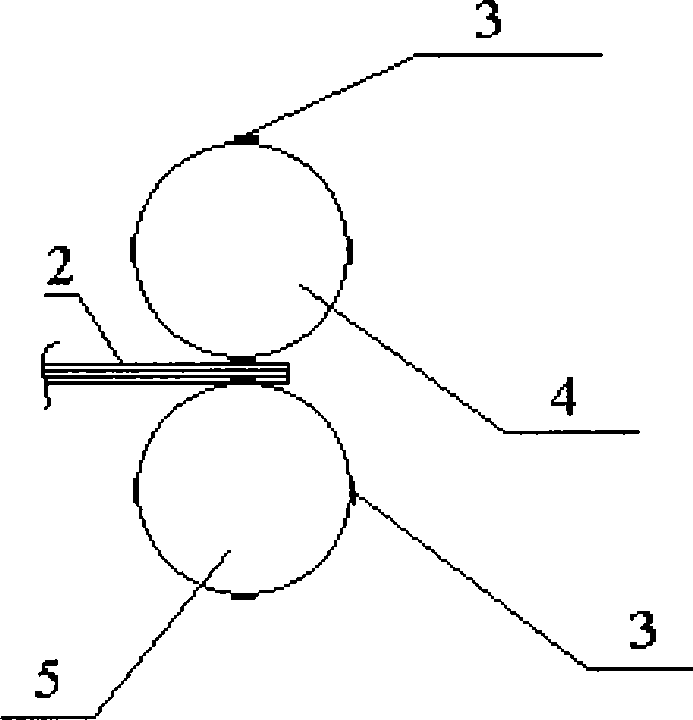

Moisture transported permeable antibacterial cushion blanket and preparation method thereof

InactiveCN101543361AMoisture-permeable, breathable and antibacterialWith anti-seepage functionBiocideStuffed mattressesPolyesterAntibiotic Agents

The invention provides a moisture-transmitting permeable antibacterial cushion blanket and a preparation method thereof. The moisture-transmitting permeable antibacterial cushion blanket comprises a water retaining permeability layer (1) and an outer layer (2) covering both the upside and the underside of the water retaining permeability layer (1). The moisture-transmitting permeable antibacterial cushion blanket is characterized in that the material of the water retaining permeability layer is polyurethane; the outer layer is needled non-woven cloth treated by an antibiotic agent; and the raw material of the needled non-woven cloth is polyester staple fiber. The moisture-transmitting permeable antibacterial cushion blanket simultaneously has the moisture-transmitting permeable antibacterial function, not only retains the soft and comfortable feeling of needled cotton, but also retains the impermeable function of rubber cushion blankets and paper liner napkins, overcomes the defect that the rubber cushion blankets and the paper liner napkins cannot be washed repeatedly, and also has the antibacterial function, thereby meeting the needs of people.

Owner:上海飞马进出口有限公司

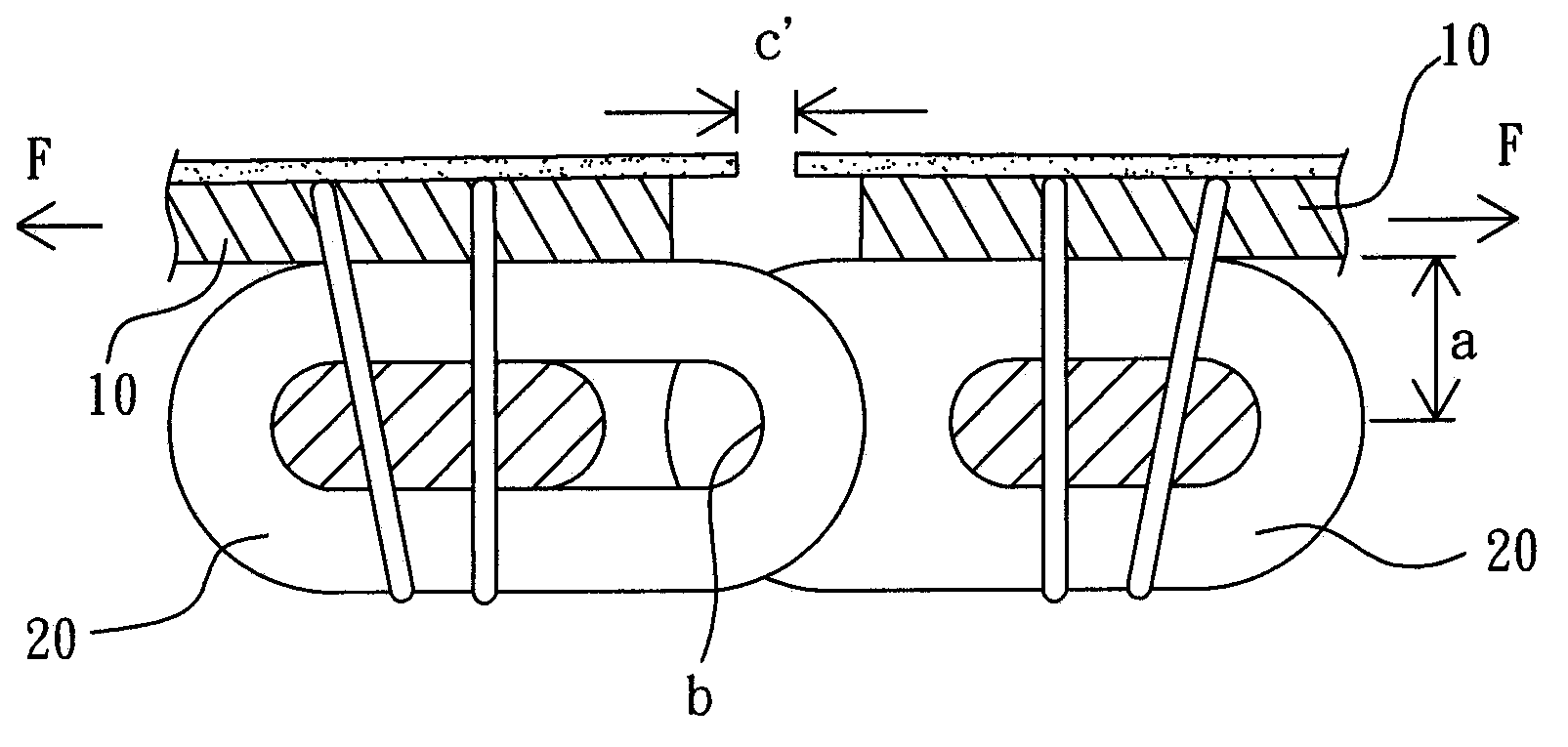

Clamping type buckling element zipper of impervious structure

The invention discloses a clamping type buckling element zipper of an impervious structure. The clamping type buckling element zipper comprises a pair of supporting cloth belts which are arrayed parallelly and laterally, two rows of clamping type buckling elements and an impervious rubber body. The two rows of clamping type buckling elements are respectively arranged on the inner edge of the first face and the inner edge of the second face of each supporting cloth belt. The impervious rubber body continually covers at least one face of the two rows of buckling elements so as to form a cover surface layer when the two rows of the buckling elements are in a buckling state, and is simultaneously injected into the interior gap of the two rows of buckling elements and the supporting cloth belts and the other face gap of the two rows of buckling elements so as to respectively form a gap filling part and an extending part. The impervious rubber body is divided from the middle of the two rows of buckling elements of the supporting cloth belts so as to enable the zipper to be buckled or separated.

Owner:周朝木

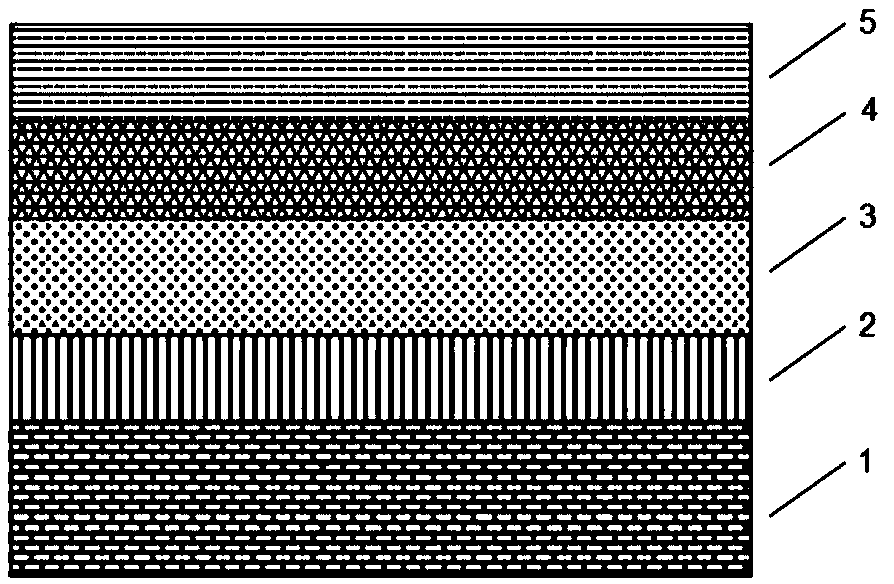

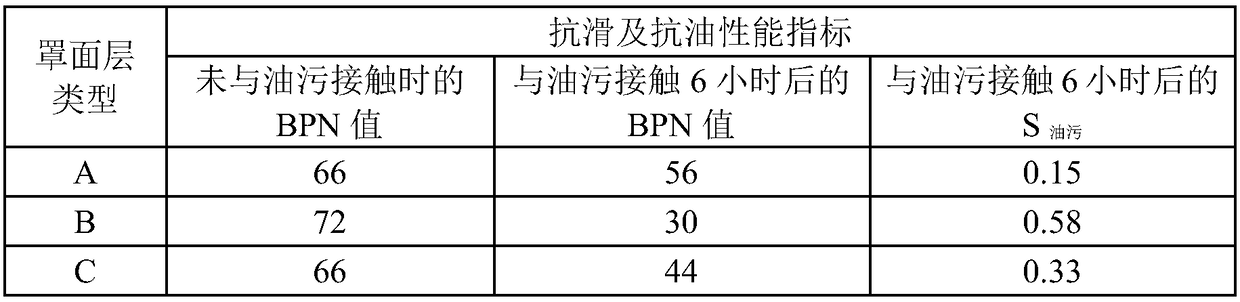

Tunnel cement concrete pavement oil-proof overlay and overlaying process thereof

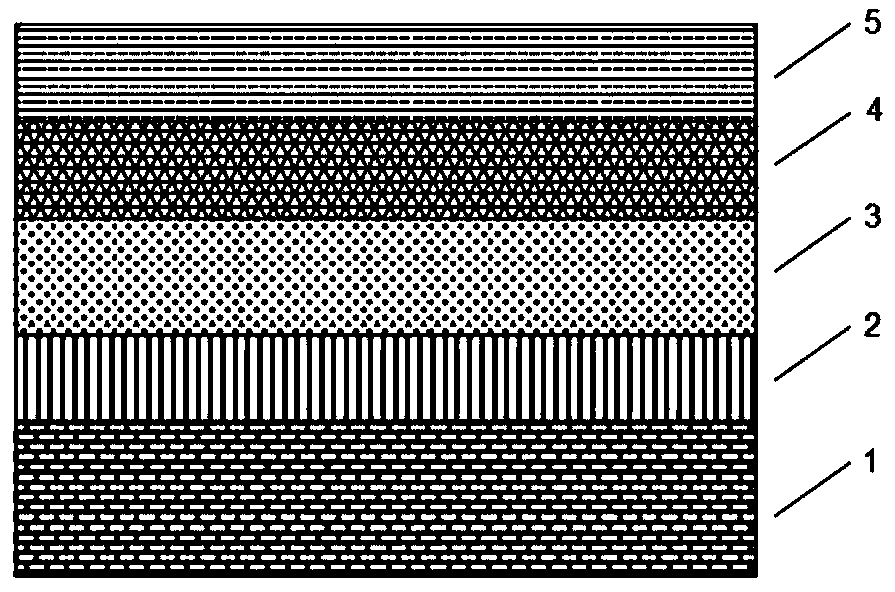

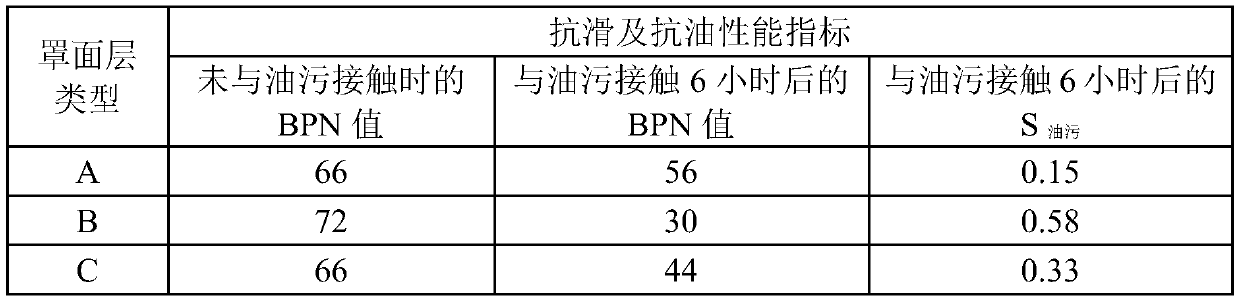

ActiveCN108842556AReduce risk of damageWith anti-seepage functionIn situ pavingsIsolation effectRoad surface

The invention provides a tunnel cement concrete pavement oil-proof overlay and an overlaying process thereof, and belongs to the technical field of road maintenance. The tunnel cement concrete pavement oil-proof overlay comprises an adhesion layer, an SMA asphalt mixture overlaying layer, a sand-containing fog sealing layer, and a waterproof and oil-proof layer; the adhesion layer, the SMA asphaltmixture overlaying layer, the sand-containing fog sealing layer and the waterproof and oil-proof layer are overlaid on the treated cement concrete pavement from bottom to top. Compared with the conventional asphalt overlay, the oil-proof overlay provided by the invention is good in water penetration resistance, the waterproof and oil-proof layer, the sand-containing fog sealing layer and the adhesion layer in the overlay structure have the water penetration resistance, the water damage risk of the pavement can be reduced; and the skidding resistance attenuation amplitude of the overlay is reduced due to the isolation effect of the waterproof and oil-proof layer under the oil contamination effect, and the recovery speed is fast.

