Comprehensive anti-seepage system of near-channel construction shortcut and construction method

A technology for construction access roads and waterways, which is applied in the direction of foundation structure engineering, construction, and sheet pile walls, etc., and can solve the problem of pile cracks, damage to the close combination of bored piles and high-pressure jet grouting piles, and the adverse effects of anti-seepage effects To achieve the effect of increasing anti-seepage stability, improving the ability to resist dynamic and static loads and water-stopping ability, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

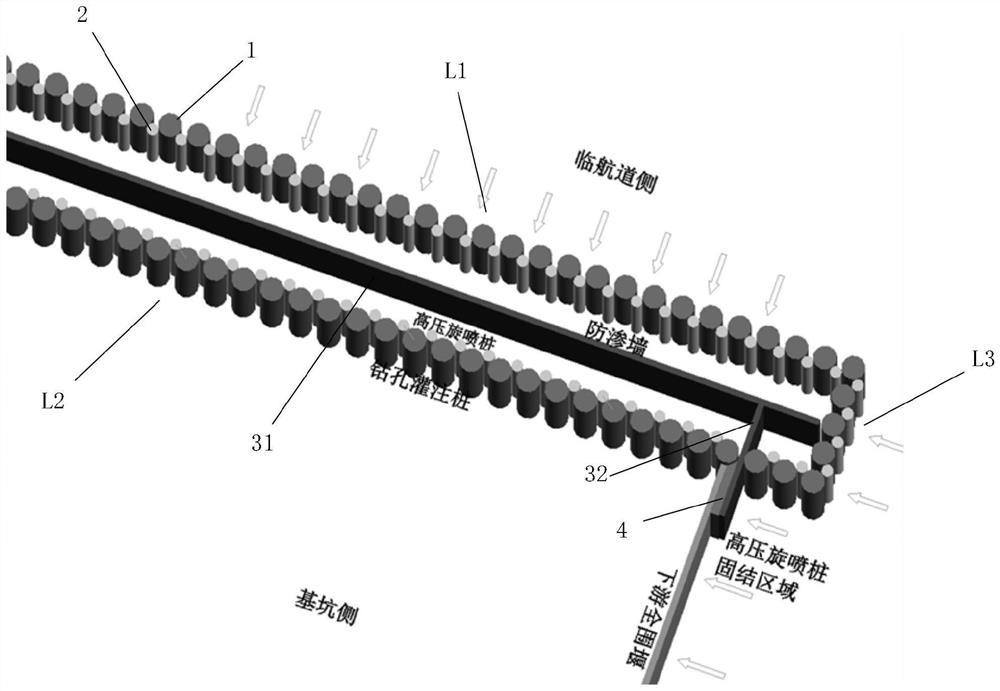

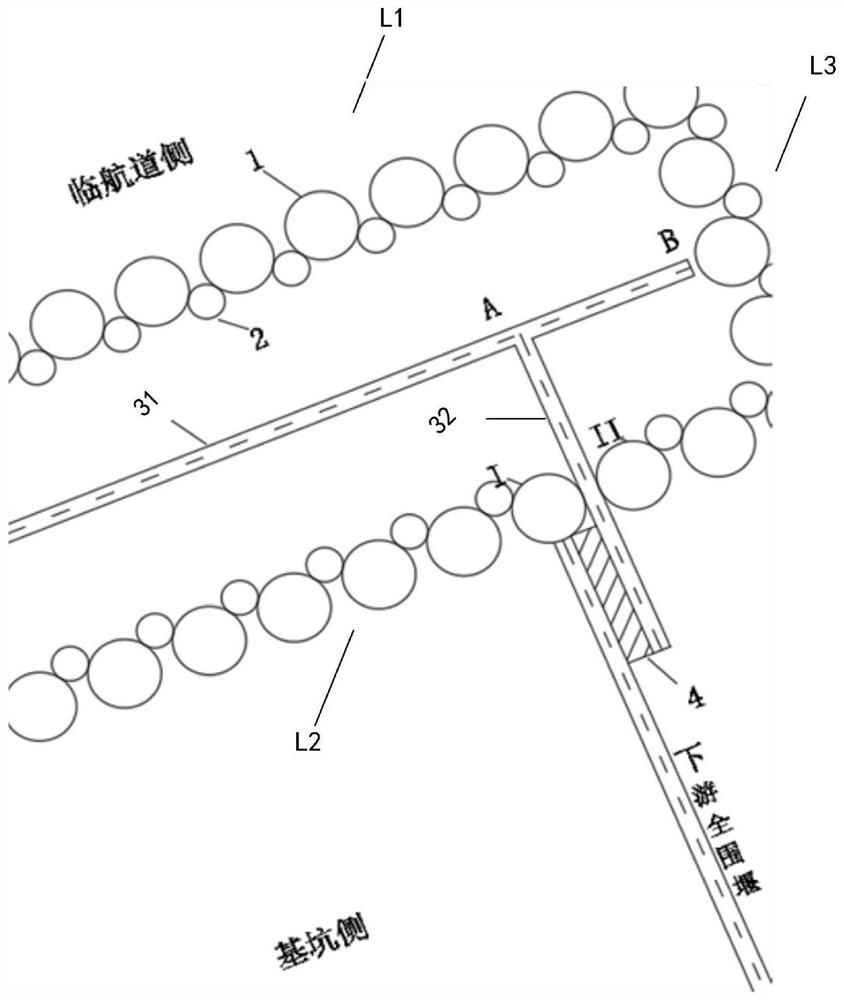

[0049] A comprehensive anti-seepage system for the construction access road near the waterway, the specific settings are as follows:

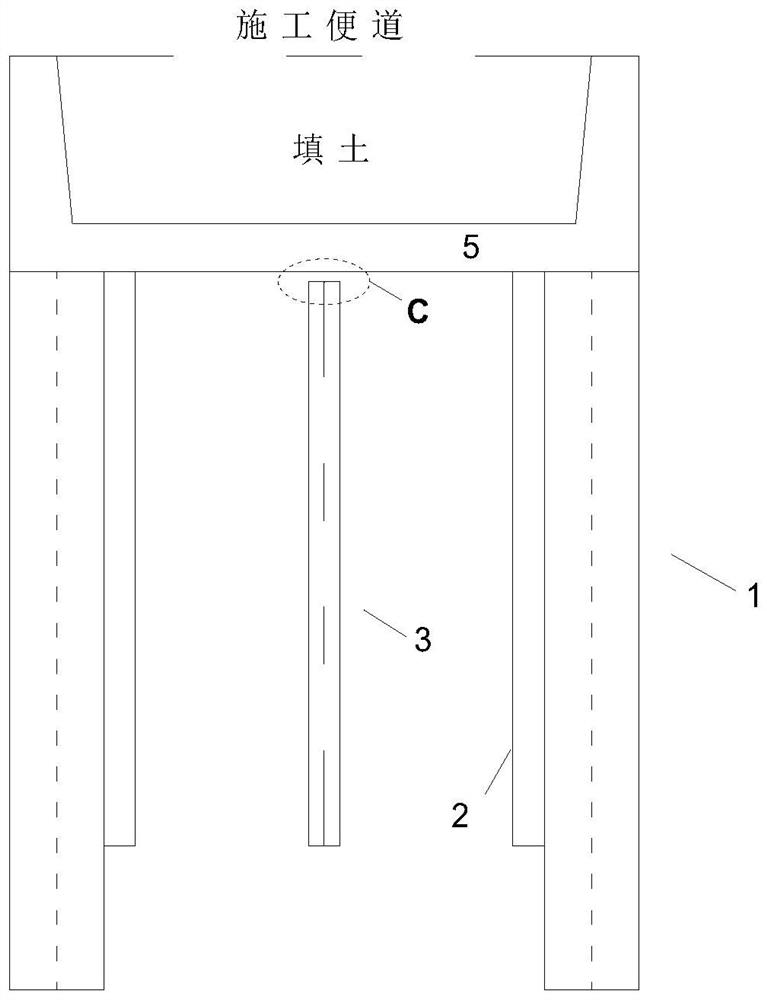

[0050] The thickness of the anti-seepage wall is 0.4m in width;

[0051] After the main anti-seepage wall in the direction of the central axis of the double-row piles is constructed to the inflection point A at the edge of the foundation pit, continue to extend 5m in the direction of the side-row piles in the double-row piles to point B to form an auxiliary anti-seepage wall;

[0052] The main anti-seepage wall is at the inflection point A at the edge of the foundation pit, and extends to the rear row of piles in the direction perpendicular to the central axis of the double row piles, and passes through the two adjacent bored piles in the rear row of piles, and is connected to the outside of the foundation pit. The downstream full cofferdam anti-seepage wall is overlapped in parallel, and the length of the overlap area 4 is 4m and the width is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com