Expanded graphite and poly alpha-olefin composite oil drag reducer blending synthesis method

A technology of expanded graphite and α-olefin, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of loss of drag reduction function, molecular weight reduction, etc., and achieve drag reduction effect and disperse shear effect force, reduce the effect of degradation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

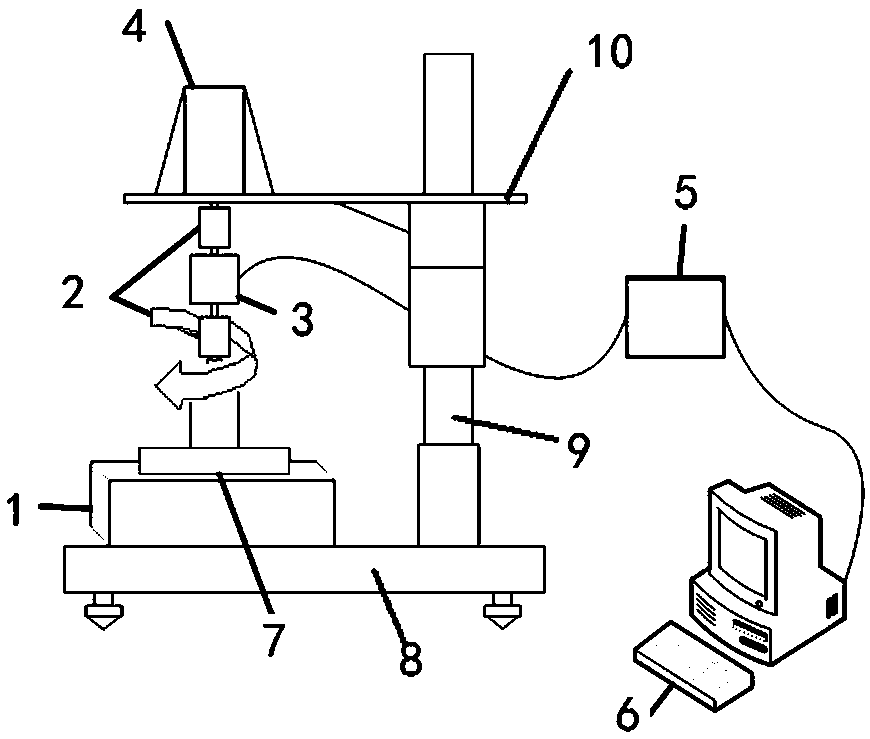

Image

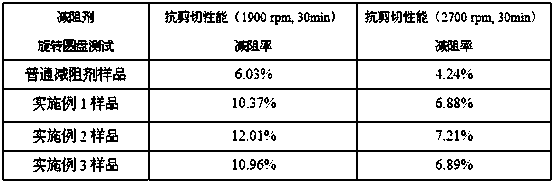

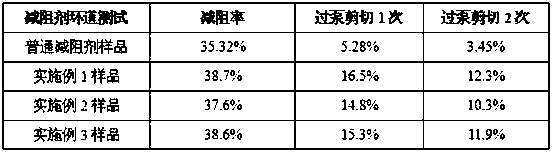

Examples

Embodiment 1

[0022] Embodiment 1: The expanded graphite polyalphaolefin composite oil drag reducer blending method that the present invention mentions comprises the following steps:

[0023] First, weigh 20g of expandable graphite in a beaker, place it in a vacuum oven at 100°C, and dry it for 24 hours; then transfer the beaker to a microwave oven and heat it for 60s, take it out, and cool it at room temperature; repeat this step 3 times to obtain expanded graphite; then follow Add expanded graphite to 1% N-methylpyrrolidone (NMP) aqueous solution at a mass ratio of 20:1 to N-methylpyrrolidone (NMP); then add dodecane dropwise at a mass ratio of 1:50 to expanded graphite Sodium phenyl sulfonate, stirred at 100r / min at room temperature for 48h; then placed in an ultrasonic generator, ultrasonicated at 25°C for 10min; put the solution in a vacuum oven at 80°C, dried for 24h, took it out after the water evaporated, and used Ultrasonic treatment for 60 minutes, pulverized and refined into modi...

Embodiment 2

[0025] Embodiment 2: The expanded graphite / polyalphaolefin composite oil drag reducer blending method mentioned in the present invention is as follows:

[0026] First, weigh 20g of expandable graphite in a beaker, place it in a vacuum oven at 100°C, and dry it for 36h; then transfer the beaker to a microwave oven and heat it for 30s, take it out, and cool it at room temperature; repeat this step 10 times to obtain expanded graphite; Add expanded graphite to 1% NMP aqueous solution at a mass ratio of 50:1 to N-methylpyrrolidone (NMP); then add sodium dodecylbenzenesulfonate dropwise at a mass ratio of 1:100 to expanded graphite, Stir at 500r / min at room temperature for 24 hours; then place it in an ultrasonic generator, and ultrasonicate for 60 minutes at 25°C; place the solution in a vacuum oven at 80°C, dry for 36 hours, take it out after the water evaporates, treat it with ultrasonic waves for 90 minutes, and crush into modified expanded graphite.

[0027] Put the polyalpha...

Embodiment 3

[0028] Embodiment 3: The expanded graphite / polyalphaolefin composite oil drag reducer blending method mentioned in the present invention is as follows:

[0029] First, weigh 20g of expandable graphite in a beaker, place it in a vacuum oven at 100°C, and dry it for 24 hours; then transfer the beaker to a microwave oven and heat it for 60s, take it out, and cool it at room temperature; repeat this step 3 times to obtain expanded graphite; Add expanded graphite to 1% NMP aqueous solution at a mass ratio of 40:1 to N-methylpyrrolidone (NMP); then add sodium tetradecylbenzenesulfonate dropwise at a mass ratio of 1:70 to expanded graphite, Stir at 300r / min at room temperature for 36h; then place it in an ultrasonic generator, and ultrasonicate for 30min at 25°C; place the solution in a vacuum oven at 80°C, dry for 24h, take it out after the water evaporates, treat it with ultrasonic waves for 50min, and crush it finely into modified expanded graphite.

[0030] Put the polyalphaolef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com