Owner:绍兴市公路管理局

Production method of multifunctional exterior wall anti-crack putty

Owner:新疆亚克希姆建材有限公司 +1

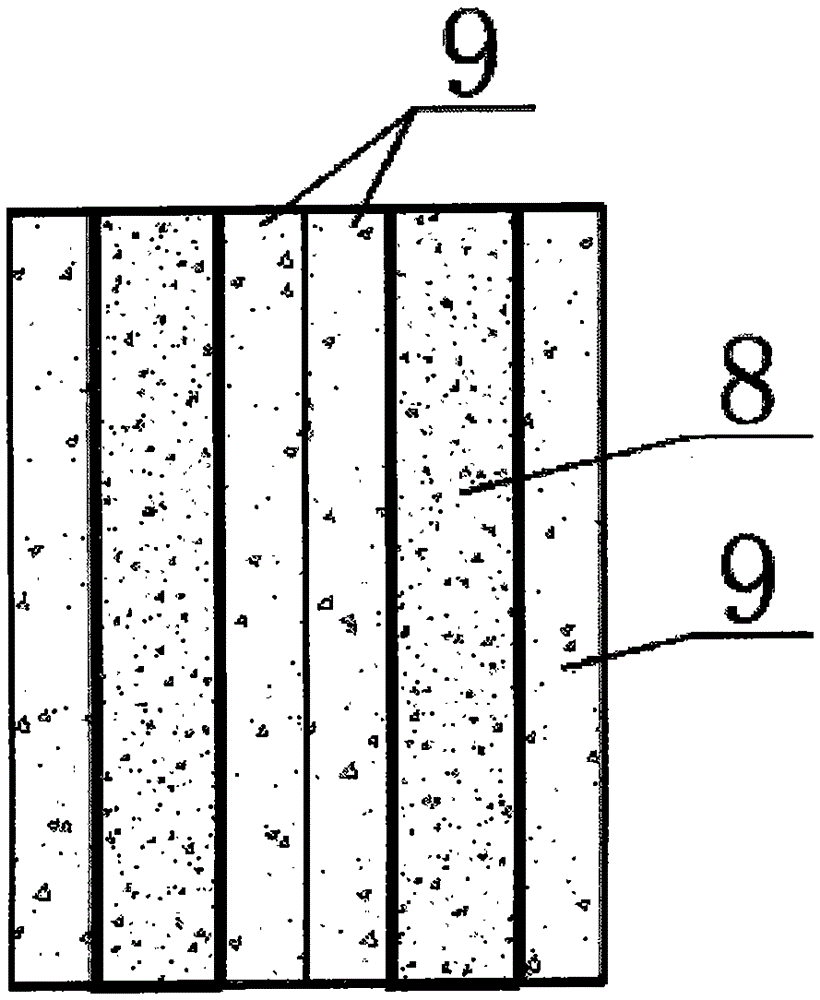

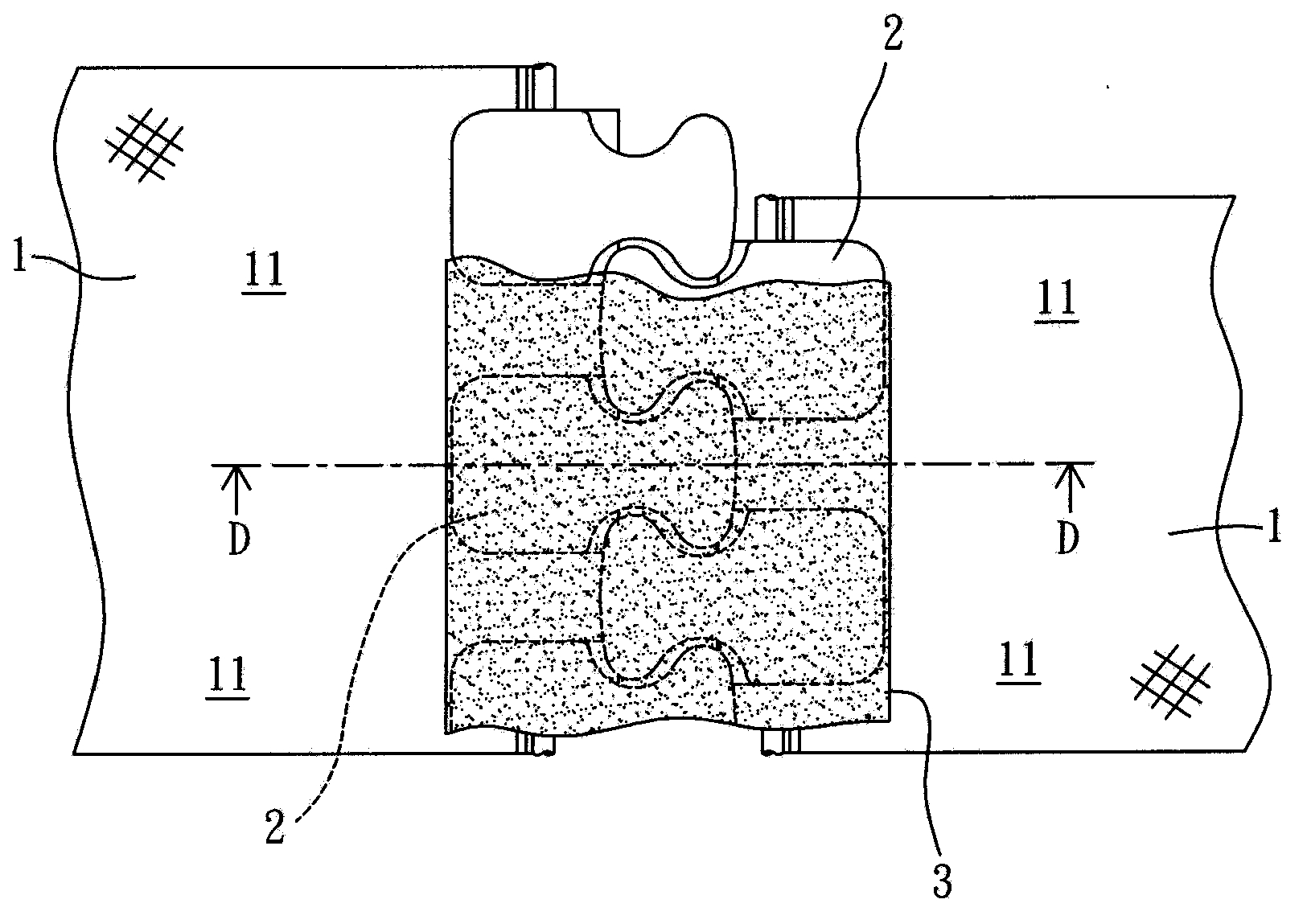

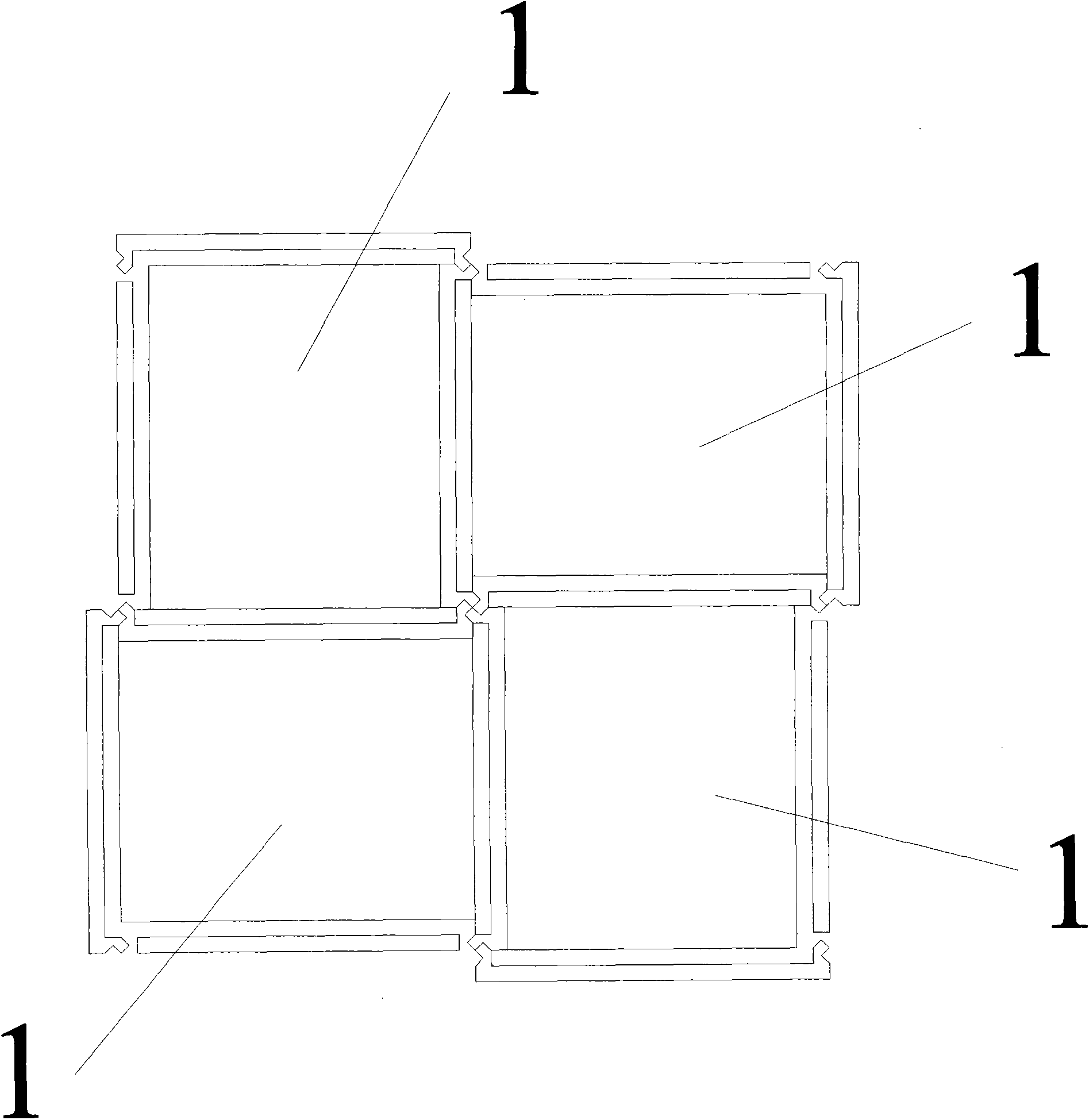

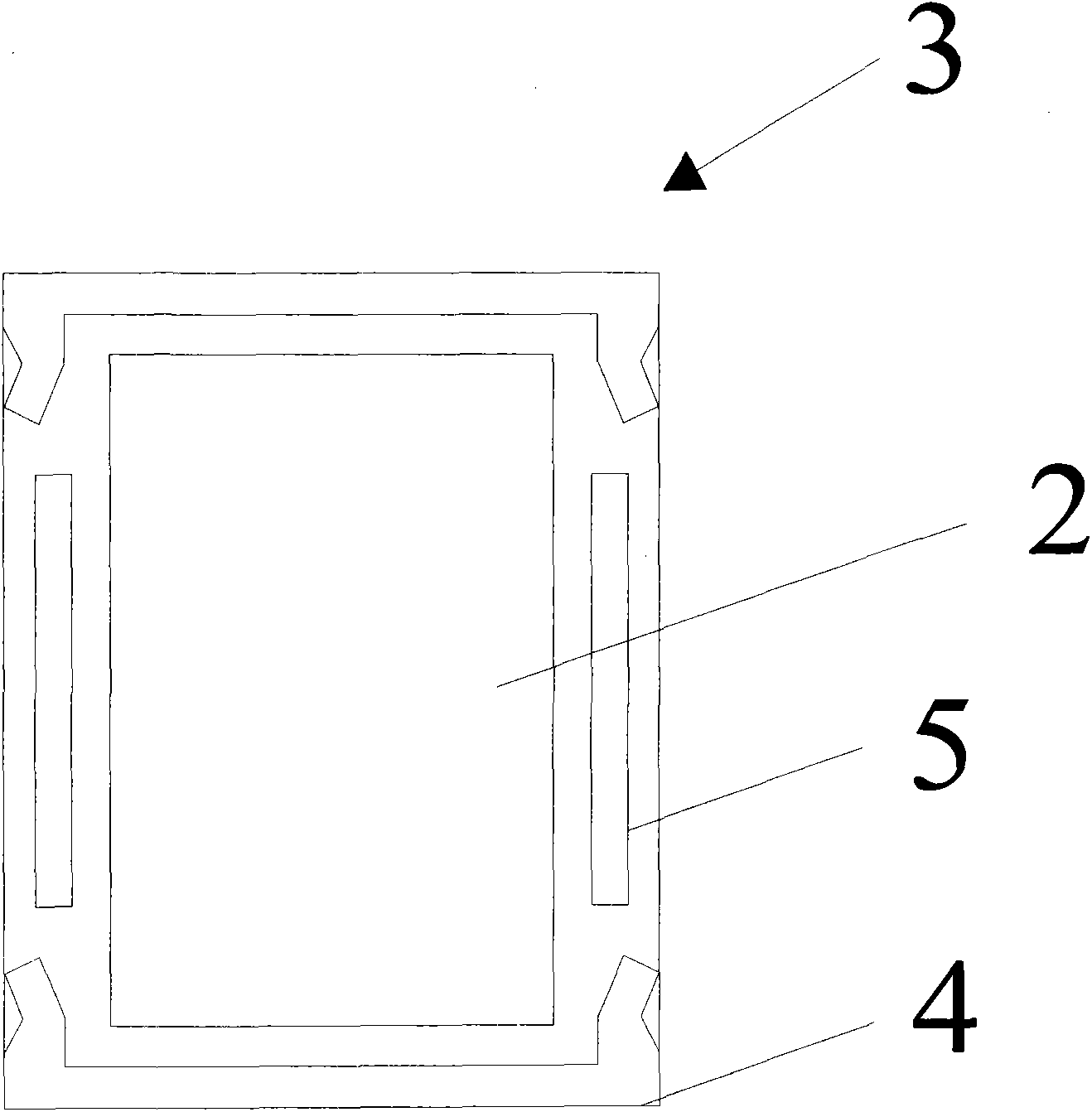

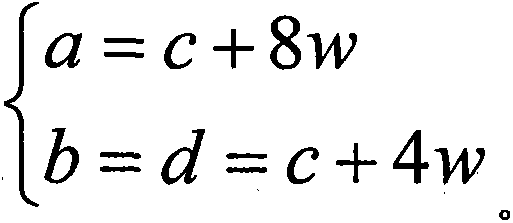

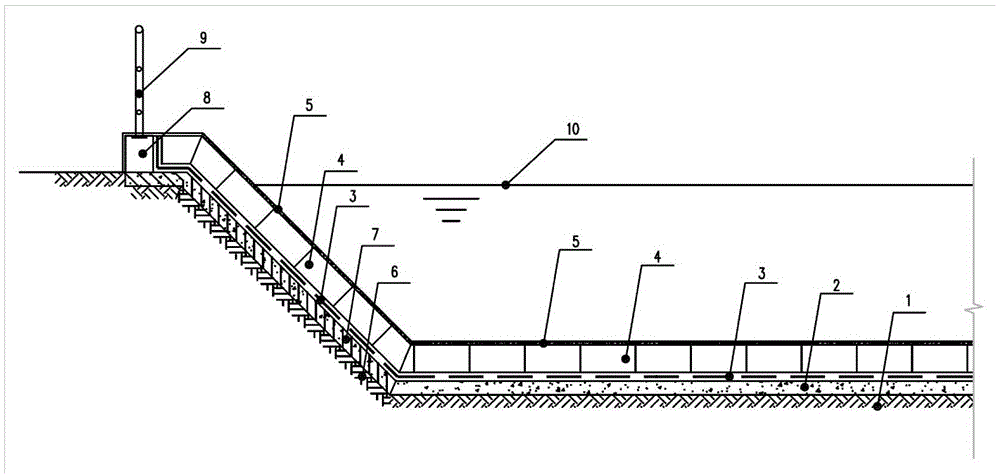

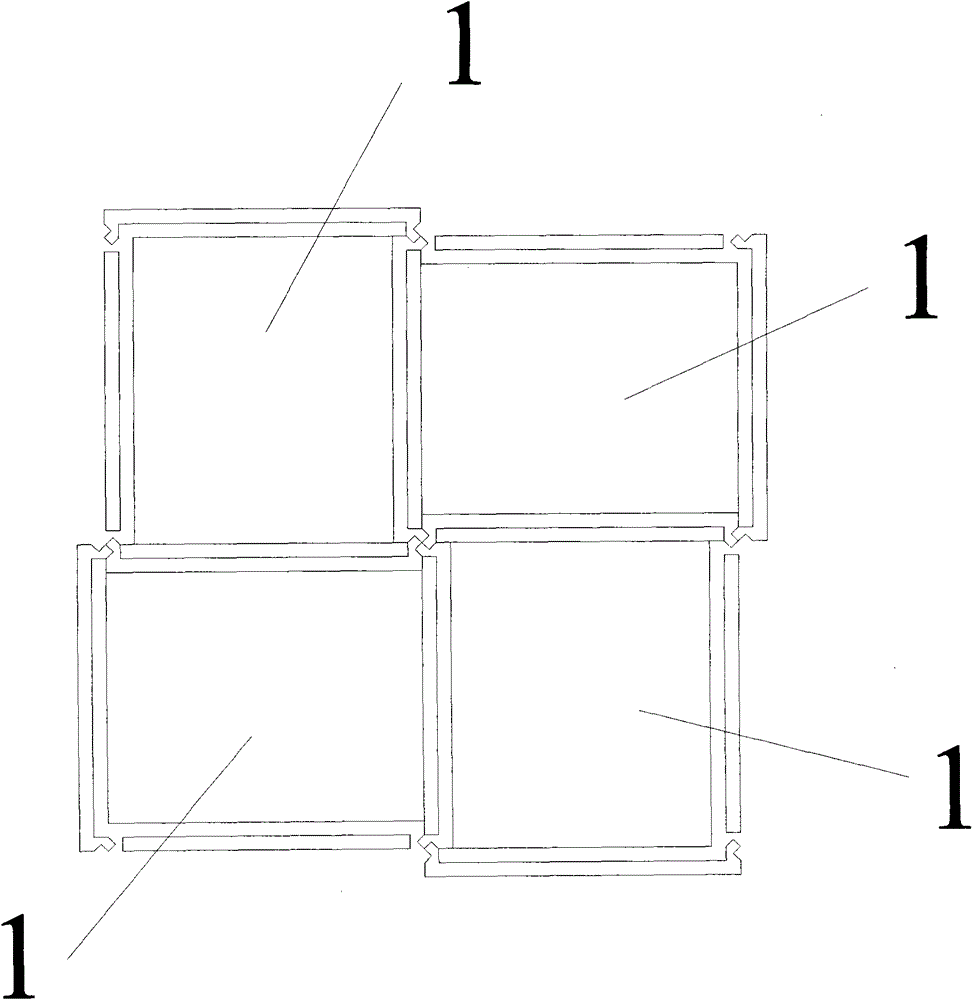

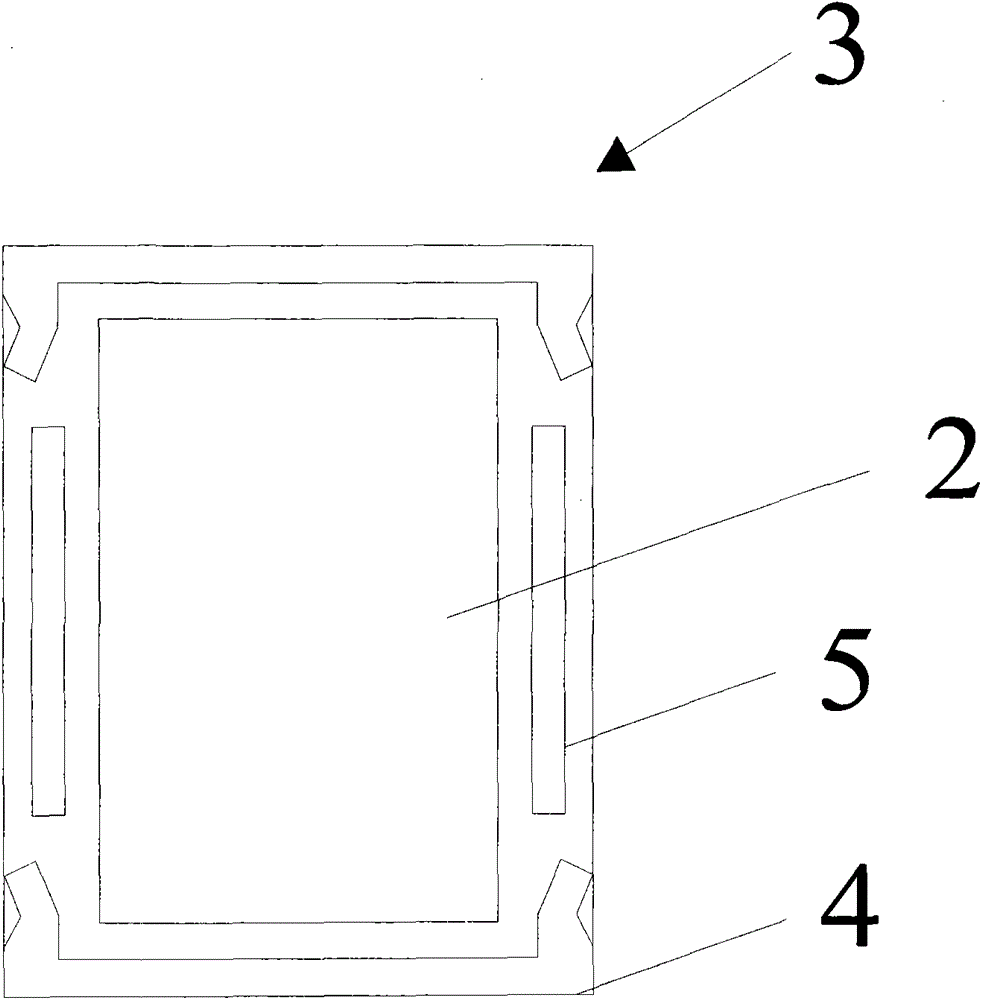

Channel anti-frostbite swelling combination type integrated seepage-proofing and thermal insulation board

InactiveCN104018469AGuaranteed stabilityAchieve reliabilityArtificial water canalsThermal insulationAgricultural engineering

The invention relates to a channel anti-frostbite swelling combination type integrated seepage-proofing and thermal insulation board. The seepage-proofing and thermal insulation board comprises a plurality of combination board bodies which are freely connected in a combined mode, wherein each combination board comprises a middle flat board structure and a peripheral connection interlocking structure, and each middle flat board structure comprises two seepage-proofing layers and a thermal insulation board body arranged between the two corresponding seepage-proofing layers; each peripheral connection interlocking structure comprises transverse beams and vertical beams, the transverse beams are arranged on the two opposite sides of the corresponding flat board structure and are of corner structures, the vertical beams are arranged on the other opposite sides of the corresponding flat board structure, the inner side of one corner structure of one combination board body makes contact with one vertical beam of one adjacent combination board body in an abutting mode, and the outer side of the corner structure of the combination board body makes contact with the outer side of one corner structure of another adjacent combination board body. The seepage-proofing and thermal insulation board has the advantages that the seepage-proofing function and thermal insulation function are integrated, and the combination technique is adopted for integrating the seepage-proofing function and thermal insulation function; the combination structure can guarantee connection stability among panels, and seepage-proofing reliability of joints of the panels can be guaranteed easily.

