Curled aerosol generating section and aerosol generating product comprising same

An aerosol generation and curling technology, applied in tobacco and other directions, can solve problems such as excessive heating, uneven distribution of metal powder, and uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

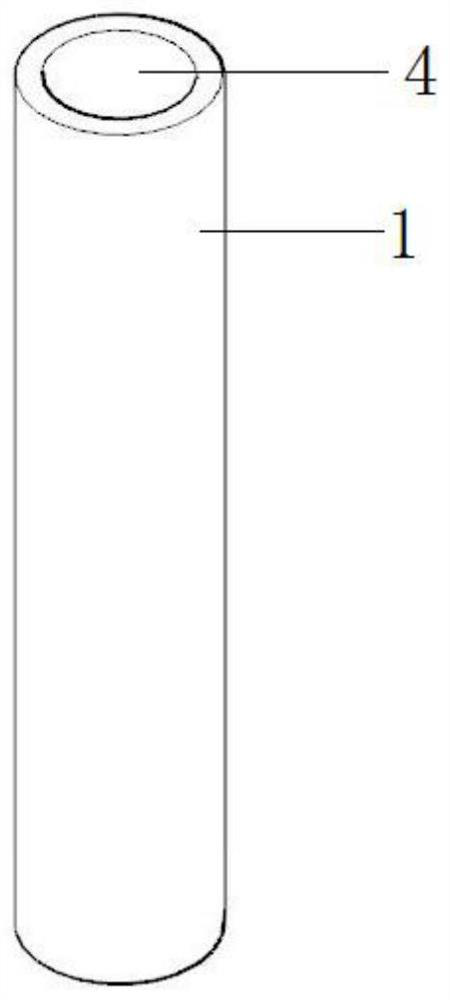

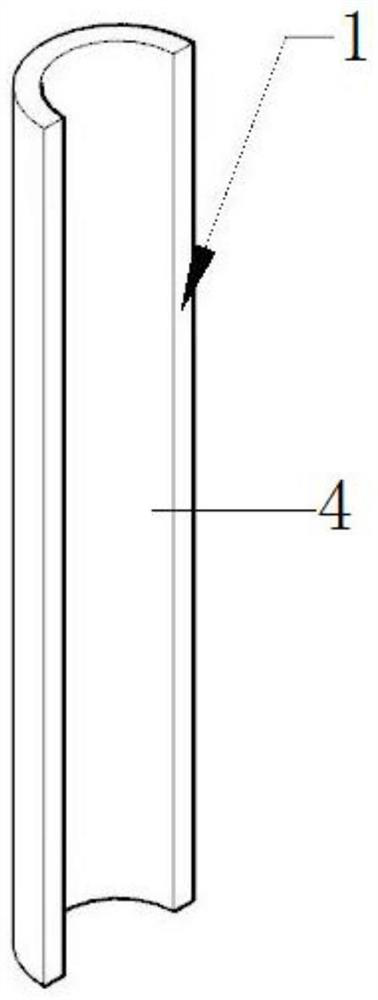

[0049] This embodiment provides a curled aerosol generating section, which is formed by curling an aerosol generating sheet toward the axial center, and has an axial airflow channel 4 in the curled aerosol generating section;

[0050] The aerosol-generating sheet includes only one layer of aerosol-generating base material layer 1, and the aerosol-generating base material layer 1 is curled toward the axial center to form a tubular curled aerosol-generating segment with a tube wall.

[0051] The air flow channel 4 runs through the curled aerosol generating section, and one end of the aerosol generating sheet is curled toward the other end, and the two ends are connected after curling.

[0052] The aerosol generating substrate layer 1 contains smoking material and metal powder, and the particle size of the metal powder is 40 mesh or less.

[0053] The aerosol-generating substrate layer 1 also contains a smoking agent, wherein the moisture content of the aerosol-generating substra...

Embodiment 2

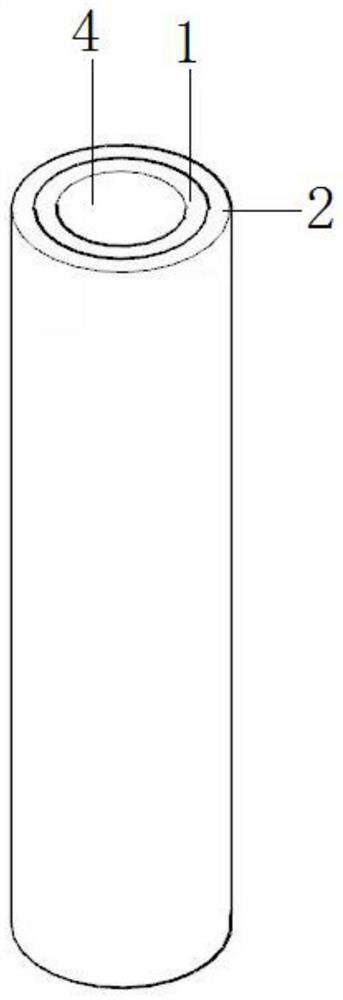

[0056] This embodiment is a curled aerosol generating section, which is formed by curling an aerosol generating sheet toward the axial center, and has an axial airflow channel 4 in the curled aerosol generating section;

[0057] The aerosol-generating sheet includes an aerosol-generating substrate layer 1 .

[0058] The air flow channel 4 runs through the curled aerosol generating section, and one end of the aerosol generating sheet is curled toward the other end, and the two ends are connected after curling.

[0059] The curled aerosol-generating section includes multi-layer contact aerosol-generating sheets that extend radially outward from the central axis, and the innermost aerosol-generating sheet forms a central cavity that penetrates axially. The air flow channel 4 of the coiled aerosol generating section is described.

[0060] The aerosol generating substrate layer 1 contains smoking material and metal powder, and the particle size of the metal powder is 40 mesh or le...

Embodiment 3

[0066] This embodiment is a curled aerosol generating section, which is formed by curling an aerosol generating sheet toward the axial center, and has an axial airflow channel 4 in the curled aerosol generating section;

[0067] The aerosol-generating sheet includes an aerosol-generating substrate layer 1 .

[0068] The air flow channel 4 runs through the curled aerosol generating section, and one end of the aerosol generating sheet is curled toward the other end, and the two ends are connected after curling.

[0069] The curled aerosol-generating section includes multi-layer contact aerosol-generating sheets that extend radially outward from the central axis, and the innermost aerosol-generating sheet forms a central cavity that penetrates axially. The air flow channel 4 of the coiled aerosol generating section is described.

[0070] The aerosol generating substrate layer 1 contains smoking material and metal powder, and the particle size of the metal powder is 40 mesh or le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com