Seepage-proof modification method for sewage storage pools of large-scale livestock and poultry farms

A technology for storage pools and farms, applied in the field of pollution prevention and control of large-scale livestock and poultry breeding, can solve the problems of poor anti-seepage effect and high construction cost, and achieve the effects of prolonging service life, saving investment costs, and good promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

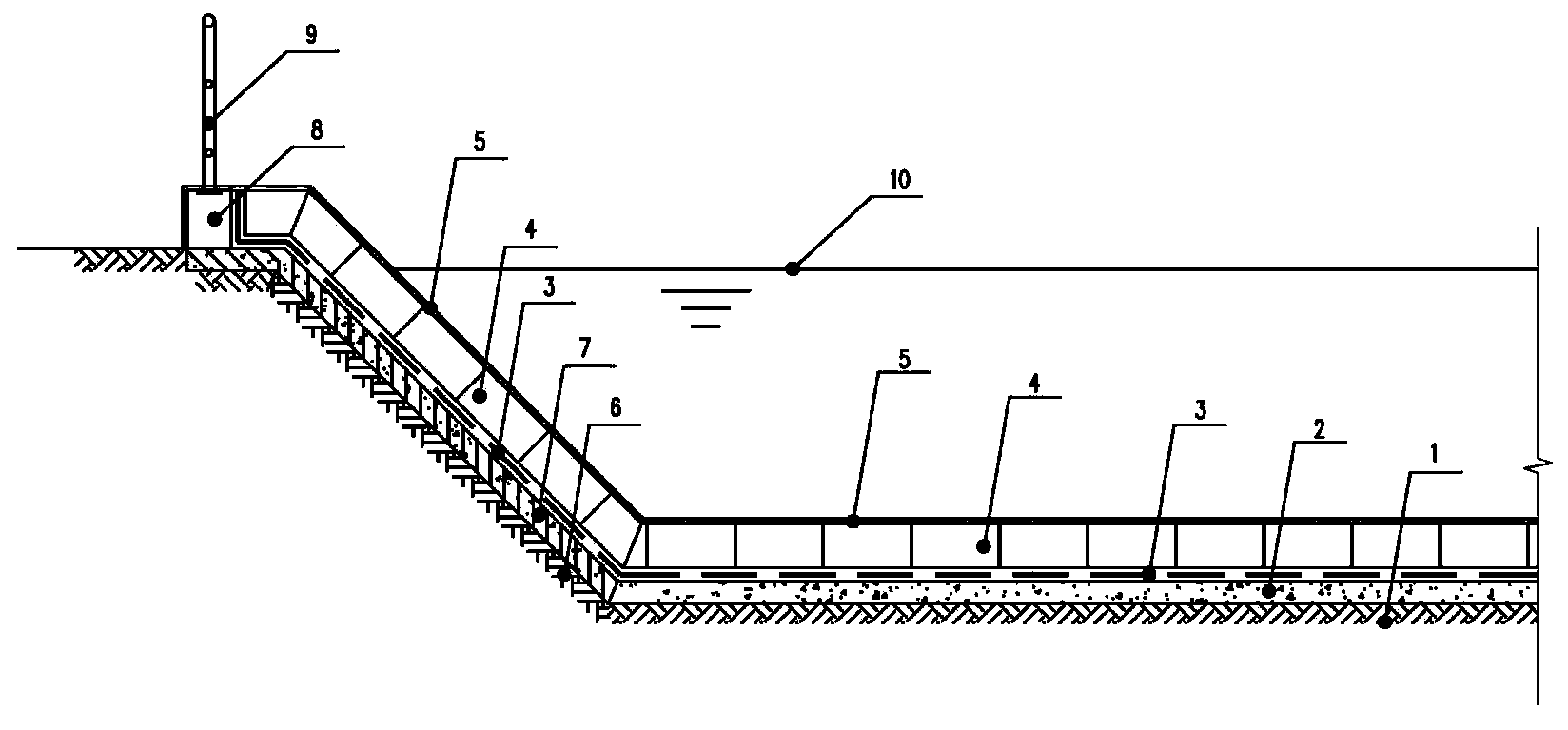

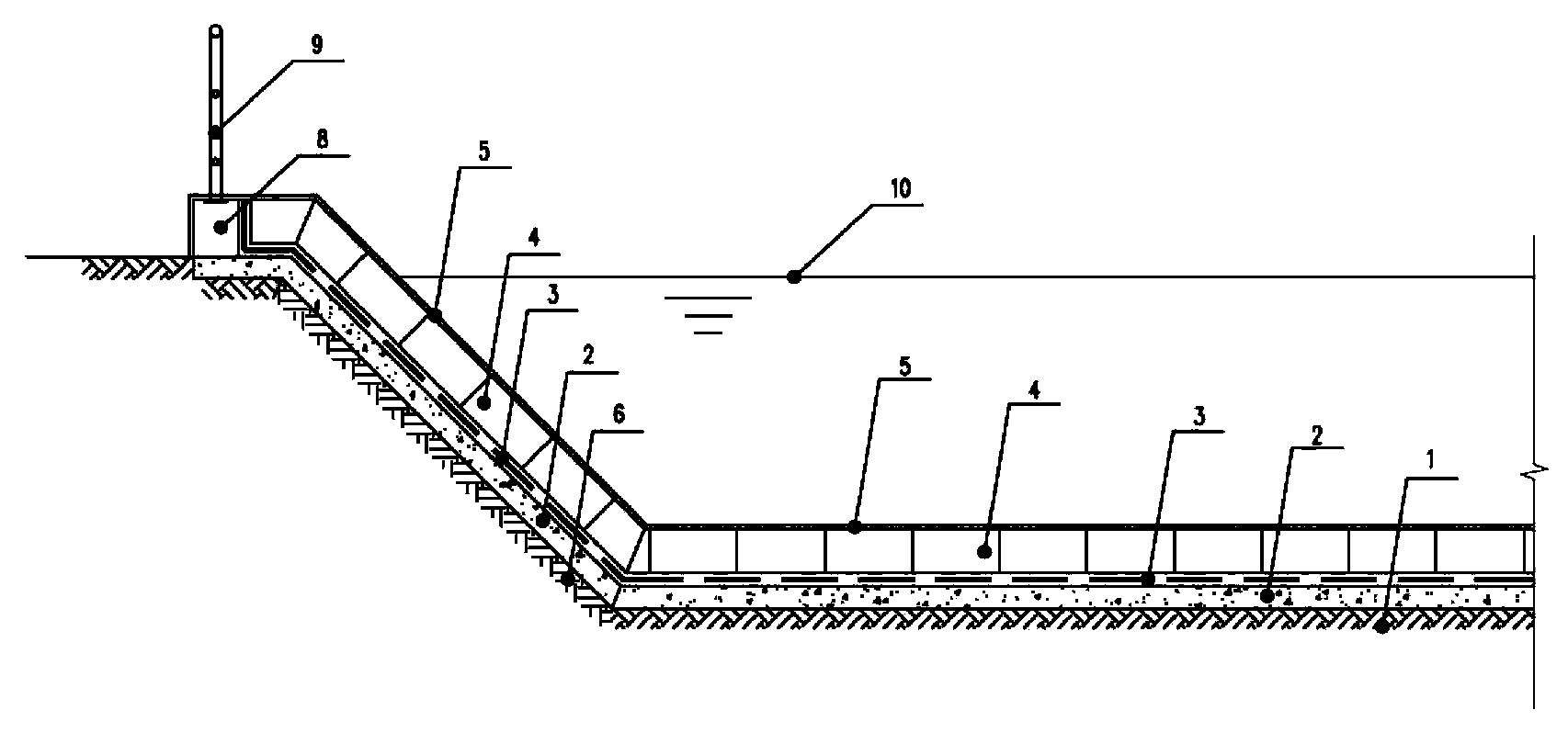

[0023] The demonstration application project of the present invention is located in the Chongming Beibataki Dairy Cattle Breeding District in the southeast of the Beibataki Reclamation Area of the Modern Agricultural Park in Chongming County, Shanghai. The geographical coordinates of the center of the field are E121.85°, N31.58°. The breeding community keeps 1,500 lactating cows all year round, and the sewage production is about 50 tons per day. The sewage adopts the "anaerobic-storage-returning" treatment process, matching more than 750 acres of cauliflower-corn rotation fields, and has a reinforced concrete anaerobic The oxygen pool is 500 cubic meters, and the sewage storage tank with pool wall revetment is 2820 cubic meters. Since the longest off-season of fertilization is more than 50 days, in the pollution reduction project implemented in 2011, the breeding area adopted the anti-seepage modification method of the present invention to transform the original sewage storag...

Embodiment 2

[0027]One of the application projects of the present invention is located in the Pudong New Area Hangtou Pig Breeding Cooperative Farm in Fengqiao Village, Hangtou Town, Pudong New Area. The geographical coordinates of the center are: E121.5677°, N31.0031°. The farm keeps 950 sows (the largest scale is 1,000) and slaughters 14,500 pigs per year. The sewage production is about 60 tons per day. The sewage adopts the "anaerobic-storage-returning" treatment process. Matching field return area of 1,100 mu (525 mu of rice, 575 mu of vegetables), transformation of anaerobic treatment pools of 1,450 cubic meters, and a total volume of sewage storage tanks of 4,350 cubic meters, but 2,187 cubic meters of them are all-earth pools (all-soil storage pools), Does not have anti-seepage function. Since the total volume of the on-site sewage storage tank must meet the longest fertilization off-season of more than 70 days, the 2187 cubic meter earthen tank must be used after anti-seepage ren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com