Owner:BEIJING IWHR KHL +1

Ecological water storage and moisture retention soil improvement composite material and preparation method thereof

ActiveCN104845632AIncrease alkalinityImprove survival rateOther chemical processesOrganic fertilisersVegetationWater storage

The invention discloses an ecological water storage and moisture retention soil improvement composite material and a preparation method thereof, and belongs to the technical field of environment engineering. The composite material contains, by weight, 100 parts of calcium bentonite, 0.1-0.5 parts of a water storage and moisture retention agent, and 0.5-1 part of ferrous sulfate. The preparation method comprises the following steps: adding calcium bentonite, the water storage and moisture retention agent and ferrous sulfate into a granulator, granulating to make the water weight percentage of 10-13% and the particle size of 1-5mm, drying, and bagging. The composite material has high water absorbency, is in favor of realizing water storage of plants, and can substantially improve the survival rate of vegetations especially when the composite material is used in saline land with the pH value of 8-10.

Owner:ELION RESOURCE GROUP

Tunnel impervious fireproof paint

InactiveCN103641423AGood fire performanceMake up for water seepageAmmonium polyphosphateSOYBEAN SEED OIL

A disclosed Tunnel impervious fireproof paint is mainly prepared by stirring the following raw materials in parts by weight: 50-60 parts of sulphoaluminate cement, 30-35 parts of AEC expansive cement, 20-24 parts soybean oil fatty acid alkyd resin, 18-24 parts of acrylate polymer emulsion, 10-12 parts of aluminium hydroxide, 5-8 parts of starch, 10-12 parts of perlite, 5-8 parts of fly ash, 10-12 parts of polypropylene short fiber, 4-8 parts of carboxymethyl cellulose, 10-15 parts of fly-ash glass microsphere, 5-9 parts of diatomite, 5-9 parts of ammonium polyphosphate and 5-8 parts of pentaerythritol. The product provided by the invention not only is good in fireproof performance, but also has water seepage resistant performance, and thus makes up the disadvantage the conventional fireproof paints are easily subjected to water seepage; and the fireproof paint is green, environment-friendly, strong in caking property, easy to construct and operate and excellent in comprehensive performance, and is suitable for the fields such as traffic tunnels, people's air defence buildings, underground buildings and the like.

Owner:上海世范乐建新材料有限公司

Tunnel Cement Concrete Pavement Oil Resistant Overlay and Overlay Technology

ActiveCN108842556BReduce risk of damageWith anti-seepage functionIn situ pavingsRoad surfaceWater damage

The invention provides a tunnel cement concrete pavement oil-proof overlay and an overlaying process thereof, and belongs to the technical field of road maintenance. The tunnel cement concrete pavement oil-proof overlay comprises an adhesion layer, an SMA asphalt mixture overlaying layer, a sand-containing fog sealing layer, and a waterproof and oil-proof layer; the adhesion layer, the SMA asphaltmixture overlaying layer, the sand-containing fog sealing layer and the waterproof and oil-proof layer are overlaid on the treated cement concrete pavement from bottom to top. Compared with the conventional asphalt overlay, the oil-proof overlay provided by the invention is good in water penetration resistance, the waterproof and oil-proof layer, the sand-containing fog sealing layer and the adhesion layer in the overlay structure have the water penetration resistance, the water damage risk of the pavement can be reduced; and the skidding resistance attenuation amplitude of the overlay is reduced due to the isolation effect of the waterproof and oil-proof layer under the oil contamination effect, and the recovery speed is fast.

Owner:绍兴市公路管理局

Anti-seepage type fireproof coating for tunnel

InactiveCN105198373AMake up for the defect of easy water seepageImprove adhesionCellulosePotassium hydroxide

The invention discloses an anti-seepage type fireproof coating for a tunnel. The anti-seepage type fireproof coating is prepared by mixing raw materials in parts by weight as follows: 80-88 parts of portland cement, 30-34 parts of baitelan cement, 20-30 parts of a styrene-acrylic emulsion, 30-35 parts of bisphenol epoxidized resin emulsion, 6-8 parts of potassium hydroxide, 10-11 parts of magnesium hydroxide, 10-14 parts of starch, 6-8 parts of ammonium dichromate, 6-8 parts of light calcium carbonate, 10-16 parts of ethyl cellulose, 5-9 parts of glass fiber, 14-18 parts of fly ash hollow floating beads, 3-5 parts of diatomaceous earth, 6-8 parts of vermiculite, 6-8 parts of mica, 6-8 parts of aluminum triphosphate, 8-10 parts of pottery clay and 5-7 parts of pentaerythritol. A product has good fireproof performance, has an anti-seepage function and makes up the defect of high probability of seepage of a conventional fireproof coating. The fireproof coating has high bonding property and excellent overall performance and is easy to use and operate during construction and suitable for the fields of traffic tunnels, civil defense, underground buildings and the like.

Owner:高科

Anti-seepage tunnel fire retardant coating

InactiveCN105218049AGood fire performanceMake up for poor waterproof functionAmmonium polyphosphatePolypropylene

The invention discloses an anti-seepage tunnel fire retardant coating which is mainly prepared by stirring the following raw materials in parts by weight: 100-105 parts of refractory cement, 20-30 parts of portland blast furnace slag cement, 30-35 parts of an acrylate polymer emulsion, 10-15 parts of an allyl acetate resin emulsion, 5-7 parts of sodium hydroxide, 10-15 parts of perlite, 4-8 parts of flyash, 3-4 parts of ammonium dichromate, 2-6 parts of light calcium carbonate, 10-16 parts of polypropylene short fiber, 2-6 parts of carboxymethylcellulose, 7-9 parts of kieselguhr, 4-9 parts of vermiculite, 3-8 parts of ammonium polyphosphate, 5-8 parts of pottery clay and 3-5 parts of pentaerythritol. The anti-seepage tunnel fire retardant coating is good in fireproof performance, and has an anti-seepage function; the defect of a poor waterproof function of the traditional fire retardant coating is compensated; the fire retardant coating is environmentally friendly, high in caking property, easy to construct and operate, good in overall performance, and suitable for the fields of traffic tunnels, civil air defence, underground buildings and the like.

Owner:陈科

Impermeable dam

InactiveCN109853469ASimple structureImprove securityDamsClimate change adaptationEngineeringPermeation

The invention provides an impermeable dam, which comprises a dam body and an impermeable structure. The dam body comprises a dam main body and a dam foundation connected with the bottom of the dam main body; and the impermeable structure covers at least part of the side wall face of the dam main body, and downwards extends to the bottom of the dam foundation, and the impermeable structure is of anintegrated structure. According to the impermeable dam, the impermeable structure covers at least part of the side wall face of the dam main body, and downwards extends to the bottom of the dam foundation, thus the dam main body and the dam foundation have impermeable functions, impermeability of the dam foundation and the dam main body is improved, and the situation that safety of the dam foundation and the dam main body is affected due to water permeation is prevented; the impermeable structure is of the integrated structure, thus through the integrated structure, the problem of contact flushing caused by the fact that impermeable structures of the dam foundation and the dam main body are made of different materials in the prior art can be effectively avoided, and the safety of the impermeable dam is effectively improved; and meanwhile, the impermeable dam is simple in structure and convenient to construct, and thus the construction cost of the impermeable dam is effectively lowered.

Owner:SHENZHEN SPRINGWOODS HLDG CO LTD

A method for anti-seepage reconstruction of sewage storage tanks in large-scale livestock and poultry farms

ActiveCN104314164BSave one-time investment costsWith anti-seepage functionSewerage structuresProtective foundationWater storage tankEngineering

The invention discloses a seepage-proof modification method for sewage storage pools of large-scale livestock and poultry farms. The pool bottom and pool walls are constructed synchronously by means of the once-forming construction process, and a seepage-proof structure employs a modification process which integrates a plain concrete cushion layer, an HPDE (high-density polyethylene) seepage-proof film and a concrete block pressure cover. Pool wall modification of the pool walls includes: modifying an all-soil storage pool, adding the plain concrete cushion layer to a compacted foundation soil layer of an original pool wall, adhering the HPDE seepage-proof film, and paving a layer of concrete blocks. Modification of a storage pool with a soil bottom and retaining walls around includes: roughening contact surfaces of original reinforced concrete retaining walls, adhering the HPDE seepage-proof films, and paving a layer of concrete blocks. Pool bottom modification includes: digging to an old soil layer, adding a plain concrete cushion layer, laying an HPDE seepage-proof film, and paving a layer of concrete blocks. The seepage-proof modification method has the advantages that seepage-proof effects can meet seepage-proof requirements of the reinforced concrete pools, the seepage-proof films can be protected effectively to prevent the problem of 'bumps' caused by rise of groundwater level, and service lives of the seepage-proof films can be prolonged greatly.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

