A method of forming a water-blocking diaphragm wall with row piles and plug-in pile-plate combined support

A pile-plate combination and pile-plate technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of high cost, large equipment investment, long construction period, etc., and achieve cost reduction, broad development space, reduction of The effect of material input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

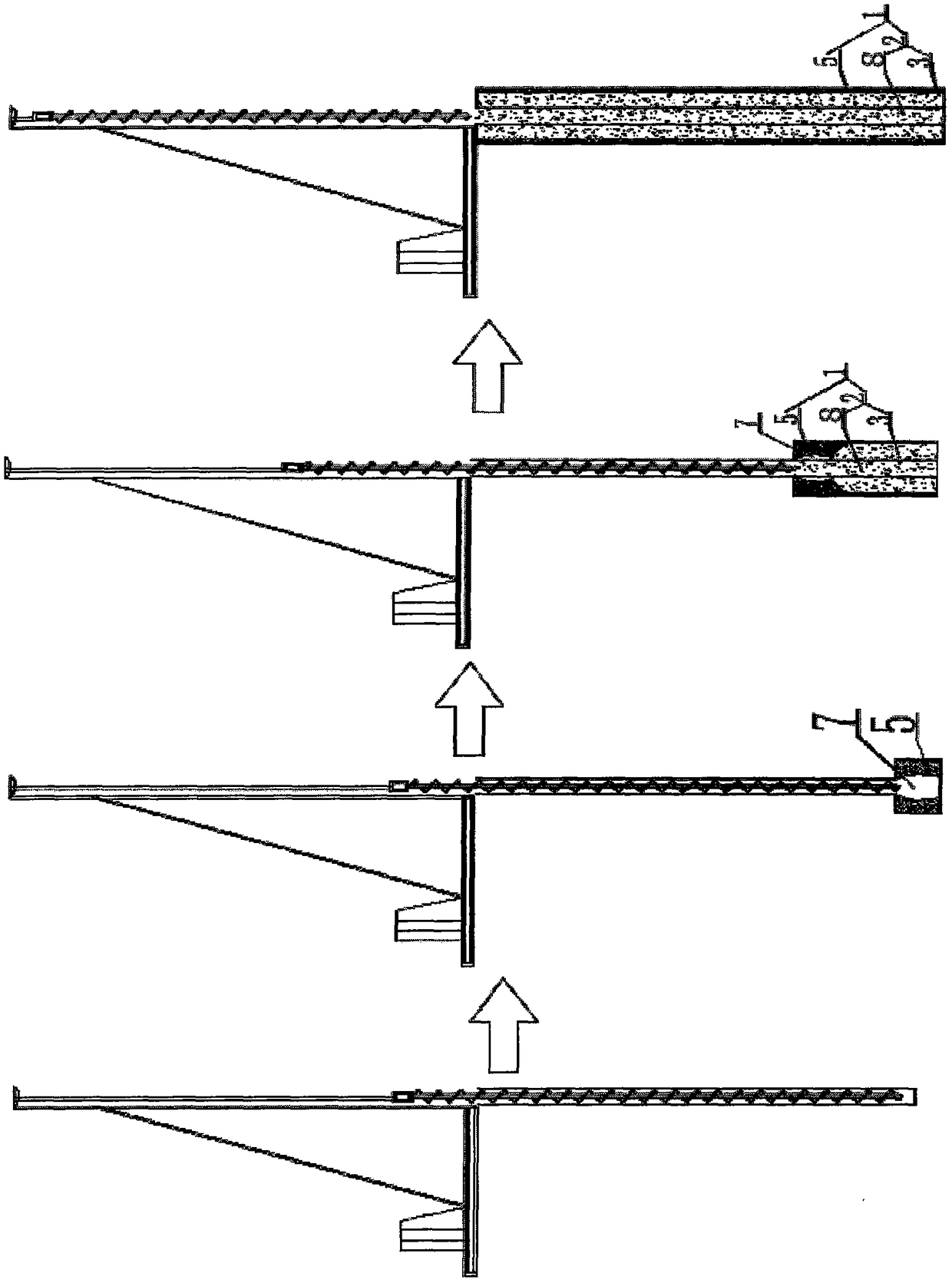

[0067] Such as figure 1 The row of piles inserted into the pile-slab combined type to support the water-blocking continuous wall, the long spiral drilled high-sprayed cement-soil composite plain concrete pile-slab composite pile includes a pile body 1, including a pile body 1, and the pile body 1 Consists of a pile body 2 and a cement-soil pile 5; a high-pressure rib cavity 7 is formed between the cement-soil pile 5 and the pile body 2; the high-pressure rib cavity 7 and the pile body 2 are expanded by concrete pressure filling ribbed concrete body 3; the expanded diameter ribbed concrete body 3 is arranged along the depth direction of the pile body 2; the plain concrete pile 8 is arranged inside the pile body 1; the plain concrete pile 8 is made of concrete pouring pile board and cement Composite soil piles.

