Clamping type buckling element zipper of impervious structure

A technology for fastening components and zippers, applied in the direction of sliding fastener components, fasteners, applications, etc., can solve the problems of loss of waterproof function, complicated process, deformation of elastic waterproof colloid, etc., to achieve the function of preventing fluid penetration and durability, expand Application range, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

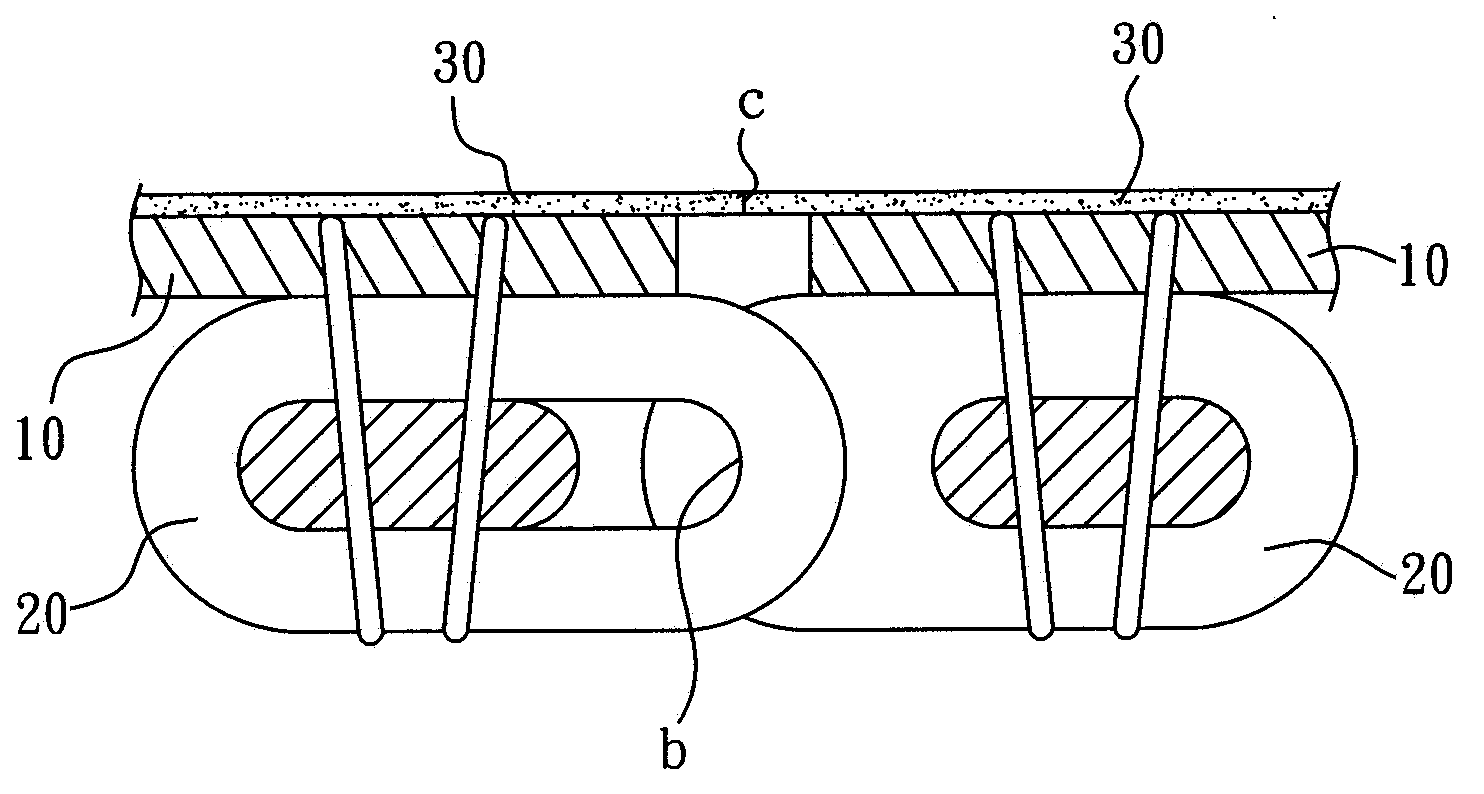

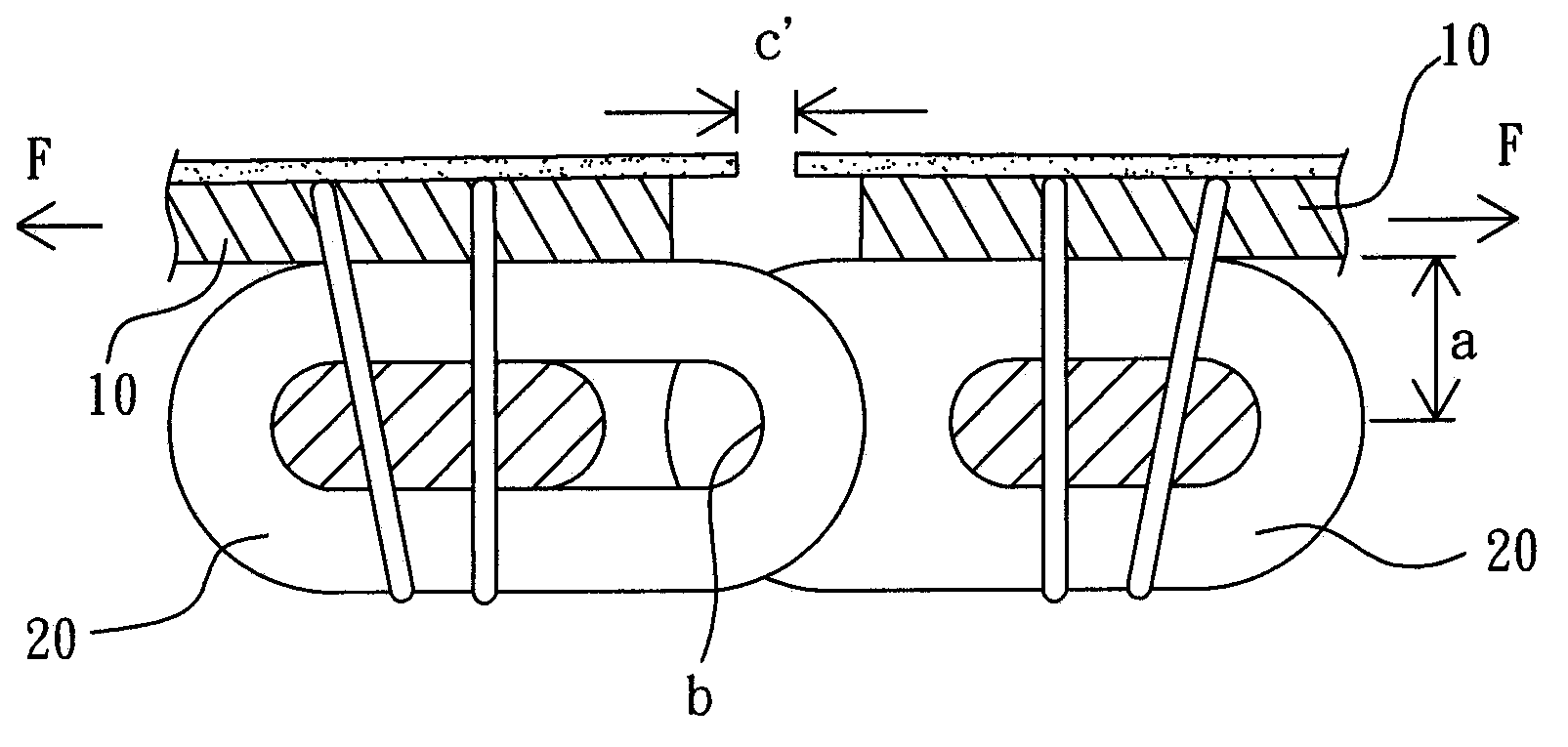