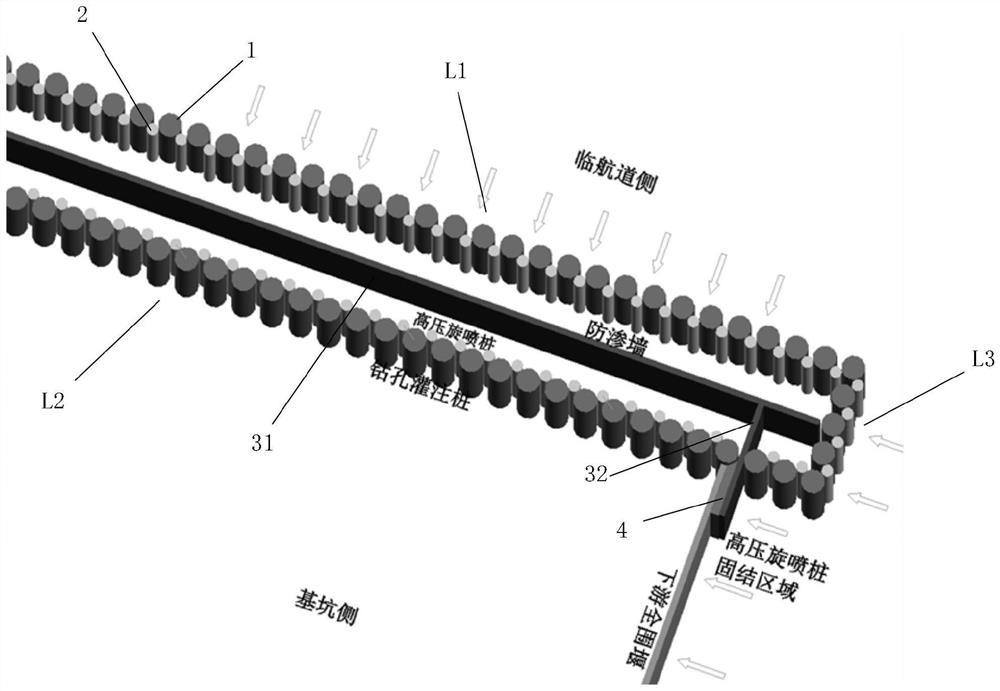

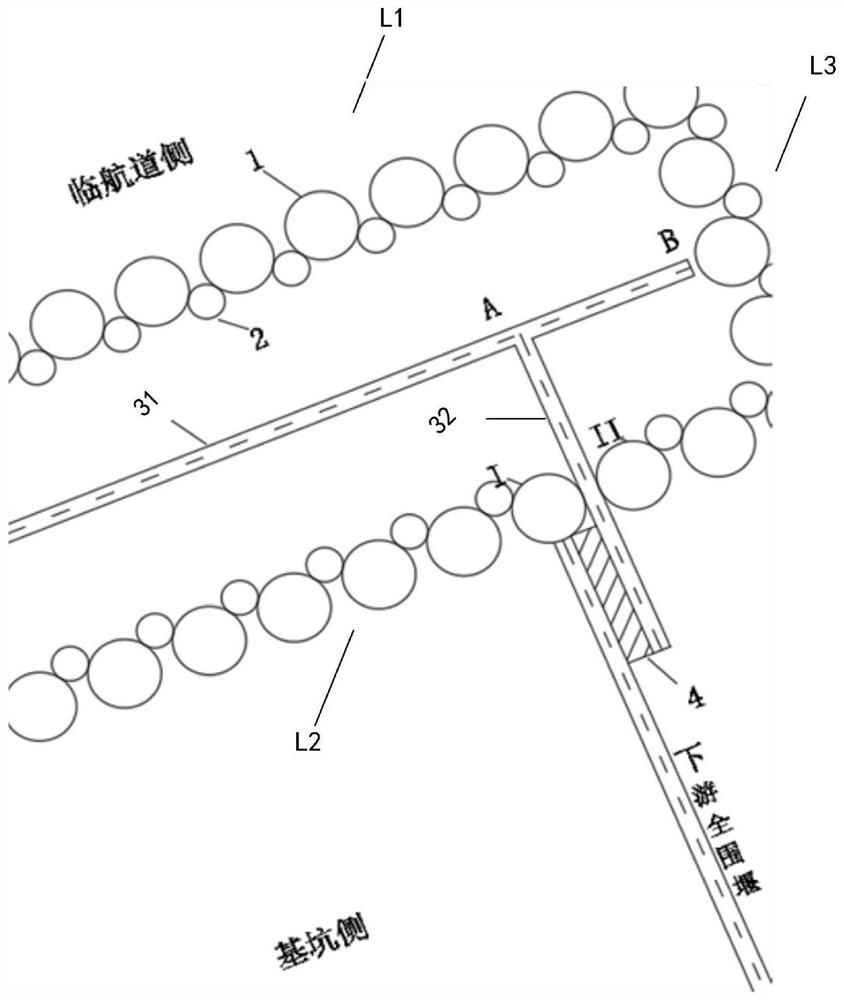

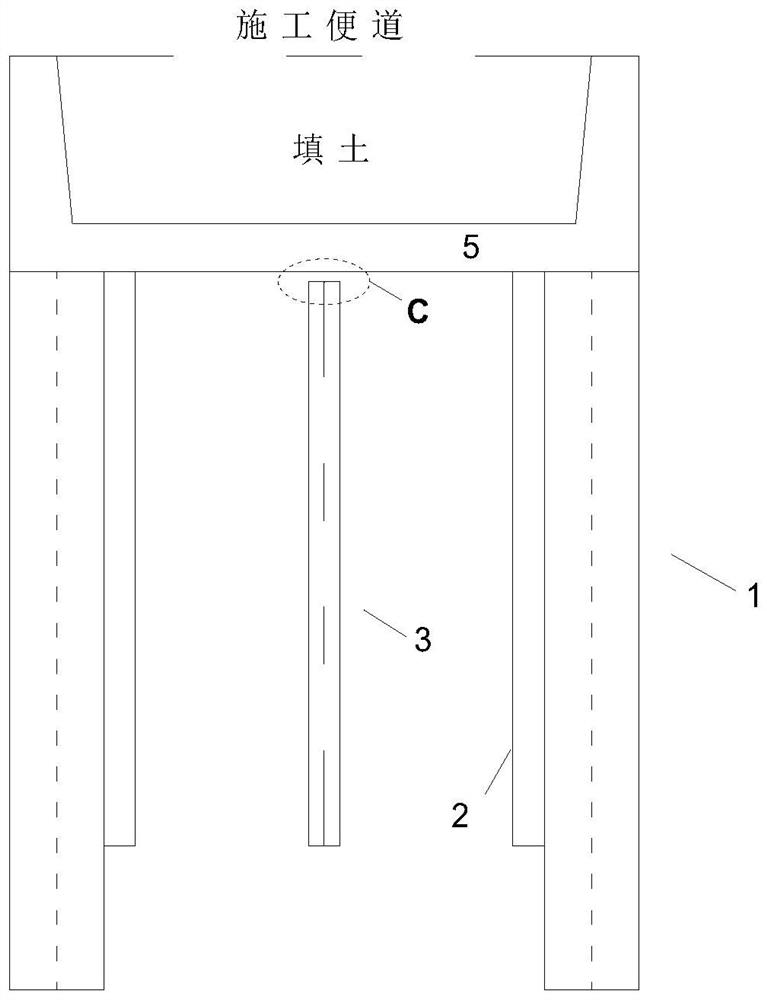

Comprehensive anti-seepage system of near-channel construction shortcut and construction method

PendingCN114673185ASolve the problem of water seepage gapAvoid affecting the anti-seepage effectBulkheads/pilesLap jointCofferdam

The invention discloses a comprehensive anti-seepage system for a near-channel construction shortcut, which adopts row piles formed by combining cast-in-situ bored piles and high-pressure jet grouting piles, and comprises front-row piles close to a near-channel side, rear-row piles close to a foundation pit side, and a main anti-seepage wall arranged in the front-row piles and the rear-row piles along the extending direction of the row piles; the end parts of the front-row piles and the rear-row piles are in closed connection through side-row piles; the main anti-seepage wall extends to the side row piles in the direction of the side row piles at the inflection point of the edge of the foundation pit; the main anti-seepage wall extends towards the rear-row piles at the inflection point of the edge of the foundation pit in the direction perpendicular to the main anti-seepage wall, and an auxiliary anti-seepage wall is formed. The auxiliary diaphragm wall penetrates through the rear-row piles and is in parallel lap joint with the downstream full-cofferdam diaphragm wall on the outer side of the foundation pit, and the lap joint area is subjected to soil consolidation through high-pressure rotary jet grouting; the top elevation of the main diaphragm wall is lower than the bottom elevation of the upper structure, and the main diaphragm wall and the upper structure are flexibly connected. The safety and reliability of the comprehensive anti-seepage system of the near-channel construction shortcut are improved.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD +2

