Tunnel cement concrete pavement oil-proof overlay and overlaying process thereof

A technology of cement concrete and oil cover, which is applied in the direction of roads, roads, on-site paved cohesive pavements, etc. It can solve the problems of the decline in the anti-skid performance of the SMA overlay and the absence of oil pollution, etc., to reduce the risk of water damage, Good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

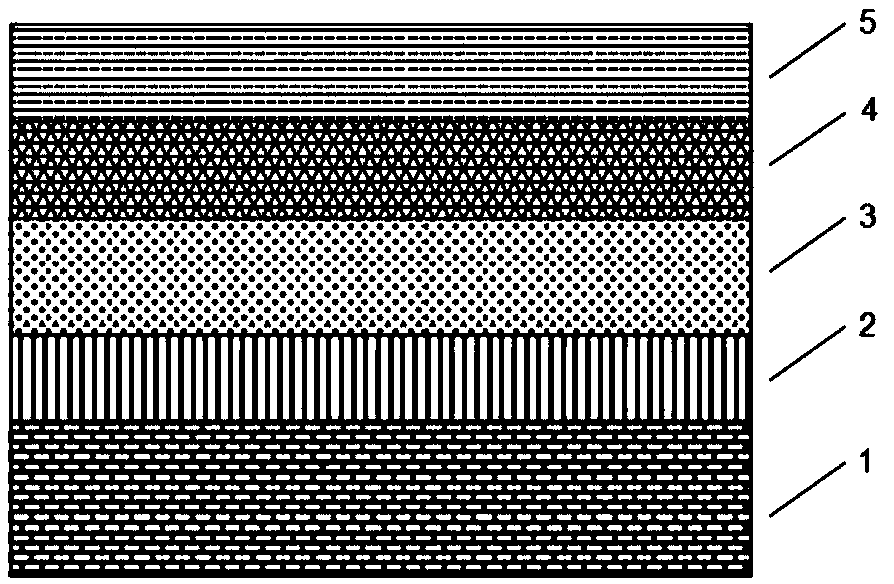

[0037] Such as figure 1 As shown, the present invention provides a kind of oil-resisting overlay of tunnel cement concrete pavement, comprising bonding layer 2, SMA asphalt mixture overlay layer 3, sand mist sealing layer 4 and waterproof and oil-resisting layer 5, bonding layer 2, SMA The asphalt mixture overlay layer 3, the sand mist seal layer 4 and the waterproof and oil-resistant layer 5 are sequentially overlaid on the treated cement concrete pavement 1 from bottom to top.

[0038] The overlaying process of the oil-resistant overlay on the cement concrete pavement of the tunnel includes the following processes in sequence:

[0039] Step 1: First, carry out disease treatment and anti-slip treatment on the original cement concrete pavement, use a blower to remove surface dust, clean it up, and form a rough and clean surface.

[0040] Step 2: Laying an adhesive layer 2 on the treated cement concrete pavement 1 . Before construction, use self-adhesive melting anti-crack pa...

Embodiment 2

[0049] In this embodiment, the oil-resistant overlay of the cement concrete pavement of the tunnel includes a bonding layer 2, an SMA asphalt mixture overlay layer 3, a sand mist seal layer 4 and a waterproof and oil-resistant layer 5, the bonding layer 2, the SMA asphalt mixture The material overlay layer 3, the sand mist seal layer 4 and the waterproof and oil-resistant layer 5 are sequentially overlaid on the treated cement concrete pavement 1 from bottom to top.

[0050] The overlaying process of the oil-resistant overlay on the cement concrete pavement of the tunnel includes the following processes in sequence:

[0051] Step 1: First, carry out disease treatment and anti-slip treatment on the original cement concrete pavement, use a blower to remove surface dust, clean it up, and form a rough and clean surface.

[0052] Step 2: Laying an adhesive layer 2 on the treated cement concrete pavement 1 . Before construction, use self-adhesive melting anti-crack paste to bond th...

Embodiment 3

[0061] In this embodiment, the oil-resistant overlay of the cement concrete pavement of the tunnel includes a bonding layer 2, an SMA asphalt mixture overlay layer 3, a sand mist seal layer 4 and a waterproof and oil-resistant layer 5, the bonding layer 2, the SMA asphalt mixture The overlay layer 3, the sand-mist seal layer 4 and the waterproof and oil-resistant layer 5 are overlaid on the treated cement concrete pavement 1 sequentially from bottom to top.

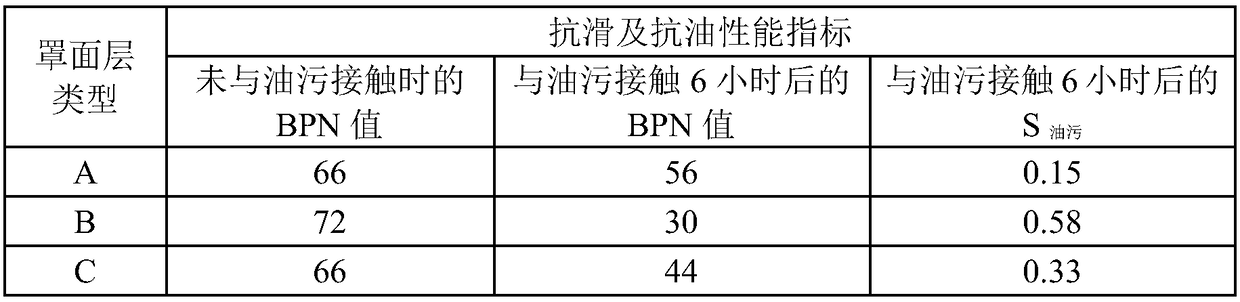

[0062] The overlay overlay process of the present invention involves many parameters, among which there are three parameters that have a key influence on the oil resistance of the overcoat, and they are respectively:

[0063] Parameter A: The amount of slurry (a mixture of sand and asphalt-based cover material) for the sand mist seal layer 4, 600g / m 2 , 800g / m 2 and 1000g / m 2 There are three levels, and their serial numbers are 1, 2, and 3 in turn.

[0064] Parameter B: The amount of waterproof and oil-repellent agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com