A high-efficiency two-way flow plate type lifting film evaporator

A bidirectional flow and lifting film technology, which is applied in evaporation, chemical instruments and methods, and separation methods, can solve the problems of low pressure bearing capacity, low steam utilization rate, and low evaporation efficiency of lifting film evaporators, and achieve a heat exchange area The effect of maximizing, increasing the processing capacity, and high evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

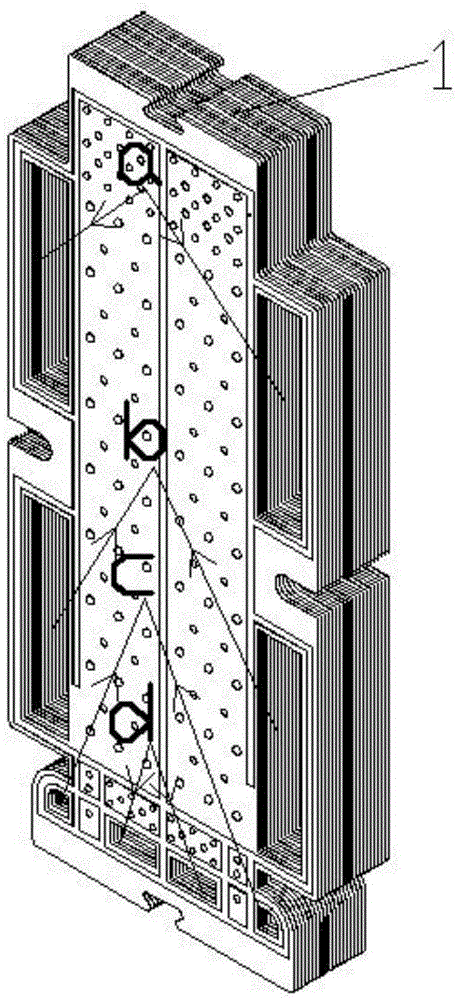

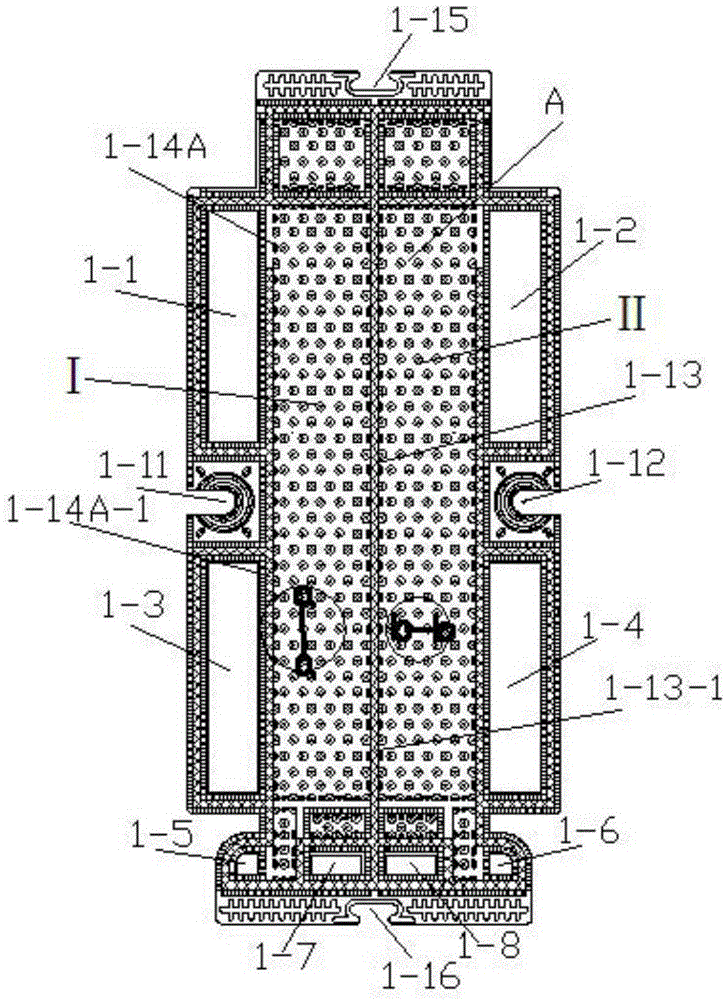

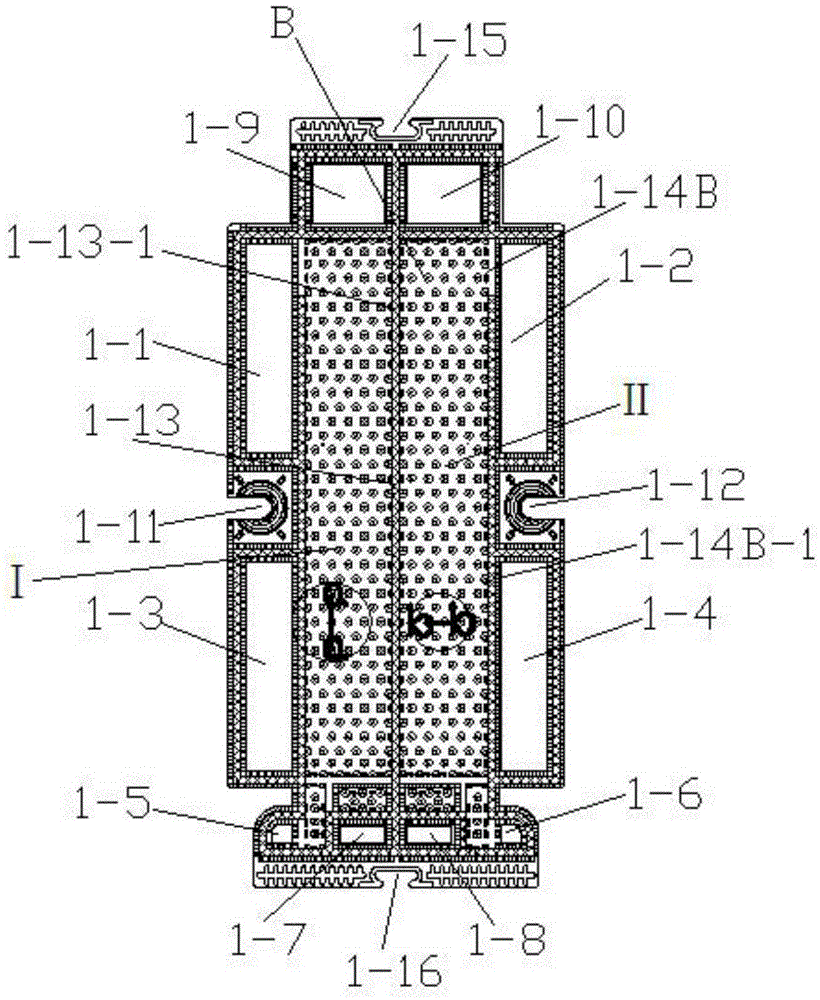

[0032] Such as figure 1 As shown, a high-efficiency two-way flow plate type lifting film evaporator of the present invention includes a plate bundle 1 for heat exchange, and the plate bundle 1 includes a plurality of stacked plate groups, and adjacent plates A steam channel is formed between the sheet groups, and each of the sheet groups includes the first sheet A, the second sheet B, the third sheet C and the fourth sheet D arranged in sequence; each of the sheet groups There are a saturated steam inlet, a non-condensed material inlet, a concentrated liquid and secondary steam outlet, and a condensed water and non-condensable gas outlet on the left and right sides of the board. The second plate B and the third plate On the left and right sides of the top of sheet C, there is an opening for the passage of concentrated liquid and secondary steam in the process. The opening positions of each of the plates correspond to the same, and the openings corresponding to the same positio...

Embodiment 2

[0039] The structure of a high-efficiency two-way flow plate type lifting film evaporator in this embodiment is the same as that in Embodiment 1, the difference is that in this embodiment, two kinds of material fluids with different properties and two kinds of steam with different properties are heated. exchange process, such as Figure 10a with 10bAs shown, the specific heat exchange process is that the fresh saturated steam ① enters the saturated steam inlet on the left side of the fixed strong plate 2, and distributes to several steam along the saturated steam channel a1 at intervals of a material rising film flow channel or a material falling film flow channel flow channel until the blind plate 10, and at the same time, the saturated steam in the saturated steam channel a1 flows through the plate heat transfer surface along several parallel saturated steam channels, and the saturated steam enters the first heat exchange zone I Finally, the saturated steam ① gradually cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com