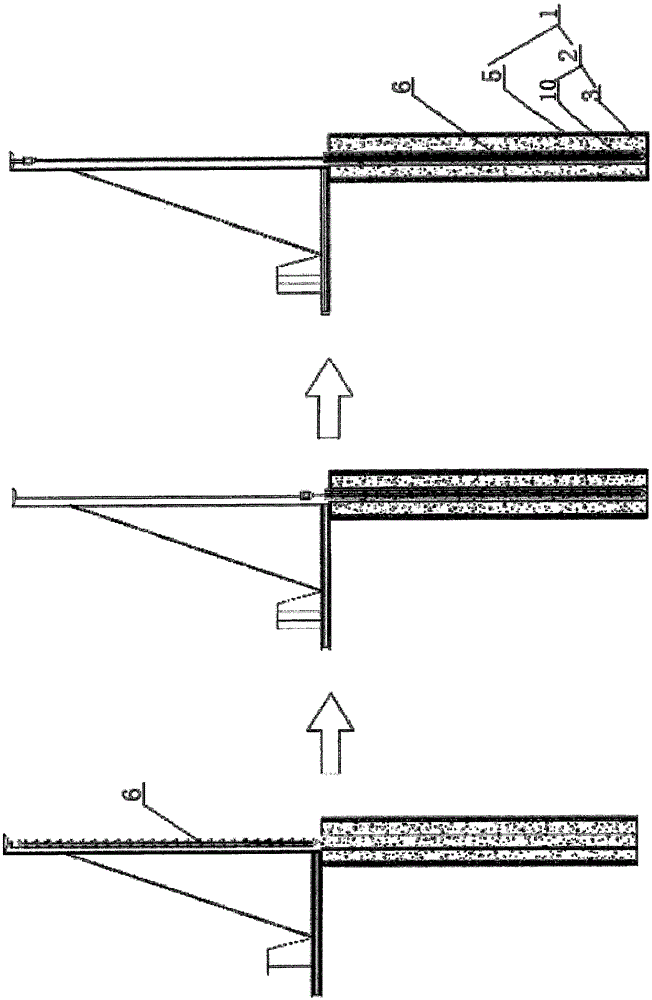

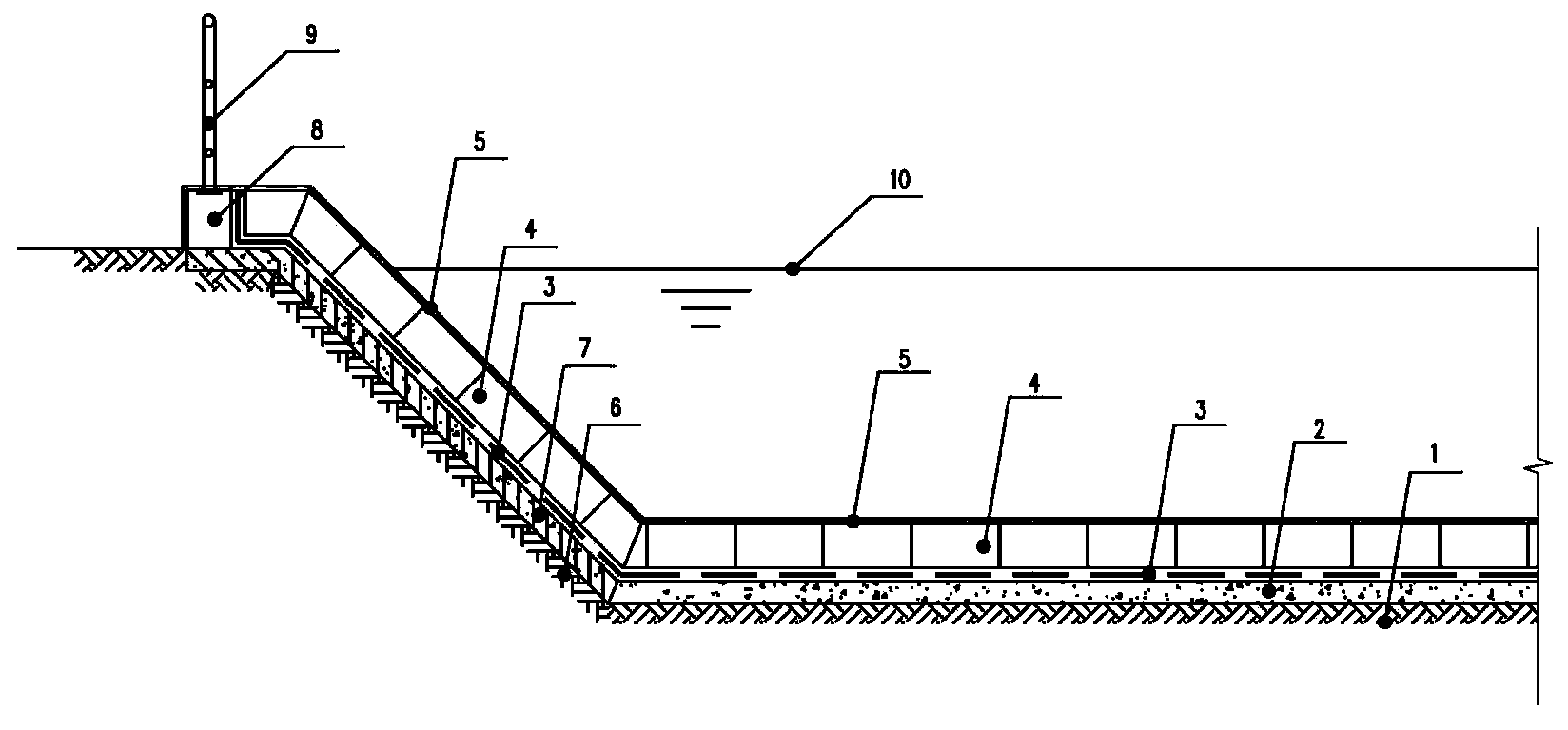

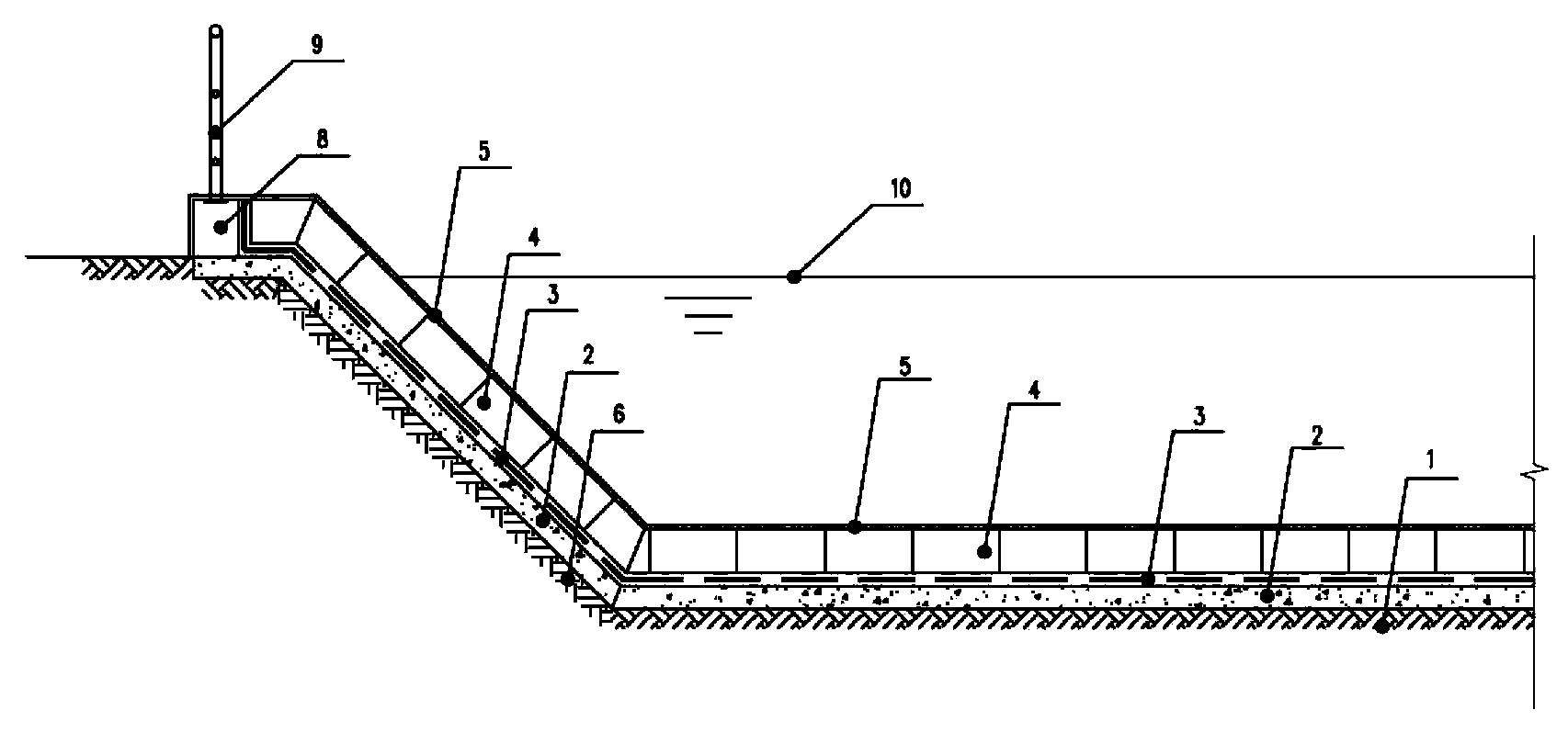

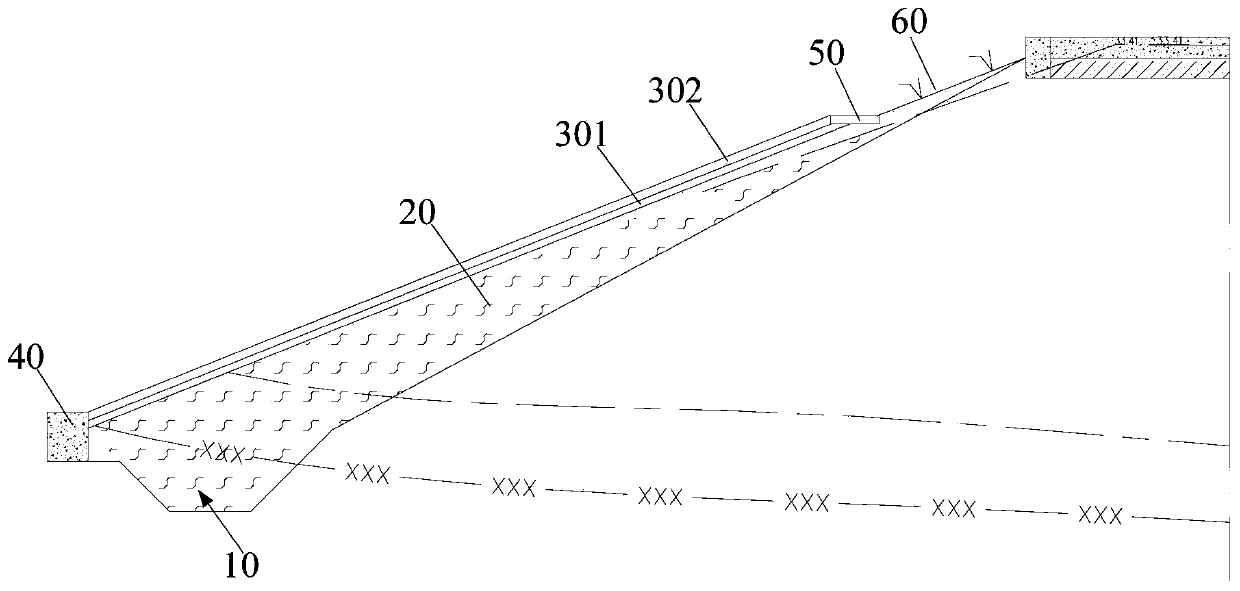

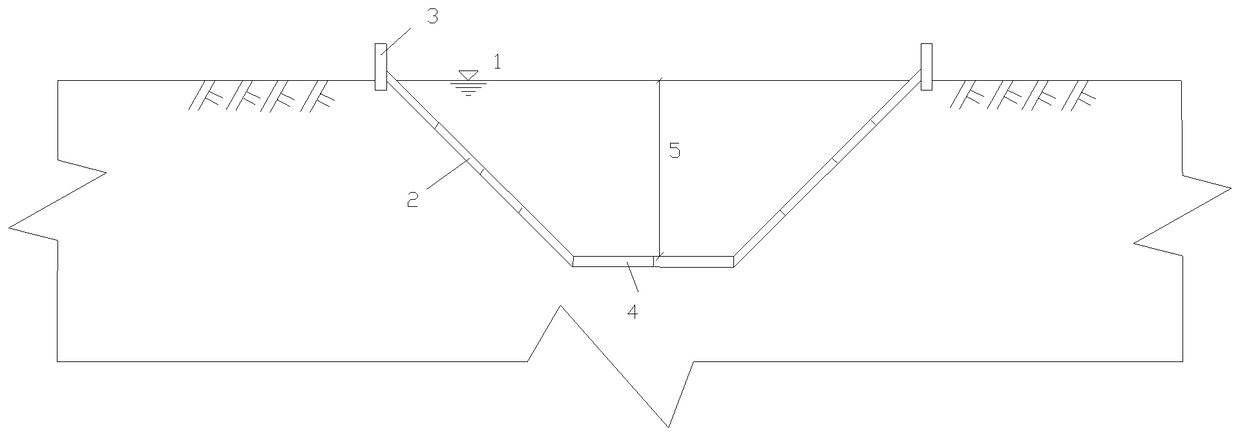

Method to Eliminate Frost Heave Damage Effect of Water Conveyance Channels without Ice Cover and High Water Level Operation in Seasonal Frozen Soil Areas in Winter

ActiveCN106759123BImprove the ability to resist frost heave damageEasy constructionArtificial water canalsFoundation engineeringEngineeringWater level

The invention relates to a method for avoiding frost heaving damage of a water delivery canal applied to a seasonally-frozen soil region and particularly relates to a method for eliminating a frost heaving damage effect of a water delivery canal having no ice covers in winter and operating at a high water level in a seasonally-frozen soil region. The method comprises: 1) the cross section of a rigid lined canal of the water delivery canal adopts a composite section way, the section below the top surface of a canal bank or a canal embankment is a trapezoidal section, and the section above the canal bank or the canal embankment is a rectangular section; 2) water in the canal plays a role in preserving the heat of canal foundation soil according to the characteristic of high specific heat capacity of the water in the canal, so that the aim that the canal foundation soil is not frozen in the whole winter is achieved, the frost heaving of the water delivery canal is eliminated, and the water level surface in the canal in the whole winter is not lower than the top surface of the canal bank or the canal embankment; and 3) no soil is provided at the outer side of a straight water retaining wall canal on the rectangular section of the canal, namely no soil is provided at the rear of the straight water retaining wall above the top surface of the canal bank or the canal embankment, so that the straight water retaining wall naturally has no the frost heaving effect. By using the method, the frost heaving effect of the canal foundation soil to a rigid lining layer of the canal is eliminated, and a rigid lining plate of the canal can be prefabricated, so that the commercialization of a canal concrete product is realized; and the canal can be built by water-running construction, so that the construction period can be shortened.

Owner:SHIHEZI UNIVERSITY

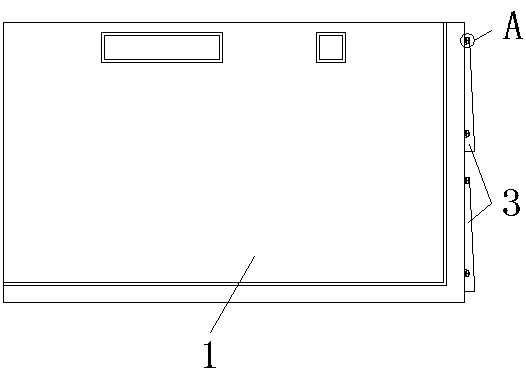

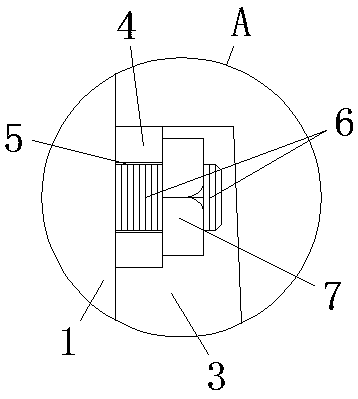

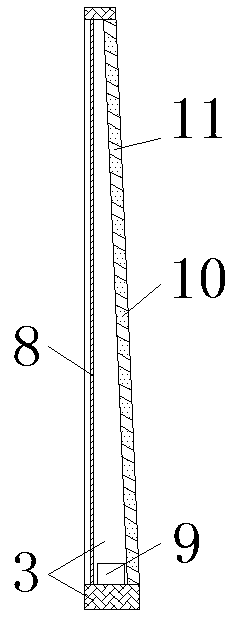

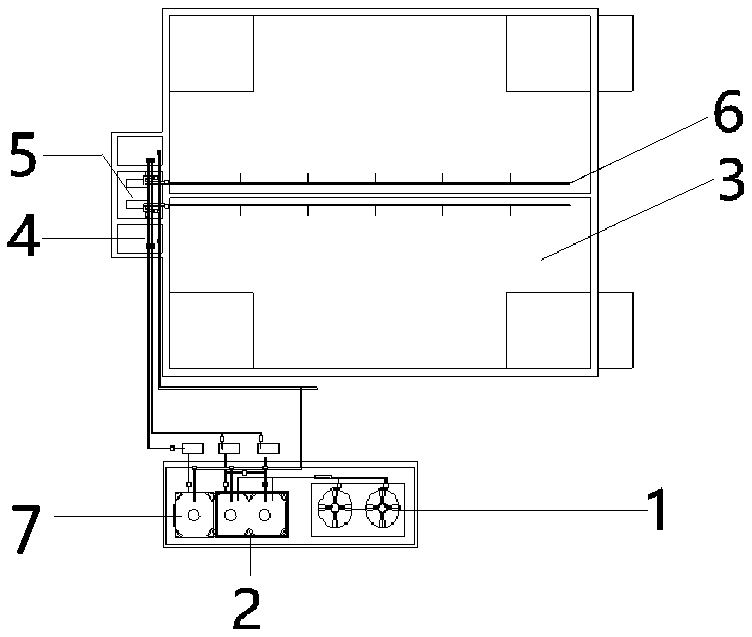

Big data host with water seepage prevention function

InactiveCN110928383AWith anti-seepage functionReduce the chance of infiltrationDigital processing power distributionWater seepageStructural engineering

The invention discloses a big data host with a water seepage prevention function. The big data host comprises a big data host body, heat dissipation holes and a breathable layer, wherein the heat dissipation holes are formed in the right surface of the big data host main body; an outer frame is arranged on the right surface of the big data host main body; a fixing plate is fixedly installed on theouter surface of the big data host main body; a connecting groove is formed in the fixing plate; the connecting groove is connected with a positioning shaft; the positioning shaft is fixedly installed on the right surface of the big data host main body; the positioning shaft penetrates through the connecting groove to be connected with a lantern ring; and the breathable layer is arranged in the outer frame. For the big data host with a water seepage prevention function, the heat dissipation holes formed in the right surface of the big data host main body can conduct protection work through the outer frame and the side plate, and when water accidentally falls to the right side of the big data host main body, the water can slide downwards through the side plate of the inclined structure, and meanwhile the seepage probability of the water can be reduced through the through holes of the inclined structure in the side plate.