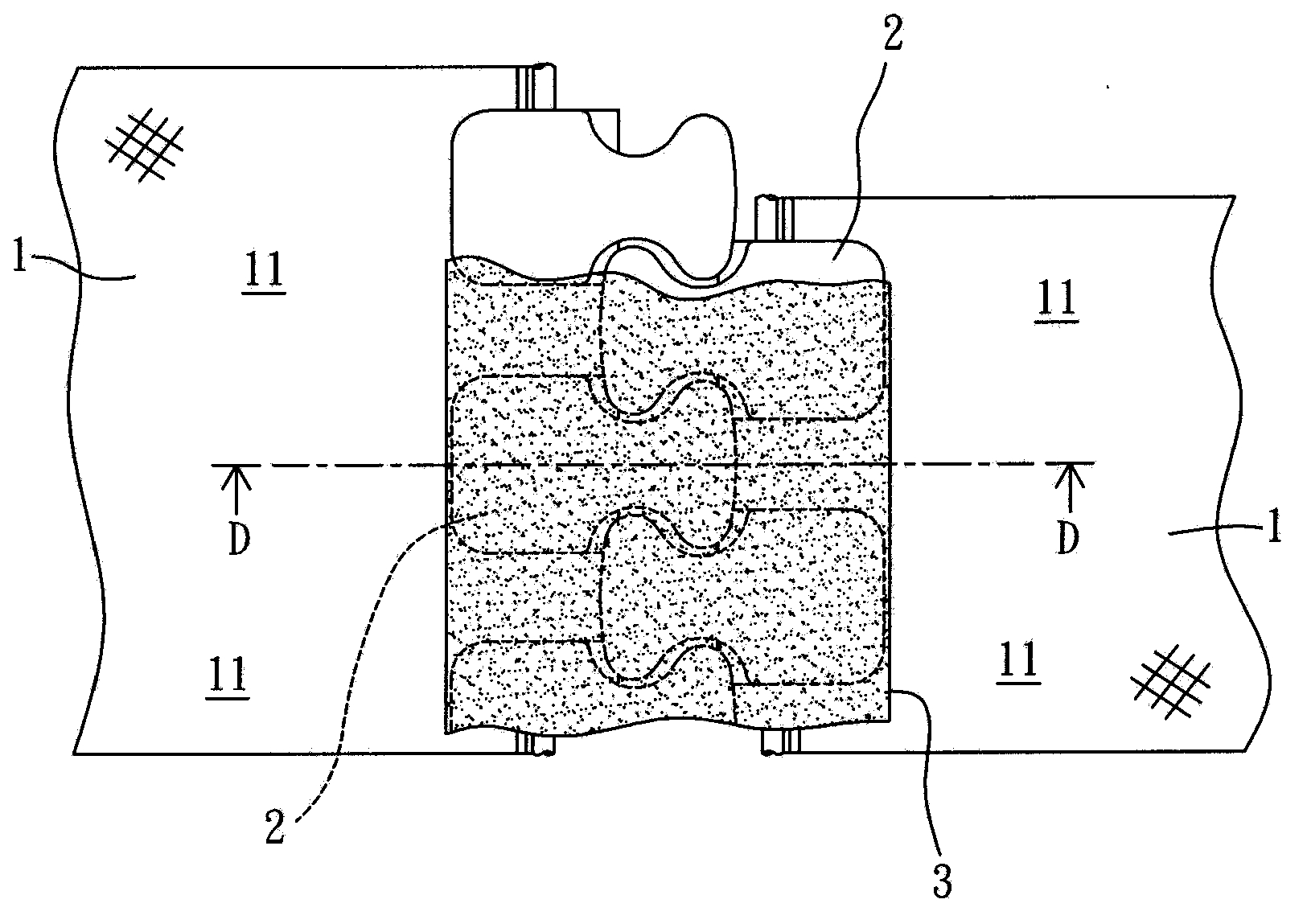

[0031] Such as Figure 3 to Figure 6As shown, basically, the clip-type fastening element zipper with anti-seepage structure of the present invention includes a pair of left-right symmetrical support tapes 1, two rows of fastening elements 2 that are arranged in parallel and are staggered and spaced apart from each other, and anti-seepage glue Composed of 3.

[0032] The pair of support tapes 1 is made of warp knitting or weaving. If necessary, one of the warp or weft directions must be made of elastic tissue, so that the warp or weft directions of the support tape 1 have stretch elasticity. . Wherein, the pair of support tapes 1 have first and second surfaces 11 and 12 respectively, and the fastening element 2 sandwiches the inner edges of the first and second surfaces 11 and 12 of each support tape 1 in a sandwich manner.

[0033] The fastening element 2 may be implemented by plastic injection molding or metal riveting, or as Image 6 As shown, the fastening element 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com