[0068] A method for constructing a spiral-drilled high-sprayed cement-soil composite plain concrete pile-slab composite pile, comprising the following steps:

[0069]...

Embodiment 2

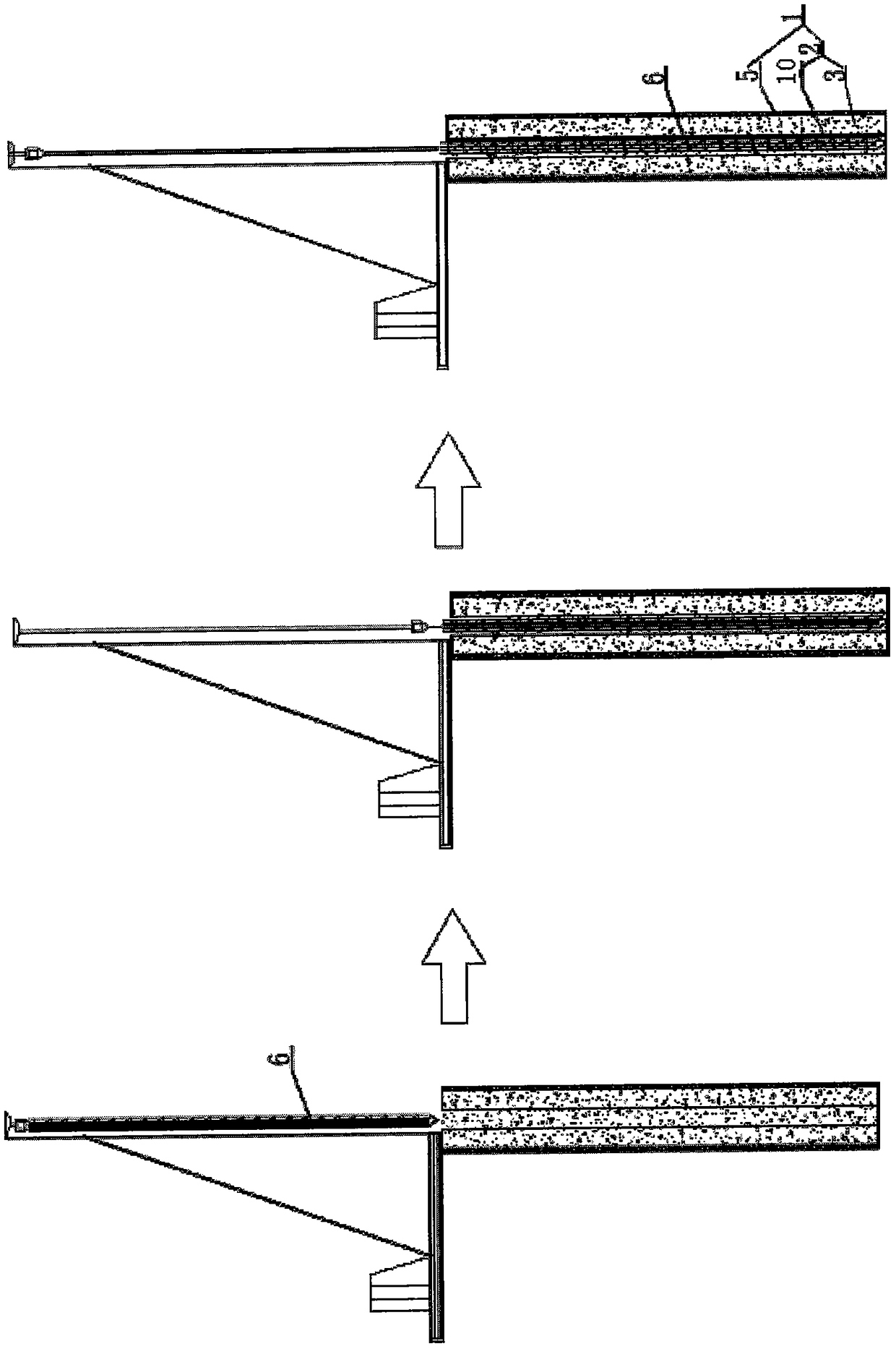

[0073] Such as figure 2 The row of piles inserted into the pile-slab combined type to support the water-blocking continuous wall, the long helical drilled high-sprayed cement-soil composite reinforced concrete pile-slab composite pile includes a pile body 1, including a pile body 1, and the pile body 1 Consists of a pile body 2 and a cement-soil pile 5; a high-pressure rib cavity 7 is formed between the cement-soil pile 5 and the pile body 2; the high-pressure rib cavity 7 and the pile body 2 are expanded by concrete pressure filling ribbed concrete body 3; the expanded diameter ribbed concrete body 3 is arranged along the depth direction of the pile body 2; the inside of the pile body 1 is provided with a reinforced concrete pile 10; the reinforced concrete pile 10 is made of a steel cage 6, concrete Pile board and cement-soil pile composite.