Owner:盐城吉研智能科技有限公司

An anti-seepage type tunnel fireproof coating

InactiveCN103641409BMake up for the defect of easy water seepageImprove adhesionCelluloseAluminium hydroxide

A disclosed impervious tunnel fireproof paint is prepared by stirring the following raw materials in parts by weight: 80-88 parts of refractory cement, 30-34 parts of portland cement, 20-30 parts of styrene acrylic emulsion, 30-35 parts of bisphenol epoxy resin emulsion, 6-8 parts of aluminium hydroxide, 10-11 parts of magnesium hydroxide, 10-14 parts of starch, 6-8 parts of ammonium bichromate, 6-8 parts of light calcium carbonate, 10-16 parts of ethyl cellulose, 5-9 parts of glass fibre, 14-18 parts of coal flying ash cenosphere, 3-5 parts of diatomite, 6-8 parts of vermiculite, 6-8 parts of mica, 6-8 parts of aluminum tripolyphosphate, 8-10 parts of potter's clay and 5-7 parts of pentaerythritol. The product provided by the invention not only is good in fireproof performance, but also has water seepage resistant performance, and thus makes up the disadvantage that the conventional fireproof paints are easily subjected to water seepage; and the fireproof paint is strong in caking property, easy to construct and operate and excellent in comprehensive performance, and is suitable for the fields such as traffic tunnels, people's air defence buildings, underground buildings and the like.

Owner:上海世范乐建新材料有限公司

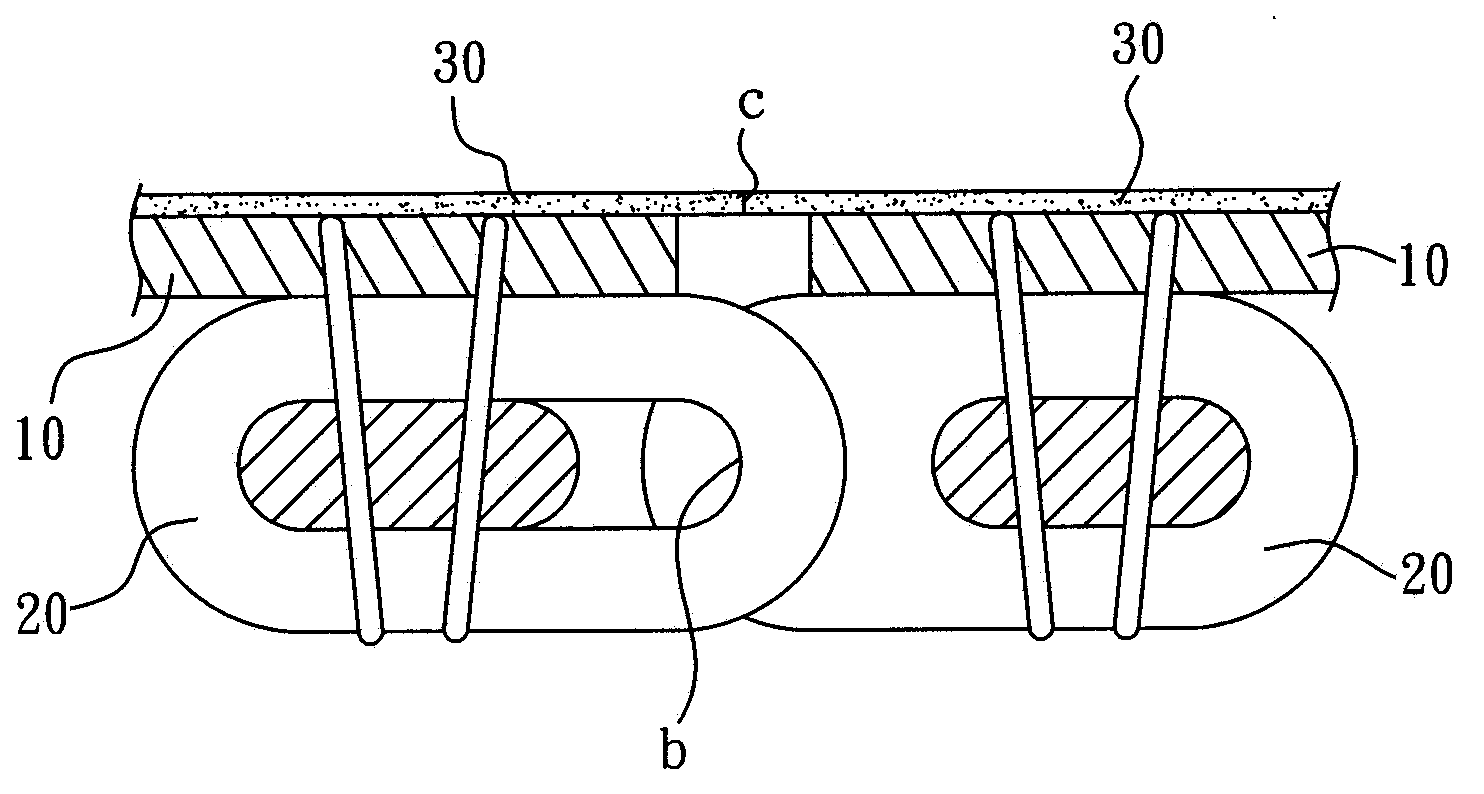

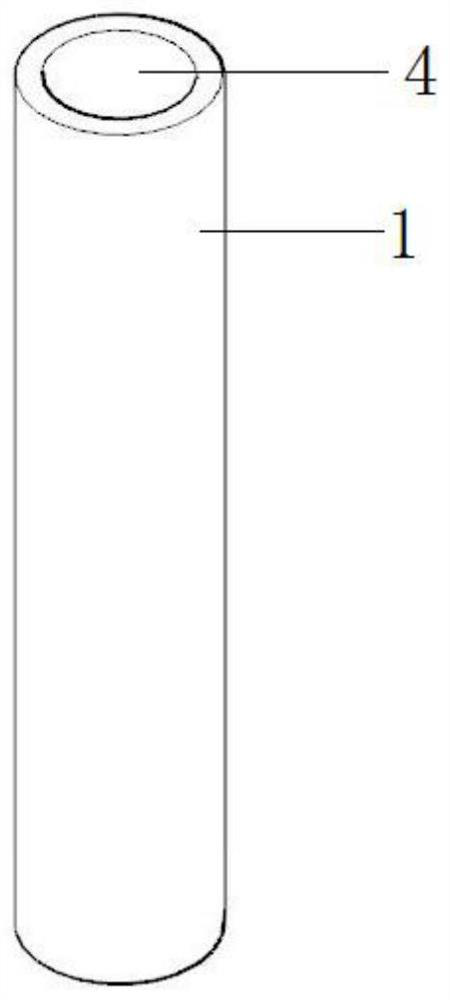

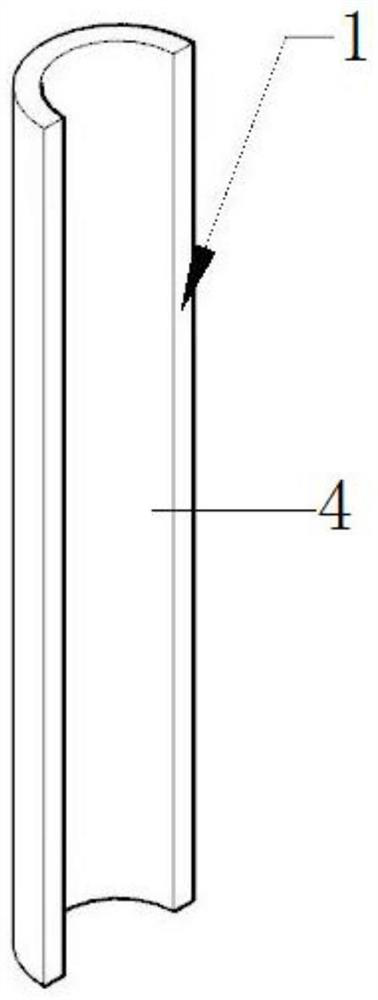

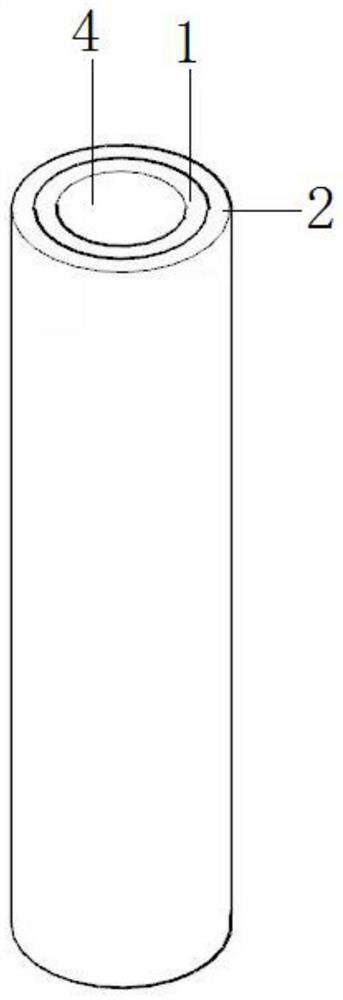

Curled aerosol generating section and aerosol generating product comprising same

PendingCN114009841AMeet the needs of high smoke productionSmooth releaseTobaccoMetallic materialsMetal powder

The invention discloses a curled aerosol generating section and an aerosol generating product comprising the same. The curled aerosol generating section is formed by curling an aerosol generating sheet towards the axial center, and an axial airflow channel (4) is arranged in the curled aerosol generating section; and the aerosol generating sheet comprises an aerosol generating substrate layer (1). Compared with an existing reconstituted tobacco sheet, the aerosol generating sheet can contain more smoke agents and metal powder, in addition, the aerosol generating sheet further comprises one or more functional layers, the functional layers are metal material layers (2) or impermeable layers (3), the aerosol generating sheet is formed after the direct metal material layers (2) are attached to the aerosol generating base material, and then the aerosol generating sheet is rolled to form the curled aerosol generating section, so that the problems that in the prior art, an electromagnetic aerosol generating product added with metal powder or a metal rod is non-uniform in heating, the center of the aerosol generating section is excessively heated, and the periphery is insufficiently heated can be solved.

Owner:YUNNAN XIKE TECH CO LTD

A kind of anti-seepage fireproof coating for tunnel

InactiveCN103641423BMake up for the defect of easy water seepageImprove adhesionFiberAluminium hydroxide

A disclosed Tunnel impervious fireproof paint is mainly prepared by stirring the following raw materials in parts by weight: 50-60 parts of sulphoaluminate cement, 30-35 parts of AEC expansive cement, 20-24 parts soybean oil fatty acid alkyd resin, 18-24 parts of acrylate polymer emulsion, 10-12 parts of aluminium hydroxide, 5-8 parts of starch, 10-12 parts of perlite, 5-8 parts of fly ash, 10-12 parts of polypropylene short fiber, 4-8 parts of carboxymethyl cellulose, 10-15 parts of fly-ash glass microsphere, 5-9 parts of diatomite, 5-9 parts of ammonium polyphosphate and 5-8 parts of pentaerythritol. The product provided by the invention not only is good in fireproof performance, but also has water seepage resistant performance, and thus makes up the disadvantage the conventional fireproof paints are easily subjected to water seepage; and the fireproof paint is green, environment-friendly, strong in caking property, easy to construct and operate and excellent in comprehensive performance, and is suitable for the fields such as traffic tunnels, people's air defence buildings, underground buildings and the like.

