Production method of multifunctional exterior wall anti-crack putty

A technology of anti-cracking putty and production method, applied in the direction of filling slurry, etc., can solve the problems of decreased crack resistance and weather resistance, decreased bonding strength of putty, air pollution, etc., and achieves simple and easy production method, excellent effect, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The raw material of producing anti-cracking putty is formulated in parts by weight, consisting of 19 parts of silicone acrylic elastic emulsion, 10 parts of pure acrylic elastic emulsion, 14 parts of water, 0.19 part of cellulose, 0.25 part of defoamer, 1.8 parts of preservative, thickener 0.9 parts, 29 parts of white cement, 7 parts of heavy calcium carbonate (particle size 800 mesh), 18 parts of quartz powder (particle size 300 mesh);

Embodiment 2

[0016] The raw materials for producing anti-cracking putty are prepared in parts by weight, consisting of 20 parts of silicone acrylic elastic emulsion, 10 parts of pure acrylic elastic emulsion, 15 parts of water, 0.2 part of cellulose, 0.3 part of defoamer, 1.5 parts of preservative, and thickener 1.0 parts, 30 parts of white cement, 8 parts of heavy calcium carbonate (750 mesh particle size), 17 parts of quartz powder (270 mesh particle size);

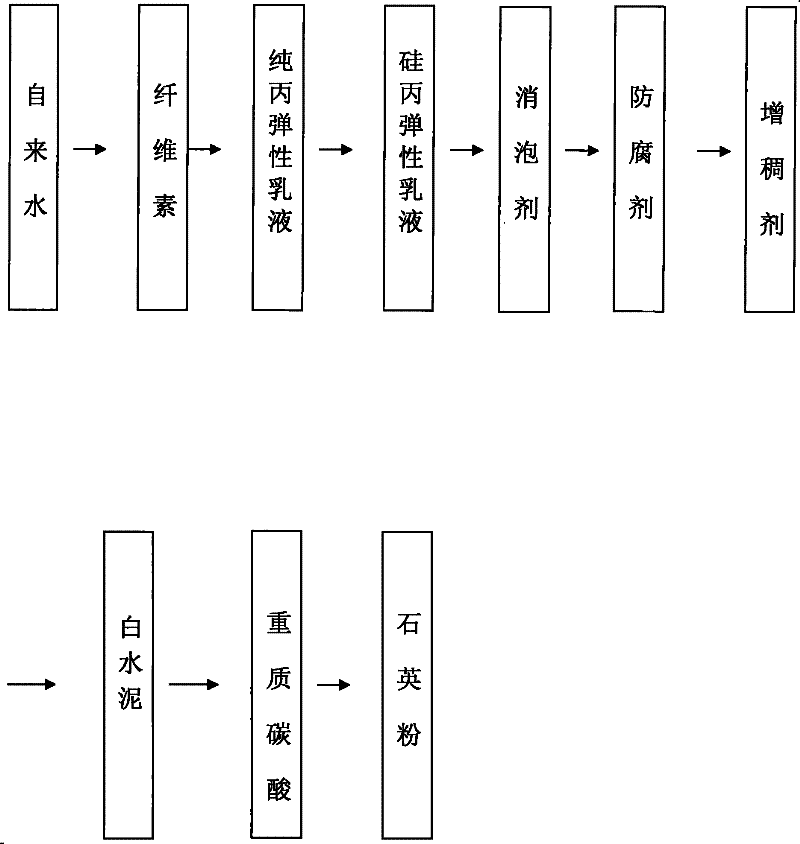

[0017] The production process of the above-mentioned examples 1 and 2: synthesized in a reactor, successively put in silicon acrylic elastic emulsion, pure acrylic elastic emulsion, water, cellulose, defoamer, preservative, thickener, fully stir for 15 minutes, add white cement , heavy calcium carbonate, and quartz powder, stir for 45 minutes until uniform, wait for 10 minutes, visually measure the required consistency, and use it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com