[0074] A construction method of spiral drilling high-sprayed cement-soil composite reinforced concrete pile-slab composite pile, co...

Embodiment 3

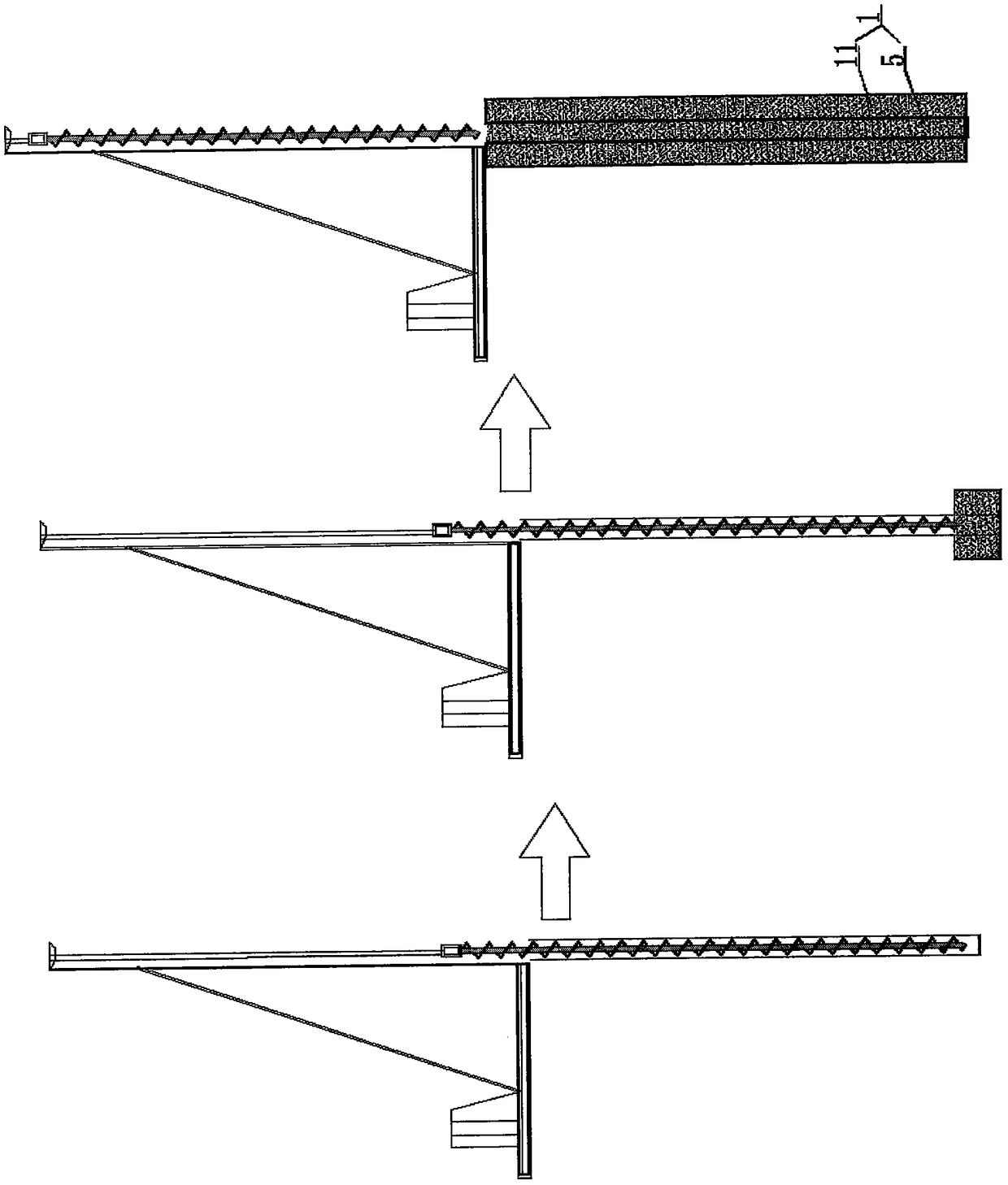

[0080] Such as image 3 The row of piles inserted into the pile-slab combined support water-blocking continuous wall, the long spiral drilled high-sprayed cement-soil pile slab includes a pile body 1, including the pile body 1, and the recently-mentioned pile body 1 is composed of cement-soil piles 5 It is composed of a cement-soil rib 11; the cement-soil rib 11 is arranged along the depth of the cement-soil pile 5.

[0081] A construction method of long helical drilling and high spray cement-soil pile slabs, comprising the following steps:

[0082] Step 1: Construction preparation. Before construction, prepare for three links and one leveling on the site, assemble and debug equipment on site, measure and set out lines, inspect lines, and check pile positions;

[0083] Step 2: Hole forming and high injection cement-soil pile slab construction, the drill bit of the multi-functional drilling rig is positioned at the set pile position, and after the multi-functional drilling rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com