Owner:上海世范乐建新材料有限公司

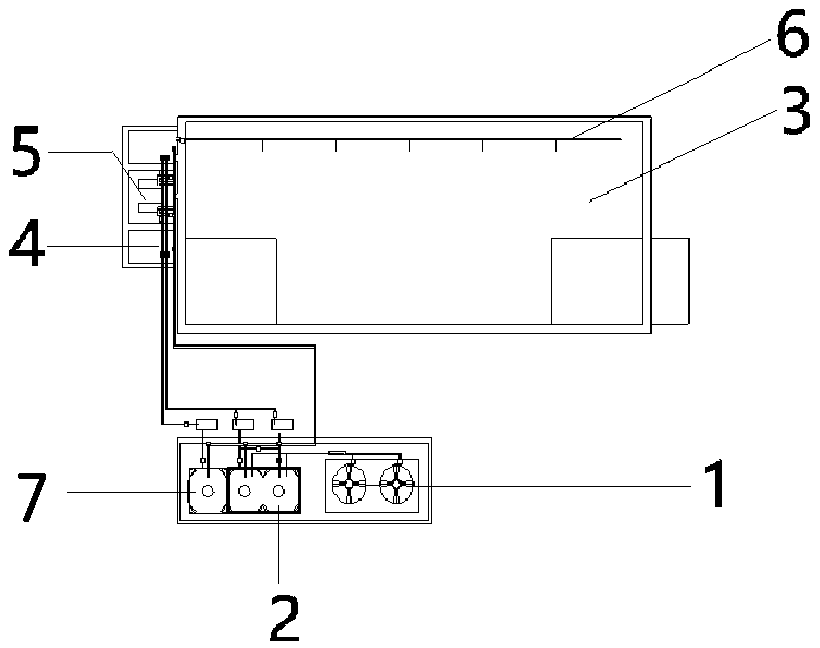

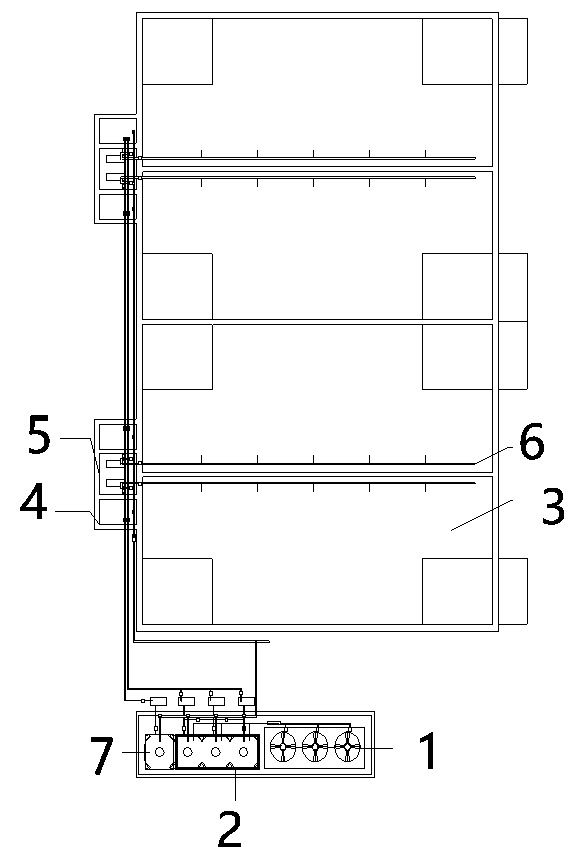

Immersion cleaning system and immersion cleaning method thereof for chromium-polluted building garbage

PendingCN109092870AReasonable designDesign specificationConstruction waste recoverySolid waste disposalSulfateLiquor store

The invention discloses an immersion cleaning system and an immersion cleaning method thereof for chromium-polluted building garbage. The immersion cleaning system comprises sulphuric acid storing jars, alkali liquor storing jars, medicament stirring jars, a water retaining and discharging tank, pump tanks, an immersion cleaning tank body of which the section is rectangular, and a medicine distributing pipeline, wherein an acid discharging opening is formed in one side of each sulphuric acid storing jar, a discharging opening is formed in the other side of each sulphuric acid storing jar, andthe discharging opening of each sulphuric acid storing jar is connected with a first feeding opening of each medicament stirring jar through a pipeline; a second feeding opening for adding ferrous sulfate and a water inlet opening are also formed in the top of each medicament stirring jar; the immersion cleaning bank body is arranged on one side of the water retaining and discharging tank; and themedicine distributing pipeline is arranged along the long edge of one side of the immersion cleaning tank body. Treating liquid after immersion cleaning of garbage flows back into the water retainingand discharging tank from the discharging opening of the immersion cleaning tank body, and is drained out through a waste liquid pipeline arranged at the bottom of the water retaining and dischargingtank. The treatment period is short, the technological process is complete, the immersion cleaning course is simple and convenient to operate, and the repair effect is good. The immersion cleaning tank body has a leakproof function, and in the immersion cleaning course, liquid medicaments form liquid seal on the building garbage, so that dust raising is avoided.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

A combined integrated anti-seepage insulation board for channel anti-freeze heave

InactiveCN104018469BGuaranteed stabilityAchieve reliabilityArtificial water canalsBeam angleEngineering

The invention relates to a channel frost-heave combined integrated anti-seepage insulation board. The anti-seepage insulation board includes a plurality of composite panels connected in any combination. Each composite panel includes a central plate structure and a peripheral connection interlocking structure. The flat plate structure includes two layers of anti-seepage layers and insulation boards arranged between the two layers of anti-seepage layers; the peripheral connection interlocking structure includes beams with curved angle structures arranged on the opposite sides of the flat plate structure, and installed on the other side of the flat plate structure Vertical beams on opposite sides, wherein the inner side of the angled structure of one composite panel is in pressure contact with the vertical beam of the adjacent composite panel, and the outer side is in pressure contact with the outer side of the angled structure of the other adjacent composite panel . The beneficial effects of the present invention are: anti-seepage and thermal insulation functions are integrated, and composite technology is adopted, which not only has the anti-seepage function, but also has the thermal insulation function; the combined structure can ensure the stability of the connection between the boards, and can simply Realize the reliability of sheet joint seepage prevention.

Owner:BEIJING IWHR KHL +1

Airtight earthwork throwing and filling construction process

InactiveCN112554196AWith anti-seepage functionImprove anti-seepage performanceSoil-shifting machines/dredgersEmbankmentsOpen seaSoil science

The invention relates to an airtight earthwork throwing and filling construction process. The airtight earthwork throwing and filling construction process comprises the following steps of (S1) preparing for construction: collecting basic data, and defining a measurement control point and a reference point of a project; (S2) dividing a soil sampling area; (S3) constructing soil retaining plates: constructing a plurality of soil retaining plates near the side, which deviates from the open sea side, of a main levee, and forming gaps between every two adjacent soil retaining plates; (S4) excavating mud flat sludge: excavating in a shallow excavation and wide extraction mode; (S5) performing airtight earthwork throwing and filling construction: firstly, pumping airtight earthwork in throwing and filling areas between the soil retaining plates and the main levee, then throwing and filling the airtight earthwork in throwing and filling areas between the adjacent soil retaining plates, finally, throwing and filling the airtight earthwork in throwing and filling areas between a sub levee and the soil retaining plates, and propelling according to the principle of thin-layer alternate addingand balanced ascending; (S6) detecting and supplementing to throw; and (S7) performing slope arrangement: repairing the slope of the airtight earthwork after the airtight earthwork is solidified. Theconstruction process of the airtight earthwork has the effect of improving the anti-seepage performance of the main levee.

Owner:浙江河海建设有限公司

A kind of anti-seepage and fireproof coating for tunnel

InactiveCN103641422BGood fire performanceMake up for poor waterproof functionHydroxypropylmethyl celluloseEmulsion

A disclosed tunnel impermeable fireproof paint is prepared mainly by stirring the following raw materials in parts by weight: 20-30 parts of refractory cement, 100-105 parts of sulphoaluminate cement, 30-35 parts of portland cement, bisphenol epoxy resin emulsion, 30-35 parts of polyacrylic acid emulsion, 6-8 parts of magnesium hydroxide, 6-8 parts of starch, 4-8 parts of ammonium bichromate, 5-9 parts of light calcium carbonate, 10-15 parts of hydroxypropyl methyl cellulose, 6-8 parts of glass hollow floating beads, 5-9 parts of diatomite, 10-14 parts of vermiculite, 5-9 parts of aluminium stearate, 10-14 parts of mica and 10-14 parts of potter's clay. The product provided by the invention not only is good in fireproof performance, but also has water seepage resistant performance, and thus makes up the disadvantage the conventional fireproof paints are bad in waterproof performance; and the fireproof paint is green, environment-friendly, easy to construct and operate and excellent in comprehensive performances, and is suitable for the fields such as traffic tunnels, people's air defence buildings, underground buildings and the like.

Owner:上海世范乐建新材料有限公司

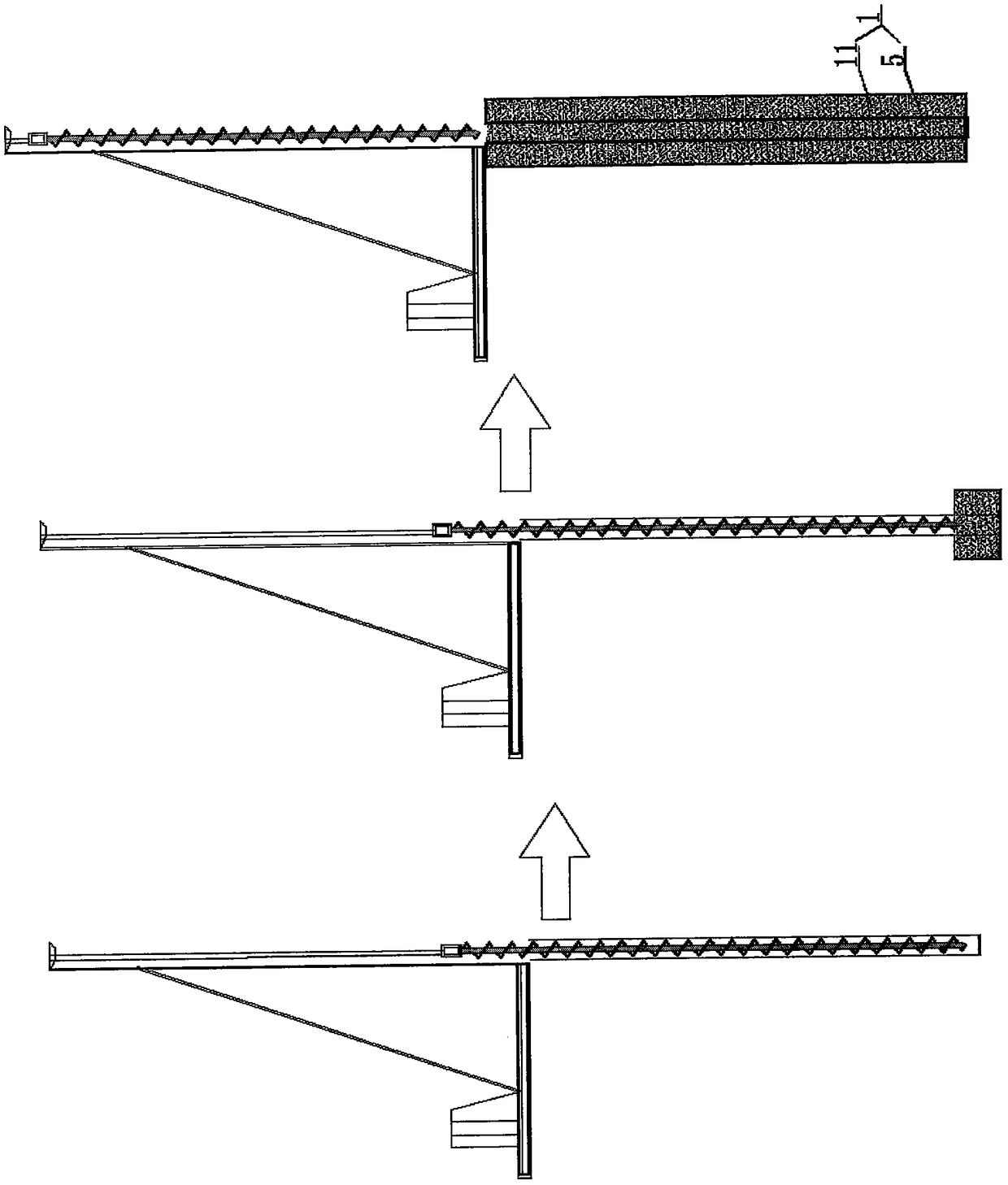

A method of forming a water-blocking diaphragm wall with row piles and plug-in pile-plate combined support

ActiveCN105507338BShear resistantWith anti-seepage functionBulkheads/pilesReinforced concreteWater block

The invention discloses a campshed and inserted piled slab combined supporting water-plugging continuous wall forming construction method. The construction method particularly comprises the following construction methods: a campshed and inserted cement soil piled slab combined supporting water-plugging continuous wall forming construction method, a campshed and inserted concrete piled slab combined supporting water-plugging continuous wall forming construction method, a campshed and inserted concrete arch piled slab combined supporting water-plugging continuous wall forming construction method, and a campshed and inserted reinforced concrete arch piled slab combined supporting water-plugging continuous wall forming construction method. The campshed and inserted piled slab combined supporting water-plugging continuous wall forming construction method disclosed by the invention is small in equipment investment quantity and low in energy consumption, is cost-saving, has good structural shearing resistance and water-plugging seepage prevention performance, is short in construction period, is economic and environmental-friendly, has obvious comprehensive benefits.

Owner:SHANDONG BEI TE LI FOUND ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com