Immersion cleaning system and immersion cleaning method thereof for chromium-polluted building garbage

A construction waste and chromium pollution technology, applied in construction waste recycling, recycling technology, solid waste removal, etc. The effect of shortening the pretreatment time, saving the treatment time and prolonging the soaking time

Pending Publication Date: 2018-12-28

BCEG ENVIRONMENTAL REMEDIATION CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a chromium-contaminated construction waste leaching system and its leaching method, to solve technical problems such as long treatment time of polluted construction waste, cumbersome treatment procedures, imperfect treatment system, and poor repair technology effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

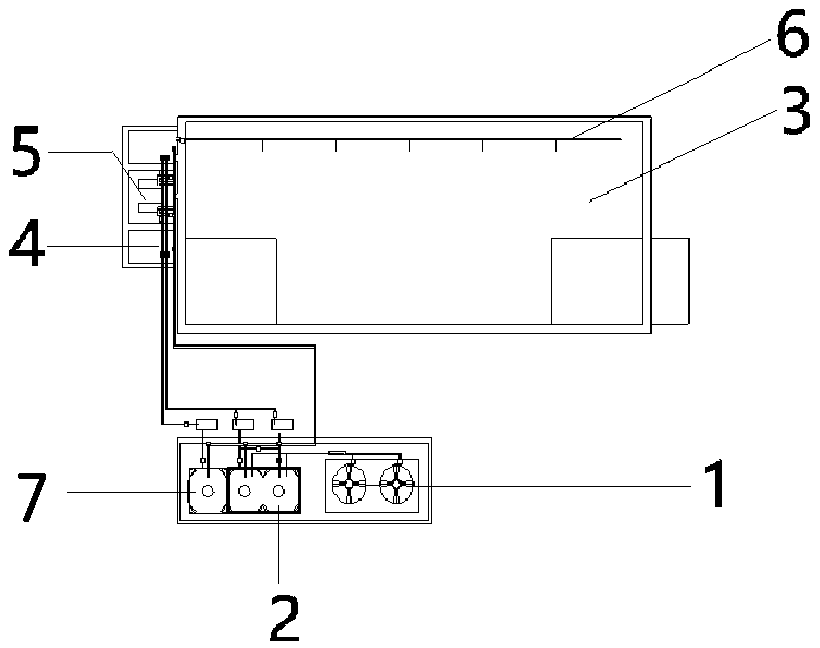

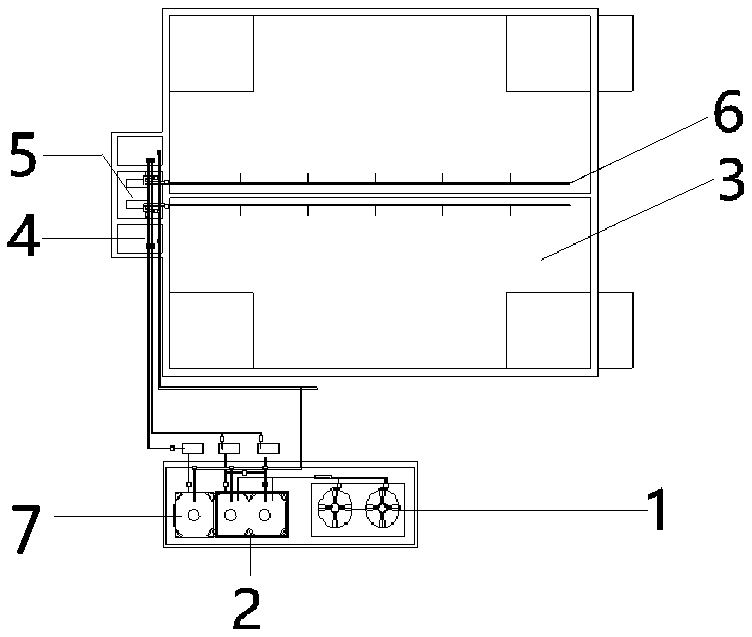

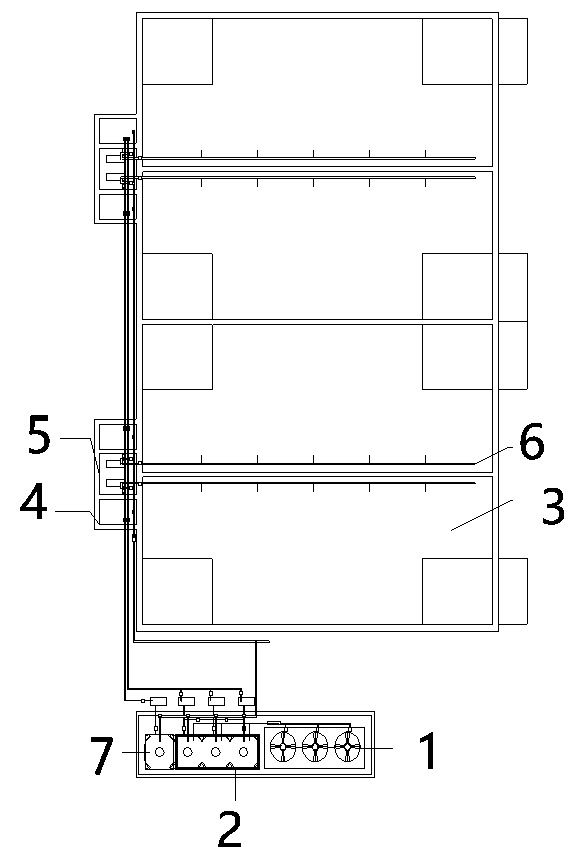

The invention discloses an immersion cleaning system and an immersion cleaning method thereof for chromium-polluted building garbage. The immersion cleaning system comprises sulphuric acid storing jars, alkali liquor storing jars, medicament stirring jars, a water retaining and discharging tank, pump tanks, an immersion cleaning tank body of which the section is rectangular, and a medicine distributing pipeline, wherein an acid discharging opening is formed in one side of each sulphuric acid storing jar, a discharging opening is formed in the other side of each sulphuric acid storing jar, andthe discharging opening of each sulphuric acid storing jar is connected with a first feeding opening of each medicament stirring jar through a pipeline; a second feeding opening for adding ferrous sulfate and a water inlet opening are also formed in the top of each medicament stirring jar; the immersion cleaning bank body is arranged on one side of the water retaining and discharging tank; and themedicine distributing pipeline is