Impermeable dam

A technology of dams and anti-seepage layers, which is applied in dikes, dams, water conservancy projects, etc., can solve the problems of high cost, groundwater impact, endangering the safety of anti-seepage bodies and dam bodies, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

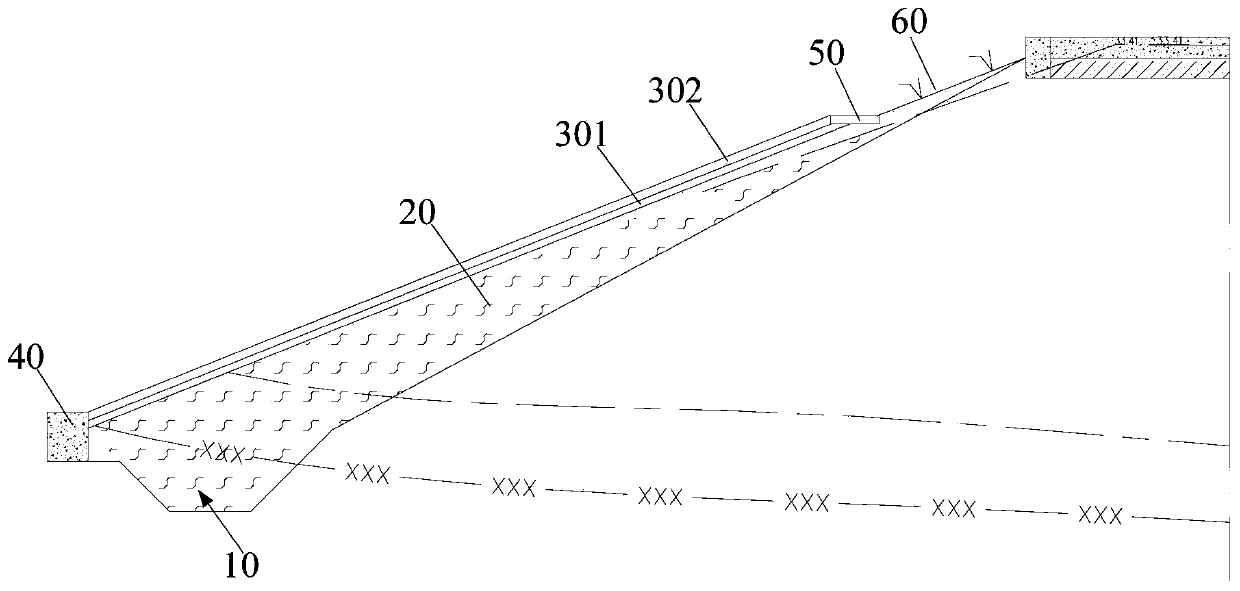

[0043] The dam foundation is partially depressed downwards to form a cut-off groove 10, and the anti-seepage structure includes an anti-seepage layer 20 covering at least part of the side wall of the dam body and an anti-seepage matrix filled in the cut-off groove 10, such as figure 1 shown.

[0044]The anti-seepage structure includes an anti-seepage layer 20 and an anti-seepage matrix. The dam foundation is partially recessed downward to form a water interception groove 10. By filling the anti-seepage matrix in the water interception groove 10, the water interception groove 10 has an anti-seepage function, and the effective wall surface Water infiltrates to the dam foundation, and by covering at least part of the side wall surface of the dam body with the anti-seepage layer 20, the dam body has an anti-seepage function, effectively preventing water from infiltrating the dam body, and improving the overall performance of the anti-seepage dam. security.

[0045] It is worth no...

Embodiment 2

[0051] The difference from Embodiment 1 is that: on the basis of Embodiment 1, further, the anti-seepage embankment further includes: buttresses 40, which are arranged at the joint between the anti-seepage layer 20 and the anti-seepage matrix, and abut against the anti-seepage structure , used to fix the position of the anti-seepage structure shown, such as figure 1 shown.

[0052] The anti-seepage embankment also includes buttresses 40. By arranging the buttresses 40 at the junction of the anti-seepage layer 20 and the anti-seepage matrix, and abutting against the anti-seepage structure, the buttresses 40 play the role of fixing the anti-seepage structure, effectively It avoids the anti-seepage function of the dam body and dam foundation due to the anti-seepage structure being washed away or dispersed by water.

[0053] Preferably, the pier 40 is a concrete pier 40 .

[0054] The buttress 40 is a concrete buttress 40, and the strength of the concrete buttress 40 is higher, ...

Embodiment 3

[0061] The difference with Embodiment 1 or Embodiment 2 is: on the basis of Embodiment 1 or Embodiment 2, further, the anti-seepage dam also includes: a protective layer, laid on the part where the clay structure covers the side wall of the dam body on, such as figure 1 shown.

[0062] The anti-seepage dam also includes a protective layer. The protective layer is laid on the part of the clay structure covering the side wall of the dam body to protect the clay structure and prevent the part of the clay structure covering the side wall of the dam body from being damaged by water. Dispersed or collapsed, thereby further improving the anti-seepage effect of the clay structure on the anti-seepage dam.

[0063] Preferably, the protection layer includes a sandstone layer 301 laid on the part of the clay structure covering the side wall of the dam body and a concrete layer 302 poured on the sandstone layer 301 .

[0064] The protective layer includes a sandstone layer 301 and a conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com