A multi-stage preheating plate evaporator

A technology of evaporator and preheating plate, which is applied in the field of multi-stage preheating plate evaporator, which can solve the problems of complicated process subsidiary process, low heat transfer efficiency, and large floor area, so as to save construction investment and increase heat transfer area , the effect of reducing the floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

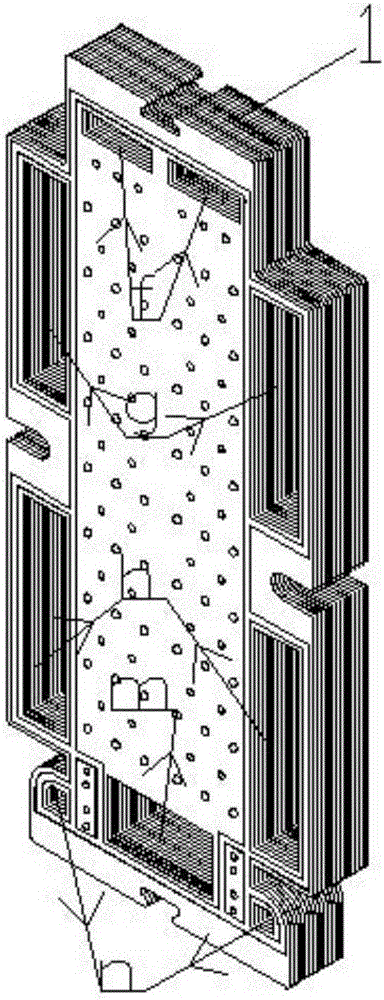

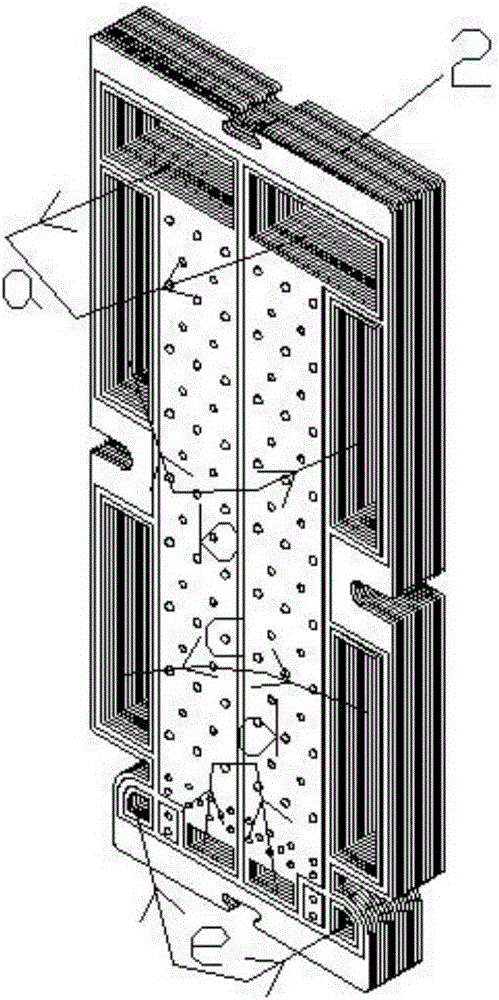

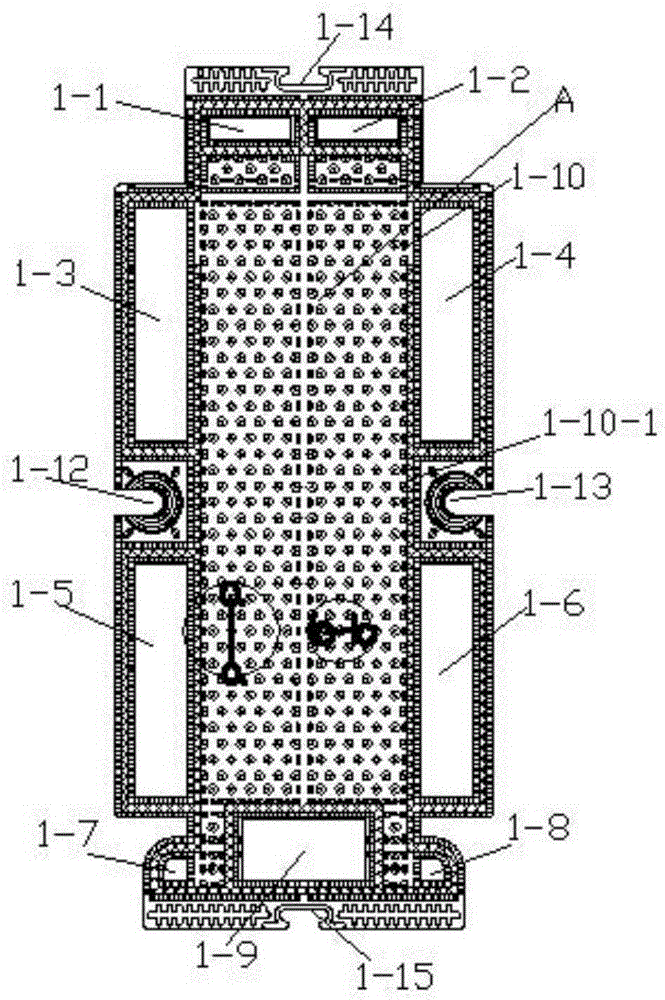

[0031] Such as figure 1 and figure 2 As shown, a multi-stage preheating plate evaporator of the present invention includes a first plate bundle 1 and a second plate bundle 2 stacked together, the first plate bundle 1 is used for preheating of unconcentrated materials, The second plate bundle 2 is used for evaporative concentration of materials; the first plate bundle 1 includes a plurality of first plates A and second plates B arranged alternately, and the second plate bundle 2 includes a plurality of alternately arranged The third plate C and the fourth plate D; the first plate bundle 1 includes a material preheating system, and the material preheating system includes an unconcentrated material fluid inlet channel f, a preheated material fluid discharge channel m, a preheating Saturated steam inlet channel g, preheated saturated steam outlet channel h, condensed water and non-condensable gas channel n, each channel is composed of openings arranged at the same position on ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com