arranged along the long edge of one side of the immersion cleaning tank body. Treating liquid after immersion cleaning of garbage flows back into the water retainingand discharging tank from the discharging opening of the immersion cleaning tank body, and is drained out through a waste liquid pipeline arranged at the bottom of the water retaining and dischargingtank. The treatment period is short, the technological process is complete, the immersion cleaning course is simple and convenient to operate, and the repair effect is good. The immersion cleaning tank body has a leakproof function, and in the immersion cleaning course, liquid medicaments form liquid seal on the building garbage, so that dust raising is avoided.

Description

technical field The invention relates to the technical field of construction waste treatment, in particular to a chromium-contaminated construction waste leaching system and a leaching method thereof. Background technique The types of chromium-contaminated sites mainly include chromium slag storage yards, legacy sites of chromium salt factories, and legacy sites of downstream users of chromium salt products. The buildings were demolished on the spot, forming tens of thousands of cubic meters of chromium-contaminated construction waste including concrete and bricks. During decades of production in the chromium salt factory, the buildings and structures of the original factory, especially the original production workshop, have been seriously polluted. Tens of mg / l, far higher than the limit of general industrial solid waste entering the landfill, must be treated before it can be safely landfilled. Chromium-contaminated construction waste from chromium salt factories has alw...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B09B3/00B09B5/00

CPCB09B3/00B09B5/00Y02W30/58

Inventor 宋子钰许超李静文郭冬雪牛永超李书鹏郭丽莉闫利刚

Owner BCEG ENVIRONMENTAL REMEDIATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com